Escolar Documentos

Profissional Documentos

Cultura Documentos

Normal Concrete: 1.2%, by Weight, of Cement

Enviado por

Joel WilliamsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Normal Concrete: 1.2%, by Weight, of Cement

Enviado por

Joel WilliamsDireitos autorais:

Formatos disponíveis

Mechanical properties of concrete Pellitization process 12.

1)Compressive strength

Binder

Admixture

1.2%, by weight, of cement

Replacement of cement by fly ash 10% 20% 30% 40% 49MPa 46.5MP -41MPa -a 0% -

50% 35MP a

Sand by fly ash Fine 20 40 60 0

coarse 20 40

60

12.2) Compressive strength (c-450,w175KG) 13) compressive strength 17) compressive strength 18) compressive strength

FAA (2351 cm2/g)- 2.21 FAB (3849 cm2/g)- 2.45 FAC (5231 cm2/g)- 2.52

cement

1.2%, by weight, of cement

--

50M Pa

51M Pa

53M Pa 40.6 29.139.1 37.5

cement clay

Silica fume 20.4

43.1MP a

38.1MPa 39.4MPa 46.9 MPa

----

--

--

------

19 normal concrete 19.1) compressive strength ( w/c -

clay

25 MPa

0.65) 19.2) compressive strength ( w/c 0.4) 19.3) 19.2) compressive strength ( w/c -0.35) High strength concrete

19.1) compressive strength ( w/c -

35 MPa 38 MPa -

0.65) 19.2) compressive strength ( w/c 0.4) 19.3) 19.2) compressive strength ( w/c -0.35)

55 MPa 48 MPa 38 MPa

12.1) water absorption (28 days)( c-450) 12.2) water absorption (28 days) 12.1) sorptivity (28 days ) (mm/min) 12.2) sorptivity (28 days , water content 250Kg/m3) (mm/min) 19.1) sorptivity (M3*10-7/min0.5) normal concrete high concrete 13) split tensile strength 18) split tensile strength

FAA (2351 cm2/g)FAB (3849 cm2/g)FAC (5231 cm2/g)-

1.2%, by weight, of cement

3.6

3.8

4.1

4.4

cement cement

5.5

1.2%, by weight, of cement

5.3

4.3

4.4

0 .043 -

0.045 -

0.048 -

0.052 0.05 0.038 0.03 0.04

4.8 5.2 Cement Cement Silica fume 5.4 4.9 4.9 5.7 3.22 2.58 3.94 2.58

13) Static elastic modulus (GPa) 19) Porosity (%)

70%OPC+30%FA+100%FBA+100%LG

Cement clay

Silica fume

22.44

18.19 23.19 19.0

Normal concrete High strength concrete

10.2 9.5

Physical properties of concrete Pellitization process

11)

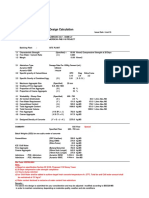

Initial slump - 90 mm Slump after 10 min= 5 65 mm Unit weight - 1815 kg/m3 Air content - 1.7% Temperature - 25C

12) Dry loose bulk density (kg/m3) Saturated surface dry sp. Gravity Waterbinder ratio-0.39 Super plasticizer (% by weight of cement + fly ash) 13) Specific surface area (cm2/g) -: cement -3499 Fly ash -3206 Silica fume -20500s fly ash specific gravity of 1.78

14) Specific gravity Class-F- 2.10 Class-C- 2.64 Bentonite- 2.65 Kaolinite - 2.57 Fineness (m2/kg) Class-F- 257 Class-C- 414 BentoniteKaolinite 16000 Use of fly ash with a fineness of 257 m2/kg exhibit lower pelletization efficiency of only 12%. clay binders (bentonite or kaolinite) significantly improved the pelletization efficiency up to 98%.

18) water/cement ratio- 0.5 Specific gravity FAA (2351 cm2/g)- 2.21 FAB (3849 cm2/g)- 2.45 FAC (5231 cm2/g)- 2.52 Blaine fineness (cm2/g) FAA - (2351 cm2/g) FAB - (3849 cm2/g) FAC - (5231 cm2/g) Percent retained on 45 m sieve FAA (2351 cm2/g)- 33 FAB (3849 cm2/g)- 18.8 FAC (5231 cm2/g)- 12.2

Percent retained on 90 m sieve FAA (2351 cm2/g)- 14.3 FAB (3849 cm2/g)- 2.3 FAC (5231 cm2/g)- 1.6 19) Lytag 1.52 1-hour water absorption (%) 32.2 Measured Slump for normal concrete Lytag( 616 kg/m3) - 51 Lytag( 627 kg/m3) 43 Measured Slump for high strength concrete Lytag( 616 kg/m3) - 30 Lytag( 627 kg/m3) 34 Measured Air Content (%) normal concrete Lytag( 616 kg/m3) - 5 Lytag( 627 kg/m3) 5 Measured Air Content (%) high strength concrete Lytag( 616 kg/m3) - 5 Lytag( 627 kg/m3)- 5

Density (kg/m3) of hardened concrete at 28 days (SSD)Normal concrete - 1725 High strength concrete 1952

Você também pode gostar

- Human Resouce ManagementDocumento8 páginasHuman Resouce Managementsuraj1111Ainda não há avaliações

- Mix Design Testing Fresh and Hardened Concrfete PDFDocumento168 páginasMix Design Testing Fresh and Hardened Concrfete PDFizharAinda não há avaliações

- Mix Design M45 PDFDocumento6 páginasMix Design M45 PDFHarsh PatelAinda não há avaliações

- FDTDocumento12 páginasFDTMansoor AliAinda não há avaliações

- Mix Design For M-30 GradeDocumento7 páginasMix Design For M-30 GradeRamesh GaddamwarAinda não há avaliações

- Case Study High Performance ConcreteDocumento4 páginasCase Study High Performance Concreteamitjag01Ainda não há avaliações

- Analysis of Subgrade Bearing Capacity Using GeotextileDocumento44 páginasAnalysis of Subgrade Bearing Capacity Using GeotextileHussain SajidAinda não há avaliações

- ICCSI32 - Shruthi B SDocumento8 páginasICCSI32 - Shruthi B Ssavinaybharadwaj23122000Ainda não há avaliações

- Test Certificate PPC - WK - 03-2013 PDFDocumento0 páginaTest Certificate PPC - WK - 03-2013 PDFanbumani123Ainda não há avaliações

- Liquid & Plastic Limit Tests - Cone Penetrometer MethodDocumento12 páginasLiquid & Plastic Limit Tests - Cone Penetrometer MethodHafiz NurahimAinda não há avaliações

- High volume slag cement grout propertiesDocumento13 páginasHigh volume slag cement grout propertiesmajedsalehAinda não há avaliações

- Concrete Design MixDocumento15 páginasConcrete Design MixM HAFEEZ RAJAAinda não há avaliações

- Concrete Mix Design - STFA - 09.06.2009Documento40 páginasConcrete Mix Design - STFA - 09.06.2009masahinAinda não há avaliações

- Mix DesignsDocumento6 páginasMix DesignsJerry TomAinda não há avaliações

- Experimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With GgbsDocumento18 páginasExperimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With Ggbsvineela saiAinda não há avaliações

- Stabilization: of Soil Using Waste Fibre MaterialsDocumento23 páginasStabilization: of Soil Using Waste Fibre MaterialsKalyan Reddy AnuguAinda não há avaliações

- Properties of Blended Cements With Limestone Filler and Fly Ash Content PDFDocumento12 páginasProperties of Blended Cements With Limestone Filler and Fly Ash Content PDFTran Huynh NamAinda não há avaliações

- Black Cotton Soil Stabilization by Using Waste TyreDocumento35 páginasBlack Cotton Soil Stabilization by Using Waste TyreMy Diploma Experience100% (2)

- Applying Fly Ash to Concrete Paving BlocksDocumento9 páginasApplying Fly Ash to Concrete Paving BlocksDarshan mAinda não há avaliações

- Ball Mill Optimization PDFDocumento82 páginasBall Mill Optimization PDFJackson Vu100% (2)

- LAB REFF 009R1 WG - SKY HOUSE PHASE 2 UPPER INT - Signed PDFDocumento1 páginaLAB REFF 009R1 WG - SKY HOUSE PHASE 2 UPPER INT - Signed PDFShinku No YoruAinda não há avaliações

- Six Lan Rocad ConstructionDocumento35 páginasSix Lan Rocad ConstructionDevendra SharmaAinda não há avaliações

- Mix design 80 MPa concrete segmentsDocumento4 páginasMix design 80 MPa concrete segmentsForood TorabianAinda não há avaliações

- Design Calculation for Merdeka PNB 118 ProjectDocumento1 páginaDesign Calculation for Merdeka PNB 118 ProjectUma Selladurai100% (1)

- Syce Sem - Iv Mini ProjectDocumento37 páginasSyce Sem - Iv Mini ProjectAmey KadulkarAinda não há avaliações

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocumento9 páginasDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedAinda não há avaliações

- Concrete Mix Design M20 GradeDocumento4 páginasConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaAinda não há avaliações

- Project GGBS 2023Documento39 páginasProject GGBS 2023GOWTHAMAinda não há avaliações

- The Effects of Electric Arc Furnace (EAF) Slag On Engineering Characteristics of Clayey Soil As An Earthquake Resistant MaterialDocumento8 páginasThe Effects of Electric Arc Furnace (EAF) Slag On Engineering Characteristics of Clayey Soil As An Earthquake Resistant MaterialCătălin CăpraruAinda não há avaliações

- Cement and steel test results summaryDocumento3 páginasCement and steel test results summaryvamsiAinda não há avaliações

- ConcreteDocumento169 páginasConcretesabareesan09Ainda não há avaliações

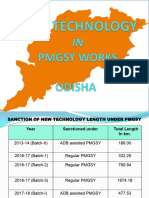

- Odisha - PMGSYDocumento31 páginasOdisha - PMGSYmohammad aamirAinda não há avaliações

- Mechanised Blending and Laying of Blanketing MaterialDocumento27 páginasMechanised Blending and Laying of Blanketing Materialj krishnanAinda não há avaliações

- Influence of Siliceous MaterialDocumento13 páginasInfluence of Siliceous MaterialMujtaba RabahAinda não há avaliações

- Project On Partial Replacement of Cement With Marble PowderDocumento8 páginasProject On Partial Replacement of Cement With Marble PowderYu Paing HanAinda não há avaliações

- M45Documento6 páginasM45Prakash HitechAinda não há avaliações

- M-20 Mix Designs as per IS-10262-2009Documento25 páginasM-20 Mix Designs as per IS-10262-2009Prasad MsrkAinda não há avaliações

- Tchumene Access Project QMS Wet Density TestDocumento9 páginasTchumene Access Project QMS Wet Density TestLoforte CumbeAinda não há avaliações

- Mix Design With SuperplasticizersDocumento8 páginasMix Design With SuperplasticizerskwameAinda não há avaliações

- Dry lean concrete mix designDocumento3 páginasDry lean concrete mix designKunal Paul100% (2)

- Experimental Studies On High Perfirmance Concrete Using MetakaolinDocumento25 páginasExperimental Studies On High Perfirmance Concrete Using Metakaolinచిమ్ముల సందీప్ రెడ్డిAinda não há avaliações

- Mix Design and Research MethodsDocumento12 páginasMix Design and Research MethodsB VAMSI KRISHNAAinda não há avaliações

- Study of Behaviour of Concrete Using Waste Materials As A Partial SubstituteDocumento50 páginasStudy of Behaviour of Concrete Using Waste Materials As A Partial SubstituteZainab SattarAinda não há avaliações

- Cement Mill Test Report3Documento3 páginasCement Mill Test Report3MT JasonAinda não há avaliações

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocumento10 páginasDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhAinda não há avaliações

- Quality Aspects of Cement Milling: Bob M QuillanDocumento18 páginasQuality Aspects of Cement Milling: Bob M QuillanSamehibrahem100% (1)

- Performance of Self-Compacting Concrete at Room and After Elevated Temperature Incorporating Silica FumeDocumento7 páginasPerformance of Self-Compacting Concrete at Room and After Elevated Temperature Incorporating Silica FumeC H TSEAinda não há avaliações

- Concrete Mix Design Record for Sabah Road ProjectDocumento16 páginasConcrete Mix Design Record for Sabah Road ProjectAldro SopiohAinda não há avaliações

- Membrane BWRO SUEZ-AG-LDocumento2 páginasMembrane BWRO SUEZ-AG-LEko SAinda não há avaliações

- SSRG-IJCE - Thin White Topping RoadDocumento5 páginasSSRG-IJCE - Thin White Topping RoadVinay RajAinda não há avaliações

- CONCRETE MIX DESIGN DETAILSDocumento24 páginasCONCRETE MIX DESIGN DETAILSaayushagarwal123100% (1)

- Chapter Four: 4.0 Results and DiscussionsDocumento10 páginasChapter Four: 4.0 Results and DiscussionsAyo OshoAinda não há avaliações

- Concrete Mix DesignDocumento5 páginasConcrete Mix DesignGlyn A. Brinquez100% (1)

- Application of volcanic pumice in structural lightweight concreteDocumento14 páginasApplication of volcanic pumice in structural lightweight concreteAniruddha DalviAinda não há avaliações

- Comparing The Field and Laboratory Curing Behavior of Cold Recycled Asphalt Mixtures For Binder CoursesDocumento19 páginasComparing The Field and Laboratory Curing Behavior of Cold Recycled Asphalt Mixtures For Binder CoursesAmirAinda não há avaliações

- High Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureDocumento16 páginasHigh Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureJHON WILMAR CARDENAS PULIDOAinda não há avaliações

- Concerete, Mix DesignDocumento31 páginasConcerete, Mix DesignVinod JogurAinda não há avaliações

- What Is Cement?: Some of The Reasons For Its Popularity and Universal Acceptance Are Listed BelowDocumento11 páginasWhat Is Cement?: Some of The Reasons For Its Popularity and Universal Acceptance Are Listed BelowVenkat SubramaniAinda não há avaliações

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsNo EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengAinda não há avaliações

- Innovative Design and Construction Methods For CFRDDocumento11 páginasInnovative Design and Construction Methods For CFRD191162100% (1)

- STL-VARUN-EHS-M-F05-Tool Box TalkDocumento1 páginaSTL-VARUN-EHS-M-F05-Tool Box Talklsm projectAinda não há avaliações

- Bài tập trên lớp buổi 11Documento4 páginasBài tập trên lớp buổi 11Thuỳ AnAinda não há avaliações

- Joints: Types of Bolted or Riveted or Pinned JointsDocumento11 páginasJoints: Types of Bolted or Riveted or Pinned JointsAhmad HamadehAinda não há avaliações

- Experimental Study On Eco-BricksDocumento7 páginasExperimental Study On Eco-BricksmelaligareAinda não há avaliações

- Erosion Control Materials: Product DataDocumento4 páginasErosion Control Materials: Product Datasean_dibartolo3668Ainda não há avaliações

- Ultra High Capacity and Totally Removable Tiebacks A D Barley and M e Bruce Published in Foundation Drilling Adsc Journal August 2005Documento5 páginasUltra High Capacity and Totally Removable Tiebacks A D Barley and M e Bruce Published in Foundation Drilling Adsc Journal August 2005Kenny CasillaAinda não há avaliações

- Appendix 4-WAREHOUSE - Hut Khoi WarehouseDocumento6 páginasAppendix 4-WAREHOUSE - Hut Khoi WarehouseMinh van LeAinda não há avaliações

- Preprufe Installation Contractor's HandbookDocumento138 páginasPreprufe Installation Contractor's HandbookJunaid TylorAinda não há avaliações

- 201306190417510.technical Guide Uni 7000FDocumento80 páginas201306190417510.technical Guide Uni 7000Fdijana387Ainda não há avaliações

- Catalogo Yz65 2023Documento55 páginasCatalogo Yz65 2023diego vazAinda não há avaliações

- NEW DSR (Effective From 01-07-2023)Documento1 páginaNEW DSR (Effective From 01-07-2023)rahul pardeshiAinda não há avaliações

- 316 SS Flow Conditioner and Thermowell CatalogDocumento25 páginas316 SS Flow Conditioner and Thermowell CatalogVictorIbañezAinda não há avaliações

- Philippine Christian University: Subject: Managerial EconomicsDocumento3 páginasPhilippine Christian University: Subject: Managerial EconomicsMara AngeliAinda não há avaliações

- Pumping Stations Design Lecture 5Documento60 páginasPumping Stations Design Lecture 5Misama NedianAinda não há avaliações

- Accelerated Bridge Construction PDFDocumento347 páginasAccelerated Bridge Construction PDFဒုကၡ သစၥာAinda não há avaliações

- Bonded Post-Tensioning Systems Using StrandsDocumento24 páginasBonded Post-Tensioning Systems Using StrandsNTLAinda não há avaliações

- Dokumen - Tips - Lighting High Mast Installation ProcedureDocumento41 páginasDokumen - Tips - Lighting High Mast Installation Procedurekatiki216Ainda não há avaliações

- Flip Chart Short 2Documento27 páginasFlip Chart Short 2Roshan RednamAinda não há avaliações

- Building A Powdercoat Oven: Construction Page Design Page Material List Contact LinksDocumento23 páginasBuilding A Powdercoat Oven: Construction Page Design Page Material List Contact Linkselkabong20gmailcom100% (1)

- Code of Practice Central HeatingDocumento8 páginasCode of Practice Central HeatingJohnAinda não há avaliações

- Mir Publishers BooksDocumento2 páginasMir Publishers Bookssuganthi1711Ainda não há avaliações

- ES201 Theory of Structures - III QPDocumento2 páginasES201 Theory of Structures - III QPnaima jaleel100% (1)

- Quantity Survey EstimatesDocumento24 páginasQuantity Survey EstimatesShahid KhanAinda não há avaliações

- Transmission and Distribution TechnologyDocumento92 páginasTransmission and Distribution TechnologySing Yew LamAinda não há avaliações

- JKRTITLEDocumento31 páginasJKRTITLERietiNateAinda não há avaliações

- Structural Towers for Wind TurbinesDocumento11 páginasStructural Towers for Wind TurbinesDhiraj KarnAinda não há avaliações

- GeoformerDocumento2 páginasGeoformerDao Ba ThanhAinda não há avaliações

- B31.3 Process Piping Course - 03 Materials-LibreDocumento45 páginasB31.3 Process Piping Course - 03 Materials-LibrejacquesmayolAinda não há avaliações

- Grundfos Data Booklet: BM and BMhp Booster ModulesDocumento84 páginasGrundfos Data Booklet: BM and BMhp Booster Modulesalexmuchmure2158Ainda não há avaliações