Escolar Documentos

Profissional Documentos

Cultura Documentos

Job Safety Analysis: Pipe Cutting Cleaning and Flushing General

Enviado por

Nico RaharjoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Job Safety Analysis: Pipe Cutting Cleaning and Flushing General

Enviado por

Nico RaharjoDireitos autorais:

Formatos disponíveis

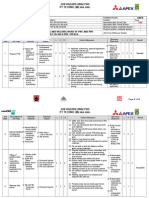

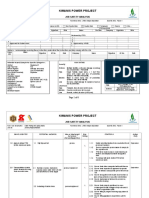

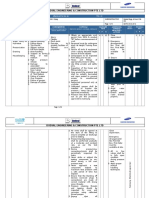

JSA NUMBER:

PTM-PS-JSA-009

JOB SAFETY ANALYSIS

CHECK PPE AND CONTROLS REQUIRED

Hard Hats Safety Shoes Safety Glasses Hearing Protection Cotton Gloves Leather Gloves Respirator Work Vest Safety Harness Face Shield Goggles Ventilation Fire Extinguisher Lockout/Tag out Permit-to-Work Stokes Basket Life Rings Barricades

PROJECT: Pengembangan Terminal BBM Pulau Sambu LOCATION: Pertamina Pulau Sambu JOB NAME: Pipe Cutting Cleaning and Flushing General 27/08/2012 INITIAL DATE: 0 LAST REVISION DATE: 0 REVISION NUMBER:

JOB STEPS/TASKS

Separate the job into the main tasks and record them in sequence

Other - List Chemical gloves/gauntlets Chemical Apron Chemical boots

HAZARD DESCRIPTION

Describe all hazards identified for each task based on observations and experience Note: Additional hazards may be caused by interaction with other work

RISK TO WHAT?

INITIAL RISK

REQUIRED CONTROLS

Describe fully all equipment, facility, and/or procedure controls applicable for each hazard (i.e. if PPE is used as a control, it must be specifically described.) If a control can only be verified by documentation then it must be available. All controls must be valid in that they reduce severity, probability or both.

RESIDUAL RISK

Classify risk rating from matrix for each hazard with controls in place.

Environment

1.

Manual Lifting.

Reputation

Personnel

Assets

Classify risk rating from matrix for each hazard with no controls in place.

Hand and Finger Injury. Physical Strain. Equi pment Damage.

1. 2. 3. 4.

2.

Manual Lifting with tools. (Chain blocks and hoists)

Hand and Finger Injury. Physical Strain. Rigging Failure.

1. 2. 3. 4. 5.

Rigger Foreman shall instruct and mentor all personnel on hand and finger placement when working. Rigger Foreman shall instruct and mentor all personnel on proper lifting techniques, Utilize legs with back in a straight position, sufficient number personnel for item to be lifted, etc., No person shall lift any item over 25 Kg. All personnel shall utilize other crew members for assistance when lifting items and inspect packaging prior to making the lift. Rigger Foreman shall instruct and mentor all personnel on hand and finger placement when working. Rigger Foreman shall instruct and mentor all personnel on proper lifting techniques, Utilize legs with back in a straight position, sufficient number personnel for item to be lifted, etc. All personnel shall utilize other crew members for assistance when lifting items and inspect packaging prior to making the lift. Rigger Foreman shall determine the weight of the load and the path of movement the load will be transferred through. Rigger Foreman shall ensure all lifting tools are fit for purpose and inspect prior to use.

Page 1 of 2

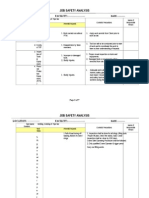

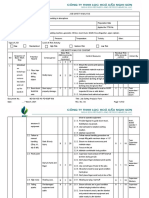

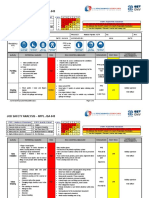

3.

JOB STEPS/TASKS Cutting pipe

HAZARD DESCRIPTION Pinch Points. Uncontrolled load. Hand and finger Injury. Equipment Damage. Fire

RISK TO WHAT?

INITIAL RISK H

1. 2. 3. 4. 5. 6.

REQUIRED CONTROLS Ensure a stable pipeline position Check cutting equipment works well and is safe to use give protection to the cutting area, and keep flamable objects from areas The person using the tool shall ensure the line of fire path is clear prior to applying force to the tool. Use Face shield with Properly welding tools & Mask Prepare a fire extinguisher Use appropriate PPE properly Work area clean of dirt and working tools Standing in the right position Ensure that wastes generated are placed in shelters Completely remove weld slag, flux, debris, grease, oil and any foreign matter on the surfaces of field

RESIDUAL RISK L

4.

Cleaning and flushing pipe

Hazardous waste Uncontrolled load. Fall and slip

1. 2. 3. 4. 5.

Approved by, PT. PERTAMINA (PERSERO)

Checked by, PT. PERTAMINA (PERSERO)

Prepared by, PT. PP-TIMAS KSO

Page 2 of 2

Você também pode gostar

- Jsa For Air Flushin & Mech. Cleaning of PipesDocumento17 páginasJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- RA For High Pressure Cleaning Using HPCE 520-330Documento3 páginasRA For High Pressure Cleaning Using HPCE 520-330George CristianAinda não há avaliações

- Jsa Chemical CleaningDocumento3 páginasJsa Chemical Cleaningyelsa otrebla75% (8)

- JSA For Holiday Testing PDFDocumento4 páginasJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- Jsa-Hot Oil FlushingDocumento2 páginasJsa-Hot Oil Flushingyelsa otrebla100% (5)

- JSA - Chemical CleaningDocumento4 páginasJSA - Chemical CleaningkrshhAinda não há avaliações

- Jsa For Blowing of Air in Underground PipesDocumento4 páginasJsa For Blowing of Air in Underground PipesMohammed MinhajAinda não há avaliações

- JHA Pneumatic Test Using N2Documento4 páginasJHA Pneumatic Test Using N2Luqman Osman89% (9)

- JSA-055 Hydro-TestDocumento24 páginasJSA-055 Hydro-TestOmar Dhieb100% (7)

- JHA Valve Leak Test and RepairDocumento16 páginasJHA Valve Leak Test and Repairrosevelvet100% (1)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocumento2 páginasJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Jsa Nitrogen PurgingDocumento2 páginasJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- Risk Assessment For Air BlowingDocumento8 páginasRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 páginasJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jsa Nitrogen PurgingDocumento2 páginasJsa Nitrogen Purgingmohammedsouqi83% (6)

- JSA For HVAC WorkDocumento8 páginasJSA For HVAC Worksathakathulla100% (3)

- Jsa For HydrotestDocumento10 páginasJsa For HydrotestAnonymous CcGYhZb080% (5)

- Appendix 18 Steam Blowing JSADocumento3 páginasAppendix 18 Steam Blowing JSAzhang75% (12)

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocumento4 páginasDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneAinda não há avaliações

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocumento4 páginasJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- HydroTest JHADocumento14 páginasHydroTest JHAorganicspolybond100% (2)

- Risk Asses 65-Piping Fabricated and Assembly - H03Documento11 páginasRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriAinda não há avaliações

- Hazard Identification and Risk Assessment For Pipe LoweringDocumento4 páginasHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- JHA General Maintenance Activity PDFDocumento5 páginasJHA General Maintenance Activity PDFdede SinbadAinda não há avaliações

- JHA - Handrails and GratingsDocumento10 páginasJHA - Handrails and GratingsVidyesh Nair67% (3)

- JSA - Hydro-Testing of Pipe & EquipmentDocumento1 páginaJSA - Hydro-Testing of Pipe & EquipmentRajuAinda não há avaliações

- JSA For Welding GrindingDocumento7 páginasJSA For Welding GrindingBabar78% (9)

- JSA - Repair-Coating and Finition WorkDocumento3 páginasJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento15 páginasSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshAinda não há avaliações

- Jsa For Drilling.Documento3 páginasJsa For Drilling.Belsyah Nofriyan75% (4)

- Manual Tig Welding (RRC) - Job ProcedureDocumento3 páginasManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- RA Templates - Tank CleaningDocumento26 páginasRA Templates - Tank Cleaningkoib78981% (16)

- 12 JSA FlushingDocumento5 páginas12 JSA FlushingYosua SitumorangAinda não há avaliações

- JSA For Hydro Test Activites (Generic)Documento4 páginasJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA Blasting and Coating KP 69.4Documento5 páginasJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JSA For Diesel Filling at Del CampDocumento6 páginasJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- JSA Cable LayingDocumento2 páginasJSA Cable Layingnishanth100% (2)

- JHA For Loop CheckDocumento8 páginasJHA For Loop CheckFrancis Enriquez Tan83% (6)

- JHA For PWHT WorkDocumento2 páginasJHA For PWHT WorkAzmi Fauzi77% (13)

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocumento7 páginasCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocumento3 páginasR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalAinda não há avaliações

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocumento3 páginasR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalAinda não há avaliações

- Jsa Grinding Welding Gas CuttingDocumento3 páginasJsa Grinding Welding Gas CuttingRyanAinda não há avaliações

- JSA Cable Pulling and Laying WorksDocumento6 páginasJSA Cable Pulling and Laying Workskabir100% (1)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Documento1 páginaJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JSA For Flange AlignmentDocumento5 páginasJSA For Flange AlignmentHưởng Phạm100% (1)

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocumento12 páginasSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJAinda não há avaliações

- Civil JSA Form Block WorkDocumento3 páginasCivil JSA Form Block Workdrmuhsin86% (7)

- JSA For Working at HeightDocumento2 páginasJSA For Working at HeightXUE JIANAinda não há avaliações

- (JSA) For Cast-In-place Reinforced ConcreteDocumento1 página(JSA) For Cast-In-place Reinforced ConcreteNazir Hussain100% (4)

- Jsa Cable TerminationDocumento4 páginasJsa Cable TerminationSyed Yousuf Ali100% (1)

- JSA HandToolsDocumento2 páginasJSA HandToolsCristina Rican100% (3)

- JSA For Cutting, Grinding and Welding in AtmosphereDocumento21 páginasJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Hydrotest & Pneumatic Test - TRADocumento6 páginasHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- JSA-049 Valves & Support Installation and DismantlingDocumento4 páginasJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Documento6 páginasJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganAinda não há avaliações

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Documento20 páginasJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Documento8 páginasFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinAinda não há avaliações

- Construction of Valve ChamberDocumento20 páginasConstruction of Valve ChamberAristotel C. Cabais, RN50% (2)

- JSA FormDocumento6 páginasJSA FormAjeesh CochinAinda não há avaliações

- Safe Work Methods Statement For Lesson Plan 1Documento1 páginaSafe Work Methods Statement For Lesson Plan 1api-402868357Ainda não há avaliações

- Zara Case StudyDocumento21 páginasZara Case StudyKP WongAinda não há avaliações

- Daewoo Fr-590nwixDocumento8 páginasDaewoo Fr-590nwixlesa33Ainda não há avaliações

- Baby Food Teething BiscuitsDocumento14 páginasBaby Food Teething BiscuitsOranje BursucAinda não há avaliações

- Washington Times PIMMDocumento4 páginasWashington Times PIMMReynald Katz100% (1)

- A Study of Brand Awareness and Consumer Perception Towards Saffola Fittify and Cocosoul ProductsDocumento20 páginasA Study of Brand Awareness and Consumer Perception Towards Saffola Fittify and Cocosoul ProductsAbhishek guptaAinda não há avaliações

- SPR NutshellDocumento6 páginasSPR NutshellZenith JinaAinda não há avaliações

- Alicia's Fruity Drinks - Las Aguas Frescas de Alicia by Lupe Ruiz-FloresDocumento34 páginasAlicia's Fruity Drinks - Las Aguas Frescas de Alicia by Lupe Ruiz-FloresArte Público Press100% (1)

- V55 Maintenance 4Documento5 páginasV55 Maintenance 4วรพงษ์ กอชัชวาลAinda não há avaliações

- PROJECTDocumento10 páginasPROJECTAzra Ahmed100% (1)

- Donatos Finding The New PizzaDocumento7 páginasDonatos Finding The New PizzaAyushi KakwaniAinda não há avaliações

- LACEY, Catherine - "Please Take"Documento8 páginasLACEY, Catherine - "Please Take"Julieta DesertiAinda não há avaliações

- E TailingDocumento24 páginasE TailingvsunilduthAinda não há avaliações

- Siemens TK 76K573Documento162 páginasSiemens TK 76K573Krešo KorbeljAinda não há avaliações

- Thermador PRD366GHUDocumento2 páginasThermador PRD366GHUPurcellMurrayAinda não há avaliações

- Glossary of Trade Support Programs.Documento31 páginasGlossary of Trade Support Programs.RogerWilliamCamposAinda não há avaliações

- BukleBabyPattern PDFDocumento21 páginasBukleBabyPattern PDFDam Nhung90% (10)

- Item DBDocumento4 páginasItem DBJoe SykesAinda não há avaliações

- English Task Describing Object - A'TianaDocumento7 páginasEnglish Task Describing Object - A'TianaHhhg Ttree4rAinda não há avaliações

- Agricultural MarketingDocumento46 páginasAgricultural MarketingAmrit Sharma100% (1)

- A Long-Term Survival Guide - Survival Mini-HeatersDocumento7 páginasA Long-Term Survival Guide - Survival Mini-Heatersbuckonbeach100% (1)

- 3705 0901 84 CS14 CrawlerDocumento34 páginas3705 0901 84 CS14 Crawleredwin100% (2)

- Chap 1Documento19 páginasChap 1davidAinda não há avaliações

- Sewing DeffectsDocumento11 páginasSewing DeffectsVeverley CarupoAinda não há avaliações

- Interviewquestions 2Documento3 páginasInterviewquestions 2api-287997424Ainda não há avaliações

- Courier Express and Parcel-Market at A CrossroadsDocumento8 páginasCourier Express and Parcel-Market at A CrossroadskokabAinda não há avaliações

- Lo1 Kitchen UtensilsDocumento74 páginasLo1 Kitchen UtensilsSharonMaeCerezoPaza-Silvestre100% (1)

- PF Defalters ListDocumento70 páginasPF Defalters ListsureshAinda não há avaliações

- Shop Press Assembly InstructionsDocumento16 páginasShop Press Assembly InstructionsOlayinka OlabanjiAinda não há avaliações

- Oneplus Report Ready For SubmissionDocumento27 páginasOneplus Report Ready For SubmissiongeetaAinda não há avaliações