Escolar Documentos

Profissional Documentos

Cultura Documentos

Florprime Esd

Enviado por

charibackupTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Florprime Esd

Enviado por

charibackupDireitos autorais:

Formatos disponíveis

FLORPRIME ESD

WATER BASED EPOXY ANTISTATIC PRIMER

Product Description FLORPRIME ESD is a solvent free black two-pack low viscosity conductive primer based on Epoxy resin. It is used prior to application of Antistatic Epoxy Floor Coating. Green Building Compliance This product is Eco-friendly, Low VOC, waterbased with a high level of mechanical, chemical resistance, ideal for use in Green Building. Features Gives very good adhesion to the top coat. Solvent free Can be applied on Concrete, Metal, Wood etc. Uses FLORPRIME ESD is recommended for priming prior to the application of the FLORGARD ESD /FLORGIENE ESD SL. Properties Application : Brush/Roller Pot Life @ 23 C : 25-30 mins Electrical resistance : 5 x 10 10 ohms Curing Time : Initial Cure 2-3 hours, Full Mech. Cure 12 hours Ready for use Within 24hrs Top coat Full Chemical Cure 7 days Mixing ratio : As supplied The values given above are average figures achieved in laboratory tests. Actual values obtained on site may show minor variations from those quoted. Coverage FLORPRIME ESD: Approximately 8-10 sq.mts /Kg depending on substrate porosity, texture, substrate temperature.

4 8

Method of Application APURVAs system should be installed by approved contractors. Following information should be used as a guideline Surface preparation a) The surface should be fully sealed and primed using FLORPRIME EP primer. b) Before application, the surface to be coated should be free from loose particles. c) Earthing points should be installed including a grid of conductive self adhesive copper tapes at the distance of 5mt. d) The FLORPRIME ESD should be applied on the surface including the copper Tape. Electrical resistance should be tested prior to over coating Concrete defects such as voids, bug holes, excess porosity, and physical and chemical damage are usually filled or repaired prior to the installation of the floor coating system. (Materials such as slurries, mortars, and polymer concrete are used to level, smooth and patch concrete surfaces). The laitance (A thin, weak, brittle layer of cement and aggregate on concrete surface) on in-situ bases and any surface sealer or curing membrane should be entirely removed by suitable mechanised equipment. Old Concrete surfaces: All surface contamination, e.g. oil, paint and rubber, should be removed and adequate mechanical preparation carried out to achieve a sound and stable surface with exposed coarse aggregate. (Existing floor paints should be removed by mechanical abrasion or contained shot blasting. When clear of all surface contamination, the concrete should be prepared mechanically to remove all laitance and expose a fresh surface). After surface preparation all loose debris and dirt should be removed by vacuum- equipment.

Version No. / Date of revision: 02/ May 2011

Mixing: Pack components are pre-weighed for optimum performance. Never split packs. Empty contents of component B into a mixing container and pre-mix to assure the suspension of solids. Add component A and continue to mix to a uniform consistency for 1-2 minutes. Mix with slow speed drill and helical spinner head for 2 minutes. Application FLORPRIME ESD must be applied immediately after mixing the two components. FLORPRIME ESD is applied with a paint brush or roller to produce a thin black film.

Packaging FLORPRIME ESD is available in 5 Kg composite packs for easy handling. Shelf life FLORPRIME ESD has a shelf life of 12 months if kept in warehouse conditions at 30 C in the original, unopened pack. Storage conditions Store in dry conditions between 5oC and 30oC, away from sources of heat and naked flames, in the original, unopened packs. If stored at high temperatures the shelf life will be reduced Handling & Safety Keep the containers tightly sealed when not in use. Avoid skin contact and inhalation of fumes (if any). While spraying it is advised to wear a mask. If it comes in contact with the body, wash affected parts with plenty of water. In case of persistent irritation, contact a physician.

Disclaimer: The manufacturer reserves the right to change the specifications. Apurva India Limited products are guaranteed against material manufactured and are sold subject to the companys Terms and Conditions of Sale. Whilst we endeavour to ensure that advice, specifications, recommendations and information given is correct, we cannot have control over how our products are applied and will not accept liability, directly or indirectly, arising from application of our materials.

Version No. / Date of revision: 02/ May 2011

Você também pode gostar

- Brushbond TI Flexicoat PDFDocumento3 páginasBrushbond TI Flexicoat PDFbalab2311Ainda não há avaliações

- EpiROOF & EpiSPAN BRANZ Apprasial 533 2013Documento5 páginasEpiROOF & EpiSPAN BRANZ Apprasial 533 2013Andrea GibsonAinda não há avaliações

- StyrofoamDocumento12 páginasStyrofoamOliveraAinda não há avaliações

- (PDS) Nitoproof RS (Green Label)Documento3 páginas(PDS) Nitoproof RS (Green Label)Hendra WahyuAinda não há avaliações

- Chartek 8 Product Data SheetDocumento4 páginasChartek 8 Product Data SheetJomer J Simpson0% (1)

- Aero 80FP Operator ManualDocumento48 páginasAero 80FP Operator ManualTimmyAinda não há avaliações

- Elastoseal EPDM Tanking SystemDocumento8 páginasElastoseal EPDM Tanking SystemStephen100% (1)

- Sikagard - 62Documento4 páginasSikagard - 62bassem kooliAinda não há avaliações

- TDS - Masterseal 381Documento2 páginasTDS - Masterseal 381Venkata RaoAinda não há avaliações

- Ardex WPM 2000EPDocumento12 páginasArdex WPM 2000EPHarsa VardhanAinda não há avaliações

- ConcreteDocumento3 páginasConcreteTran DtrungAinda não há avaliações

- National Guard Epoxy Red Oxide PrimerDocumento3 páginasNational Guard Epoxy Red Oxide PrimerCyril J PadiyathAinda não há avaliações

- Masterflow 544Documento3 páginasMasterflow 544Raed BeetawiAinda não há avaliações

- Mad Dog Crack Fix Primer Technical SpecificationsDocumento4 páginasMad Dog Crack Fix Primer Technical SpecificationsMad Dog Paint ProductsAinda não há avaliações

- Thermo Poly RockDocumento15 páginasThermo Poly RockMiguel MartinezAinda não há avaliações

- Dichtol Sealer Broschure ENDocumento12 páginasDichtol Sealer Broschure ENgersom100% (1)

- Ecor WoodDocumento27 páginasEcor Woodxavier668Ainda não há avaliações

- Damp FreeDocumento3 páginasDamp FreeblaqhaqarAinda não há avaliações

- Ti - e - Protegol 130 HT L - Jan 08Documento3 páginasTi - e - Protegol 130 HT L - Jan 08A MahmoodAinda não há avaliações

- 95 44Documento2 páginas95 44Vivek VenugopalAinda não há avaliações

- Koroglass 1000Documento3 páginasKoroglass 1000Sandeep gangulyAinda não há avaliações

- Acrylic Resin FundamentalsDocumento5 páginasAcrylic Resin FundamentalsvaducAinda não há avaliações

- Vistamaxx Processing Guidlines Spunbond Fabrics PDFDocumento2 páginasVistamaxx Processing Guidlines Spunbond Fabrics PDFA MahmoodAinda não há avaliações

- Demidekk Translucent Woodstain Colour Card PDFDocumento4 páginasDemidekk Translucent Woodstain Colour Card PDFkormatekAinda não há avaliações

- Nitoflor TF5000: Constructive SolutionsDocumento3 páginasNitoflor TF5000: Constructive SolutionstalatzahoorAinda não há avaliações

- AAC Vs CLCDocumento23 páginasAAC Vs CLCsandipgargAinda não há avaliações

- Bridges, EnglishDocumento4 páginasBridges, EnglishSyaiful Arif WicaksonoAinda não há avaliações

- SikaflexPRO TdsDocumento6 páginasSikaflexPRO TdsidontlikeebooksAinda não há avaliações

- Ti e Protegol 32-55 H Nov 07Documento3 páginasTi e Protegol 32-55 H Nov 07A MahmoodAinda não há avaliações

- Guia Seleccion Productos AffinityDocumento4 páginasGuia Seleccion Productos AffinityFrank MariniAinda não há avaliações

- Asian Finish Paint Pc0246Documento2 páginasAsian Finish Paint Pc0246m_geniusAinda não há avaliações

- Brake Pad Performance Characteristic Assessment MethodsDocumento13 páginasBrake Pad Performance Characteristic Assessment MethodsGabriel AgyemangAinda não há avaliações

- Ti e Protegol 32-47 R Jan 08Documento3 páginasTi e Protegol 32-47 R Jan 08A MahmoodAinda não há avaliações

- Nitoprime 31Documento2 páginasNitoprime 31Balasubramanian AnanthAinda não há avaliações

- Idrostop SW - 434 7 28e9 PDFDocumento4 páginasIdrostop SW - 434 7 28e9 PDFCheong Wei HaoAinda não há avaliações

- Expanfo PDFDocumento4 páginasExpanfo PDFWolf Lilly0% (1)

- Vibradamp DC30 122IPMDocumento3 páginasVibradamp DC30 122IPMtrublu260112Ainda não há avaliações

- Bison KitDocumento1 páginaBison KitdavethiyaguAinda não há avaliações

- Ice Detection SystemsDocumento6 páginasIce Detection SystemsbnolascoAinda não há avaliações

- Liquid Applied Waterproofing - ProtectowrapDocumento3 páginasLiquid Applied Waterproofing - ProtectowrapYndia SorianoAinda não há avaliações

- Anti-Graffiti Coating PresentationDocumento22 páginasAnti-Graffiti Coating PresentationZenZen F CzoraAinda não há avaliações

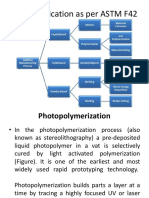

- AM Classification As Per ASTM F42Documento19 páginasAM Classification As Per ASTM F42RajijackAinda não há avaliações

- Renderoc Galvashield XP: Unit SketchDocumento2 páginasRenderoc Galvashield XP: Unit SketchVenkata RaoAinda não há avaliações

- Jotapipe HT Tcm108-27985Documento10 páginasJotapipe HT Tcm108-27985adam051286Ainda não há avaliações

- Orona and Lasma Reatment: N VerviewDocumento25 páginasOrona and Lasma Reatment: N VerviewRaja Pathamuthu.G0% (1)

- 9000 Gloss Finish: Technical Data SheetDocumento2 páginas9000 Gloss Finish: Technical Data Sheetmates isAinda não há avaliações

- MSDS Quickmast 341-BaseDocumento5 páginasMSDS Quickmast 341-BaseM.FAIZAN ARSHAD100% (1)

- Jotun Penguard Midcoat MIO Application GuideDocumento8 páginasJotun Penguard Midcoat MIO Application GuideSANKARAN.KAinda não há avaliações

- Nitocote PE135 : Constructive SolutionsDocumento2 páginasNitocote PE135 : Constructive SolutionsMPS KALIBARUAinda não há avaliações

- Waterproofing Systems BrochureDocumento8 páginasWaterproofing Systems BrochureUpulHettiarachchiAinda não há avaliações

- Masteremaco N 303 Grey Ad Plus: Safety Data SheetDocumento8 páginasMasteremaco N 303 Grey Ad Plus: Safety Data SheetAbdülhalim ChaouatiAinda não há avaliações

- UltraTech Powergrout NS2Documento2 páginasUltraTech Powergrout NS2Savalia HardikAinda não há avaliações

- Terokal 5089-EN PDFDocumento2 páginasTerokal 5089-EN PDFLuis Velasquez SilvaAinda não há avaliações

- Interclene 165Documento4 páginasInterclene 165Trịnh Minh KhoaAinda não há avaliações

- Formula 150 Primer (MILDTL-24441)Documento4 páginasFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaAinda não há avaliações

- Epoxy InjectionDocumento6 páginasEpoxy InjectionPraveenkumar ShanmugamAinda não há avaliações

- Emcephob LE enDocumento2 páginasEmcephob LE enpetronela.12Ainda não há avaliações

- Florgard EsdDocumento3 páginasFlorgard Esddox4printAinda não há avaliações

- Florgard SLDocumento3 páginasFlorgard SLcharibackupAinda não há avaliações

- Fosroc Dekguard PU: Constructive SolutionsDocumento4 páginasFosroc Dekguard PU: Constructive SolutionsganmosesAinda não há avaliações

- Echo Arch RoofingDocumento8 páginasEcho Arch RoofingcharibackupAinda não há avaliações

- United InsulationDocumento3 páginasUnited InsulationcharibackupAinda não há avaliações

- Advance MakeButterfly Valve-Concentric DesignDocumento6 páginasAdvance MakeButterfly Valve-Concentric DesigncharibackupAinda não há avaliações

- AssemblyDocumento17 páginasAssemblycharibackupAinda não há avaliações

- Kailash Innovative RoofingDocumento16 páginasKailash Innovative RoofingcharibackupAinda não há avaliações

- Epack Polymers (P) LTDDocumento20 páginasEpack Polymers (P) LTDcharibackupAinda não há avaliações

- Roofs & Ceilings India PVT LTDDocumento4 páginasRoofs & Ceilings India PVT LTDcharibackupAinda não há avaliações

- Porosil Fibre Free InsulationDocumento7 páginasPorosil Fibre Free InsulationcharibackupAinda não há avaliações

- Vision VenturesDocumento6 páginasVision VenturescharibackupAinda não há avaliações

- Ind Gypsum LimitedDocumento14 páginasInd Gypsum LimitedcharibackupAinda não há avaliações

- Green Form PDFDocumento2 páginasGreen Form PDFcharibackupAinda não há avaliações

- Upvc Pressure Pipes & Pressure FittingsDocumento8 páginasUpvc Pressure Pipes & Pressure FittingscharibackupAinda não há avaliações

- KM Charlebois P5 Structural Design ReportDocumento64 páginasKM Charlebois P5 Structural Design ReportcharibackupAinda não há avaliações

- AutoCAD 2013 What's NewDocumento11 páginasAutoCAD 2013 What's NewLarry GossAinda não há avaliações

- Ameeta Enterprise Introduction LetterDocumento1 páginaAmeeta Enterprise Introduction LettercharibackupAinda não há avaliações

- Field Quality Plan-ADocumento10 páginasField Quality Plan-AcharibackupAinda não há avaliações

- Vennela ConstrcutionsDocumento4 páginasVennela ConstrcutionscharibackupAinda não há avaliações

- Autodoor CatalogueDocumento4 páginasAutodoor CataloguecharibackupAinda não há avaliações

- Hardware Stock ListDocumento14 páginasHardware Stock ListcharibackupAinda não há avaliações

- Epoxy Grout DAVCODocumento2 páginasEpoxy Grout DAVCOcharibackupAinda não há avaliações

- Ameeta Enterprise Introduction LetterDocumento1 páginaAmeeta Enterprise Introduction LettercharibackupAinda não há avaliações

- Air Hand DryersDocumento8 páginasAir Hand DryerscharibackupAinda não há avaliações

- Upvc Pressure Pipes & Pressure FittingsDocumento8 páginasUpvc Pressure Pipes & Pressure FittingscharibackupAinda não há avaliações

- Under Ground Drainage SystemDocumento2 páginasUnder Ground Drainage SystemcharibackupAinda não há avaliações

- Anti Static Vinyl Flooring - Electra - CatalogDocumento2 páginasAnti Static Vinyl Flooring - Electra - CatalogcharibackupAinda não há avaliações

- Anand Metal Roofing Corporate Profile - 2012Documento15 páginasAnand Metal Roofing Corporate Profile - 2012charibackupAinda não há avaliações

- NEW Star - Doors AccessoriesDocumento38 páginasNEW Star - Doors AccessoriescharibackupAinda não há avaliações

- Tonality CladdingDocumento24 páginasTonality CladdingcharibackupAinda não há avaliações

- Fire Door CatalogDocumento29 páginasFire Door CatalogcharibackupAinda não há avaliações

- Upvc Pressure Pipes & Pressure FittingsDocumento8 páginasUpvc Pressure Pipes & Pressure FittingscharibackupAinda não há avaliações

- Evaporation TutorialDocumento2 páginasEvaporation TutorialjayaprinaAinda não há avaliações

- Dow Value ParkDocumento4 páginasDow Value Parkebook ebookAinda não há avaliações

- Electrochemical DyeingDocumento19 páginasElectrochemical DyeingAmit Sharma100% (1)

- ACTI-Mag Brochure 2016Documento4 páginasACTI-Mag Brochure 2016Atharva UlangwarAinda não há avaliações

- CH 3 Chapter 3 Lecture NotesDocumento40 páginasCH 3 Chapter 3 Lecture NotesAffan HassanAinda não há avaliações

- Shaft Failure AnalaysisDocumento36 páginasShaft Failure Analaysisbalaji100% (1)

- Experiment-2 ChemistryDocumento2 páginasExperiment-2 Chemistryanshsoni1101Ainda não há avaliações

- Rock Blasting For MiningDocumento24 páginasRock Blasting For MiningSantha Raman R RAinda não há avaliações

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocumento4 páginasThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312Ainda não há avaliações

- Text BooksDocumento2 páginasText BooksRithik AgrawalAinda não há avaliações

- Chemistry: Redox & Equivalent ConceptsDocumento13 páginasChemistry: Redox & Equivalent ConceptsSubham roushanAinda não há avaliações

- Steam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpiDocumento4 páginasSteam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpidislocationAinda não há avaliações

- Steel Companies ProwessDocumento9 páginasSteel Companies ProwessKshitij AgrawalAinda não há avaliações

- Catalyst and CatalysisDocumento11 páginasCatalyst and CatalysisRehinaAinda não há avaliações

- CWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)Documento129 páginasCWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedAinda não há avaliações

- Proraso Shaving Cream Common Ingredients of 3 TypesDocumento2 páginasProraso Shaving Cream Common Ingredients of 3 Typeschimene madiAinda não há avaliações

- MSC ProjectDocumento1 páginaMSC ProjectmicronaguAinda não há avaliações

- SartoriusDocumento12 páginasSartoriusSarto RosAinda não há avaliações

- Toughened Glass Data SheetsDocumento2 páginasToughened Glass Data SheetsAr Aayush GoelAinda não há avaliações

- SUewBSEA CORROSION11Documento4 páginasSUewBSEA CORROSION11mayheartAinda não há avaliações

- Water and Sediment in Crude Oil by The Centrifuge Method (Laboratory Procedure)Documento13 páginasWater and Sediment in Crude Oil by The Centrifuge Method (Laboratory Procedure)Jeferson RosalesAinda não há avaliações

- AS Chem CH 1.2 Hess LawDocumento21 páginasAS Chem CH 1.2 Hess LawRaymond Chan100% (1)

- Module 2 Filler SlabDocumento19 páginasModule 2 Filler SlabShahnaaz SyediAinda não há avaliações

- D1149Documento4 páginasD1149ABe MustofaAinda não há avaliações

- Chemistry Paper 3 TZ2 HLDocumento36 páginasChemistry Paper 3 TZ2 HLJuan Camilo VargasAinda não há avaliações

- Nsec 2013 PaperDocumento15 páginasNsec 2013 PaperShivamGuptaAinda não há avaliações

- Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products For Compositional AnalysisDocumento8 páginasSampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products For Compositional AnalysisHAMCHI MohammedAinda não há avaliações

- The Innovative New Edjpro Narrow: Suitable For A 125Mm Panel WidthDocumento2 páginasThe Innovative New Edjpro Narrow: Suitable For A 125Mm Panel WidthJacky LeongAinda não há avaliações

- 9.2 Heat Flow & Thermal EquilibriumDocumento32 páginas9.2 Heat Flow & Thermal EquilibriumNabila FarhanaAinda não há avaliações

- MSDS, Hysol Ea 9309.3 NaDocumento5 páginasMSDS, Hysol Ea 9309.3 NaAlexandre PortelaAinda não há avaliações