Escolar Documentos

Profissional Documentos

Cultura Documentos

Saddle 4

Enviado por

RUDHRA DHANASEKARDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Saddle 4

Enviado por

RUDHRA DHANASEKARDireitos autorais:

Formatos disponíveis

Page

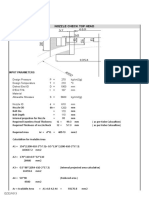

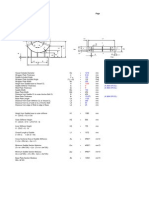

SADDLE, BASE PLATE & ANCHOR BOLT DESIGN - Acceleration due to Transportation

(4 bolts per saddle) Fv

Fl

Fh

H1

Fixed L R

Sliding

f W

tb

Saddle Centres Reaction Height for Longitudinal Force Reaction Height for Lateral Force Bolt Reaction Distance Root Area of 1 Anchor Bolt Base Plate Width Base Plate Thickness Roll Inclination Pitch Inclination Maximum Inclination Angle Vertical Acceleration Longitudinal Acceleration Lateral Acceleration Lateral Acceleration (Av^2 + Ah^2)^0.5 Condition Weight of Vessel Vertical Force at Saddle due to Wd 9.81 x Wd/2 x Cos f Overturning Moment at Saddle Base due to Wd 9.81 x Wd/2 x H x Sin f Reaction at Saddle due to Motw Motw/W Lateral Shear Force due to Wd 9.81 x Wd/2 x Sin f Vertical Force at Saddle due to Av Av x 9.81 x Wd/2 x Cos f Overturning Moment at Saddle Base due to Av Av x 9.81 x Wd/2 x H x Sin f Reaction at Saddle due to Motv Motv/W Lateral Shear Force due to Av 9.81 x Av x Wd/2 x Sin f Vertical Force at Saddle due to A A x 9.81 x Wd/2 x Sin f Overturning Moment at Saddle Base due to A A x 9.81 x Wd/2 x H x Cos f Reaction at Saddle due to A Moth/W Lateral Shear Force at Saddle due to A A x 9.81 x Wd/2 x Cos f

L H1 H W Ra Wb tb +/- fr +/- fp f +/- Av Al Ah A

= = = = = = = = = = = = = =

#REF! #REF! #REF! #REF! #REF! #REF! #REF! 12.83 7.59 20.42 0.57 0.23 0.75 0.94

mm mm mm mm mm^2 mm mm Deg Deg Deg G G G G

(Conservative) #REF! (Conservative) #REF! A 325 Bolt

Dry (Empty Weight) Wd Fvw = = #REF! #REF! kg N

Motw

#REF!

Nmm

Rw

#REF!

Vw

#REF!

+/- Fvv

#REF!

Motv

#REF!

Nmm

+/- Rv

#REF!

Vhv

#REF!

+/- Fvh

#REF!

Moth

#REF!

Nmm

+/- Rh

#REF!

Vhh

#REF!

Page

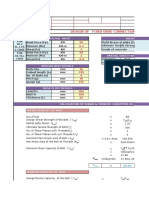

Longitudinal Shear Force at Saddle due to Al Al x 9.81 x Wd/2 Overturning Moment at Saddle Base due to Al Al x 9.81 x Wd x H1/2 Reaction at Saddle due to Al Al x 9.81 x Wd x H1/L Maximum Compressive Load in Saddle Fvw + Rw + Fvv + Rv +Fvh + Rh + Rl Minimum Compressive Load in Saddle Fvw - (Rw + Fvv + Rv +Fvh + Rh + Rl) Tensile Stress in Bolts ((Rw + Rv + Rh)/2 + (Fvv + Fvh + Rl)/4 - Fvw/4)/Ra

Vl

#REF!

Motl

#REF!

Nmm

+/- Rl

#REF!

Fcsmax

#REF!

Fcsmin

#REF!

fbt

#REF!

N/mm^2

<

303.37

N/mm^2

#REF!

Shear Stress in Bolts (Fixed Saddle) fbs ((Vw + Vhv +Vhh)^2 + Vl^2)^0.5/(4 x Ra) - Assumes no friction

#REF!

N/mm^2

<

158.58

N/mm^2

#REF!

Saddle Condition Compressive Stress in Saddle Fcsmax/As Combined Bending Stress in Saddle ((Motw + Motv + Moth)/Zyy)^2 + (Motl/Zxx)^2)^0.5 Shear Stress in Saddle (((Vw + Vhv + Vhh)^2 + Vl^2)^0.5)/As fcs = Dry (Empty Weight) #REF! N/mm^2 < 193.61 N/mm^2 (1.3 x 0.6 x Sy) 212.97 N/mm^2 (1.3 x 0.66 x Sy) 119.04 N/mm^2 (1.3 x 0.8 x Sa) #REF!

fbs

#REF!

N/mm^2

<

#REF!

fss

#REF!

N/mm^2

<

#REF!

Base Plate Maximum Tensile Load in Bolt Max Tensile Stress x Ra Bending Moment at Stiffener 4 x Ftb x L3/L1 Stress in Base Plate 6 x Mb/tb^2 Ftb = #REF! N

Mb

#REF!

Nmm/mm

fbb

#REF!

N/mm^2

<

212.97

N/mm^2

#REF!

Note : Material Min. Yield Stress Min. Allowable Stress Allowable Bending Stress Allowable Compressive Stress Allowable Shear Stress Sy Sa Sb Sc Ss = = = = = A 36M OR EQ. 248.22 114.46 163.83 148.93 91.57 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 (A 325 Bolt)

Allowable Tensile Stress Sy = 303.37 Allowable Bolt Shear Stress Fs = 158.58 Allowable Load as per AISC Steel Construction 9th Edt.

Você também pode gostar

- Saddle 3Documento3 páginasSaddle 3RUDHRA DHANASEKAR100% (1)

- Horizontal Vessel Stress AnalysisDocumento12 páginasHorizontal Vessel Stress AnalysissridharAinda não há avaliações

- Nozzle FEA CalculationDocumento64 páginasNozzle FEA CalculationberylqzAinda não há avaliações

- Saddle Calc PD5500Documento4 páginasSaddle Calc PD5500rsubramaniAinda não há avaliações

- KONARK CHIMNEY Chimney Calculation SheetDocumento18 páginasKONARK CHIMNEY Chimney Calculation SheetBimal DeyAinda não há avaliações

- Chimney Calculation SheetDocumento14 páginasChimney Calculation SheetSrinivasa Rao VenkumahanthiAinda não há avaliações

- PV Elite ResultDocumento239 páginasPV Elite ResultChaitanya Sai TAinda não há avaliações

- Combined Load TowerDocumento21 páginasCombined Load TowerHusin SaputraAinda não há avaliações

- Slot Expansion CalculationDocumento1 páginaSlot Expansion CalculationSarfaraz KhanAinda não há avaliações

- Shell Type Boiler CalculationsDocumento17 páginasShell Type Boiler Calculations9913489806Ainda não há avaliações

- Cone dimensions and calculationsDocumento4 páginasCone dimensions and calculationsanil4u29100% (1)

- Output Data: Design CaseDocumento3 páginasOutput Data: Design CaseAnonymous RytT6uvX1Ainda não há avaliações

- TubesheetDocumento8 páginasTubesheetVaibhavAinda não há avaliações

- DmTank Ring Wall Foundation+&+Annular+RaftDocumento5 páginasDmTank Ring Wall Foundation+&+Annular+RaftRM PaduaAinda não há avaliações

- JI2048-978-MS-DAT-0014 - Rev001 (SP-1090)Documento9 páginasJI2048-978-MS-DAT-0014 - Rev001 (SP-1090)Tech DesignAinda não há avaliações

- HORIZONTAL VESSEL STRESS CALCULATIONSDocumento12 páginasHORIZONTAL VESSEL STRESS CALCULATIONSSanket BhaleraoAinda não há avaliações

- SS GratingDocumento1 páginaSS GratingM. Ali ZouhairyAinda não há avaliações

- Analysis of Corrugated Web Beam To Column Extended End Plate Connection UsingDocumento75 páginasAnalysis of Corrugated Web Beam To Column Extended End Plate Connection UsingLina Lina LoulouAinda não há avaliações

- Plate RectangularDocumento8 páginasPlate RectangularRUBEN BARTOLOME GARCIAAinda não há avaliações

- Anchor Bolt Design for 26 kip Axial LoadDocumento34 páginasAnchor Bolt Design for 26 kip Axial LoadPioneer Design and Development LimitedAinda não há avaliações

- Sample FLG CalcDocumento6 páginasSample FLG CalcameyyammaiAinda não há avaliações

- Muk 61 2 PLL 0007 9H8Documento34 páginasMuk 61 2 PLL 0007 9H8Suresh MahalingamAinda não há avaliações

- Saddle v1-10: Fixed Saddle Sliding SaddleDocumento30 páginasSaddle v1-10: Fixed Saddle Sliding SaddleidiazgAinda não há avaliações

- Platform Cleat Calculations for No. 1 at El. 47700Documento4 páginasPlatform Cleat Calculations for No. 1 at El. 47700shaishavAinda não há avaliações

- Nozzle Check Top Head: Input ParametersDocumento2 páginasNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Studding Flange Calculations Gasket SelectionDocumento6 páginasStudding Flange Calculations Gasket SelectionDarshan PanchalAinda não há avaliações

- Cdo CalcDocumento3 páginasCdo CalcJeric FarinAinda não há avaliações

- Stress at Junction of Shell & HeadDocumento13 páginasStress at Junction of Shell & HeadRey Fiedacan100% (1)

- AISC ASD Base Plate Thickness V2016-2Documento9 páginasAISC ASD Base Plate Thickness V2016-2yusuf_jtAinda não há avaliações

- Cover Pages For PV Elite VenvelDocumento14 páginasCover Pages For PV Elite VenvelSakthi VelAinda não há avaliações

- Insert Plate Design - LugsDocumento8 páginasInsert Plate Design - Lugsnavneet3bawaAinda não há avaliações

- Bolt Load Design CalculationDocumento2 páginasBolt Load Design CalculationDamanpreet SinghAinda não há avaliações

- Clip PlatformDocumento24 páginasClip Platformwisnu_bayusaktiAinda não há avaliações

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Documento26 páginas019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaAinda não há avaliações

- 05-1 Base Plate-FixedDocumento49 páginas05-1 Base Plate-FixedJames AugustineAinda não há avaliações

- Beam Column - IS 800Documento2 páginasBeam Column - IS 800parishith0% (1)

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocumento10 páginasDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5Ainda não há avaliações

- CH Design-R1 PDFDocumento12 páginasCH Design-R1 PDFmazumdar_satyajitAinda não há avaliações

- Internal CoilDocumento2 páginasInternal CoilwhngomjAinda não há avaliações

- Pa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyDocumento33 páginasPa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyHmilkAinda não há avaliações

- Design of base plate for columnDocumento6 páginasDesign of base plate for columnsoumyaAinda não há avaliações

- 7 PDFDocumento26 páginas7 PDFargaAinda não há avaliações

- PO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDDocumento18 páginasPO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDUmair RazaAinda não há avaliações

- Superheated Steam Condensate TankDocumento4 páginasSuperheated Steam Condensate TankGanesh BhardwajAinda não há avaliações

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocumento1 páginaNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191Ainda não há avaliações

- Tailing LugDocumento3 páginasTailing LugSajad AbdulAinda não há avaliações

- API 650 STORAGE TANK DESIGN CALCULATIONDocumento14 páginasAPI 650 STORAGE TANK DESIGN CALCULATIONhgagselim2012Ainda não há avaliações

- Sectional Properties Root DistanceDocumento4 páginasSectional Properties Root DistanceVenkatasubramanian IyerAinda não há avaliações

- NozzleDocumento11 páginasNozzleharyfadlyAinda não há avaliações

- Waste Water Equalising Tank Anchor Chair DetailsDocumento4 páginasWaste Water Equalising Tank Anchor Chair DetailsShaheed HossainAinda não há avaliações

- F Q GC A: Wind Load On StructuresDocumento55 páginasF Q GC A: Wind Load On StructuresAna Bella RosarioAinda não há avaliações

- 003-Heat ExchangerDocumento299 páginas003-Heat ExchangerVijayshanker GuptaAinda não há avaliações

- Skirt Support TrialDocumento11 páginasSkirt Support TrialAbhishek Nag0% (1)

- Tailing LugDocumento2 páginasTailing Lugjagannadha varmaAinda não há avaliações

- Fuel Diesel Storage Tank Calculation SheetDocumento4 páginasFuel Diesel Storage Tank Calculation SheetAbhijeetAinda não há avaliações

- Pressure Vessel Design Old (Eugyene F Megysey)Documento31 páginasPressure Vessel Design Old (Eugyene F Megysey)David FonsecaAinda não há avaliações

- Saddle 1Documento3 páginasSaddle 1RUDHRA DHANASEKARAinda não há avaliações

- Crane Load-Chemical Storage ShelterDocumento44 páginasCrane Load-Chemical Storage ShelterAndreas HendiAinda não há avaliações

- T - Shear Force and Bending Moment Diagr-1Documento95 páginasT - Shear Force and Bending Moment Diagr-1Freddie Burnham100% (2)

- Beam To Beam Web - Shear ConnectionDocumento2 páginasBeam To Beam Web - Shear ConnectionGautam SharmaAinda não há avaliações

- PE FeestructDocumento1 páginaPE FeestructRUDHRA DHANASEKARAinda não há avaliações

- AutoPipe Vessel PresentationDocumento32 páginasAutoPipe Vessel PresentationRUDHRA DHANASEKARAinda não há avaliações

- HVAC Ducting - Principles and FundamentalsDocumento56 páginasHVAC Ducting - Principles and FundamentalsRiddhi Patel100% (1)

- Gc-27 (West Kuwait) : Arabi Enertech K.S.CDocumento1 páginaGc-27 (West Kuwait) : Arabi Enertech K.S.CRUDHRA DHANASEKARAinda não há avaliações

- Design and Study of Floating Roof For Oil Storage TanksDocumento20 páginasDesign and Study of Floating Roof For Oil Storage TanksswaminathanAinda não há avaliações

- Diploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)Documento2 páginasDiploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)RUDHRA DHANASEKARAinda não há avaliações

- Stiffness Coefficients For Nozzles in API 650 Tanks PDFDocumento8 páginasStiffness Coefficients For Nozzles in API 650 Tanks PDFvijay10484100% (1)

- Cygnus Surface Brochure Iss7Documento12 páginasCygnus Surface Brochure Iss7RUDHRA DHANASEKARAinda não há avaliações

- Kill Your Limiting Beliefs PDFDocumento8 páginasKill Your Limiting Beliefs PDFBhupesh PatelAinda não há avaliações

- Power Capacity HVAC CalculationDocumento12 páginasPower Capacity HVAC CalculationEdAinda não há avaliações

- Hvac Formulas PDFDocumento25 páginasHvac Formulas PDFSaraswatapalit0% (1)

- Api 610Documento11 páginasApi 610prakasharmyAinda não há avaliações

- M-2214 - SHT 2 PDFDocumento1 páginaM-2214 - SHT 2 PDFRUDHRA DHANASEKARAinda não há avaliações

- Pipe SupportDocumento5 páginasPipe SupportRUDHRA DHANASEKARAinda não há avaliações

- Li Cad 10 SettingsDocumento2 páginasLi Cad 10 SettingsRUDHRA DHANASEKARAinda não há avaliações

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityDocumento67 páginasWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- Syllabus - : Week 1 2: Simulation Tool TrainingDocumento16 páginasSyllabus - : Week 1 2: Simulation Tool TrainingRUDHRA DHANASEKARAinda não há avaliações

- Bottle SupportsDocumento2 páginasBottle SupportsRUDHRA DHANASEKARAinda não há avaliações

- Parents' Handbook of Careers After SchoolDocumento32 páginasParents' Handbook of Careers After Schoolraj50% (4)

- Ga-Key PlanDocumento1 páginaGa-Key PlanRUDHRA DHANASEKARAinda não há avaliações

- Symbols Pipe SupportDocumento1 páginaSymbols Pipe SupportRUDHRA DHANASEKARAinda não há avaliações

- What's New - PV Elite 2018Documento36 páginasWhat's New - PV Elite 2018RUDHRA DHANASEKARAinda não há avaliações

- Trigonometry Formulas PDFDocumento2 páginasTrigonometry Formulas PDFsasi15augAinda não há avaliações

- Internal & DetailDocumento1 páginaInternal & DetailRUDHRA DHANASEKARAinda não há avaliações

- What S New - PV Elite 2018Documento5 páginasWhat S New - PV Elite 2018NirmalAinda não há avaliações

- Man Crane Cages Check Sheet GuideDocumento1 páginaMan Crane Cages Check Sheet GuideRUDHRA DHANASEKAR100% (1)

- Lifting DetailDocumento1 páginaLifting DetailRUDHRA DHANASEKARAinda não há avaliações

- Algebra Formulas Cheat SheetDocumento3 páginasAlgebra Formulas Cheat Sheetyuvarajr30Ainda não há avaliações

- Series FormulasDocumento3 páginasSeries FormulasBachchan MishraAinda não há avaliações

- Chapter 13: The Electronic Spectra of ComplexesDocumento42 páginasChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniAinda não há avaliações

- Network of Global Corporate Control. Swiss Federal Institute of Technology in ZurichDocumento36 páginasNetwork of Global Corporate Control. Swiss Federal Institute of Technology in Zurichvirtualminded100% (2)

- Code - Aster: Multiaxial Criteria of Starting in FatigueDocumento44 páginasCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoAinda não há avaliações

- XI-Opt. Syllabus (2023-24)Documento29 páginasXI-Opt. Syllabus (2023-24)INDERDEEPAinda não há avaliações

- Brake SystemDocumento19 páginasBrake SystemSudarshan NepalAinda não há avaliações

- p-4500 Technical InformationDocumento13 páginasp-4500 Technical InformationElhoiAinda não há avaliações

- Problem Set 1 CirclesDocumento2 páginasProblem Set 1 Circlesapi-339611548100% (1)

- Kollidon 30 Technical InformationDocumento10 páginasKollidon 30 Technical InformationhomarearisugawaAinda não há avaliações

- Inductive TransducersDocumento12 páginasInductive TransducersMUKESH SUNDARARAJANAinda não há avaliações

- Writing Iap Smarten Up in Maths Age 7 8Documento38 páginasWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Paracetamol Overdose: BW 40 KG Without Fluid RestrictionDocumento2 páginasParacetamol Overdose: BW 40 KG Without Fluid RestrictionAndy TanAinda não há avaliações

- Effect of Temperature on Chemical ReactionDocumento8 páginasEffect of Temperature on Chemical ReactionnajihahAinda não há avaliações

- Correct AnswerDocumento120 páginasCorrect Answerdebaprasad ghosh100% (1)

- FINAL Painless Algebra For DavaoDocumento28 páginasFINAL Painless Algebra For DavaozapleekillsAinda não há avaliações

- Chapter 2Documento2 páginasChapter 2LolmasterAinda não há avaliações

- Service Manual (V1.22)Documento529 páginasService Manual (V1.22)JensAinda não há avaliações

- Forrester Roi StudyDocumento30 páginasForrester Roi StudymcgettsAinda não há avaliações

- Probability DPP (1 To 7) 13th WADocumento16 páginasProbability DPP (1 To 7) 13th WARaju SinghAinda não há avaliações

- The Architecture Tradeoff Analysis MethodDocumento11 páginasThe Architecture Tradeoff Analysis MethoducinfpracticasAinda não há avaliações

- Basic C MCQ - FinalDocumento51 páginasBasic C MCQ - FinalDhivya DharshniAinda não há avaliações

- Open Hole Logs Introduction GR SP CALDocumento21 páginasOpen Hole Logs Introduction GR SP CALmagedAinda não há avaliações

- Essay For Villa Savoye AbstractDocumento1 páginaEssay For Villa Savoye AbstractFrancis PohAinda não há avaliações

- Chapter 1Documento11 páginasChapter 1bekemaAinda não há avaliações

- Excerpt From Surely Youre Joking, Mr. FeynmanDocumento4 páginasExcerpt From Surely Youre Joking, Mr. FeynmanElbis Santos CardosoAinda não há avaliações

- 3G Commands in EricssonDocumento2 páginas3G Commands in EricssonKeshav Singh0% (1)

- Water Pinch PresentationDocumento14 páginasWater Pinch PresentationDafiMaboAinda não há avaliações

- Balmer PDFDocumento3 páginasBalmer PDFVictor De Paula VilaAinda não há avaliações

- AMCP 706-185, Military Pyrotechnics - Theory and ApplicationDocumento270 páginasAMCP 706-185, Military Pyrotechnics - Theory and ApplicationASDAFF ASADAinda não há avaliações

- Phase Transition of RNA Protein Complexes Into Ordered Hollow CondensatesDocumento9 páginasPhase Transition of RNA Protein Complexes Into Ordered Hollow CondensatesMilan StepanovAinda não há avaliações

- Refinery TankagesDocumento4 páginasRefinery Tankagesmayuresh1101100% (1)