Escolar Documentos

Profissional Documentos

Cultura Documentos

Lab Report #1 Materials Scienc

Enviado por

Rob JohnsonDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lab Report #1 Materials Scienc

Enviado por

Rob JohnsonDireitos autorais:

Formatos disponíveis

Robert Johnson Materials Science Laboratory Report #1 Selection of a Piping Material for a Corrosive Environment

Introduction I have been hired by Kaufmann Enterprises tasked with providing a recommendation of the best material to be used for piping a reactor vessel that will operate at 525C. Kaufmann Enterprises has also asked me to provide recommendations as to how this piping should be added to the vessel. The reactor itself will be constructed out of a special stainless steel. I have been supplied five potential materials for piping: Brass, bronze, copper, aluminum, and stainless steel. Each of these materials has different characteristics and costs associated with them. I have performed an experiment in order to determine which of these options will be most effective. The main goal of this experiment was to determine the coefficients of linear expansion for each material. My lab partner (Austin Kleinmeyer) and I conducted this experiment on February 21, 2013. The experiment was performed in the Seamans Center located in Iowa City, Iowa. Background The materials being tested in this lab are brass, bronze, aluminum, and stainless steel. Each of these materials has a theoretical coefficient of thermal expansion. The equation for the coefficient of thermal expansion is given below:

In this equation, is equal to the coefficient of thermal expansion, L is equal to the change in length of the member, Lo is equal to the original length of the member, and T is equal to the change in temperature of the member. The coefficient of linear expansion is important because it governs what material is best for a certain application. It essentially tells you how much a materials length will change when subjected to a change in temperature. In engineering design, if you want to use a material that wont expand during temperature changes (ex. Change of seasons), then you will want that material to have a low coefficient of linear expansion. In the engineering field, sometimes it is desirable to combine two different materials in order to obtain a certain result. In this case, it is sometimes useful to combine materials to obtain different coefficients of linear expansion. For example, sometimes it is desirable to combine two materials with similar coefficients of linear expansion. If one wants to have characteristics of two different materials in one alloy, but would like to retain a certain coefficient of linear expansion, then one would want those two materials to have similar coefficients of linear expansion. On the other hand, if one would like characteristics of two different metals in one alloy, but would like a different coefficient of linear expansion, then one would want the two materials to have not similar coefficients of linear expansion. The main goal of this lab was to measure the coefficient of thermal expansion for each of the said materials. The theoretical coefficients of linear expansion according to www.engineeringtoolbox.com are located on the next page.

Material Aluminum Brass Copper Stainless Steel

5.40E-06 1.87E-05 1.66E-05

Table 1: Theoretical coefficients of linear expansion Experimental Methods In this experiment, the main goal was to measure the coefficients of linear expansion for each material. This was done using a very methodical process. Below is an outline of the process. Each step will be described in detail below the outline. 1. Measure initial length of material. 2. Place material inside of heat exchanger.

3. Apply water to material within heat exchanger. Apply for approximately one minute. 4. Remove water from heat exchanger and connect steam generator. 5. Carefully monitor the micrometer until the material has stopped expanding. Record change in length. 6. Remove steam connection and material from the heat exchanger. 7. Repeat with next material. Before the process can be described in detail, it is important to define each of the pieces of equipment used in this experiment. The first piece of equipment used is the heat exchanger. The heat exchanger is an apparatus which houses a material while heat is applied to it. In this

case, heat is applied through the use of steam. The second piece of equipment used is the micrometer. A micrometer measures change in length. In this case, the rod will be changing in length, and the micrometer will measure that change. The third piece of equipment used in this lab will be the steam generator. The steam generator produces steam through the heating of water. This steam is transferred to the heat exchanger through the use of a tube. The equipment used can be seen in the figures below.

Figure 1: Steam Generator

Figure 2: Heat Exchanger

Figure 3: Micrometer

Now that the equipment has been defined, the process can be described in detail. In step 1, the initial length of the material was measured. This was done using a meter stick. Once the material was measured, the results were recorded as Lo. In step 2, the material was placed inside of the heat exchanger. While one group member held up the heat exchanger at an angle, the other group member would carefully insert the material. In step 3, water was applied to the material. First, a water line was connected from the sink nozzle to the heat exchanger. The water handle was turned on letting water freely flow in the heat exchanger. This water was applied for one minute. In step 4, the water line was disconnected and the steam generator tube was connected. The tube running from the generator was connected to the heat exchanger via the same opening that the water was connected. In step 5, the micrometer was carefully monitored until the needle in the gauge stopped moving. This indicated that the material has stopped expanding. The value that the micrometer read was recorded and was labeled L.

Você também pode gostar

- Mat. Sci. Lab 1Documento13 páginasMat. Sci. Lab 1quikmusic10Ainda não há avaliações

- PHY12L Experiment 1Documento6 páginasPHY12L Experiment 1'Arth Llantos100% (1)

- 301 - Phy12lDocumento13 páginas301 - Phy12lSayre BongoAinda não há avaliações

- Exp301 Linear ExpansionDocumento4 páginasExp301 Linear ExpansionJhenz Santos Bayadas0% (1)

- ConclusionDocumento1 páginaConclusionMark Asesor Calonzo100% (1)

- Thermo Lab Rep 1 Di Pa Tapos WahaDocumento3 páginasThermo Lab Rep 1 Di Pa Tapos WahaKristel May SomeraAinda não há avaliações

- Experiment No. 1: Linear ExpansionDocumento4 páginasExperiment No. 1: Linear ExpansionTreksha DCAinda não há avaliações

- School of Humanities and Social Sciences HW0210 Technical Communication (Semester 1) Assignment 1 ReportDocumento23 páginasSchool of Humanities and Social Sciences HW0210 Technical Communication (Semester 1) Assignment 1 ReportElearning TuitionAinda não há avaliações

- Experiment 3Documento14 páginasExperiment 3Ria Divine Dela CruzAinda não há avaliações

- Lab Exp. No. (5) : Linear Expansion CoefficientDocumento13 páginasLab Exp. No. (5) : Linear Expansion CoefficientM. NAinda não há avaliações

- Experiment 7 ReportDocumento5 páginasExperiment 7 ReportMuhammad Yusazrien100% (1)

- ExperimentDocumento9 páginasExperimentshaina.planco4Ainda não há avaliações

- Linear Thermal ExpansionDocumento13 páginasLinear Thermal ExpansionDhanvini BasavaAinda não há avaliações

- Tan - ECE1 - PHYICS 2 - EXPT3Documento6 páginasTan - ECE1 - PHYICS 2 - EXPT3Jazzle eirol tanAinda não há avaliações

- p6 En303 Manvi Nilaya (2k20 - en - 44)Documento9 páginasp6 En303 Manvi Nilaya (2k20 - en - 44)2K20 EN 63 Sankalp PurwarAinda não há avaliações

- AC1 Thermal ConductivityDocumento2 páginasAC1 Thermal ConductivityPhillip CookAinda não há avaliações

- De Guzman, Anne K.: 2013150302 Bsche-2 Group 2 Phy12L-A4Documento4 páginasDe Guzman, Anne K.: 2013150302 Bsche-2 Group 2 Phy12L-A4Keven DalidaAinda não há avaliações

- Lab1 CPDocumento4 páginasLab1 CPVinícius CastellaniAinda não há avaliações

- What You Need: Calorimeter, Thermometer, Samples of Aluminum, Copper and Lead, Triple Beam Balance, BoilingDocumento1 páginaWhat You Need: Calorimeter, Thermometer, Samples of Aluminum, Copper and Lead, Triple Beam Balance, BoilingRodney ManuelAinda não há avaliações

- Experiment No. 4 Temperature Measuring Instruments: ObjectivesDocumento5 páginasExperiment No. 4 Temperature Measuring Instruments: ObjectivesAltamash MunirAinda não há avaliações

- Experiment 301: Linear Expansion: SUMMARY (E301)Documento3 páginasExperiment 301: Linear Expansion: SUMMARY (E301)RitzAinda não há avaliações

- Heat Loss Calculations in Bare and Lagged Pipes: Research WorkDocumento22 páginasHeat Loss Calculations in Bare and Lagged Pipes: Research WorkHeraldBayocaAinda não há avaliações

- Experiment 301Documento9 páginasExperiment 301Jason DignosAinda não há avaliações

- Meier Experiment 3Documento7 páginasMeier Experiment 3sekarnanoAinda não há avaliações

- Observation of Abundant Heat Production From A Reactor Device and of Isotopic Changes in The FuelDocumento53 páginasObservation of Abundant Heat Production From A Reactor Device and of Isotopic Changes in The Fuelecatworld67% (3)

- ECAT Test Report 2014Documento53 páginasECAT Test Report 2014ecatdotcomAinda não há avaliações

- Lab 11Documento11 páginasLab 11jutkiewiczAinda não há avaliações

- Individual ReportDocumento2 páginasIndividual ReportmagandasitinsAinda não há avaliações

- Full PaperDocumento42 páginasFull Paperapi-280634280Ainda não há avaliações

- Temperature MeasurementDocumento10 páginasTemperature MeasurementTemitayo SolankeAinda não há avaliações

- Experiment 105 Linear Expansion: PhysicsDocumento4 páginasExperiment 105 Linear Expansion: PhysicsJag MasterAinda não há avaliações

- Coefficient of Linear ExpansionDocumento3 páginasCoefficient of Linear ExpansionJameil Decatoria Magomnang Jr.Ainda não há avaliações

- Coefficient of Linear ExpansionDocumento2 páginasCoefficient of Linear ExpansionnavinjohnAinda não há avaliações

- Linear Heat Conduction LabDocumento19 páginasLinear Heat Conduction LabJeffrey Oshiro100% (2)

- DesignDocumento5 páginasDesignokoya marvinAinda não há avaliações

- Specific Heat LabDocumento4 páginasSpecific Heat Labpauleid998807100% (2)

- Department of Mechanical EngineeringDocumento15 páginasDepartment of Mechanical EngineeringDharmendra BelwanshiAinda não há avaliações

- Lab 4 Thermal ConductivityDocumento8 páginasLab 4 Thermal ConductivityShung Tak Chan100% (1)

- Experimental Investigation Increse Rate of Heat Transfer inDocumento15 páginasExperimental Investigation Increse Rate of Heat Transfer inpalash kadamAinda não há avaliações

- Soda Can Solar Air HeaterDocumento8 páginasSoda Can Solar Air HeaterMatthew Zaragoza100% (1)

- PHY12L Experiment 1Documento6 páginasPHY12L Experiment 1Trixia Mae Regalado OsoAinda não há avaliações

- Experiment 105 Linear ExpansionDocumento5 páginasExperiment 105 Linear ExpansionHunter JonesAinda não há avaliações

- Butler Belcher GermanDocumento27 páginasButler Belcher GermanKumaranAinda não há avaliações

- Thermal - Expansion and ConductivityDocumento7 páginasThermal - Expansion and ConductivityrasprasadAinda não há avaliações

- Temperature Measuring Devices ExperimentDocumento3 páginasTemperature Measuring Devices ExperimentNoman Iqbal BhattiAinda não há avaliações

- Cheverda 2019 J. Phys. Conf. Ser. 1369 012053Documento5 páginasCheverda 2019 J. Phys. Conf. Ser. 1369 012053Hammad AhmedAinda não há avaliações

- EXPERIMENT 1 ThermoDocumento7 páginasEXPERIMENT 1 ThermoDogus HurdoganogluAinda não há avaliações

- Our Physical World (Part 2)Documento40 páginasOur Physical World (Part 2)knoxphysicsAinda não há avaliações

- Cooling of Electronic Equipmentteam8Documento7 páginasCooling of Electronic Equipmentteam8Amey Puranik100% (1)

- Experiment B Temperature Measurement and Control: ObjectivesDocumento11 páginasExperiment B Temperature Measurement and Control: ObjectivesVishalAinda não há avaliações

- تقرير انتقال جديدDocumento3 páginasتقرير انتقال جديدسجاد جابر رمضان موازيAinda não há avaliações

- Specific Heat Lab ReportDocumento28 páginasSpecific Heat Lab ReportCreisttiano Raymond83% (6)

- Contoh LaporanDocumento16 páginasContoh LaporanFatimah Mohd JamilAinda não há avaliações

- Muschen BroekDocumento24 páginasMuschen BroekArdy25Ainda não há avaliações

- Lab Report DilatometerDocumento7 páginasLab Report DilatometerHadia SAULATAinda não há avaliações

- EXPERIMENT 301: Linear Expansion: AnalysisDocumento2 páginasEXPERIMENT 301: Linear Expansion: AnalysisJosephAinda não há avaliações

- And Mass TransferDocumento13 páginasAnd Mass TransferUsama ArifAinda não há avaliações

- Engineering Instrumentation Lab Report 2Documento6 páginasEngineering Instrumentation Lab Report 2Rob JohnsonAinda não há avaliações

- Homework 4 Code For Finite Element AnalysisDocumento1 páginaHomework 4 Code For Finite Element AnalysisRob JohnsonAinda não há avaliações

- Problem Statement For Design For ManufacturingDocumento3 páginasProblem Statement For Design For ManufacturingRob JohnsonAinda não há avaliações

- Rough Draft of Design For Manufacturing Electric CarDocumento6 páginasRough Draft of Design For Manufacturing Electric CarRob JohnsonAinda não há avaliações

- Materials Science Polymers Lab ReportDocumento10 páginasMaterials Science Polymers Lab ReportRob Johnson100% (1)

- Exam 1 ReviewDocumento15 páginasExam 1 ReviewRob JohnsonAinda não há avaliações

- Thermodynamics One Homework CodeDocumento1 páginaThermodynamics One Homework CodeRob JohnsonAinda não há avaliações

- Assignment 2 Design For ManufacturingDocumento3 páginasAssignment 2 Design For ManufacturingRob JohnsonAinda não há avaliações

- Proposal To The Grants For Furthering EducationDocumento1 páginaProposal To The Grants For Furthering EducationRob JohnsonAinda não há avaliações

- Price List EcoLum Price List March 2023 IssueDocumento12 páginasPrice List EcoLum Price List March 2023 IssueGrace Mecate VillanuevaAinda não há avaliações

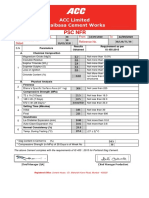

- Acc PSC - NFR - 38 - 2020Documento1 páginaAcc PSC - NFR - 38 - 2020kartick adhikaryAinda não há avaliações

- Klima Ormar 15 KW Data SheetDocumento2 páginasKlima Ormar 15 KW Data SheetCallany AnycallAinda não há avaliações

- Project Profile On Vacuum Cleaner1Documento9 páginasProject Profile On Vacuum Cleaner1Rock TalAinda não há avaliações

- Original Material "S" Green: Technical InformationDocumento1 páginaOriginal Material "S" Green: Technical InformationPedro Henriques RamosAinda não há avaliações

- S.No Activity ID Activity Name Number of Resource Team Normal Resource Team ProductivityDocumento3 páginasS.No Activity ID Activity Name Number of Resource Team Normal Resource Team ProductivitySAMEER AHMEDAinda não há avaliações

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDocumento5 páginasDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorAinda não há avaliações

- Astm A307Documento1 páginaAstm A307SAlman Khan100% (1)

- Dear Ashok PathakDocumento60 páginasDear Ashok Pathakcpmishra2010Ainda não há avaliações

- Tigb006 03Documento2 páginasTigb006 03Berhanu ZelalemAinda não há avaliações

- Polyfuse Report MaterialDocumento53 páginasPolyfuse Report Materialgauravpgi4567% (3)

- VPAKDocumento2 páginasVPAKPingu3Ainda não há avaliações

- 2 Plastic DeformationDocumento33 páginas2 Plastic DeformationpremquilonAinda não há avaliações

- Presentation of Circuit Breaker: Name of Student: Rubina Begum Id: 172-142-003 Batch: EEE-EVE/34thDocumento12 páginasPresentation of Circuit Breaker: Name of Student: Rubina Begum Id: 172-142-003 Batch: EEE-EVE/34thMoniruzzaman JuwelAinda não há avaliações

- Corrosion ResistanceDocumento482 páginasCorrosion ResistanceJosé Ramírez100% (1)

- Sika Backing RodDocumento2 páginasSika Backing Rodthe pilotAinda não há avaliações

- No.2 Calculation of Pump Head. (Condenser Water) Air-Conditioning SystemDocumento1 páginaNo.2 Calculation of Pump Head. (Condenser Water) Air-Conditioning SystemRey ObiasAinda não há avaliações

- Scaph SpecnDocumento3 páginasScaph SpecnV U P RaoAinda não há avaliações

- Solution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodDocumento6 páginasSolution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodacckypenrynAinda não há avaliações

- Buoyant Foam TutorialDocumento26 páginasBuoyant Foam TutorialWagner GaluppoAinda não há avaliações

- Is 2062 1999Documento2 páginasIs 2062 1999Vishal BhapkarAinda não há avaliações

- Thermal ComfortDocumento25 páginasThermal Comfortshahzadali0786Ainda não há avaliações

- W11 Normal and Higher Strength Hull Structural Steels W11Documento45 páginasW11 Normal and Higher Strength Hull Structural Steels W11Fernando ReyesAinda não há avaliações

- Rawalpindi 1 2024Documento213 páginasRawalpindi 1 2024zubair5208434Ainda não há avaliações

- Hvac Report 20140604Documento198 páginasHvac Report 20140604Muhammad Yusuf FirdausAinda não há avaliações

- TRO CX7323 - E11 - Ad PDFDocumento2 páginasTRO CX7323 - E11 - Ad PDFJosip DuvnjakAinda não há avaliações

- THAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ADocumento10 páginasTHAIOIL - BEAM TO BEAM - FIN PLATE - BOLTED - 001 - Rev ACivil StructureAinda não há avaliações

- NPSHDocumento7 páginasNPSHsateesh chandAinda não há avaliações

- Gabion, Geo Textile & RenomatressDocumento4 páginasGabion, Geo Textile & RenomatressSandun NimanthaAinda não há avaliações

- HSR Basic Rate 2018Documento10 páginasHSR Basic Rate 2018R A P RathnaseeliAinda não há avaliações