Escolar Documentos

Profissional Documentos

Cultura Documentos

M25 Mix Designs As Per IS102622009

Enviado por

gdesh90Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

M25 Mix Designs As Per IS102622009

Enviado por

gdesh90Direitos autorais:

Formatos disponíveis

e ngine e ringcivil.

co m

http://www.engineeringcivil.co m/m-25-mix-designs-as-per-is-10262-2009.html

M-25 Mix Designs as per IS-10262-2009

Po sted in Mix Design | Email This Po st |

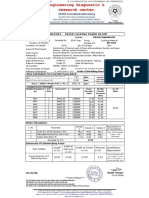

Dear All Again I am back with M-25 Mix Designs as per IS-10262-2009. Regards Raj Mohammad Khan M-25 CONCRET E MIX DESIGN As per IS 10262-2009 & MORT &H A-1 1 2 Stipulations for Proportioning Grade Designation Type of Cement M25 OPC 53 grade conf irming to IS-122691987 20 mm 310 kg/m3 0.45

3 4 5

Maximum Nominal Aggregate Size Minimum Cement Content (MORT &H 1700-3 A) Maximum Water Cement Ratio (MORT &H 17003 A) Workability (MORT &H 1700-4) Exposure Condition Degree of Supervision Type of Aggregate Maximum Cement Content (MORT &H Cl. 1703.2) Chemical Admixture Type Test Data for Materials Cement Used

6 7 8 9 10

50-75 mm (Slump) Normal Good Crushed Angular Aggregate 540 kg/m3

11 A-2 1

Superplasticiser Conf irming to IS-9103

Coromandal King OPC 53 grade

2 3 4 5 6 7 8 9 10 11 12 13 14 15 15 16 A-3 1 2 A-4 1

Sp. Gravity of Cement Sp. Gravity of Water Chemical Admixture Sp. Gravity of 20 mm Aggregate Sp. Gravity of 10 mm Aggregate Sp. Gravity of Sand Water Absorption of 20 mm Aggregate Water Absorption of 10 mm Aggregate Water Absorption of Sand Free (Surf ace) Moisture of 20 mm Aggregate Free (Surf ace) Moisture of 10 mm Aggregate Free (Surf ace) Moisture of Sand Sieve Analysis of Individual Coarse Aggregates Sieve Analysis of Combined Coarse Aggregates Sp. Gravity of Combined Coarse Aggregates Sieve Analysis of Fine Aggregates Target Strength for Mix Proportioning Target Mean Strength (MORT &H 1700-5) Characteristic Strength @ 28 days Selection of Water Cement Ratio Maximum Water Cement Ratio (MORT &H 17003 A) Adopted Water Cement Ratio Selection of Water Content

3.15 1.00 BASF Chemicals Company 2.884 2.878 2.605 0.97% 0.83% 1.23% nil nil nil Separate Analysis Done Separate Analysis Done 2.882 Separate Analysis Done

36N/mm2 25N/mm2

0.45

2 A-5

0.43

1 2 3 A-6 1 2

Maximum Water content (10262-table-2) Estimated Water content f or 50-75 mm Slump Superplasticiser used Calculation of Cement Content Water Cement Ratio Cement Content (138/0.43)

186 Lit. 138 Lit. 0.5 % by wt. of cement

0.43 320 kg/m3 Which is greater then 310 kg/m3

A-7 1 2

Proportion of Volume of Coarse Aggregate & Fine Aggregate Content Vol. of C.A. as per table 3 of IS 10262 Adopted Vol. of Coarse Aggregate Adopted Vol. of Fine Aggregate ( 1-0.62) 62.00% 62.00% 38.00%

A-8 1 2

Mix Calculations Volume of Concrete in m3 Volume of Cement in m3 (Mass of Cement) / (Sp. Gravity of Cement)x1000 1.00 0.10

Volume of Water in m3 (Mass of Water) / (Sp. Gravity of Water)x1000

0.138

Volume of Admixture @ 0.5% in m3 (Mass of Admixture)/(Sp. Gravity of Admixture)x1000

0.00134

Volume of All in Aggregate in m3 Sr. no. 1 (Sr. no. 2+3+4)

0.759

Volume of Coarse Aggregate in m3

0.471

Sr. no. 5 x 0.62 7 Volume of Fine Aggregate in m3 Sr. no. 5 x 0.38 A-9 1 2 3 4 Mix Proportions for One Cum of Concrete (SSD Condition) Mass of Cement in kg/m3 Mass of Water in kg/m3 Mass of Fine Aggregate in kg/m3 Mass of Coarse Aggregate in kg/m3 Mass of 20 mm in kg/m3 Mass of 10 mm in kg/m3 5 6 Mass of Admixture in kg/m 3 Water Cement Ratio 320 138 751 1356 977 380 1.60 0.43 0.288

We are thankf ul to Er. Raj M. Khan f or sharing this inf ormation with us on engineeringcivil.com. We hope this would be of great signif icance to civil engineers. More Entries : M-20 Mix Designs as per IS-10262-2009 M-30 Mix Designs as per IS-10262-2009 M-35 Mix Designs as per IS-10262-2009 M 15 Mix Designs as per IS-10262-2009 Mix Design For M35 Grade Of Concrete Mix Design M-40 Grade Mix Design M-50 Grade Concrete Mix Design M 20 Grade Of Concrete

Você também pode gostar

- 46 - 23-Jul-2014-03-00 - LED Uploaded RFP 21.07.2014Documento80 páginas46 - 23-Jul-2014-03-00 - LED Uploaded RFP 21.07.2014gdesh90Ainda não há avaliações

- Monitoring RelaysDocumento7 páginasMonitoring Relaysgdesh90Ainda não há avaliações

- India's Best Boarding Schools League TableDocumento2 páginasIndia's Best Boarding Schools League Tablegdesh90Ainda não há avaliações

- Induction MotorDocumento59 páginasInduction MotorAkama Kulasekara100% (3)

- My Visit To A Jain Dairy FarmDocumento10 páginasMy Visit To A Jain Dairy FarmSant Mat100% (2)

- Butk Fact Sheet Variants Efficient Lighting Final Adapt GsDocumento4 páginasButk Fact Sheet Variants Efficient Lighting Final Adapt Gsgdesh90Ainda não há avaliações

- PDD PGPLDocumento58 páginasPDD PGPLgdesh90Ainda não há avaliações

- Butk Fact Sheet Variants Efficient Lighting Final Adapt GsDocumento4 páginasButk Fact Sheet Variants Efficient Lighting Final Adapt Gsgdesh90Ainda não há avaliações

- High Mast Lowering System: Technical InstructionDocumento11 páginasHigh Mast Lowering System: Technical Instructiongdesh90Ainda não há avaliações

- TotakashtakamDocumento3 páginasTotakashtakamSanatanDharmaAinda não há avaliações

- Three Boys in The Wild North Land: Egerton Ryerson YoungDocumento124 páginasThree Boys in The Wild North Land: Egerton Ryerson YoungFenil DesaiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Astm D2172 95Documento6 páginasAstm D2172 95Raj BalasubramaniamAinda não há avaliações

- 2.5 Determination of Particle Size of Soils-Astm D 422: Soil Fabric. Loose and Dense Packing of SpheresDocumento6 páginas2.5 Determination of Particle Size of Soils-Astm D 422: Soil Fabric. Loose and Dense Packing of SphereslenanaAinda não há avaliações

- Ce 344Documento120 páginasCe 344Md Mufazzel Hossain ChowdhuryAinda não há avaliações

- Astm D 2419Documento9 páginasAstm D 2419Yasmin AminAinda não há avaliações

- Frac SandsDocumento36 páginasFrac SandsDavid A. CuéllarAinda não há avaliações

- Sieve analysis determines grading of fine and coarse aggregatesDocumento6 páginasSieve analysis determines grading of fine and coarse aggregatesKyle MoolmanAinda não há avaliações

- Lab by Dks PDFDocumento31 páginasLab by Dks PDFDhirean Kumar SunarAinda não há avaliações

- LabEx No. 9 Fineness of Hydraulic Cement Using No. 200 SieveDocumento3 páginasLabEx No. 9 Fineness of Hydraulic Cement Using No. 200 SieveGerman BarlisAinda não há avaliações

- Test Report-Inter Locking Paver BlockDocumento9 páginasTest Report-Inter Locking Paver Blockudit shahAinda não há avaliações

- IS2720(Part36)-1987 Permeability TestDocumento8 páginasIS2720(Part36)-1987 Permeability TestSoundar PachiappanAinda não há avaliações

- Final Spec Biomass PDFDocumento21 páginasFinal Spec Biomass PDFRAM KrishanAinda não há avaliações

- ISO 4610 - Retentia Pe SitaDocumento10 páginasISO 4610 - Retentia Pe SitaAndrei SimionAinda não há avaliações

- Iso-5074-1994 HgiDocumento12 páginasIso-5074-1994 Hgifatmachemist1Ainda não há avaliações

- Chapter - 2 (BMC-I)Documento38 páginasChapter - 2 (BMC-I)muludibo7Ainda não há avaliações

- Exp 2 Preparation of Disturbed Soil Sample For TestDocumento4 páginasExp 2 Preparation of Disturbed Soil Sample For TestMark Lester PonteAinda não há avaliações

- Astm C144-18Documento3 páginasAstm C144-18ing.mtorresgAinda não há avaliações

- Geotech Lab Report 1 FinalDocumento11 páginasGeotech Lab Report 1 FinalkennethcyinAinda não há avaliações

- Concrete Mix Design (35 MPa)Documento3 páginasConcrete Mix Design (35 MPa)Chileshe Mulenga Phiri100% (1)

- Ilovepdf MergedDocumento3 páginasIlovepdf MergedCriss JungAinda não há avaliações

- Design of Concrete Mixtures Bulletin Provides InsightsDocumento28 páginasDesign of Concrete Mixtures Bulletin Provides InsightsjoaorioAinda não há avaliações

- NFA Geotech Consultancy for Bataan Building SiteDocumento11 páginasNFA Geotech Consultancy for Bataan Building SiteJohnny Jr TumangdayAinda não há avaliações

- Sieve Analysis TestDocumento4 páginasSieve Analysis TestScarlet Kaye DelivigneAinda não há avaliações

- Dm-dcld-f-cm-0017 Rev 4 Ems Test ChargesDocumento112 páginasDm-dcld-f-cm-0017 Rev 4 Ems Test ChargesPervaiz BaigAinda não há avaliações

- 15) Average Least DimensionDocumento3 páginas15) Average Least DimensionPn Ekanayaka100% (1)

- Thesis Document For Seiving Machine EditedDocumento110 páginasThesis Document For Seiving Machine EditedAbebaw WorkieAinda não há avaliações

- Slide Presentation Fyp 1Documento14 páginasSlide Presentation Fyp 1aina kejoraAinda não há avaliações

- MOISTURE DETERMINATIONDocumento79 páginasMOISTURE DETERMINATIONUma Shankar YaligarAinda não há avaliações

- Astm 702Documento5 páginasAstm 702Alexander Pinto P.Ainda não há avaliações

- Sieve Shaker Analysis of Soil SampleDocumento2 páginasSieve Shaker Analysis of Soil SampleKashif RazaqAinda não há avaliações

- CON4341 - E - Note - 03 PSD, Consistency, DescriptionsDocumento22 páginasCON4341 - E - Note - 03 PSD, Consistency, Descriptions123Ainda não há avaliações