Escolar Documentos

Profissional Documentos

Cultura Documentos

Sap MM Configuration Transaction Codes

Enviado por

Gadigota Suresh ReddyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sap MM Configuration Transaction Codes

Enviado por

Gadigota Suresh ReddyDireitos autorais:

Formatos disponíveis

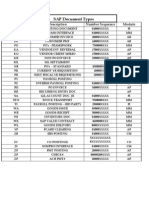

Below you will find most of configuration transaction codes in SAP MM/WM in the areas of Purchasing, MRP, IM,

LIV,WM,CBP,Services,LoGen. Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing M/03 M/04 M/05 M/06 M/07 M/08 M/32 M/36 M/42 M/48 M/50 M/52 M/54 M/56 M/57 M/58 M/59 M/60 M/61 M/62 M/63 M/64 M/65 M/66 M/67 M/68 OLME OME1 OME2 OME4 OME5 OME9 OMEC OMEE Create Conditions Table (Purchasing) Change Conditions Table (Purchasing) Displ. Conditions Table (Purchasing) Condition Type: (Purchasing) Access: Maintain (Price Purchasing) Conditions: Schema for Purchasing Maint. Message Determ. Schema: RFQ Maintain Message Determ. Schema: PO Maintain Message Schema: Del. Sched. Maintain Access Sequences: RFQ Maintain Access Sequences: PO Maint. Access Sequences: Outl. Agmt. Maint. Access Sequences: Del. Sched. Messages: Create Cond. Table: RFQ Messages: Change Condition Table Messages: Display CondTab: RFQ Messages: Create CondTab: Pur. Order Messages: Change CondTab: Pur. Order Messages: Disp. CondTab: Pur. Order Messages: Create CondTab: Del. Schd. Messages: Change CondTab: Del. Schd. Messages: Disp. CondTab: Del. Sched. Messages: Create CondTab: O. Agmt. Messages: Change CondTab: O. Agmt. Messages: Disp. CondTab: Outl. Agmt. Maintain Message Schema: Outl. Agmt. IMG View: Purchasing C MM-PUR Purchasing Value Keys C MM-PUR Terms of Payment C MM-PUR Purchasing Groups C MM-PUR Activate Plant: Source List C MM-PUR Acct. Assignment Categories Copying Control Maintenance C MM-PUR Reorganization RFQ

Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing

OMEH OMEI OMEL OMEN OMEO OMEP OMEQ OMES OMET OMEW OMEX OMEY OMEZ OMF0 OMFI OMFJ OMFK OMFM OMFN OMFO OMFP OMFQ OMFR OMFS OMFT OMFZ OMG0 OMG1 OMG2 OMG3 OMG4 OMG5 OMG6 OMG7 OMG8 OMG9 OMGA OMGB

C MM-PUR User Maintenance C MM-PUR User Profiles C MM-PUR Certificate Categories C MM-PUR Reorg. Sched. Agrmnt Time C MM-PUR Number Ranges: Info Record C MM-PUR Number Ranges: Source List C MM-PUR Quota Arrangement Rules C MM-PUR Comments on Quotation Settings for Function Authorizations C MM-PUR Requisition Processing Time C MM-PUR Reorganization: Requisition C MM-PUR Reorganization PO C MM-PUR Reorg. Contract Time C MM-PUR Activate Cond. for Plant Settings for Default Values C MM-PUR Rec. Layout for Batch Input C MM-PUR Field Selection: Vendor C MM-PUR Schema Groups: Purch. Org. C MM-PUR Schema Groups: Vendor C MM-PUR Find Calculation Schema C MM-PUR Schema Group <-> Pur. Org. C MM-PUR Scope of List: Conditions C MM-PUR Mkt. Price Schema: P. Org. CC-MM-PUR Chge.-Notice-Relev. Fields Message Determination Requirements C MM-PUR: Stock Transfer Schema CS MM-PUR Item Cat./Acc. Assgt. Cat. C MM-PUR Commodity Code C MM-PUR Customs Offices C MM-PUR Modes of Transport C MM-PUR Business Transaction Type C MM-PUR Default Busn. Trans. Type C MM-PUR Import Procedures C MM-PUR Authorizations C MM-PUR Conditions/Sequence C MM-PUR Assignment Conditions/TCode C MM-PUR Texts: Creditor (Central) C MM-PUR Texts: Creditor (Purch.)

Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing

OMGF OMGG OMGH OMGM OMGV OMGX OMGY OMH6 OMH7 OMH8 OMH9 OMHJ OMHK OMHL OMHM OMHN OMHO OMHP OMHS OMHT OMHU OMHV OMI0 OMKA OMKE OMKF OMKG OMKH OMKI OMKJ OMKK OMKL OMKM OMKN OMKO OMQA OMQK OMQL

C MM-PUR Output Device: Messages Settings for Message Determination C MM-PUR: Transaction/Event Keys Settings for Subcontracting Intrastat MM-PUR Form for Buyers Neg. Sheet MM-PUR Buyers Neg. Sheet Routines Number Ranges for Purch. Documents Number Ranges for Purch. Requisition Number Ranges for Service Package Number Ranges for Entry Sheet Purchasing: Condition Index Batch Input, Purchase Requisitions C MM-PUR Matchcode Info Record C MM-PUR Matchcode Requisition C MM-PUR Matchcode Purch. Document C MM-PUR Matchcode Source List Updating of Order Price History Display Info Record Transfer File Display Requisition Transfer File Example File: Batch Input Info Rec. Example File, Batch Input Requisn. Error List for Intrastat Declaration Conditions: V_T681F for A V C MM-PUR: Optimize Access C MM-PUR: Exlusion Indicators C MM-PUR: Limits C MM-PUR Reg. Vend. Source of Supply C MM-PUR Default Purchasing Org. C MM-PUR P.Org. Cross-CoCode Release C MM-PUR Tax Indicators: Material C MM-PUR Tax Indicators: Acc. Assgt. C MM-PUR Tax Indicators: Plant C MM-PUR Assign Tax Inds. to Plant C MM-PUR Assign Tax Inds. to A. Ass. C MM-PUR: Take-Back Agreement Fine-Tuned Control: RFQ C MM-PUR: Supply Region for Plant

Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing Purchasing IM IM IM IM IM IM IM

OMQN OMQO OMQP OMQQ OMQR OMQS OMQT OMQU OMQV OMQW OMRO OMRP OMRQ OMRR OMRS OMRT OMTA OMTB OMTC OMTD OMTE OMTF OMTG OMTH OMTI OMTJ OMZE OX01 OX08 OX17 VOK3 MN21 MN22 MN23 MN27 MN28 MN29 OLMB

Fine-Tuned Control: Purchase Order Fine-Tuned Control: Outl. Agreement Fine-Tuned Ctr.: Sch. Agmt. Schedule Fine-Tuned Control: Service Entry Assign Schema to RFQ Assign Schema to Purchase Order Assign Schema to Outline Agreement Assign Schema to Sch. Agmt. Schedule Assign Schema to Service Entry Sheet Entry Aids w/o Material Master G/L Account Auth. in Requisition G/L Account Auth. in Purchase Order G/L Account Auth. in Contract Transaction/Event Key Usage Transaction/Event Key Usage Transaction/Event Key Usage Output Program: RFQ Output Program: Purchase Order Output Program: Outline Agreement Output Program: Delivery Schedule Output Program: Service Entry Sheet Output Partner: RFQ Output Partner: Purchase Order Output Partner: Outline Agreement Output Partner: Delivery Schedule Output Partner: Service Entry C MM-PUR Reorg. Contract Extra Company Code -> Purchasing Org. Define Purchasing Organization Plants -> Purchasing organization Message Determination: Purchasing Create Condition: Inventory Mgmt Change Condition: Inventory Mgmt Display Condition: Inventory Mgmt Create message: rough goods receipt Change message: rough goods receipt Display message: rough goods receipt IMG Inventory Management

IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM

OLMW OMB0 OMB1 OMB2 OMB3 OMB4 OMB5 OMB6 OMB7 OMB8 OMB9 OMBA OMBB OMBC OMBD OMBF OMBG OMBH OMBI OMBJ OMBK OMBM OMBN OMBO OMBP OMBR OMBS OMBU OMBV OMBW OMBX OMBZ OMC0 OMC1 OMC2 OMC3 OMC4 OMC6

IMG Valuation/Acct Assgt List of document types Dynamic Availability Check Create SLoc. Automatically (GI) Create SLoc. Automatically (GR) Maintain Print Indicator (GI) Maintain Print Indicator (GR) Change Manual Account Assgt. Test Data: Init.Entry of Stock Balcs Test Data: Reservations Transfer Change Document Lives Number Assgmt. for Accounting Docs. Batch Where-Used List Set Missing Parts Check Business Area from MM View Control BTCI Sessions for Goods Mvmt Set Stock Balance Display Phys. Inventory Settings in Plant Suggest Items Preselected GR Suggest Items Preselected GI Suggest Items Preselected: Reservtn Control BTCI Sessions for Reserv. Defaults for Reservation Assign Forms and Programs Freeze Book Inventory Balance General Print Settings Reasons for Movements Allocate Layout Sets to Reports Control BTCI Sessions for Phys. Inv. Set Screen Layout for Goods Movement Stock Balance Display Rev. GR Despite Invoice Tolerance Limits for Goods Receipt Goods Receipt/Issue Slip Number Number Assignment for Reservations Suggest Items Preselected: Phys.Inv. BTCI Data Transfer: Inventory Count Test Data Transfer: Phys. Inventory

IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM

OMC7 OMC8 OMC9 OMCC OMCD OMCE OMCF OMCG OMCH OMCJ OMCK OMCL OMCM OMCN OMCO OMCP OMCQ OMCR OMCS OMCT OMCU OMCV OMJ1 OMJ2 OMJ3 OMJ4 OMJ7 OMJH OMJI OMJJ OMJK OMJL OMJM OMJN OMJR OMJS OMJU OMJV

BTCI Data Transfer: Inv.Count + Diff BTCI Data Tranfer: Inv. Doc./Count BTCI Data Tfr.: Inv.Doc./Count/Diff. Generate Phys.Inv.Doc.for Goods Mvmt Suggest Del. Completed Indicator Define Batch Level Print Label Search Procedures: Batch Determ. MM Set Manual Account Assignment (GR) Screen Layout: Goods Receipt Inventory Sampling Profile Inventory Sampling: St. Mgmt Levels Dynamic Availability Check: GR Control BTCI Sessions for Phys. Inv. Set Cycle Counting Dynamic Availability Check: GI Settings for System Messages Inventory Sampling: St.Mgmt Lvl: WM Activate Batch Status Management Batch Definition Batch Status Management in Plant Classify Batches Allow Negative Stocks Maintain Phys.Inv.Tolrnce->Employee Printer Determination Plant/SLoc. Printer Determ: Plant/SLoc./User Grp Plant/Val.Area Divis. -> Busin.Ar. Maintain Dataset for Phys. Inventory Set Material Block Customizing: New Movement Types Number Ranges for Reservations Maintain Print Indicator (autom.MvT) Comprn plnt/val.area divis.->BusAr General field selection: goods mvmnt Printer Determin.: Message Type/User Check expiration date at goods issue Gen. field selection, physical inv. Subsequent Calculation of Value

IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM IM LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV

OMJW OMJX OMJY OMSB OMSK OMT1 OMW0 OMW1 OMW9 OMWA OMWB OMWC OMWD OMWF OMWG OMWK OMWM OMWN OMWO OMXL OX09 OX10 OX14 OX18 M804 M806 M808 M810 OLMR OMR0 OMR14 OMR2 OMR3 OMR4 OMR5 OMR6 OMR8 OMR9

Create Purchase Order Automatically GR Field Selection From Procurement GR Field Selec. Fr. Procment (Table) C MM-BD Special Stock Description C MM-BD Valuation Classes T025 C MM-BD Consistency Check Updating C MM-IV Control Valuation C RM-MAT MW Price Control C RM-MAT MW Doc.Type/F-u.Csts.Pr.Ch. C RM-MAT MW Doc.Type/F-up Csts.D/C C MM-IV Autom. Acct. Assgt. (Simu.) C MM-IV Split Material Valuation C RM-MAT MB Grouping Valuation Area C MM-IV User Maintenance C RM-MAT MW User Profiles C MM-IV Authorizations C MM IV Control: Accnt Determination MM-IM: Acct Group. Code for Mvt.Type C MM-PUR: Purchase Account Mgmt Configure empties processing Customize storage locations Customize plant C MM-IV Valuation area val. level Assignment Plants -> Company Code Message Processing Program (IV) Message Types (Invoice Verification) Message Schema (Inv. Verification) Message Access Sequence (Inv. Ver.) IMG Invoice Verification C MM-IV Autom. Acct. Assgt. (Simu.) Define Variant Name C RM-MAT MR Default Incoming Invoice C MM-IV Default Account Maintenance MM-IV Doc.Type/NK Incoming Invoice MM-IV Doc.Type/NR Acct Maintenance Tolerance limits: Inv.Verification C RM-MAT MR PO Supplement C RM-MAT MR Payment Block Reasons

LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV LIV WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM

OMRA OMRB OMRC OMRDC OMRF OMRG OMRH OMRI OMRK OMRL OMRMA OMRMB OMRU OMRV OMRX OMRY OMRZ LN09 LS10 OL19 OL20 OL21 OL22 OLML OMK0 OMK1 OMK2 OMK7 OMKW OMKX OMKY OMKZ OML1 OML2 OML3 OML4 OML5

C MM-IV Val.Cat./Subs.Debit/Credit C MR Tolerance Groups C MR Alloc. User/Tolerance Group Configure Duplicate Invoice Check C MM_IV Activate Stochastic Block C MM-IV Stochastic Block Values C MM-IV Activate Item Amount Check C MM-IV Item Amount Check Parameters Mail to Purchasing Tax Version Screen Selection Initial Screen Screen Selection Header Data Screen Sender Texts, Form Invoice Status Change Vendor-Specific Tolerances EDI Program Parameters Runtime Invoice Document Archiving Number Range Maintenance: LVS_LBELN Generate Storage Bins Generate Distribution Model Consistency Check (Centr.Processing) Consistency Check (Decentr.Process.) Check LE /HU Number Assignment IMG structure Warehouse Management Link to PP interface Batch search method for Whse Mgmt Customer exits for strategies Batch WM.. (will be deleted) Stock removal strategy SLED Automatic Transfer Orders Link to External System via ALE Automatic Transfer Orders Overview of Criticl Whse Monitor Obj Var. Report RLLL01SE: TOs Var. Report RLLL02SE: TR Items Var. Report RLLL03SE: Post.Chge Doc. Var. Report RLLL04SE: Deliveries

WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM

OML6 OML7 OML8 OML9 OMLA OMLB OMLC OMLD OMLE OMLF OMLG OMLH OMLI OMLJ OMLK OMLL OMLM OMLN OMLO OMLP OMLQ OMLR OMLS OMLT OMLU OMLV OMLW OMLX OMLY OMLZ OMM1 OMM2 OMM3 OMM4 OMM5 OMM6 OMM7 OMM8

Var. Report RLLL05SE: Negative Stock Var. Report RLLL06SE: Interim Stock Var. Report RLLL07SE: Stock Product. Customizing MOB Interface Putaway Near Picking Bin MObj.01: Critical TOs MObj.02: Critical TRs MObj.03: Critical Post. Chge Notices M.Obj.04: Critical Deliveries M.Obj.05: Negative Stocks M.Obj.06: Stocks Interim Stor.Bins M.Obj.07: Critical Stocks in Prod. Report Variant: Single Entry ActData Movement Types for Whse Management Default Values for Inventory WM Movement Type: Clear Invent.Diff. Definition Empty Bin Index Warehouse Control Link Sectioning of Storage Bins Plan Jobs for Whse Activity Monitor Stock Removal Strategy FIFO WM Interface to Inventory Management Stock Removal Strategy LIFO Stock Removal Strat. Partial Qty Stock Placement Strategy Empty Bin Print Control for Whse Management Number Ranges for Whse Management Confirmation Storage Type Search Storage Section Search Storage Bin Type Search Haz.Material Stock Placement Stock Placement Strat.for Pallets Putaway Strategy for Bulk Storage Storage Type Definition Storage Type Definition Storage Type Maintenance Stock Removal Strat. Stringent FIFO

WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM

OMM9 OMMA OMMB OMMC OMMD OMME OMMF OMMG OMMH OMMI OMMJ OMMK OMML OMMM OMMN OMMO OMMP OMMQ OMMR OMMS OMMT OMMU OMMV OMMW OMMX OMMY OMMZ OMN0 OMN1 OMN2 OMN3 OMN4 OMN5 OMN6 OMN7 OMN8 OMN9 OMNA

Stock Removal Strat. Large/Small Print Assignment per Storage Type Inventory No.Ranges for Whse Mgmt Printer Assignment per WM Mov.Type Confirmation Ctrl per Storage Type Confirmation Ctrl per Movement Type Number Ranges per Warehouse Number ranges physical inventory Type Search per Movement Section Check per Storage Type Storage Unit Check per Storage Type Putaway Strategies Hazardous Materials Storage Type Storage Type Maintenance Stringent FIFO Storage Type Consistency Check for MM-WM Tables Decentralized Warehouse Management Pre-allocated stock Group numbers Reference Number Documents Reference Number Documents 2 Link to Decentralized Unit Accumulation Decentralized Error Recovery Decentralized Printer Determination Print Code Spool Parameters for WM Print Ctrl Control of Transaction Codes (MM-WM) Print Reference Number Stor.Type Control, Block Storage Storage Classes Allowed Storage Section Search Storage Units Allowed Storage Bin Type Search Storage Type Search Difference Indicators Block Sectioning Assignment for Bin Sectioning

WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM WM CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP

OMNB OMNC OMND OMNE OMNF OMNG OMNH OMNI OMNJ OMNK OMNL OMNM OMNN OMNO OMNQ OMNR OMNS OMNT OMNU OMNV OMNW OMNX OMNY OMNZ MD93 OLMD OM0A OM0C OM0D OM0E OM0F OM0I OM0J OM0K OM0L OM0M OM0N OM0O

Assignment PF Status Control of Subsequent Screen Field Selection for Whse Mgmt Control of Transactions in MM-WM Requirement Types for Whse Mgmt Queues Warehouse Management System APPC Interface per Warehouse Number Print Program per Warehouse Number Link to Warehouse Control Unit Inventory Control per Storage Type Warehouse Number Maint./Inventory Define Mail Recipient Conversion Exit SU Number Define Mail Recipient Special Movement Indicators TO Print Control with SU Management Print Code for TOs with SU Mgmt Printer Pool for SU Management Print Control with SU Management Number Range Intervals for Whse Mgmt System Parameters for Dec.Whse Mgmt Bulk Storage Indicators Access Strategy for Stor.Type Search Parameters for Activity in WM Maintain Number Range: MDSM Customizing For MRP Storage Mode for MRP Lists Requirements Grouping Period Profile for Safety Time Define Scope of Planning Convert MDVM/MDVL for MRP Areas Declaration Selection Rule Declaration Display Filter Define Navigation Profile Texts for Exception Groups Define MRP Views Activate Parallel Reading of SRL Evaln Profile Ranges of Coverage

CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP

OM0P OM0R OMD0 OMD2 OMD3 OMDQ OMDR OMDS OMDT OMDU OMDV OMDW OMDX OMDY OMDZ OMI1 OMI2 OMI3 OMI4 OMI5 OMI7 OMI8 OMI9 OMIA OMIB OMIC OMIG OMIH OMII OMIL OMIM OMIN OMIO OMIP OMIQ OMIR OMIS OMIT

Define Extraction Mode Activate Material Groupings C RM-MAT MRP Controllers C RM-MAT MD Weighting Groups C RM-MAT MD Exception Message T458A C RM-MAT MRP Types T438A C MD Run Time Statistics C MD Number of Planned Orders C MM-MRP External Procurement C MD Activate MRP C MD Convert Planning Run C MD Rescheduling C MD Planning Horizon C MD Planning Run Abend C MD MRP Creation Indicator C MD Safety Stock C MM-MRP Number Ranges: Mat. plg. C MM-MRP No. Ranges for Pld Ords C MD Lot Sizes C MD Item Numbers C MM-MRP No. Ranges for Pld Ords Plant Parameters PP MRP C Direct Procurement C MRP Range of Coverage Profile C MRP Start Times Background Jobs MatMasterCust.:Batch Job Start Times MRP Group per Material Type Check. rule for updating backorders Missing Parts Controller Sel. Receipt Elements for Coverage Maximum MRP Period Firming Scheduling Agreements Screen Seq. MRP List ; Ext.Header Reference Plant for MRP Master Data Destinations Parallel MRP Storage Location MRP Convert Planned Order -> Prod. Order Start Date in the Past

CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP CBP Services Services Services Services Services Services Services Services Services Services Services Services

OMIU OMIV OMIW OMIX OMIY OMPG OPP1 OPP3 OPPA OPPB OPPC OPPD OPPE OPPF OPPH OPPI OPPJ OPPK OPPM OPPN OPPP OPPS OPPT OPPU OPPZ OSPN AC10 M/10 M/11 M/12 M/13 M/14 M/15 M/16 M/70 M/71 M/72 M/73

Action Code Planned Order Control Action Control Planned Order BOM Explosion Text: User Exit Planning Run Plng File Entries for Goods Mvmts Maintain Consumption Mode Customizing MRP Customizing Repetitive Manufacturing PP/MRP Customizing Explosion Direct Procurement Period Grouping Customizing Planning Time Fence Conversion Plnnd Order -> Prod.Order Customizing for Order Report Customizing Purchase Req. Conversion Available Stock MRP Checking Rule Hierarchy Element Evaluation Profiles Layout Customizing Direct Procurement Strategy Strategy Group Strategy Group for MRP Group MRP Group Background Job: Adjmt. of Dep. Reqs Class Hierarchy with Services Condition Type: Services Access: Maintain (Price Services) Conditions: Schema for Services Create Condition Table (Service) Change Condition Table (Services) Display Condition Table (Services) Conditions: Var. Schema for Service Messages: Create CondTab.: Entry Sh. Messages: Change CondTab.: Entry Sh. Messages: Disp. CondTab.: Entry Sh. Maintain Access Sequences: Entry

Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services

M/74 M/75 M/76 M/77 M/78 ME2S ME3S MEDL MEW10 MEW7 MEW8 MEWS ML01 ML02 ML03 ML05 ML10 ML100 ML11 ML12 ML15 ML20 ML30 ML31 ML32 ML33 ML34 ML35 ML36 ML37 ML38 ML39 ML40 ML41 ML42 ML43 ML44 ML45

Maintain Access Sequences: Entry Maintain Messages: Serv. Entry Sheet Display Messages: Entry Maintain Message Schema: Entry Sheet Disp. Message Determ. Schema: Entry Services per Purchase Order Service List for Contract Price Change: Contract Service Entry in Web Release of Service Entry Sheets Release of Service Entry Sheet Service Entry (Component) Create Standard Service Catalog Maintain Standard Service Catalog Display Standard Service Catalog Purchasing Object for Service Create Model Service Specifications Calculate Taxes at Service Level Change Model Service Specifications Display Model Service Specifications List of Model Service Specifications Create Conditions Create Vendor Conditions Change Vendor Conditions Display Vendor Conditions Create Vendor Conditions Change Vendor Conditions Display Vendor Conditions Create Vendor Conditions Change Vendor Conditions Display Vendor Conditions Create Vendor Conditions Change Vendor Conditions Display Vendor Conditions Create Service Conditions Change Vendor Conditions Display Vendor Conditions Display Service Conditions

Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services

ML46 ML47 ML48 ML49 ML50 ML51 ML52 ML53 ML81 ML81N ML82 ML83 ML84 ML85 ML86 ML87 ML89 ML90 ML91 ML92 ML93 ML94 ML95 ML96 ML97 ML98 ML99 MLRP MLS5 MLS6 MLV1 MLV2 MLV3 MLV4 MLV5 MLV6 MN13 MN14

Change Service Conditions Display Service Conditions Create Conditions Change Conditions Display Conditions Create Conditions Change Conditions Create Conditions Maintain Service Entry Sheet Service Entry Sheet Display Service Entry Sheet Message Processing: Service Entry List of Service Entry Sheets Collective Release of Entry Sheets Import Service Data Export Service Data Definition of Formulas Field Selection for Services Stand. Values f. Ext.Services Mgmt. Entry Sheets for Service Purchasing Object for Service External Services Mgmt.: Direct Call List Display: Contracts for Service Purchase Requisitions for Service Recompile Index Std. EKORG Values f. Ext. Srv. Mgmt. Formula Variable IDs Periodic Invoicing Plans Import Standard Service Type Report for Standard Service Catalog Conditions: Services Create Total Price (PRS) Create Total Price (PRS) Create Total Price (PRS) Change Currency (Contracts) Create Other Create Message: Service Entry Sheet Change Message: Service Entry Sheet

Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services Services LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen

MN15 MSRV1 MSRV2 MSRV3 MSRV4 MSRV5 MSRV6 OLMSRV OM1R OM2R OM3R OM4R OM5R OM6R OM7R OM8R OM9R OMCB OMCI OMH0 OMK8 OMQM OMS1 OMS2 OMS2OLD OMS3 OMS4 OMS5 OMS6 OMS7 OMS8 OMS9 OMSA OMSD OMSE OMSF OMSH

Display Message: Service Entry Sheet List for Service Service List for Requisition Service List for Purchase Order Service List for RFQ Service List for Contract Service List for Entry Sheet Customizing MM-SRV Maint. Periodic Invoicing Plan Types Maint. partial invoicing plan types Maintain Date IDs Maint. Date Cat. for Invoicing Plan Default Date Category for Inv. Plan Maintain Dates Rule Table for Date Determination Invoicing Plan: Blocking Reasons Purch. Order: Reasons for Rejection Service Lists Scope of List: Service Lists Interface to Activity Allocation Services: Exclusion Indicator C MM-PUR Matchcode: Entry Sheet Units of Measure Grouping Maintain Material Types C MM-BD Material Types Configure Industry Sectors C MM-BD Material Status C MM-BD Set Up Laboratory C MM-BD Storage Condition(s) C MM-BD Temperature Condition(s) C MM-BD Container Requirement(s) Configure Field/Screen Selection C MM-BD T130W Plant-Specific C MM-BD F. Sel. Spec. T148G C MM-BD F. Sel. Reference T148W C MM-BD Material Groups C MM-BD Matchcode for Material

LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen LoGen

OMSM OMSR OMSS OMST OMSU OMSW OMSY OMT0 OMT5 OMT8 OMY1

CS MM Set Up Administrative Data C MM-BD Field Groups C MM-BD Field Groups: Special Stocks C MM-BD Record Layout f. BATCH INPUT C MM-BD Mat. Master Data Transfer C MM-BD Record Layout f. BATCH INPUT C MM-BD Company Code for Matl Master C MM-BD Global Setting Auth. Group MatMaster (Inactive) Transfer Material Master Data by DI Create Input File from Material

Você também pode gostar

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyNo EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyNota: 4 de 5 estrelas4/5 (6)

- Configuration T Codes in SAP MMDocumento15 páginasConfiguration T Codes in SAP MMbeema1977Ainda não há avaliações

- SAP MM Frequently Asked 50 Q&A With Screenshots-1 PDFDocumento35 páginasSAP MM Frequently Asked 50 Q&A With Screenshots-1 PDFManoj LoharAinda não há avaliações

- SAP TCodesDocumento28 páginasSAP TCodesgoenkavishal100% (1)

- Batch ManagementDocumento18 páginasBatch ManagementDarsh RathodAinda não há avaliações

- Overview of Stock Transfer Configuration in SAP-WMDocumento11 páginasOverview of Stock Transfer Configuration in SAP-WMMiguel TalaricoAinda não há avaliações

- Account Key Sap MMDocumento2 páginasAccount Key Sap MMKumar AjitAinda não há avaliações

- MM PM 300 v3 PDFDocumento123 páginasMM PM 300 v3 PDFsajjadAinda não há avaliações

- EWM Organizational StructureDocumento25 páginasEWM Organizational Structurezak100% (1)

- Replenishment of Fixed Bins in SAP WM - Aroop's NotepadDocumento3 páginasReplenishment of Fixed Bins in SAP WM - Aroop's NotepadnikAinda não há avaliações

- Enhancements in MMDocumento2 páginasEnhancements in MMSanket KohliAinda não há avaliações

- Creation of Plant in SAPDocumento31 páginasCreation of Plant in SAPnagibvbAinda não há avaliações

- Create Material Master MRP Views and Assign MRP TypesDocumento12 páginasCreate Material Master MRP Views and Assign MRP Typesdudhmogre23Ainda não há avaliações

- Material Type ConfigurationDocumento24 páginasMaterial Type ConfigurationShailendra TiwariAinda não há avaliações

- Material MasterDocumento17 páginasMaterial Mastermic29100% (3)

- SD PreparationDocumento20 páginasSD PreparationRamesh Kumar BAinda não há avaliações

- Sap Fashion Management SolutionDocumento3 páginasSap Fashion Management SolutionSamAnguriaAinda não há avaliações

- SAP Overview: ACC LimitedDocumento37 páginasSAP Overview: ACC LimitedSrinivasa ReddyAinda não há avaliações

- FSD For Ageing Report For Blocked StockDocumento3 páginasFSD For Ageing Report For Blocked StockLuisOrtizAinda não há avaliações

- MM Price Procedure......Documento6 páginasMM Price Procedure......Manas Kumar SahooAinda não há avaliações

- Order Confirmation ParametersDocumento14 páginasOrder Confirmation ParameterskrishnaAinda não há avaliações

- PP - Reference Operation Set Creation PDFDocumento10 páginasPP - Reference Operation Set Creation PDFMostafa AdamAinda não há avaliações

- SAP Warehouse Management 50 Hr CourseDocumento3 páginasSAP Warehouse Management 50 Hr CourseNikhil RaviAinda não há avaliações

- Sap WM User Manual: Published by Team of SAP Consultants at SaptopjobsDocumento3 páginasSap WM User Manual: Published by Team of SAP Consultants at SaptopjobsDISHIMUKH YADAVAinda não há avaliações

- Sap MM Master DataDocumento19 páginasSap MM Master DataImran PatelAinda não há avaliações

- Requirment Priority SAP MMDocumento14 páginasRequirment Priority SAP MMNagendra EtikalaAinda não há avaliações

- INTERVIEWDocumento8 páginasINTERVIEWSireesha ReddyAinda não há avaliações

- Automatic Purchase Order Creation in SAPDocumento5 páginasAutomatic Purchase Order Creation in SAPAndre CarvalhoAinda não há avaliações

- Combined Production Order ProcessingDocumento12 páginasCombined Production Order Processingsaps4hana ppAinda não há avaliações

- Lorhan-Texpro Solution - V3.0Documento41 páginasLorhan-Texpro Solution - V3.0sihalim17100% (1)

- EWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books WeightingDocumento2 páginasEWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books Weightingguru_3112Ainda não há avaliações

- How To Activate MRP For MaterialsDocumento11 páginasHow To Activate MRP For Materialstawny0511100% (1)

- Create PO ME21NDocumento5 páginasCreate PO ME21Nbainab100% (1)

- SAP IS Oil Gas Functionalities PDFDocumento1 páginaSAP IS Oil Gas Functionalities PDFmohannaiduram0% (1)

- #1 Service Desk Software: What Is SAP Production PlanningDocumento3 páginas#1 Service Desk Software: What Is SAP Production PlanningAnonymous IpnRP293100% (1)

- Configuration Rationale Document - Personnel StructureDocumento11 páginasConfiguration Rationale Document - Personnel Structurepkank09100% (1)

- SAP Stock Transport Order and Stock Transfer Process - SAP MM TrainingDocumento13 páginasSAP Stock Transport Order and Stock Transfer Process - SAP MM TrainingShayne229Ainda não há avaliações

- Sap SCM - Producs - MaterialsDocumento10 páginasSap SCM - Producs - MaterialsAdaikalam Alexander RayappaAinda não há avaliações

- CIFDocumento5 páginasCIFvijayjeoAinda não há avaliações

- Tips and Tricks About MM-IMDocumento13 páginasTips and Tricks About MM-IMpuditimeAinda não há avaliações

- Stock Transport Order SAP MMDocumento3 páginasStock Transport Order SAP MMvampire_18th100% (2)

- Goods movement and consumption transactionsDocumento7 páginasGoods movement and consumption transactionssaurabhudr_grinfraAinda não há avaliações

- Expertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsDocumento6 páginasExpertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsArun PadhiAinda não há avaliações

- SAP ATP CalculationDocumento6 páginasSAP ATP Calculationaprian100% (1)

- 7.1.1 MM-J1ID-Excise Master DataDocumento19 páginas7.1.1 MM-J1ID-Excise Master DataPriyanka BarotAinda não há avaliações

- Material Type ConfigurationDocumento5 páginasMaterial Type Configurationmbraghumb9019Ainda não há avaliações

- MM - Material - Master - User ManualDocumento21 páginasMM - Material - Master - User ManualajayAinda não há avaliações

- SAP PP Master Data TablesDocumento3 páginasSAP PP Master Data TablesSachin Karekar100% (1)

- What Is Subsequent Adjustment in Process of SubcontractingDocumento4 páginasWhat Is Subsequent Adjustment in Process of Subcontractingsidharth kumarAinda não há avaliações

- 28 Points You Need To Know About SAP WM ImplementationDocumento5 páginas28 Points You Need To Know About SAP WM ImplementationeddiemedAinda não há avaliações

- Putaway Using Id PointDocumento5 páginasPutaway Using Id PointAnonymous 0jKoQiWLF0Ainda não há avaliações

- Sap SDDocumento9 páginasSap SDSouvik_DasAinda não há avaliações

- Common COGI ErrorsDocumento4 páginasCommon COGI Errorsfaisalkhan55100% (1)

- Reorder Point Planning: © Sap Ag TAMM10 4.0B 34-1Documento7 páginasReorder Point Planning: © Sap Ag TAMM10 4.0B 34-1lymacsauokAinda não há avaliações

- SAP Real Time Interview Questions and Answers 1Documento14 páginasSAP Real Time Interview Questions and Answers 1Sarang KulkarniAinda não há avaliações

- SAP ECM Transaction Codes and What Is Engineering Change ManagementDocumento2 páginasSAP ECM Transaction Codes and What Is Engineering Change ManagementRogério Andrade Dos SantosAinda não há avaliações

- Message Determination in Purchasing (Output Determination) in SAPDocumento8 páginasMessage Determination in Purchasing (Output Determination) in SAPsthiyagaraajAinda não há avaliações

- Warehouse Management Systems A Complete Guide - 2019 EditionNo EverandWarehouse Management Systems A Complete Guide - 2019 EditionAinda não há avaliações

- 1y 1st Sem Management Accounting p4Documento472 páginas1y 1st Sem Management Accounting p4Gadigota Suresh Reddy100% (1)

- SAP MM Configuration Document - V1Documento29 páginasSAP MM Configuration Document - V1Gadigota Suresh Reddy100% (5)

- SAP document types and descriptionsDocumento1 páginaSAP document types and descriptionshembeck119Ainda não há avaliações

- Sap Table MMDocumento7 páginasSap Table MMChandu SekharAinda não há avaliações

- 1 - SAP OverviewDocumento4 páginas1 - SAP OverviewGadigota Suresh ReddyAinda não há avaliações

- Sap MM Interview QuestionaireDocumento34 páginasSap MM Interview QuestionaireGadigota Suresh ReddyAinda não há avaliações

- Sap MM Interview QuestionaireDocumento34 páginasSap MM Interview QuestionaireGadigota Suresh ReddyAinda não há avaliações

- SAP MM Interview Questions Answers and ExplanationsDocumento128 páginasSAP MM Interview Questions Answers and ExplanationsAbhinav96% (28)

- (+) Manufacturing OverheadsDocumento3 páginas(+) Manufacturing OverheadsJahin faiyazAinda não há avaliações

- (Eap4-0922wsb-7) - Case StudyDocumento5 páginas(Eap4-0922wsb-7) - Case StudyLinh NguyễnAinda não há avaliações

- Production Planning and Control MCQsDocumento11 páginasProduction Planning and Control MCQsHVFTOOLS HVFAinda não há avaliações

- AA025 Chapter AT7Documento3 páginasAA025 Chapter AT7norismah isaAinda não há avaliações

- 5 - Hospitality Services MarketingDocumento29 páginas5 - Hospitality Services MarketingBenedict MuringakumweAinda não há avaliações

- Implementing ERP SystemsDocumento12 páginasImplementing ERP Systemsprachi_rane_4Ainda não há avaliações

- Maithili AmbavaneDocumento62 páginasMaithili Ambavanerushikesh2096Ainda não há avaliações

- Impact of CRM Practices On Organization Performance With Spe-Cial Reference To Selected Pharmaceutical Companies in Rajasthan RegionDocumento24 páginasImpact of CRM Practices On Organization Performance With Spe-Cial Reference To Selected Pharmaceutical Companies in Rajasthan RegionArnab DasAinda não há avaliações

- 04a-Local and Global OptimaDocumento16 páginas04a-Local and Global OptimaFahad ZiaAinda não há avaliações

- 2018 Resume Kathleen McShea ErvilleDocumento7 páginas2018 Resume Kathleen McShea ErvilleKathy McSheaAinda não há avaliações

- Heat TreatmentDocumento44 páginasHeat Treatmentapexg3838Ainda não há avaliações

- Reading Sample SAP PRESS 1015 Upgrading SAPDocumento50 páginasReading Sample SAP PRESS 1015 Upgrading SAPjstathourosAinda não há avaliações

- CLEANROOM PramoteDocumento28 páginasCLEANROOM Pramotedavincicode888100% (2)

- 04 - Cost Accounting by Usry (Part2)Documento3 páginas04 - Cost Accounting by Usry (Part2)AkiAinda não há avaliações

- Stock Control and InventoryDocumento8 páginasStock Control and Inventoryadede2009Ainda não há avaliações

- 202-0101-001 - ARIF HOSEN - Management Accounting Assignment 1Documento11 páginas202-0101-001 - ARIF HOSEN - Management Accounting Assignment 1Sayhan Hosen Arif100% (1)

- Iso 8504-3-1993-08Documento9 páginasIso 8504-3-1993-08Zaheer Ahmad RazaAinda não há avaliações

- Futures Margin CalculationDocumento79 páginasFutures Margin CalculationMUSKAAN BAHLAinda não há avaliações

- M105 93to9Documento21 páginasM105 93to9Ravi RanjanAinda não há avaliações

- Chapter-1 Introduction To Warehouse Management System: 1. Content IndexDocumento95 páginasChapter-1 Introduction To Warehouse Management System: 1. Content Indexiiftgscm batch2Ainda não há avaliações

- Module 2 - Process FMEA Training Rev 1Documento47 páginasModule 2 - Process FMEA Training Rev 1kkhelilAinda não há avaliações

- Indy Displays: Indy Displays Has The Perfect Trade Show Displays Solution For YouDocumento7 páginasIndy Displays: Indy Displays Has The Perfect Trade Show Displays Solution For YouindydisplaysAinda não há avaliações

- BusiDocumento9 páginasBusiRomel Endonila BoncalonAinda não há avaliações

- Strategic Management PresentationDocumento6 páginasStrategic Management Presentationiqra waseemAinda não há avaliações

- IFSM 432 Historical Events Analysis PaperDocumento4 páginasIFSM 432 Historical Events Analysis PaperZumer FatimaAinda não há avaliações

- FINALDocumento106 páginasFINALSangeethRaj PSAinda não há avaliações

- PHR-PP-QC-GG-001 Project Quality Assurance PlanDocumento27 páginasPHR-PP-QC-GG-001 Project Quality Assurance Planmashari budiAinda não há avaliações

- Intra-organizational e-commerce workflowsDocumento16 páginasIntra-organizational e-commerce workflowsPadma Reddy ChAinda não há avaliações

- An Integrative Perspective On Information ManagementDocumento22 páginasAn Integrative Perspective On Information ManagementRik Maes100% (1)

- The Impact of Inventory Management Practice On Firms Competitiveness and Organizational Performance Empirical Evidence From Micro and SmallDocumento17 páginasThe Impact of Inventory Management Practice On Firms Competitiveness and Organizational Performance Empirical Evidence From Micro and SmallGizachew BeyeneAinda não há avaliações