Escolar Documentos

Profissional Documentos

Cultura Documentos

9 Open Pit Mining

Enviado por

Daneshwer VermaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

9 Open Pit Mining

Enviado por

Daneshwer VermaDireitos autorais:

Formatos disponíveis

9.

9.1 9.1.1

Open pit mining

Introduction Basicdescriptionofopenpitmining

Openpitminingisappliedtotheextractionofnearsurfacedeposits.Overburdenremoval (stripping)andminingarecarriedoutsystematicallyfromaseriesofbenches(steps)asthepitis progressivelydeepened.Thebenchlayoutisdesignedtoproduceanoverallslopeanglethatis compatiblewithslopestabilitysothatanopenpitresemblesaninvertedcone.Asthebaseofthe pitisdeepened,theupperbenchesarepushedoutsoastomaintaintherequiredslopeangle. Overburdenisstrippedfrombenchestouncoverthedepositandtransportedtoadumpatsome pointremotefromtheoperationitself.Asthedepthincreasestheratioofoverburdentovolumeof oreextractedsteadilyincreasesand,atacertainpoint,thecostofoverburdenremovalmakesthe operationuneconomic.Theremainderofthedepositmightthenbeworkedbyunderground mining. Advantagesofsurfaceminingcomparedwithundergroundmining. HigherProductivitydueto:greaterdegreeofmechanisation,largerequipmentcanbeused economiesofscale,fewerpersonnelrequired Loweroperatingcostspertonnedueto:higherproductivity,concentrationofproduction, lessconstraintonproductionlevel(easiermaterialshandling) Lowergradedepositscanbemined Reduceddevelopmenttime(generally).Thereforemorefavourablecashflowandquicker repaymentofcapitalinvestment. Greatergeologicalcertainty. Saferoperations Disadvantagesofsurfacemines: Largeproportionofwastetoore. Highlevelofenvironmentalimpact. Affectedbyclimaticconditions. Depthlimit

Fig.9.1:Palaboraopenpitcoppermine,SouthAfrica

59530725.doc 8 5/30/2011

9.1.2

PitLimits

Thepitlimitsaretheverticalandlateralextenttowhichtheopenpitminingmaybeeconomically conducted.Establishmentofthepitlimitsisthefirststageinmineplanning(Laurich1990).They determinethe: amountofeconomicallyrecoverableore, metalcontent, volumeofwastetobeexcavatedandmoved, locationofwastedumps,tailingslagoons,processingplant,accessroadsandallothersurface facilities. 9.2 9.2.1 Stripping ratio Definitions

Thepitlimitsandsequenceofminingaredeterminedultimatelybyeconomics.Theconceptof strippingratio(SR)isthemethodofanalysisused.Itisameasureoftheamountofwastethat mustberemovedinordertomineoneunitofore. Grade Cutoffgrade Ore Waste Thecontentofvaluablemetal(%,g/torkg/t)inamineral. Thegradeatwhichthevalueofthemetalequalsthecostofminingand processingthemineral. Mineralthatisabovethecutoffgrade Mineralthatisbelowthecutoffgrade

TheSRatanylevelofthepitisdefinedas:

SR = volume of waste removed tonnes of ore recovered m3 t

SR is also sometimes expressed as tonnes/tonne (tonnage of ore removed per tonne of ore). However,thefirstdefinitionismoreconvenientasthecostsofwasteremovalaredirectlyrelated toitsvolumeandtherevenuefromtheoreisdirectlyrelatedtoitsmass. ThePitLimitisdefinedbytheeconomicstrippingratioSRecon.Thisvalueisthestrippingratioat whichthecostsofminingandprocessingtheoreandstrippingthewasteareequaltotherevenue fromtheore. SR econ (Bm 3 /t) = revenue from ore ($/t) - ore mining cost ($/t) - ore processing cost ($/t) waste stripping cost ($/Bm 3 )

9.2.2

Simplestrippingratiocalculation

Todeterminethepitlimitforasimpleorebody(Figure9.2) CalculatetheeconomicSR: Multiplybyoredensitytoconverttom3/m3(multiplyingtoplineofSRequationtoobtainnet valueoforein$/Bm3

59530725.doc 9 5/30/2011

EstimateontheorebodysectionwherethepitlimitmaylieanddrawinlineABCatthe requiredslopeangle TheSRatthispoint=AB/BCm3/m3 ComparewitheconomicSR;iflower,movelinedownto,sayA1B1C1;ifhigher,movebackup toA2B2C2 ContinueuntilSRrepresentedbylineonsectionequalseconomicSR

Inpractice,theprocedureismuchmorecomplicated;forexample,theoregradewillusually varythroughouttheorebody.AsimplesolutionistoexpresstheeconomicSRasafunctionof grade thendraw astraight line graph of economic SRvs grade. For anygrade value in the orebody,thecorrespondingeconomicSRcanbereadoffthegraph.

Fig.9.2:Simplepitlimitestimation 9.3 Overburden stripping strategies

Describedbelowarethefourbasictypesofstrippingschedule.Thefirsttwoareextremecasesand wouldnotbeappliedinpractice.(BucyrusErie1979,Fourie&Dohm,1992) 9.3.1 DecliningStrippingRatioMethod(Figure9.3)

Aseachbenchoforeismined,allthewasteonthatbenchisremovedtothepitlimit. Advantages: goodoperatingspace goodaccessibilitytooreonnextbench, allequipmentworkingonsamelevel, nocontaminationfromwasteblastingabovetheore, equipmentrequirementsaminimumtowardsthedepletionoftheorebody. operatingcoststendtobeconstantinlateryearsastheincreasedminingcostwithdepthis offsetbythedecreasedstrippingratio. Disadvantage:overalloperatingcostsaremaximumduringtheinitialyearswhenmaximum profitsarerequiredtohandleinterestchargesandrepaytheprojectcapitalinvestment.

59530725.doc 10 5/30/2011

Fig.9.3:Reducingstrippingratiomethod 9.3.2 IncreasingStrippingRatioMethod(Figure9.4)

Onlysufficientstrippingrequiredtouncovertheoreiscarriedout.Thismethodallowsfor maximumprofitintheinitialyearsofoperationandgreatlyreducestheinvestmentriskinwaste removalfororetobeminedatalaterdate.Itmaybeappliedwheretheeconomicsofthe operationandcutoffstrippingratioisliabletochangeonveryshortnotice.Themain disadvantageistheimpracticabilityofoperatingalargenumberofstackednarrowbenches simultaneouslytomeetregularproductionrequirements.

Fig.9.4:Increasingstrippingratiomethod 9.3.3 ConstantStrippingRatioMethod(Figure9.5)

Wasteisremovedatarateapproximatelyequaltotheoverallstrippingratio.Themethodisa compromisethatremovestheextremeconditionsoftheformertwomethodsdescribed. Equipmentfleetsizeandlabourrequirementsarerelativelyconstant.

Fig.9.5:Constantstrippingratiomethod

59530725.doc 11 5/30/2011

9.3.4

PhasedMiningSequence(Figure9.6)

Inpractice,theoptimumstrippingsequenceforalargedepositwouldfeaturealowstrippingratio intheinitialandfinalyearsofoperation.Thisplanhasthefollowingadvantages. Ahighlevelofprofitcanbegeneratedattheoutsettoimprovethecashflow. Thelabourandequipmentfleetcanbebuiltuptomaximumsizeoveraperiodoftime.This approachisalsoadvantageousfromacashflowpointofview. Labourandequipmentrequirementsdecreasegraduallytowardstheendoftheminelife. Distinctminingandstrippingareascanbeoperatedsimultaneously,allowingforflexibilityin planning. Thenumberofminingandstrippingfacesrequiredisnottoohigh. Inalargeorebody,theminingandstrippingareasaresufficientlywidetocreategood operationalconditions.

Fig.9.6:Phasedminingsequence 9.4 9.4.1 Bench design Benchheight

Benchheightisthemostimportantparameterasitlargelydeterminestheotherdimensions. Valuesrangefromabout2.5mforsmallgoldminesto20mforlargeopenpits.Thefinalbench heightmaybesubdividedforextractionpurposesintoanumberofsubbenchesorflitches. Benchheightisinfluencedby: 1. excavatingequipmentdimensions(reach,operatingheight) 2. sizeandgeometryoforebodysmallbenchesusedfornarrowlodesorlensesinorderto minimisedilutionandfacilitategoodgradecontrol. Benchheightisnolongerlimitedbydrillingdepth.Theprimedeterminingparameteristhe maximumdiggingheightdimensionofashovel.Table9.1givessomeadvantagesand disadvantagesofmaximizingthebenchheight.

Table9.1:Featuresofhighwidebenches Advantages Highproductivityandefficiency Canuselargescaleequipment Largerblasts Fewerequipmentmovesandsetups Facilitatesmoreeffectivesupervision Disadvantages Lessselectivity Moredilution Fewerworkingplaces,thereforelessflexibility Flatterworkingslopes(largershovels)

59530725.doc

12

5/30/2011

Generally,itismoreadvantageous,intermsofdrillingandshovelefficiency,todesignbenchesas highaspossible. a) DrillingEfficiency

Agreaterbenchheightreducessetuptimepermeterdrilled.Also,foragivenblastdesign,the subgradedrillingrequiredisindependentofthebenchheight.Thismeansthatthegreaterthe benchheight,thegreaterthetonnageyieldpermeterdrilledorperkgofexplosiveused. Considerbenchheightsof10mand12m,eachtobedrilledona5mx5mpatternwitha1m subgrade.Therespectivedrillingyieldsare:

Drilling Y ield = Burden x S pacing x B ench Heigh t x Densit y Hole Depth

Assumingrockdensity=2.5tonnes/m3,fora10mbench:

Drilling Y ield =

Fora12mbench:

5 x 5 x 10 x 2.5 = 56.8 tonnes / m 10 + 1 5 x 5 x 12 x 2.5 = 57.7 tonnes / m 12 + 1

Drilling Y ield =

Theyieldforthe12mbenchrepresentsanincreaseindrillingyieldofsome1.6%.Although seeminglysmall,for10,000mofdrilling,itwouldresultinanextra9000tonnesproduction. Similarly,drillingcostspertonnearereducedasbenchheightisincreased b) ShovelEfficiency

Increasedbenchheightalsoimprovesoverallproductivityofshovels,FELs,orexcavators.The numberofrowsinablastingpatternisgenerallygovernedbytheholediameterandexplosive type.Iftheseparametersarefixedforagivenoperation,thetotalvolumeofbenchthatcanbe blastedatoncedependsonthebenchheight.Thegreaterthevolumeofbrokenground,thelower thenumberoftimesashovelhastobemovedinorderforblastingoperationstobecarriedout. 9.4.2 Benchwidth

Figure9.7ashowsthecommonterminologyforopenpitslopes.Abenchisahorizontalledgefrom whichdrilling,blasting,excavationandloadingoforeorwasteiscarriedout.AWorkingbenchis onethatisintheprocessofbeingmined.Thewidthextractedfromtheworkingbenchiscalledthe cut.Theworkingbenchwidthisdeterminedbythedimensionsoftrucksandtherequiredreachof excavatingequipment.Figure9.7billustratesaslopeprofilecuttingacrossanoperatingbench.It showsanarrowbenchwidthofonlysome3m,notsufficientlywidetoaccommodateequipment. However,eachbenchissystematicallyminedfromoneend,givingadequateroomfordrilling rigs,shovelsandtrucks. Afterthecuthasbeenremovedabenchofwidthtypically2.53.0mislefttocatchandcollect material,whichslidesdownfromupperbenches.Normally,thebenchslopeangleis7580oanda bermeverysecondorthirdbenchissufficient.

59530725.doc 13 5/30/2011

9.4.3

Benchangle

Benchfacesarenormallyminedassteeplyaspossible.Thesteeperthebenchangle,thesmallerthe strippingratio.Safeanglesaredeterminedby: geotechnicalconsiderations,takingintoaccountthecohesiveandfrictionalpropertiesofthe rockandthecharacter,spacingandorientationofjointsandbeddingplanes. thedipoftheorebody. Therearetwoangleswhichdefineabenchdesign: Overallslopeangle Theangleconsistentwithslopestabilityoverthefullheight/depthofthe mine.Usuallyliesbetween45oand60o.Theoverallangleisafunctionof thebenchfaceangleandthebenchwidth.Notethatahaulroadonapit slopewillflattentheoverallslopeangle. Themaximumangleconsistentwithstabilityofasinglebench(say,5to 10minheight).Typicalvaluesliebetween60oand80o.

Benchfaceangle

Theoverallslopeangleislessthanthebenchfaceanglebecausethelargertheslope,themore planesofweaknessithas.

Fig.9.7a:Pitslopecrosssection,withtypicaldimensions

Fig.9.7bGeometryofworkingbench (Atkinson1992)

9.5

Method of working benches

Operationsoneachbenchareconductedincycles;typically: 1. 2. 3. 4. 5. 6. Gradecontrolmarkoutorezoneswithtapeorsurveystaffs Drillblastholes Chargeholes Fireholes Excavateblastedmaterialandloadintotrucksforhaulageoutofpit Cleanbenchandpreparefordrilling

14 5/30/2011

59530725.doc

9.5.1

Miningdirection

Orebodylensesmaybeexcavatedineitheratransverseorlongtudinaldirection.Atransverse miningdirection(digginginadirectionnormaltotheorevein)ismoresuitableforthinlenses.It allowsbettergradecontrolandlessdilution.Withathickerlens,itmaybepossiblewith longitudinalextractiontoblastandloadtheore,leavingthewastetemporarilyinsitu.The numberofworkingfacesisdeterminedbytherequiredproductionrateandequipmentcapacities. Figure9.8illustrateshowexcavationcantakeplacesimultaneouslyandonmultiplelevels.

Fig.9.8:Miningonmultiplebenches(Hustrulid&Kuchta1995) 9.5.2 Selectionofexcavatingequipment

Inamine,certainproductionrequirementshavetobesatisfiedandinacivilconstructionproject theoperationwillhavetocomplywiththeprojectschedule.Asequipmentisveryexpensivein termsofcapitalorcontractandoperatingcosts,itsutilisationshouldbemaximisedinorderto minimisetheunitcostsofearthmoving. Table9.2:Guidelinesforselectionofexcavatingequipment

Typeofmachine Electricropeshovel Hydraulicexcavator(frontendloader) Backhoesitsontopofbench,diggingdown Ripper,Impactripper Mechanicalcutter(drumlacedwithpicks) Bulldozer,Scraper Application Largebenches Smallbenchesonly(<5.0m) Mediumhardmaterial,lowdepth Mediumhardmaterial Permitsveryselectivemining Softmaterial,lowdepth

Inrockandearthmovingprojects,plannersareusuallyconcernedwithinsituvolumesasthe quantitiescanreadilybedeterminedfromexcavationormineplans.Thebasicunitof measurementistermedthebankcubicmeter(BCMorBm3).However,manufacturersgive equipmentbucketcapacitiesintermsofthenominalbucketcapacity,thevolumeenclosedwithin theperimeterofthebucket.Thefirsttaskinaproductivitydeterminationexerciseistoconvert thismeasurementintoBCMunits.ThetablesgiveninthissectionarefromAtkinson(1992),unless

59530725.doc

15

5/30/2011

otherwisestated.Figure9.9showsthetwoalternativemethodsofexcavatingabenchandof spottingtrucks.

a)Parallelcut

b)Frontcut

Fig.9.9:Methodsofexcavatingbenches(Hustrulid&Kuchta1995) 9.6 Haul road layout

Theformofhaulroadsmaybespiralorswitchback(zigzag).Theymayalsobeeithertemporary orpermanent,dependingontheconfigurationoftheorebody.Wherebenchesarebeing systematicallyworkedallroundthepitasitisdeepened,haulroadswillbeminedthroughand newonesformedasthepitdevelops.Often,however,itispossibletoconstructpermanenthaul roadsatonesideofthepit.Thiswouldbethecaseforadippingorebody,wherethepermanent haulroadcouldbelocatedatthefootwallandextendedasthepitdeepened(figure9.10).Note thattheinclusionofahaulroadinapitwallwilllowertheoverallslopeangleandhenceincrease thestrippingratio.Wheretheorebodydipsatashalloweranglethanthestablepitslope, constructingthehaulroadasaswitchbackonthefootwallwilltaketheoverallpitslopecloseto theorebodydip.Thehangingwallslope,formedwithoutahaulroad,canbemadeassteepas possible,consistentwithslopestability.

Fig.9.10:Illustrationofhowpermanenthaulroadscanbeestablishedinafootwall Factorsdeterminingselectionoflayoutincludethefollowing.(Atkinson1992) 1. Theswitchbacklayoutallowsapermanenthaulroadtobelocatedatonesideofthepit. 2. Inlargepits,aspirallayoutcanresultinahaulagedistancethatistoogreat. 3. Areaswherepotentialslopestabilityhazardsexistshouldbeavoided,possiblyeliminatingthe spiraloption.

59530725.doc 16 5/30/2011

4. Thepitwallsmaybetoosteeptoallowsuitablebendstobeformedforaswitchbacklayout withoutgreatlyincreasingthestrippingratio. 5. Tightbendsassociatedwithaswitchbackmaybedetrimentaltotruckandtyrelife. 9.7 Haul road Construction 9.7.1 Roadbase

Goodhaulroaddesignandconstructionpromoteslowerhaulagecostsandimprovedsafety. Roadsareconstructedwiththreeorfourlayers(figure9.10): 1. 2. 3. 4. Subgrade Subbase(optional) Base Wearingsurface

Thesubgradeisthefoundationlayer,usuallycomprisingcompactedrockorsoil.Itmustbe strongenoughtobeartheloadsassociatedwithvehicles,whicharetransmittedfromtheroad surface. Asubbasemayormaynotbepresent,dependingonlocalconditions.Itisusedwherethereis veryweaksubgradematerialorinareassubjecttoseverefrost.Itisgenerallyconstructedfroma clean,granularmaterial.

Fig.9.11:Haulroadconstruction(Hustrulid&Kuchta1995) Thebaseisalayerofveryhighstabilityanddensity.Itsmainpurposeistodistributetheload fromvehicletyres.Italsoservestoinsulatethesubgradefromfrostpenetrationandprotectthe upperwearingsurfacefromanyswellingorsofteningofthesubgrade. Thetoproadlayeristhewearingsurface,whichshouldprovidetraction,reducerolling resistance,andresistabrasion,ravelingandshear.Itisformedusuallyofcrushedrock. 9.7.2 Straightsections

Thecrosssectionofanopenpithaulroadfeaturesaoneortwowaytravellane,asafetybermand adrainageditch(figure9.11).Fordeterminationoflanewidth,anumberofrulesofthumbcanbe applied,inwhichthewidestvehiclesdeterminetheroadwidth.Threeoftheserulesare: Theclearanceoneachsideofatruckshouldbeequaltoabouthalfthetruckwidth. For2waytraffic,thelanewidthshouldbegraterthanorequalto4xthetruckwidth.

17 5/30/2011

59530725.doc

Forastraight,evengrade,onelanehaulroad,theminimumroadwidthis2timestruck width;fortwolanes,3.5timestruckwidth.Theroadcrosssectionshouldalsoberaisedor crownedslightly,tofacilitatewaterrunoff.Theheightofthecrownisexpressedinmmper meterofroadwidth.Afigureof45mm/mistypical.

Fig.9.12:Typical2wayroadsection(Hustrulid&Kuchta1995) RoadGradeisdeterminedfromthetruckperformancechartswithrespecttospeedandbraking. Gradientsof4.5to6o(8to10%)areusuallyadopted,withreardumptrucksbeingthepreferred haulageunit.A12%grademaybeusedfortrolleyassisttrucks.(Atkinson1992) 9.7.3 Curves

Forsharpcurves,additionalwidthmustbeincluded,bothonthecurveandthetangenttothe curve,tocoverthefrontandrearoverhangsofthevehicleandthedifficultyofnegotiatingthe curve.Arecommendedadditionalallowanceforareardumptruckona6mradiusis125%anda 45mradius118%.(Atkinson1992.)Table9.3givesminimumturningradiiforarangeoftrucks, classifiedaccordingtogrossweight.Theseradiicanthenbeusedintable9.4tofindthe recommendeddesignwidthforsingleanddoublelanecurvesofaparticularminimumradius. Table9.3:Minimumtruckturningradius(adaptedfromHustrulid&Kuchta1995) Vehicleweightclass Grossvehicleweight(tonnes) Minimumturningradius(m) 1 2 3 4 <45.5 45.591 91181 >181 5.8 7.3 9.4 11.9

Table9.4:Designwidthsforcurvesrigidbodytrucks(adaptedfromHustrulid&Kuchta1995) Radiusoninner Singlelaneroad Doublelaneroad edgeofroad(m) Truckcategory Truckcategory Minimum 7.6 15.2 30.5 45.7 61.0

59530725.doc

1 8.8 8.2 7.6 7.3 7.3 7.0

2 10.4 10.4 9.4 8.8 8.8 8.8

3 13.7 13.4 12.5 11.9 11.9 11.6

18

4 21.3 20.7 19.2 18.0 17.7 17.4

1 15.5 14.6 13.4 12.8 12.5 12.2

2 18.3 18.3 16.5 15.5 15.2 14.6

3 24.1 23.2 21.9 21.0 20.7 19.8

4 37.5 36.3 33.5 31.4 30.8 29.9

5/30/2011

Tangent

7.0

8.5

11.3

17.1

12.2

14.6

19.8

29.9

Dependingonvehiclespeedsandbendradius,acurvemayalsohavetobebanked(super elevation).Typicalsuperelevationsforminehaulroadsandtrucksarearound40mmpermeterof roadwidth(Hustrulid&Kuchta1995).Thedistancerequiredtomakethetransitionfromthe normalcrossslopesectiontothesuperelevatedsectionandbackagain(superelevationrunout) alsoneedstobeconsidered. 9.8 Equipment

ThefollowingdiagramsillustratesomemodernequipmentcurrentlyoperatinginAustralian mines. Fig.9.13:Hitachi20m3 hydraulicshovelloadinginto Komatsu240tonnetruck

Fig.9.14:TheKOMATSU DEMAGH655Sistheworlds largestprovenhydraulicshovel atover685tgrossweightand 35m3bucket.

Fig.9.15:TheKOMATSU HAULPAK930Eisthelargest truckinminingtodayandwas thefirsttouseACdrive.Over 100930Esareoperating worldwide,providing productionupto320tpercycle.

59530725.doc

19

5/30/2011

9.9

References

AtkinsonT.Designandlayoutofhaulroads.SMEMiningEngineeringHandbook,Vol2,Chapt13.4, pp13341342.SME(1992). BucyrusErieCompany.MinePlanning.SurfaceMiningSupervisoryTrainingProgramme,Chapt 3.BucyrusErieCo.(1979). FourieGA,DohmGC.Openpitplanninganddesign.SMEMiningEngineeringHandbook,Vol2, Chapt13.1,pp12741297.SME(1992). HartmanHL.IntroductoryMiningEngineering.Wiley(1987). HustrulidW,KuchtaM,(1995),OpenPitMinePlanningandDesign,AABalkema,Rotterdam. LaurichR.Ultimatepitdefinition.SurfaceMining,2ndEdition,pp465469.SME(1990).

59530725.doc

20

5/30/2011

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- 1 SOP+for+Explosives+and+Blasting+OperationDocumento10 páginas1 SOP+for+Explosives+and+Blasting+OperationDaneshwer Verma67% (12)

- Chetan Bhagat - Three Mistakes of My LifeDocumento144 páginasChetan Bhagat - Three Mistakes of My LifeGayathri ParthasarathyAinda não há avaliações

- Best Practice Conveyor Belt SystemsDocumento50 páginasBest Practice Conveyor Belt SystemsDaneshwer Verma100% (1)

- Curso Cat d6r III STMGDocumento73 páginasCurso Cat d6r III STMGSilas F Pimenta90% (20)

- V.V.I. Question For F M R - 2014Documento1 páginaV.V.I. Question For F M R - 2014Daneshwer VermaAinda não há avaliações

- Statement Showing Amount of PRP Payable To Daneshwar Prasad Verma, D2774 FOR THE YEAR 2012-13Documento1 páginaStatement Showing Amount of PRP Payable To Daneshwar Prasad Verma, D2774 FOR THE YEAR 2012-13Daneshwer VermaAinda não há avaliações

- Mine Rescue HandbookDocumento22 páginasMine Rescue HandbookRussell Hartill100% (1)

- Sound Mind Leads To Safe BankingDocumento16 páginasSound Mind Leads To Safe BankingsanketbshethAinda não há avaliações

- Medicinal PlantDocumento6 páginasMedicinal PlantDaneshwer VermaAinda não há avaliações

- Learn Sanskrit Through Self StudyDocumento209 páginasLearn Sanskrit Through Self Studyramkumaran88% (40)

- Hand Book The Indian Electricity Rules1956Documento148 páginasHand Book The Indian Electricity Rules1956Vivek Kumar100% (8)

- 2013Documento4 páginas2013Daneshwer VermaAinda não há avaliações

- CBDT PressRelease 09102009Documento1 páginaCBDT PressRelease 09102009Daneshwer VermaAinda não há avaliações

- Sky Py ReleaseNotes 4.1.x.179 Hotfix 3Documento16 páginasSky Py ReleaseNotes 4.1.x.179 Hotfix 3Daneshwer VermaAinda não há avaliações

- M/S. Sri Kanakadurga Tribal Labour Contract Mutually Aided Co-Op Society.Documento11 páginasM/S. Sri Kanakadurga Tribal Labour Contract Mutually Aided Co-Op Society.Daneshwer VermaAinda não há avaliações

- Employment Notification No.01/12 Application For The Post of Junior Officer (Mining)Documento2 páginasEmployment Notification No.01/12 Application For The Post of Junior Officer (Mining)Daneshwer VermaAinda não há avaliações

- Report of Rajya Sabha Select Committee On Lokpal BillDocumento104 páginasReport of Rajya Sabha Select Committee On Lokpal BillShivendra Singh ChauhanAinda não há avaliações

- SMR2009Documento2 páginasSMR2009Daneshwer VermaAinda não há avaliações

- Metal Mining and The Environment (2003)Documento68 páginasMetal Mining and The Environment (2003)etsimoAinda não há avaliações

- First+Class+Unrestricted+Metal+Question+Papers Signed COALDocumento12 páginasFirst+Class+Unrestricted+Metal+Question+Papers Signed COALDaneshwer Verma100% (5)

- Coarse-Grained Structure Is Easier To DrillDocumento50 páginasCoarse-Grained Structure Is Easier To DrillAmilton filhoAinda não há avaliações

- Operations ManagementDocumento64 páginasOperations Managementsanjay97% (36)

- Fragblast 10-First CircularDocumento8 páginasFragblast 10-First CircularDaneshwer VermaAinda não há avaliações

- Yog SandeshDocumento60 páginasYog SandeshDaneshwer VermaAinda não há avaliações

- Employee EngagementDocumento37 páginasEmployee EngagementArchin PadiaAinda não há avaliações

- Mar 2012Documento40 páginasMar 2012Daneshwer VermaAinda não há avaliações

- Meai Mar 2010Documento36 páginasMeai Mar 2010Daneshwer VermaAinda não há avaliações

- Meai Nov 2010Documento36 páginasMeai Nov 2010Daneshwer VermaAinda não há avaliações

- Safety Officer - ROLES & RESPONSIBILITIESDocumento19 páginasSafety Officer - ROLES & RESPONSIBILITIESrashmi_shantikumar69% (29)

- Meai Oct 2009Documento36 páginasMeai Oct 2009Daneshwer VermaAinda não há avaliações

- Meai July 2010Documento36 páginasMeai July 2010Daneshwer VermaAinda não há avaliações

- Plan PA Desember 2019rev1Documento6 páginasPlan PA Desember 2019rev1Donny Prasetya ManginsihAinda não há avaliações

- Heavy Engineering BrochureDocumento4 páginasHeavy Engineering Brochureganeshkharabe001Ainda não há avaliações

- d8r Track-Type Tractor 7xm00001-Up (Machine) Powered by 3406 Engine (Sebp2439 - 153) - DocumentationDocumento6 páginasd8r Track-Type Tractor 7xm00001-Up (Machine) Powered by 3406 Engine (Sebp2439 - 153) - Documentationgulam husseinAinda não há avaliações

- Oil Consumption HighDocumento46 páginasOil Consumption HighRangga NagaraAinda não há avaliações

- D7E Tractor Track-TypeDocumento16 páginasD7E Tractor Track-TypeForomaquinas100% (1)

- Gen00062 00Documento137 páginasGen00062 00Ebrahim Sabouri100% (1)

- Tire and Rim (Front) - Remove and Install - 2Documento4 páginasTire and Rim (Front) - Remove and Install - 2CarlosAinda não há avaliações

- WD600 6Documento8 páginasWD600 6Ootteehhb UuqAinda não há avaliações

- D6-GC MediumDocumento4 páginasD6-GC MediumPram BudiAinda não há avaliações

- Drivers & Operators Awareness Training: Project: Sky Venture Project, Location: Yas Island-Abudhabi-UaeDocumento34 páginasDrivers & Operators Awareness Training: Project: Sky Venture Project, Location: Yas Island-Abudhabi-UaeSaifuddin AhmedAinda não há avaliações

- Excavation - Final ReportDocumento5 páginasExcavation - Final Reportkhunany89Ainda não há avaliações

- D11RDocumento24 páginasD11RRicardo Contreras B100% (1)

- D65ex 16Documento8 páginasD65ex 16David Adco Apaza100% (2)

- Blackcat DresstaDocumento30 páginasBlackcat DresstaMICHAEL MONGUIAinda não há avaliações

- Fungsi:: Technical Analysis Report (Tar)Documento47 páginasFungsi:: Technical Analysis Report (Tar)Rohmat adenibrahimAinda não há avaliações

- Standard Data Book Road Bridge - 2019-1Documento253 páginasStandard Data Book Road Bridge - 2019-1Rajat JaggiAinda não há avaliações

- Trilift Catalog USA WEB 20160907 English USADocumento36 páginasTrilift Catalog USA WEB 20160907 English USAJohn GrayAinda não há avaliações

- 650KDocumento16 páginas650KBeny Stephen0% (1)

- DSR 2016 (Vol.1) PDFDocumento234 páginasDSR 2016 (Vol.1) PDFJoe78% (54)

- TD-14 TD-15 TD-20: Mid-Size Crawler DozersDocumento32 páginasTD-14 TD-15 TD-20: Mid-Size Crawler DozersjddiazmAinda não há avaliações

- Earthmoving EquipmentDocumento63 páginasEarthmoving EquipmentCakama MbimbiAinda não há avaliações

- Motor Graders C Series Brochure 202106Documento16 páginasMotor Graders C Series Brochure 202106Heesler PerezAinda não há avaliações

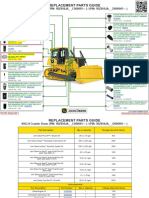

- Replacement Parts GuideDocumento3 páginasReplacement Parts Guidebayu prasetyoAinda não há avaliações

- A - 11 - A Rippability Classification System For Marls in Lignite MinesDocumento17 páginasA - 11 - A Rippability Classification System For Marls in Lignite MinesjimmyAinda não há avaliações

- Technical Specifications ZD160-3 (UNIVERSAL SHOVEL)Documento11 páginasTechnical Specifications ZD160-3 (UNIVERSAL SHOVEL)Hoàng Anh PhạmAinda não há avaliações

- Caterpillar d9l Crawler Parts Manual SN 14y1 UpDocumento7 páginasCaterpillar d9l Crawler Parts Manual SN 14y1 UpMelTosiKAinda não há avaliações

- Futura MiningDocumento28 páginasFutura MiningAvaa AmgaaAinda não há avaliações

- Construction Equipments and Methods PDFDocumento944 páginasConstruction Equipments and Methods PDFAnonymous 5B1cgFjyLj33% (3)

- Datas 2023-24 (SOR 2023-24) - BSRDocumento67 páginasDatas 2023-24 (SOR 2023-24) - BSRVannurSwamyAinda não há avaliações