Escolar Documentos

Profissional Documentos

Cultura Documentos

Tutorial - Session 5

Enviado por

samprof4vwDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tutorial - Session 5

Enviado por

samprof4vwDireitos autorais:

Formatos disponíveis

STRESS ANALYSIS BASED DESIGN OF PIPELINES TUTORIAL on Session 5 Q1.

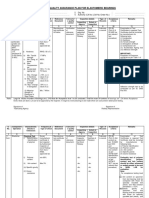

You have just been given the engineering (or nominal) stress, S, and engineering (or nominal) strain, e, data obtained from a uniaxial tensile test of a pipeline material. (a) Show how you would obtain the corresponding true stress and true strain . (b) Hence, show that the nominal measure of the ultimate tensile strength, Su, and the true ultimate tensile strength, u, are related by u Su .exp( u ) where u is the true strain at u. (c) The true stress and the true plastic strain p data can be fitted to the power law equation K n p where n is the strain hardening index and K is the strength coefficient. It is possible to determine the material constants from a ln() - ln(p) plot of the experimental data. But the accuracy of this approach depends on the stress range used in the plot. Hence show that the strain hardening index n and the strength coefficient K can be alternatively be obtained from the relations : n = u; and K = Su (e/n)n , where e = 2.718 is the base of natural log. Q2. A subsea pipeline with outer diameter 220 mm is to be used at a water depth of 500 m to transport non-flammable fluids at a pressure of 25 MPa and temperature of 80 oC . The material from which the pipe is made has a room temperature yield strength of 448 MPa and tensile strength of 610 MPa, and the pipe is be manufactured to a wall thickness tolerance of 0.5 mm. The estimated loss of thickness due to corrosion over the design life is 0.25 mm. Assume the pipe is straight, the deformation is elastic, and there is no restraint to the axial movement. Determine the minimum nominal thickness of the pipe using the hoop-stress based approach. Assume thin-walled pipe and water density of 1000 kg/m3. Ans: [7.57 mm by PD8010; 6.67 mm by DNV]

Q3. The pipe in Q2 is to be concrete-coated. The concrete is 30 mm thick and has a Youngs modulus of 20 GPa and Poissons ratio of 0.2. The pipeline steel has a Youngs modulus of 200 GPa and Poissons ratio of 0.33. Using the nominal thickness of the pipe based on BS PD8010-2 obtained from Q2 and assuming plane sections remain plane, determine (a) the interface pressure at the pipeline-concrete interface after the internal pressure is applied, and [Ans: 8 MPa] (b) the minimum allowable tensile strength of the required concrete material, if the concrete in most likely to fail in tension. [Ans: 12.7 MPa]. Assume the deformation is linear elastic.

Você também pode gostar

- Bearing Capacity of SoilsDocumento138 páginasBearing Capacity of SoilsMuqeem Khan100% (1)

- Piping Stress Analysis Specification for PTTEP Arthit Field DevelopmentDocumento23 páginasPiping Stress Analysis Specification for PTTEP Arthit Field Developmentsamprof4vw83% (6)

- 49MHDocumento17 páginas49MHsamprof4vwAinda não há avaliações

- Free SpanDocumento2 páginasFree Spansamprof4vwAinda não há avaliações

- Process Piping Design2Documento175 páginasProcess Piping Design2samprof4vw100% (1)

- Norsok Standard Structural DesignDocumento19 páginasNorsok Standard Structural Designsamprof4vwAinda não há avaliações

- Pipeline Instation Using Orcaflex Master ThesisDocumento144 páginasPipeline Instation Using Orcaflex Master Thesissamprof4vw100% (1)

- 02 - Pipeline Systems Engineering and Routing ConsiderationsDocumento31 páginas02 - Pipeline Systems Engineering and Routing ConsiderationsOlusola OguntuberuAinda não há avaliações

- Off Shore Pipelines and RisersDocumento17 páginasOff Shore Pipelines and RisersMiroslav Aleksic100% (2)

- Numerical-Simulation-of-Submarine-Pipelines-In EARTHQUAKE ENGINEERING AND STRUCTURAL DYNAMICS PDFDocumento22 páginasNumerical-Simulation-of-Submarine-Pipelines-In EARTHQUAKE ENGINEERING AND STRUCTURAL DYNAMICS PDFhamza2085Ainda não há avaliações

- Offshore Loading SystemDocumento5 páginasOffshore Loading Systemsamprof4vw100% (1)

- Pro-Piping Basic Training PresentationDocumento34 páginasPro-Piping Basic Training Presentationsamprof4vw100% (1)

- 02 - Input BasicsDocumento35 páginas02 - Input Basicssamprof4vwAinda não há avaliações

- 02 - Input BasicsDocumento35 páginas02 - Input Basicssamprof4vwAinda não há avaliações

- Hanger SizingDocumento26 páginasHanger SizingBùi Văn HợpAinda não há avaliações

- CAESAR II Pipe Stress Analysis GuideDocumento37 páginasCAESAR II Pipe Stress Analysis GuideEko Idris Hutagaol100% (1)

- 2010-10!11!13-Finite Element Analysis LeafletDocumento2 páginas2010-10!11!13-Finite Element Analysis Leafletsamprof4vwAinda não há avaliações

- 02 - Manifold MDocumento1 página02 - Manifold Msamprof4vwAinda não há avaliações

- Guidelines For MooringsDocumento37 páginasGuidelines For MooringsKin Lai Kong100% (6)

- 03 - V50 ToolsDocumento17 páginas03 - V50 Toolssamprof4vwAinda não há avaliações

- 03 - V50 ToolsDocumento17 páginas03 - V50 Toolssamprof4vwAinda não há avaliações

- 02 - When & Why Stress Analysis MetricDocumento1 página02 - When & Why Stress Analysis Metricsamprof4vwAinda não há avaliações

- VerificationDocumento80 páginasVerificationsamprof4vw100% (3)

- Assessment of Existing Offshore Structures For Life ExtensionDocumento225 páginasAssessment of Existing Offshore Structures For Life ExtensionrmahadevappaAinda não há avaliações

- 2220100905037812500Documento3 páginas2220100905037812500samprof4vwAinda não há avaliações

- KTP Application Form 2012Documento7 páginasKTP Application Form 2012samprof4vwAinda não há avaliações

- VerificationDocumento80 páginasVerificationsamprof4vw100% (3)

- VerificationDocumento80 páginasVerificationsamprof4vw100% (3)

- 1st ISODC05-Ufrj TeamDocumento114 páginas1st ISODC05-Ufrj TeamIan Soares MunizAinda não há avaliações

- VerificationDocumento80 páginasVerificationsamprof4vw100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- (INCO 2980) Austenitic Chromium-Nickel Stainless Steels at Elevated Temperatures Mechanical and Physical PropertiesDocumento20 páginas(INCO 2980) Austenitic Chromium-Nickel Stainless Steels at Elevated Temperatures Mechanical and Physical PropertiesYuanqing WangAinda não há avaliações

- Tension and Torsion TestsDocumento19 páginasTension and Torsion Testsyeast taeAinda não há avaliações

- Unit - I Simple Stresses and StrainsDocumento6 páginasUnit - I Simple Stresses and StrainsNavin SinghAinda não há avaliações

- En 10270 1 2001 Filo Per MolleDocumento26 páginasEn 10270 1 2001 Filo Per MolleGizem AkelAinda não há avaliações

- ASME V QuizDocumento14 páginasASME V Quizamalhaj2013100% (1)

- ProblemSession1 2024Documento2 páginasProblemSession1 2024s2038163Ainda não há avaliações

- Material Science Cheatsheet For Midterm New 2Documento1 páginaMaterial Science Cheatsheet For Midterm New 2DillAinda não há avaliações

- Elastomeric Materials PDFDocumento84 páginasElastomeric Materials PDFAnonymous oyUAtpKAinda não há avaliações

- C864 PDFDocumento3 páginasC864 PDFĐường Nguyễn ThừaAinda não há avaliações

- Astm - Specification - For - Carbon - Structural - Steel - A36 Sa-36sa-36m - 2001Documento7 páginasAstm - Specification - For - Carbon - Structural - Steel - A36 Sa-36sa-36m - 2001eAinda não há avaliações

- A101 Design Calculation For Foundation of New VCM Storage TankDocumento25 páginasA101 Design Calculation For Foundation of New VCM Storage TankzatenneAinda não há avaliações

- Maryland Metrics - Metric ASTM Structural FastenersDocumento5 páginasMaryland Metrics - Metric ASTM Structural Fastenerslimulsa78Ainda não há avaliações

- Mechanical Clinching of Ultra-High Strength Steel Sheets and Strengthof JointsDocumento7 páginasMechanical Clinching of Ultra-High Strength Steel Sheets and Strengthof JointsThong LeAinda não há avaliações

- Effect of Mechanical Properties On Multi Axial Forged LM4 Aluminium AlloyDocumento6 páginasEffect of Mechanical Properties On Multi Axial Forged LM4 Aluminium AlloySharath P CAinda não há avaliações

- MetalDocumento0 páginaMetalhrk100Ainda não há avaliações

- Underhung Cranes & MonorailsDocumento33 páginasUnderhung Cranes & MonorailsChar Rob100% (1)

- Experiment 1 - TENSION TEST OF MILD STEEL SPECIMENDocumento10 páginasExperiment 1 - TENSION TEST OF MILD STEEL SPECIMENSamiha Maysoon Nooria100% (1)

- AWS Electrode ClasssifiDocumento1 páginaAWS Electrode Classsifigsenthil15Ainda não há avaliações

- BBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallsDocumento12 páginasBBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallssandycastleAinda não há avaliações

- Standard QA Plan (Elastomeric Bearings)Documento8 páginasStandard QA Plan (Elastomeric Bearings)ghaghra bridgeAinda não há avaliações

- CT 100 Cryogenic Valve Performance Whitepaper - FINALDocumento8 páginasCT 100 Cryogenic Valve Performance Whitepaper - FINALSanket WalimbeAinda não há avaliações

- NeenahCatalog PDFDocumento332 páginasNeenahCatalog PDFalbertmunoz100% (1)

- Design Guide BC1-2012Documento86 páginasDesign Guide BC1-2012lwin_oo2435100% (1)

- Laboratory Handout Semester 1Documento12 páginasLaboratory Handout Semester 1Taras GorevoiAinda não há avaliações

- Tensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Documento4 páginasTensile Test of Copper Fibers in Conformance With ASTM C1557 Using Agilent UTM T150Celeste LopezAinda não há avaliações

- 10 1016@j Engfailanal 2020 104610Documento21 páginas10 1016@j Engfailanal 2020 104610CHONKARN CHIABLAMAinda não há avaliações

- Structural Design IIDocumento47 páginasStructural Design IIHamza KaleemAinda não há avaliações

- Coating Procedure PPDocumento55 páginasCoating Procedure PPMuhamad Hassan100% (2)

- Park and Pauley PDFDocumento388 páginasPark and Pauley PDFDinakar PraneethAinda não há avaliações

- Mechanical Properties of Structural Steels. NISTDocumento322 páginasMechanical Properties of Structural Steels. NISTmahsa_ci80Ainda não há avaliações