Escolar Documentos

Profissional Documentos

Cultura Documentos

Eor Ior Course T Ahmed

Enviado por

Miguel Angel ValladaresDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Eor Ior Course T Ahmed

Enviado por

Miguel Angel ValladaresDireitos autorais:

Formatos disponíveis

12/1/2011

1

Dr. Tarek Ahmed

Tarek Ahmed & Associates Ltd

www.TarekAhmedAssociates.com

Tahmed@Mtech.edu

Principals of

Secondary & Enhanced Oil Recovery

Professor Emeritus of Petroleum Engineering

Montana Tech of the University of Montana

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

OUTLINE

1. Introduction and Review of Basic Reservoir Engineering

2. Stages of Oil Recovery

3. Factors to Consider When Planning an IOR

4. Introduction to Secondary Recovery Methods

5. Enhanced Oil Recovery Methods

6. Equations of State and Compositional Modeling

7. Simulation

8. Team project: Developing and the Nameless Field

11/21/2011 2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

2

Segmented Stages of Oil Recovery

Three Stages:

1. Primary Recovery

2. Secondary Recovery

3. Tertiary (Enhanced) Oil Recovery

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

11/21/2011

Primary Oil Recovery:

describes the production of hydrocarbons under the natural driving mechanisms

present in the reservoir without supplementary help from injected fluids such as

gas or water.

Secondary Oil Recovery:

1. Refers to the additional recovery that results from the conventional

methods of water injection and immiscible gas injection.

2. Usually, the selected secondary recovery process follows the primary

recovery but it can also be conducted concurrently with the primary

recovery.

3. Before undertaking a secondary recovery project, it should be clearly

proven that the natural recovery processes are insufficient; otherwise

there is a risk that the substantial capital investment required for a

secondary recovery project may be wasted.

Tertiary (Enhanced) Oil Recovery:

is that additional recovery over and above what could be recovered by primary

and secondary recovery methods. Various methods of enhanced oil recovery

(EOR) are essentially

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

3

Segmented Stages of Oil Recovery

Gas Injection

(Pressure Maintenance)

Micellar-Polymer

ASP

Polymer

Others

Artificial Lift

Primary Recovery

Natural Flow

Secondary Recovery

Water Flood

Tertiary Recovery

Thermal Miscible Flood Chemical

Steam

In-situ Combustion

Huff-and-Puff

Hot Water

SAGD

CO

2

Lean Gas

LPG

. N

2

Air

Enriched Gas

E

O

R

I

m

p

r

o

v

e

d

O

i

l

R

e

c

o

v

e

r

y

(

I

O

R

)

11/21/2011 2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

EOR Assessment & Approach

1. Screening & Field Selection

2. Cost estimates

3. Go or No-Go

4. Experimental program and qualitative simulation

5. Pilot Study, Tracer Survey, and monitoring program

6. economic evaluation

7. Go or No-Go

8. Matching pilot data and quantitative simulation

9. Decision making Go or No-Go

10. Full Field simulation and Implementation

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

4

IOR/EOR questions

miscible

immiscible

chemical

polymer

1- What is the anticipated phase behavior between reservoir fluid and injectant ?

2- What is S

orm

?

3- what is the mobility of phases ?

4- will process be first contact or multi-contact?

1- What is the remaining oil saturation after H

2

O, i.e. S

orw

?

2- what is S

org

to immiscible gas?

3- Aquifer? Gas cap? Size? Strength?

1- What is the design of the chemical slug to reduce ? S

orm

?!!!

2- To what extend will chemical interact with clays in the formation through

adsorption?

3- what is the salinity of the reservoir water and how it will impact the

effectiveness of the slug ?

4- How will mobility control of the oil bank and chemical bank accomplished ?

1- What is the polymer concentration necessary to provide mobility the control?

2- What is % of the polymer slug that will be adsorbed on the reservoir rock ?

1- What are the anticipated thermal losses in the wellbore, to cap and base rock?

2- Can the thermal front be controlled in the reservoir?

Thermal

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

EOR Target

45% OOIP

EOR Target

90% OOIP

Primary

25% OOIP

Primary

5% OOIP

Secondary

30% OOIP

Heavy Oils

Light Oils

Target for different crude oil systems

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

5

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Residual Oil !!!!

What Does That Mean? and Why?

A. Wettability

B. Capillary Forces

C. Heterogeneity of the Reservoir

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

12/1/2011

6

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Initial Reservoir Condition at Equilibrium

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Initial Reservoir Condition at Equilibrium

12/1/2011

7

11/21/2011

Wettability

Consider the Displacement in a Single Pore

11/21/2011

Displacement in Multiple Channels

Capillary forces cause water to

Move ahead faster in low permeability

channel

Gas displaces oil from

High permeability channels

12/1/2011

8

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Thread of the oil gets smaller at restricted points

A &B; where oil film subsequently breaks

Target Setting for Recovery Factors

1) Tertiary EOR can Contribute by 7-15% Increase in Ultimate Recovery, i.e.

P+S+T 45-65%. However, Vast Majority of Fields are below 40%.

2) How realistic is Setting a Target for RF > 70%? Can we do Better ?

3) The Key: a More Proactive Longer-Term minded Reservoir

Management Approach; that includes:

a) Understanding the HEALTH and Behavior of reservoir by analyzing

Early production data

b) Identify boundaries, un-drained and upswept areas

c) Improve fluid distribution mapping (avoid Average S

o

) throughout the

life of the Field

d) May Require New Techniques

e) Very Important that you Start Planning VERY EARLY

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

9

Oil Recovery

Flow Rate

Tertiary

Secondary

Primary

Time

Oil Recovery Categories

? ?

Timing to Start Injection!

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

For any IOR process, important issues to consider

A. Movable Oil or Residual Oil

B. Time to start project, secondary or Tertiary

C. Economics of the project

D. Given the reservoir rock and fluid properties; can the selected

process be used in the chosen reservoir, i.e. screening ?

Time

Rate

Primary

Secondary Tertiary

?

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

10

First Step for

A Successful for IOR Flood

Performing a Screening Test

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

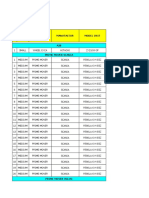

Process Crude Oil Reservoir

N

2

& Flue Gas

>35 API

<0.4 cp

High C

m

So: >40%

Formation: SS or carbonate with few fractures

h: Relatively thin unless formation is dipping

K: Not Critical

D: >6000 ft

T: Not Critical

High Pressure Gas

Injection

>23 API

<3 cp

High C

m

So: >30%

Formation: SS or carbonate with min fractures

h: Relatively thin unless formation is dipping

K: Not Critical

D: >4000 ft

T: Can have a significant effect on MMP

Miscible CO

2

>22 API

<10 cp

High C

5

-C

12

So: >20%

Formation: SS or carbonate

h: Relatively thin unless dipping

K: Not Critical

D: MMP=f(D,T)

Chemical (ASP;

micellar, etc)

>20 API

<10 cp

ASP: organic acid

groups in the oil are

need

So: >35%

Formation: SS preferred

h: Not Critical

K: >10md

D: <9000 ft

T: < 200 F

Polymer >15 API

<100 cp

So: >50%

Formation: SS but can be used in carbonates

h: Not Critical

K: >10 md

D: <9000 ft

T: <200 F

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

11

Questions and Issues

1. How much oil remains at the end of primary and where is it?

Volumes remaining in selected patterns

S

or

in selected Flow patterns

2. What factors control or limit recovery?

Reservoir quality (k,, etc)

Field maturity (current pressure, free gas,etc)

Operational effectiveness (availability of H

2

O/gas, capacity of surface

facilities, handling water production,..etc)

3. How can we improve recovery?

4. Plans after Secondary? EOR? Timing?

5. S

orm

? (S

or

)

res

= f [ (S

or

)

core

, M, V ] ?

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

Brief Review of

Reservoir Engineering

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

12/1/2011

12

What is the Original-Oil-in-Place? What Tools are Used?

1. A geological/petrophysical study is the key in

understanding and answering the question

2. Supplemented by mathematical formulations; that

include:

- Material Balance Equation MBE

- Decline Curves Analysis

- Type Curves Analysis

OOIP from Volumetric & MBE calculations !!!!!!!

are they the same?

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

1- Material Balance Equation

Oil

Zone

Gas Cap

Zone Oil of Volume

Cap Gas of Volume

= m

P

P

P

N

G

R =

Unknowns:

N

m

R

P

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

13

2- Decline Curves

b> 1 !!

When can be applied?

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

3- Type Curves

?

q

Dd

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

14

Where is the current Oil-in-Place?

1. How the CURRENT oil saturation is distributed in the

reservoir; i.e. available oil for IOR Process?

2. Knowing the distribution is the Key for a successful IOR

3. Project.

4. The objective is to target remaining movable oil

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

Adjustments to the

Remaining Oil Saturation

To account for:

1. The water influx zone

2. The expansion of the gas cap

3. Combined effect of water influx & gas cap expansion

4. Shrinking of the gas cap

5. The gas migration to form a secondary gas cap

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

12/1/2011

15

volume pore

volume oil remaining

=

o

S

( )

oi

o

p

wi o

B

B

N

N

S S

|

|

.

|

\

|

= 1 1

Pore Volume P.V = 7758 A h

N B

oi

= (P.V) (1 S

wi

)

However; how this oil saturation is distributed in the

reservoir?

|

|

.

|

\

|

=

wi

oi

S

B N

V P

1

) . (

( )

|

|

.

|

\

|

=

wi

oi

o p

o

S

B N

B N N

S

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

( )

orw wi

w p e

WIZ

S S

B W W

V P

=

1

.

( )

(

|

|

.

|

\

|

=

orw wi

w p e

wi

oi

orw

orw wi

w p e

o p

o

S S

B W W

S

B N

S

S S

B W W

B N N

S

1 1

1

1- Oil Saturation Adjustment to Water Influx

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

16

2- Oil Saturation Adjustment Gas Cap Expansion

( )

org wi

gi

g

oi

GIZ

S S

B

B

B N m

V P

|

|

.

|

\

|

=

1

1

.

( )

|

|

.

|

\

|

(

(

|

|

.

|

\

|

(

(

(

(

(

|

|

.

|

\

|

=

1

1 1

1

1

gi

g

org wi

oi

wi

oi

org

org wi

gi

g

oi

o p

o

B

B

S S

B N m

S

B N

S

S S

B

B

B N m

B N N

S

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

3- Oil Saturation Adjustment to

Gas Cap Expansion & Water Influx

( )

( )

(

(

(

(

(

+

|

|

.

|

\

|

(

(

(

(

(

+

|

|

.

|

\

|

=

orw wi

w p e

org wi

gi

g

oi

wi

oi

orw wi

orw p e

org wi

org

gi

g

oi

o p

o

S S

B W W

S S

B

B

mNB

S

NB

S S

S W W

S S

S

B

B

mNB

B N N

S

1 1

1

1

1 1

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

17

oa gr wi

org

gi

g

oi g pc

B S S

S

B

B

B N m B G

Lost Oil

) 1 (

] ) 1 ( [

=

Oil saturation adjustment for shrinking gas-cap:

The volume of oil lost as a result of oil migration to the

gas cap can also be calculated from:

Where:

G

pc

= Cumulative gas production from the gas cap, scf

B

g

= Gas FVF, bbl/scf

You Must Consider:

Migration of oil to the Gas Cap !!

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Secondary gas cap

Lost Residual Oil

Oil saturation adjustment in

Gravity Drainage Reservoirs

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

18

) 1 (

]

1

[ ] ) ( [

P.V) (

SGC

gc org wi

gc

wi

oi

g P P s P si

S S S

S

S

B N

B R N R N N R N

=

( )

SGC

SGC

P.V) (

1

P.V) (

|

|

.

|

\

|

=

wi

oi

org o p

o

S

B N

S B N N

S

S

o

Adjustment for Gravity Drainage

Secondary gas cap pore volume; gives:

Adjust the saturation equation to account for the migration of the evolved

gas to the secondary gas cap, to give:

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Important Comment

In these types of reservoirs, the gravity effects result in

much lower producing gas-oil ratios than would be

expected from reservoirs producing without the benefit

of gravity drainage. This is due to the upstructure

migration of the gas and consequent higher oil

saturation in the vicinity of the completion intervals of the

production wells which should be used when calculating

the oil relative permeability k

ro

.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

19

FACTORS TO CONSIDER

The following reservoir characteristics must be considered

when determining the suitability of a candidate reservoir for

IOR flood:

1. Wettability

2. Fluid properties

3. Lithology and rock properties

4. Heterogeneity of the Reservoir

5. Reservoir depth

6. Fluid saturations

7. Reservoir Uniformity and Pay Continuity

8. Primary reservoir driving mechanisms

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

1- Wettability

Wettability is one of the most important rock properties that must be

considered and accounted for when planning an IOR project.

Wettability significantly effects and controls the success or the

failure of the injection fluid. Waterflooding option is generally not

considered appropriate in Oil Wet Reservoir Systems

2- Fluid Properties

The physical properties of the reservoir fluids have pronounced effects

on the suitability of a given reservoir for further development by

immiscible fluid injection. The viscosity of the crude oil is considered

the most important fluid property that affects the degree of success of

an IOR project.

The oil viscosity has the important effect of determining the mobility

ratio that, in turn, controls the sweep efficiency.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

20

3- Lithology and Rock Properties

Reservoir lithology and rock properties that affect flood ability and success are:

Porosity

Permeability (impact of thief zones)

Clay content

Net thickness

Tight reservoirs or reservoirs with thin net thickness possess water-injection problems

in terms of the desired water injection rate or injection pressure. The governing

relationship:

k h

i

p

w

inj

The above relationship suggests that to deliver a desired daily injection

rate of i

w

in a tight or thin reservoir, the required injection pressure

might exceed the formation fracture pressure.

To deliver a desired

injection rate

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

4- Heterogeneity of the Reservoir

The reservoir existing directional permeability and orientation of

natural/induced fractures can be effectively utilized when selecting the

flooding pattern to improved the EUR. Efforts (conducting traditional well

testing, pulse testing, tracer surveys,etc) should be placed to properly

characterize the heterogeneity of the reservoir as a first preliminary step in

design a waterflood project.

K

y

>>> K

x

K

y

K

y

K

x

K

x

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

21

Injection-well Hydraulic Fracture Orientation

Improves sweep efficiency

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

5- Reservoir Depth

I. Maximum injection pressure will increase with depth. However, The

costs of lifting oil from very deep wells will limit the maximum economic

wateroil ratios that can be tolerated, thereby reducing the ultimate

recovery factor and increasing the total project operating costs.

II. a shallow reservoir imposes a restraint on the injection pressure that can

be used, because this must be less than fracture pressure. In waterflood

operations

There is a critical pressure (approximately 1 psi/ft of depth) that, if

exceeded, permits the injecting water to expand openings along fractures or

to create fractures. This results in the channeling of the injected water or the

bypassing of large portions of the reservoir matrix. Consequently, an

operational pressure gradient of 0.75 psi/ft of depth normally is allowed

to provide a sufficient margin of safety to prevent pressure parting.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

22

6- Fluid Saturations

In determining the suitability of a reservoir for waterflooding, a

high oil saturation that provides a sufficient supply of

recoverable oil is the primary criterion for successful flooding

operations. Note that higher oil saturation at the beginning of flood

operations increases the oil mobility (through K

ro

) that, in turn,

gives higher recovery efficiency.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

7- Reservoir Uniformity and Pay Continuity

Substantial reservoir uniformity is one of the major physical

criterions for successful waterflooding. For example:

I. Thief zone will cause rapid channeling, high WOR, and

bypassing will develop. This zone must be located and

shut off

II. These thief zones will contain less oil than the other layers,

and their flooding will lead to relatively lower oil recoveries

than other layers.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

23

8- Primary Reservoir Driving Mechanisms

Six driving mechanisms basically provide the natural energy

necessary for oil recovery:

I. Rock and liquid expansion

II. Solution gas drive

III. Gas cap drive

IV. Water drive

V. Gravity drainage drive

VI. Combination drive

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Driving Mechanism Oil Recovery Range

Rock & liquid expansion

3 7 %

Solution Gas drive

5 30 %

Gas Cap

20 40 %

Water drive

35 75%

Gravity drainage

<80%

Combination drive

30 60%

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

24

I. SOLUTION GAS DRIVE

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

25

II. GAS-CAP DRIVE

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

26

Size of the Gas Cap

Oil recovery

Oil

Zone

Gas Cap

Zone Oil of Volume

Cap Gas of Volume

= m

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Managing Gas Cap Drive reservoirs

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

27

III. WATER DRIVE

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

IV. Gravity Drainage Drive

Factors that affect ultimate recovery from gravity drainage reservoirs

are:

1- permeability in the direction of dip

2- dip of the reservoir

3- reservoir producing rates

4- oil viscosity

5- relative permeability characteristics (lab does not consider it) 11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights

Reserved

12/1/2011

28

To maximize the oil recovery by gravity segregation; Q

o

should not exceed a Critical Maximum oil Rate to allow

gas migration

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Secondary gas cap

Lost Residual Oil

What is the Maximum Oil Rate to Ensure

Counter Flow?

q

o

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

29

This calculated value of q

o

represents the maximum oil rate that should not

be exceeded without causing the gas to flow downward.

Where:

q

o

= oil production rate, bbl/day

o

= oil density, lb/ft

3

g

= gas density, lb/ft

3

A = cross-sectional area open to flow, ft

2

k = absolute permeability, md

= dip angle.

o

g o ro

o

A k k x

q

o ) sin( ) ( 10 83 . 7

6

=

Production should not exceed a critical maximum rate of

gravity drainage .The maximum rate of gravity drainage is

defined as the rate at which complete counter-flow exists

and mathematically by the following expression:

Comment; can be unrealistic

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Class Problem:

An oil reservoir is produced under gravity drainage driving

mechanism with the following fluid and reservoir

characteristics:

Oil density = 49 lb/ft

2

Gas density = 8 lb/ft

2

Oil viscosity = 2.3 cp

Cross sectional area = 24,000 ft

2

K= 120 md

K

ro

= 0.85

Dip angle = 60 degree

Calculate the maximum oil rate that should not be

exceeded for counter flow

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

30

Reservoir Pressure and GOR Trends

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Understanding your Reservoir Driving

Mechanisms

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

12/1/2011

31

( )

( )

( ) ( )

1

1

1

/

= + +

+

+

+

A

B G

A

B W

A

p p

S

c S c

m B N

A

B W W

A

B B B B Nm

A

B B N

ginj inj w inj

i

wi

f wi w

oi

w p e gi gi g ti

ti t

with:

A = N

p

[B

t

+ (R

p

R

si

) B

g

]

DDI + SDI + WDI + EDI + WII+ GII = 1.0

Most efficient

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

MBE is an Essential Tool; dont forget to use

( )

( )

1

/

=

A

B W W

A

B B B B Nm

A

B B N

w p e gi gi g ti

ti t

A = N

p

[B

t

+ (R

p

R

si

) B

g

]

A

B W W

w p e

A

B W W

w p e

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

32

Parameters to Consider When Selecting

Optimum Time to Start an IOR Project

1. Reservoir oil viscosity

2. Cost of injection equipment.

3. Productivity of producing wells.

4. Effect of delaying investment

5. Oil saturation

6. Free gas

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

1- Reservoir oil viscosity.

Fluid injection should be initiated when the reservoir pressure reaches its

bubble-point pressure since the oil viscosity reaches its minimum value at this

pressure. The mobility of the oil will increase with decreasing oil viscosity,

which in turns improves the sweeping efficiency.

p

b

0

R

s

B

o

o

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

33

ob

o

p

b

oil

Effect of oil viscosity on mobility ratio

o s

s

rs

w

o

ro

o

k k

s

= =

: Best

&

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

2- Cost of injection equipment.

at higher pressures, the cost of injection equipment increases. Therefore,

a low reservoir pressure at initiation of injection is desirable.

3- Productivity of producing wells.

A high reservoir pressure is desirable to increase the productivity of producing wells,

which prolongs the flowing period of the wells, decreases lifting costs, and may

shorten the overall life of the project.

4. Effect of delaying investment on the time value

of $$.

A delayed investment in injection facilities is desirable from this standpoint.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

34

11/21/2011

5- Oil Saturation

The principal requirement for a successful fluid injection

project is that sufficient oil must remain in the reservoir

after primary operations ; e.g. starting waterflood at a

higher pressure.

High residual oil saturation after primary recovery is essential not only

because there must be a sufficient volume of oil left in the reservoir, but also

because of relative permeability considerations. A high oil relative

permeability, i.e., high oil saturation, means more oil recovery with less

production of the displacing fluid.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

I. High S

o

improved mobility; i.e. higher k

ro

II. High S

o

required to develop an oil bank

III. High S

o

required to improve sweep efficiencies

Questions:

A. Average Remaining Oil Saturation; What does it mean?

B. How you identify areas with high S

o

?

C. How you select areas for infill drilling?

Distribution of the remaining S

o

is a

MAJOR Problem

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

35

volume pore

volume oil remaining

=

o

S

( )

oi

o

p

wi o

B

B

N

N

S S

|

|

.

|

\

|

= 1 1

Pore Volume P.V = 7758 A h

N B

oi

= (P.V) (1 S

wi

)

|

|

.

|

\

|

=

wi

oi

S

B N

V P

1

) . (

( )

|

|

.

|

\

|

=

wi

oi

o p

o

S

B N

B N N

S

1

How this oil saturation is distributed in the reservoir;

where is the Movable Oil?

MBE on a well-by-well basis !

However; Simulation is a key answer

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

6- Effect of Free gas saturation.

A. In water injection projects. It is desirable to have initial

gas saturation, possibly as much as 10%. This will

occur at a pressure that is below the bubble point

pressure (probably unrealistic)

B. In Miscible or Immiscible gas injection projects; zero

gas saturation in the oil zone is desired. This occurs

while reservoir pressure is at or above bubble-point

pressure.

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

36

Effect of trapped gas on waterflood recovery

Initial Oil S

oi

Free Gas S

gi

Initial Water Saturation S

wi

Free Gas S

gi

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

No trapped gas

Initial Water Saturation S

wi

Free Gas S

gi

Oil Bank

Initial Oil S

oi

S

orw

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

37

With Trapped Gas

Initial Water Saturation S

wi

Free Gas S

gi

Oil Bank

Initial Oil S

oi

Trapped Gas S

gt

S

hrw

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

S

hrw

S

orw

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

38

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

39

Coefficients Equation (14-1) Equation (14-2)

a

1

0.030517211 0.026936065

a

2

0.4764700 0.41062853

a

3

0.69469046 0.29560322

a

4

-1.8994762 -1.4478797

a

5

-4.1603083 x 10

-4

-3.0564771 x 10

-4

gi

gi gi gi gt

S

a

S a S a S a a S

5 3

4

2

3 2 1

+ + + + =

gt

gt gt gt or

S

a

S a S a S a a S

5 3

5

2

3 2 1

+ + + + = A

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Class problem

An oil reservoir is being considered for further

development by initiating a waterflooding project.

The oilwater relative permeability data indicate

that the residual oil saturation is 35%. It is

projected that the initial gas saturation at the start

of the flood is approximately 10%. Calculate the

anticipated reduction in residual oil, S

or

, due to

the presence of the initial gas at the start of the

flood.

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

40

The waterflood recovery can possibly be improved if a so-called

optimum gas saturation is present at the start of the flood.

This optimum gas saturation is given by:

( )

152 . 1

166 . 0 352 . 0

902 . 0 634 . 0

001867 . 0

|

|

|

.

|

\

|

|

|

.

|

\

|

=

w

wi

o

o

o

opt

g

S S

B k

S

(S

g

)

opt

= Optimum gas saturation, fraction

S

o

,

S

wi

= oil and initial water saturations, fraction

o

,

w

= oil and water viscosities, cp

k = Absolute permeability, md

B

o

= Oil formation volume factor, bbl/STB

| = Porosity, fraction

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

The above correlation is not explicit and must be used in conjunction

with the material balance equation (MBE). The proposed methodology of

determining (S

g

)

opt

is based on calculating the gas saturation as a

function of reservoir pressure (or time) by using both the MBE and the

proposed expressions. When the gas saturation as calculated by the two

equations is identical, this gas saturation is identified as (S

g

)

opt

.

Pressure

Psi

B

o

BBL/STB

o

cp

MBE

S

o

S

g

= 1- S

o

- S

wi

(S

g

)

opt

1925 1.333 0.600 0.700 0.000 --

1760 1.287 0.625 0.628 0.072 0.119

1540 1.250 0.650 0.568 0.132 0.122

1342 1.221 0.700 0.527 0.173

( )

152 . 1

166 . 0 352 . 0

902 . 0 634 . 0

001867 . 0

|

|

|

.

|

\

|

|

|

.

|

\

|

=

w

wi

o

o

o

opt

g

S S

B k

S

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

41

But; there is a problem

Variable Bubblepoint Pressures !!!

11/21/2011

Oil

Gas

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

( ) ( )

( ) ( )

( ) ( )

o

o

g

gt

S

o

o

new

s

B

Volume Pore S

B

Volume Pore S

R

B

Volume Pore S

R

(

(

+

(

=

|

|

.

|

\

|

|

|

.

|

\

|

+ =

g

o

o

g

S

new

S

B

B

S

S

R R

( )

oi

o

p

wi o

B

B

N

N

S S

|

|

.

|

\

|

= 1 1

S

g

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

42

Again; Important Equations

11/21/2011

S

g

= 1 S

o

- S

wi

( )

oi

o P

wi o

wi

oi

o p

o

wi

oi

oi

wi

B

B

N

N

S S

S

B N

B N N

S

S

B N

B

S

N

|

.

|

\

|

=

|

|

.

|

\

|

=

1 ) 1 (

1

1

Volume Pore

) 1 ( volume) (pore

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Class Problem:

The Big Butte Field is a solution gas-drive reservoir that is under consideration

for a waterflood project. The volumetric calculations of the field indicate that the

areal extent of the field is 1612.6 acres. The field is characterized by the

following properties:

oThickness h = 25 ft

oPorosity = 15%

oInitial water saturation S

wi

= 20%

oInitial pressure pi = 2377 psi

Results from the MBE in terms of cumulative oil production N

p

as a function of

reservoir pressure are given below:

Pressure

Psi

N

p

MMSTB

2377 0

2250 1.10

1950 1.76

1650 2.64

1350 3.3

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

43

Pressure

psi

B

o

Bbl/STB

R

s

scf/STB

B

g

bbl/scf

2377 1.706 921 --

2250 1.678 872 0.00139

1950 1.555 761 0.00162

1650 1.501 657 0.00194

1350 1.448 561 0.00240

1050 1.395 467 0.00314

750 1.336 375 0.00448

450 1.279 274 0.00754

The PVT properties of the crude oil system are tabulated below:

Assume that the waterflood will commence when the reservoir

pressure declines to 1650 psi; find:

1- the pressure that is required to dissolve the evolved gas.

2- the pressure that is required to dissolve the trapped gas.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Simulation is the key

I. Calculations should be performed for

several assumed times and the net

income for each case determined.

II. The scenario that maximizes the profit and

perhaps meets the operators desirable goal

is selected.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

44

Fundamentals of

Waterflooding

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

11/21/2011

Considerations & Requirements

When

Planning Onshore or Offshore IOR Project

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

12/1/2011

45

Considerations When Planning an

IOR Flood

1. Purpose of the flood

2. Onshore or Offshore

3. Defining the Aquifer

4. Permeability Consideration, k

x

,k

y

, and k

z

5. Optimum Time to Start the Flood

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

Consideration #1: Purpose for Onshore or Offshore; same:

A. Maintaining the reservoir pressure

B. supplementing partial/strong natural water drive !!!

C. Displacing oil

Aquifer

Aquifer

Oil Oil

Offshore; What do you know about the reservoir?

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

46

Consideration #2: Offshore vs. Onshore Field Development

Time

Oil Rate

Offshore:

Discovery well can

not produced at

continuous basis

since the offshore

production facilities

are not in existence

Onshore:

Discovery well is

tied back to the

nearest production

facilities and

produced at high

rate at continuous

basis

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Aquifer

Aquifer

Oil Oil

Offshore Appraisal Stage

No Continuous Flow

Minimum information?

Major question deals with the aquifer

(strength, communication, etc)

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

47

Onshore:

Discovery well is tied back to the nearest production facilities and

produced at high rate at continuous basis to provide a positive cash flow

from day one. The most important advantage; however, it permits to

observe and evaluate the reservoir under dynamic conditions.

Continuous production creates a pressure sink at the discovery well which

propagates radically and vertically throughout the formation. With

subsequent appraisal/development well is drilled, the conducting of DST

and RFT will provide with the degree of areal and vertical communications

that are ESSENTIAL in:

A. Planning a secondary recovery and scale of the process

B. Estimation of the strength of the natural driving

mechanism

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Offshore:

Appraisal wells can not produced at continuous basis since the

offshore production facilities are not in existence. Perhaps

adequate data may be collected with each appraisal well;

however, it might be the lowest quality because they are

collected under purely STATIC conditions. No adequate data

are collected under DYNAMIC CONDITIONS (few thousands

bbl during DST) to allow:

A. Degree of the areal and vertical communications within

the formation

B. Strength and type of the natural driving mechanism

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

48

Consideration #3: The Aquifer Problem (Basel or Edge):

A. Degree of communication; radial and vertical

B. Degree of communication with Aquifer!!!

C. Strength of the Aquifer

Aquifer Aquifer

Basel Waterflood

Aquifer

Oil

Edge Waterflood

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Consideration #4: Permeability:

1. With high K, large oil accumulations can be developed with relatively

few wells; with more importantly fewer production platforms in offshore

reservoirs

2. Offshore Platforms usually have finite lifetime which leads to the fact that

maximizing oil recovery (function of k, tight or permeable) is required

before any significant mechanical deterioration occurs. Decision is

based on:

3. Value of remaining recoverable oil vs. cost of platform refurbishing

Selection of flood pattern and infill drilling locations are very strong

function of permeability distribution

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

49

11/21/2011

Consideration #5: Time to Initiate the Flood

A. Start the flood above P

b

; at P

b

or below P

b

?

B. Effect of oil viscosity on mobility ratio

C. Effect of trapped gas on waterflood recovery

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Mobility Ratio M:

11/21/2011

( )

( )

w

o

S

ro

S

rw

o

w

wi

wBT

k

k

M

M

=

= =

Fluid displaced

Fluid displacing

ob

o

p

b

oil

Effect of oil viscosity on mobility ratio

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

50

The magnitude of the reduction and mobilization of residual oil saturation and

improving the sweep efficiency by any IOR process is controlled by the

following two major factors:

1) Capillary Number N

C

; Question is: how to increase?

2) Mobility Ratio M, Question is: how to reduce it?

Controlling Parameters for a

Successful IOR Process

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

|

.

|

\

| A

|

|

.

|

\

|

=

L

p

o

k

c

N

o |

(

|

|

.

|

\

|

= = =

w

o

ro

rw

o ro

w rw

displaced

displacing

k

k

k

k

M

) / (

) / (

Critical N

c

before or

after or

S

S

) (

) (

1.0

0

1) Effect of N

C

on residual oil saturation

|

.

|

\

| A

|

|

.

|

\

|

=

L

p

o

k

c

N

o |

Increase p/L

is the only practical way of increasing N

C

Range of

Waterflood

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

51

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

2) Effect of Mobility Ratio on Sweep Efficiency

(

|

|

.

|

\

|

= = =

w

o

ro

rw

o ro

w rw

displaced

displacing

k

k

k

k

M

) / (

) / (

12/1/2011

52

I. Objective: provide the injection fluid with the

maximum possible contact with the crude oil system

II. Strategies: convert existing production wells to

injection wells, or drill infill injection wells

III. Factors that need to be considered:

Reservoir heterogeneity and directional permeability

Direction of formation fractures

Availability of the injection fluid (gas or water)

Desired and anticipated flood life

Maximum oil recovery

Well spacing, productivity, and injectivity

Flooding Patterns

11/21/2011 2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Injection Wells Placement Requirements:

1. Take advantage of directional permeability,

fractures, dip,etc

2. Provide sufficient fluid injection rate to yield the

desired production rate

3. Maximize recovery with minimum production of

the injected fluid

4. In most cases, require a minimum of new wells

(usually; the target field has been developed)

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

53

16 wells per section (1 sq-mile)

5280 ft

Well Spacing

40-acre for oil wells

160-320 ac for gas wells

Leases are divided into square miles and quarter square miles

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Essentially four types of well arrangements are used in fluid

injection projects:

Irregular injection patterns

Peripheral injection patterns

Regular injection patterns

Crestal and basal injection patterns

106

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

54

Could be caused by:

a) a planned, irregular pattern of vertical wells

b) irregular surface or subsurface topology

c) inclined wells

d) faulting

e) localized variations in porosity or

permeability

1- Irregular Injection Patterns

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

2- Peripheral Injection Patterns

In peripheral flooding, the injection wells are located at the

external boundary of the reservoir and the oil is displaced

toward the interior of the reservoir, as shown below

108

injector

Producer

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

55

Forms of Peripheral and Central Flooding Patterns

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

1. Relatively small number of injectors compared with producers.

Generally yield maximum oil recovery with minimum produced

water.

2. Significant water Production can be delayed until only the last row

of producers remains.

3. Results from peripheral flooding are more difficult to predict than

other patterns.

4. For a successful peripheral flood, k must be large enough to

permit the movement of the injected water at the desired rate

over the distance of several well spacing from injection wells to

the last line of producers.

5. Because of the unusually small number of injectors compared with

the number of producers, it takes a long time for the injected

water to fill up the reservoir gas space. The result is a delay in the

field response to the flood

6. Injection rates are generally a problem because the injection

wells continue to push the water greater distances.

Characteristics of the Peripheral Flood:

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

56

3- Regular Injection Patterns

Due to the fact that oil leases are divided into square miles and quarter

square miles, fields are developed in a very regular pattern. A wide variety of

injection-production well arrangements have been used in injection projects.

The most common patterns are:

a) Direct line drive.

b) Staggered line drive.

c) Five spot.

d) Seven spot.

e) Nine spot.

111

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

3- Regular Injection Patterns

Seven-Spot

Direct Line

Drive

Staggered Line Drive

The patterns termed inverted have only one injection well per

pattern. This is the difference between normal and inverted well

arrangements.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

57

113

A. Direct line drive.

The lines of injection and production are directly opposed to each other.

The pattern is characterized by two parameters:

a = distance between wells of the same type

d = distance between lines of injectors and producers.

B. Staggered line drive.

The wells are in lines as in the direct line, but the injectors and producers

are no longer directly opposed but laterally displaced by a distance of a/2.

C. Five spot.

This is a special case of the staggered line drive in which the distance

between all like wells is constant, i.e., a = 2d. Any four injection wells thus

form a square with a production well at the center.

D. Seven spot.

The injection wells are located at the corner of a hexagon with a production

well at its center.

E. Nine spot.

This pattern is similar to that of the five spot but with an extra injection well

drilled at the middle of each side of the square. The pattern essentially

contains eight injectors surrounding one producer.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

4- Crestal and Basal Injection Patterns

In Crestal Injection, as the name implies, the injection is through wells

located at the top of the structure. Gas injection projects typically use

a crestal injection pattern. Traditionally; a combination of Crestal and

Basal Injection (injection at the bottom of the structure) are used to

improve sweep efficiency. Many water-injection projects use basal

injection patterns with additional benefits being gained from gravity

segregation.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

58

SWEEP EFFICIENCIES

Areal Sweep Efficiency E

A

Vertical Sweep Efficiency E

V

Displacement Sweep Efficiency E

D

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

Recovery Performance

Recovery Performance of an IOR Flood is based

On:

1. Displacement Efficiency E

D

2. Areal Sweep Efficiency E

A

3. Vertical Sweep Efficiency E

V

Implicitly input to simulation models

in a form of a number of

Zonation or layering system

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

59

Cumulative Oil Production:

N

P

= N

s

E

A

E

V

E

D

Recovery Factor:

RF=(N

P

/N

s

) = E

A

E

V

E

D

Volumetric Sweep Efficiency:

E

vol

= E

A

E

V

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Oil Recovery Equations for Any

IOR Process

The displacement efficiency E

D

is the fraction of movable oil that has been

displaced from the swept zone at any given time or

pore volume injected. Because an immiscible gas

injection or waterflood will always leave behind

some residual oil, E

D

will always be less than 1.0.

oi

o oi

D

S

S S

E

=

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

60

Areal Sweep Efficiency:

The areal sweep efficiency E

A

is the fractional area of the pattern that is swept by the

displacing fluid. The major factors determining areal sweep are:

a) Fluid mobilities

b) Pattern type

c) Areal heterogeneity

d) Total volume of fluid injected

Area Total

A

E

A

=

A

Swept Area

A

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Line Drive

K

x

K

y

5-Spot

K

x

K

y

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

61

The vertical sweep efficiency E

V

is the fraction of the vertical section of the pay zone that is contacted by

injected fluids. The vertical sweep efficiency is primarily a function of:

a) Vertical heterogeneity

b) Degree of gravity segregation

c) Fluid mobilities

d) Total volume injection

Vertical Sweep Efficiency

Area Section Cross

A

E

V

=

The problem is

its defined by the USER;

5,10,,25-layer system !!!!

A

k

1

k

2

k

3

k

4

A

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Volumetric Sweep Efficiency = E

A

E

V

Volumetric Sweep Efficiency

E

V

E

A

S

w

e

p

t

a

r

e

a

Swept area

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

62

Displacement Sweep Efficiency

Areal Sweep Efficiency

Vertical Sweep Efficiency

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

In general, reservoir heterogeneity has more

influence than any other factor on the

performance of a secondary or tertiary injection

project. The most important two types of

heterogeneity affecting sweep efficiencies (E

V

and E

A

) are:

The Reservoir Vertical Heterogeneity; and

The Reservoir Areal Heterogeneity.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

63

Vertical Heterogeneity

Stratification is by far the most significant parameter influencing

the vertical sweep and in particular its degree of variation in the

vertical direction; i.e. permeability variation V

Water injected into a stratified system will preferentially enter the

layers of highest permeability (thief zone s are major problems)

and consequently, a significant fraction of the less-permeable zones

will remain unflooded.

Operators spend millions of dollars coring, logging, and drilling

appraisal wells, all of which permits direct observation of vertical

heterogeneity. Therefore, if the data are interpreted correctly, it

should be possible to quantify the vertical sweep E

V

quite

accurately; however; determining optimum number of layers for

simulation could be a problem (fine to coarse)

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Areal Heterogeneity

Areal heterogeneity includes areal variation in formation

properties and geometrical factors; such as:

1. position and nature of sealing faults

2. boundary conditions due to the presence of an aquifer

or gas cap.

3. direction of fractures

4. Principle axis of permeability k

x

& k

y

5. Porosity, permeability, and net thickness variations

Areally, matters are much more uncertain since methods of

defining heterogeneity are indirect

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

64

11/21/2011

All three efficiency factors (i.e., E

D

, E

A

,

and E

V

) are variables that increase during

the flood and reach maximum values at

the economic limit of the injection project.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Simple Equation: N

P

= N

s

E

A

E

V

E

D

; What is the problem

then?

Understanding Sweep Efficiencies

And Oil Recovery

E

V

E

A

S

w

e

p

t

a

r

e

a

Swept area

! ! ! of functions are , ,

s

V A D

S E E E

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

65

I. DISPLACEMENT EFFICIENCY

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

I. DISPLACEMENT EFFICIENCY

Displacement efficiency is the fraction of movable oil that has been recovered from

the swept zone at any given time. Mathematically, the displacement efficiency is

expressed as:

flood of start at oil of volume

volume oil remaining flood of start at oil of volume

=

D

E

( ) ( )

( )

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

=

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

=

oi

oi

o

o

oi

oi

oi

oi

o

o

oi

oi

D

B

S

B

S

B

S

B

S

Volume Pore

B

S

Volume Pore

B

S

Volume Pore

E

wi

w wi

oi

o oi

D

S

S S

S

S S

E

=

1

) 1 ( ) 1 (

Assuming constant B

o

wi

wi w

D

S

S S

E

=

1

average remaining oil &water saturation in the swept area

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

66

11/21/2011

Class Problem

A saturated oil reservoir is under consideration to be waterflooded

immediately after drilling and completion. Core analysis tests indicate

that the initial and residual oil saturations are 70 and 35%, respectively.

Assuming that B

o

will remain constant throughout, calculate:

1- The displacement efficiency when the oil saturation is reduced

to 65, 60, 55, 50, and 40%

2- Maximum displacement efficiency that can be achieved during the

project life

3- The displacement efficiency under miscible displacement with an

estimated S

orm

of 10%;

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Last example shows that E

D

will continually increase with

increasing water saturation in the reservoir. The problem, of

course, lies with developing an approach for determining

the increase in the average water saturation in the swept

area as a function of cumulative water injected (or injection

time), i.e:

Buckley and Leverett (1942) developed a well established

theory, called the frontal displacement theory, which provides

the basis for establishing such a relationship. This classic

theory consists of two equations:

1. Fractional flow equation

2. Frontal advance equation

wi

wi w

D

S

S S

E

=

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

67

Fractional flow equation

Based on:

1) Water Cut f

w

2) Darcys Equation

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

11/21/2011

w o

t

w

o w

w

w

f f

q

q

q q

q

f

=

=

+

=

1

Water and Oil Cut

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

68

11/21/2011

L

p p k A

q

p p

k A

L q

p

k A

x q

p

k A

x q

x

p k A

q

P

p

L

) (

) (

2 1

1 2

0

2

1

=

c

= c

c

= c

(

c

c

=

} }

Darcys Equation

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

L

p

1

p

2

11/21/2011

( )

(

c

c

= o

sin g

x

p k A

q

Darcys Equation & Water Cut

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

( ) o

sin : Flow Oil

o

o

o

o o

g

x

p

k A

q

c

c

=

( ) o

sin : Flow Water

w

w

w

w w

g

x

p

k A

q

c

c

=

12/1/2011

69

11/21/2011

( ) ( ) o

sin

o w

w o

o

ow o

w

w w

g

x

p

x

p

k A

q

k A

q

|

.

|

\

|

c

c

c

c

=

w o c

p p p = : Pressure Capillary

x

p

x

p

x

p

w o c

c

c

c

c

=

c

c

( )

t w o t w w

q f q and q f q = = 1

( )

o

w

w

o

c

t o

o

w

k

k

g

x

p

q

A k

f

+

(

A

c

c

|

|

.

|

\

|

+

=

1

sin 1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Developing the Fractional Flow Equation:

Step 1:

Step 2:

Step 3:

11/21/2011

( )

o

w

w

o

c

t o

o

w

k

k

x

p

q

A k

f

+

(

A

c

c

|

|

.

|

\

|

+

=

1

sin 433 . 0

001127 . 0

1

( )

( )

o

w

rw

ro

c

w o

ro

w

k

k

x

p

i

A k k

f

+

(

A

c

c

|

|

.

|

\

|

+

=

1

sin 433 . 0

001127 . 0

1

Noting that the relative permeability ratios k

ro

/k

rw

=k

o

/k

w

and the total

flow rate q

t

is essentially equal to the water injection rate, i.e. i

w

= q

t

,

the density difference = (

w

o

) in g/cm

3

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

70

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

( )

o

w

w

o

c

t o

o

w

k

k

g

x

p

q

A k

f

+

(

A

c

c

|

|

.

|

\

|

+

=

1

sin 1

FOCUS FOCUS FOCUS

f

o

= 1 - f

w

That is at ANY POSITION IN THE RESERVOIR,

i.e. ANY DISTANCE FROM THE INJECTION WELL

11/21/2011

( )

( )

o

s

rs

ro

c

s o

ro

s

k

k

x

p

i

A k k

f

+

(

A

c

c

|

|

.

|

\

|

+

=

1

sin 433 . 0

001127 . 0

1

the density difference = (

s

o

) in g/cm

3

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Water, Gas, or Solvent Injection:

12/1/2011

71

11/21/2011

The effect capillary pressure is usually neglected

because the capillary pressure gradient is generally

small and thus,

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

( )

( ) ( ) | |

o

D

rD

ro

o D

D o

ro

D

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

Similarly for ANY Type of Displacing Fluid:

the density difference (

w

o

) in g/cm

3

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

The shape of the water cut versus water saturation curve is

characteristically S-shaped, as shown below

Gas-Oil

Oil-Water

12/1/2011

72

f

o

= 1 f

w

The above expression indicates that during the displacement of oil by

waterflood, an increase in f

w

at any point in the reservoir will cause a

proportional decrease in f

o

and oil mobility. Therefore, the objective is to

select the proper injection scheme that could possibly reduce the water

fractional flow. This can be achieved by investigating the effect of:

1. the injected water viscosity

2. formation dip angle, and

3. water-injection rate on the water cut.

( )

( ) ( ) | |

o

w

rw

ro

o

w

rw

ro

o w

w o

ro

w

k

k

G

k

k

i

A k k

f

+

=

+

|

|

.

|

\

|

=

1

1

1

sin 433 . 0

001127 . 0

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

In general; any influences that cause the fractional flow curve to shift

upward (i.e., increase in f

w

or f

g

) will result in a less efficient displacement

process. It is essential, therefore, to determine the effect of various component

parts of the fractional flow equation on the displacement efficiency:

S

w

f

w

r

e

a

s

o

n

i.e:

1. Water & Oil viscosities

2. Wettability

3. Injection rate i

w

4. Updip or downdip injection

( )

( ) ( ) | |

o

w

rw

ro

o

w

rw

ro

o w

w o

ro

w

k

k

G

k

k

i

A k k

f

+

=

+

|

|

.

|

\

|

=

1

1

1

sin 433 . 0

001127 . 0

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

We need to increase G!

12/1/2011

73

S

w

f

w

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

We want to reduce f

w

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

1- Effect of Water Viscosity

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

w

= 0.5 cp

w

= 10 cp

w

= 5 cp

w

= 2 cp

w

= 1 cp

Objective is to reduce f

w

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

74

2- Effect of Oil Viscosity of f

w

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

Objective is to reduce f

w

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

3- Effect of Wettability

11/21/2011

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Objective is to reduce f

w

12/1/2011

75

4- Combined Effect of Wettability and Oil Viscosity

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

5- Effect of Dip Angle & Injection Rate

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

( )

Y

i

X

f

w

w

+

(

=

1

sin

1

o

a) Injection Well is Located Downdip:

sin() is positive when injecting downdip indicating a more efficient performance

is obtained. This improvement is due to the fact that the term [X sin()/i

w

] will

always remain positive, which leads to a decrease (downward shift) in the f

w

curve.

Injection Rate:

The fractional flow equation also reveals that a lower water-injection rate i

w

is

desirable since the nominator {1 [X sin()/i

w

]} will decrease with a lower

injection rate i

w

, resulting in an overall downward shift in the f

w

curve.

Sin() > 0

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

76

b) Injection Well is Located Updip:

sin() is negative. When the oil is displaced downdip (i.e., injection well is located

updip), the term [X sin()/i

w

] will always remain negative and, therefore, the

numerator of fractional flow equation will be 1+[X sin()/i

w

], i.e.:

( )

Y

i

X

f

w

w

+

(

+

=

1

sin

1

o

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

Injection Rate:

which causes an increase (upward shift) in the f

w

curve. It is beneficial, therefore,

when injection wells are located at the top of the structure to inject the water at a

higher injection rate to improve the displacement efficiency.

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Sin() < 0

( )

Y

i

X

f

w

w

+

(

=

1

sin

1

o

Sin() > 0

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

77

Water Cut f

w

>1 !!!!! How and Why?

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

Water Cut f

w

>1 !!!!!!!! How?

Counter Flow IN THE RESERVOIR

11/21/2011

Y

i

C

f

w

w

+

|

|

.

|

\

|

+

=

1

1

( )

Y

i

X

f

w

w

+

(

+

=

1

sin

1

o

Sin() < 0

( )

( ) ( ) | |

o

w

rw

ro

o w

w o

ro

w

k

k

i

A k k

f

|

|

.

|

\

|

=

1

sin 433 . 0

001127 . 0

1

Sin() < 0

2006Tarek Ahmed & Associates, Ltd. All

Rights Reserved

i

w

is low

if

(C/i

w

) > Y

f

w

> 1

12/1/2011

78

11/21/2011

Class Problem

Use the relative permeability as shown in the next slide to plot the

fractional flow curve for a linear reservoir system with the following

properties:

Dip angle = 0

Absolute permeability = 50 md

Bo = 1.20 bbl/STB, B

w

= 1.05 bbl/STB

o

= 45 lb/ft3;

w

= 64.0 lb/ft3

Cross-sectional area A = 25,000 ft

2

Perform the calculations for the following values of oil and water

viscosities:

w

= 0.5, 1.0, 5, and 10 cp with a constant

o

= 5 cp

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

S

w

K

r

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

79

11/21/2011

Class Problem:

The linear system in last example is under consideration

for a waterflooding project with a water injection rate of

1000 bbl/day.; which has the following characterization:

Absolute permeability = 50 md

B

o

= 1.20 bbl/STB, B

w

= 1.05 bbl/STB

o

= 45 lb/ft3;

w

= 64.0 lb/ft3

Cross-sectional area A = 25,000 ft

2

The oil viscosity is considered constant at 1.0 cp.

Calculate and PLOT the fractional flow curve for the

reservoir dip angles of: 10, 20, and 30, assuming:

updip displacement

downdip displacement

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

11/21/2011

Surface and Reservoir Water Cut

In waterflooding calculations, the reservoir water cut f

w

and the wateroil

ratio WOR are both traditionally expressed in two different units: bbl/bbl and

STB/STB. The interrelationships that exist between these two parameters

are conveniently presented below:

Q

o

= oil flow rate, STB/day q

o

= oil flow rate, bbl/day

Q

w

= water flow rate, STB/day q

w

= water flow rate, bbl/day

f

ws

= surface water cut, STB/STB f

w

= reservoir water cut, bbl/bbl

WOR

s

= surface wateroil ratio, STB/STB

WOR

r

= reservoir wateroil ratio, bbl/bbl

2006Tarek Ahmed & Associates, Ltd. All Rights Reserved

12/1/2011

80

11/21/2011

Surface and Reservoir Water Cut

In waterflooding calculations, the reservoir water cut f

w