Escolar Documentos

Profissional Documentos

Cultura Documentos

An Energy Harvesting Circuit For Self-Powered Sensors

Enviado por

João Cunha0 notas0% acharam este documento útil (0 voto)

12 visualizações5 páginasThis document presents a circuit designed to harvest energy from radio waves or magnetic coupling for powering self-powered sensors. The circuit uses a stack of full-wave rectifiers with MOS transistors operating in sub-threshold region. It can output up to 197mV from a 200mV peak-to-peak input signal and is able to power a ring oscillator load without an external power source. Simulation results show that the output voltage increases with higher input amplitude and reference voltage, but decreases with higher frequency due to bandwidth limitations. Transistor dimensions mainly impact rise time, not final output voltage. This proof-of-concept circuit demonstrates self-powered operation from low-voltage energy harvesting.

Descrição original:

inesc

Título original

B24

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document presents a circuit designed to harvest energy from radio waves or magnetic coupling for powering self-powered sensors. The circuit uses a stack of full-wave rectifiers with MOS transistors operating in sub-threshold region. It can output up to 197mV from a 200mV peak-to-peak input signal and is able to power a ring oscillator load without an external power source. Simulation results show that the output voltage increases with higher input amplitude and reference voltage, but decreases with higher frequency due to bandwidth limitations. Transistor dimensions mainly impact rise time, not final output voltage. This proof-of-concept circuit demonstrates self-powered operation from low-voltage energy harvesting.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

12 visualizações5 páginasAn Energy Harvesting Circuit For Self-Powered Sensors

Enviado por

João CunhaThis document presents a circuit designed to harvest energy from radio waves or magnetic coupling for powering self-powered sensors. The circuit uses a stack of full-wave rectifiers with MOS transistors operating in sub-threshold region. It can output up to 197mV from a 200mV peak-to-peak input signal and is able to power a ring oscillator load without an external power source. Simulation results show that the output voltage increases with higher input amplitude and reference voltage, but decreases with higher frequency due to bandwidth limitations. Transistor dimensions mainly impact rise time, not final output voltage. This proof-of-concept circuit demonstrates self-powered operation from low-voltage energy harvesting.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

An Energy Harvesting Circuit

for Self-Powered Sensors

Jorge R. Fernandes

1,2

, Miguel Martins

2

, Moiss Piedade

1,2

, Hugo Gonalves

2

1

Instituto Superior Tcnico/TU Lisbon

2

INESC-ID

Lisbon, Portugal

{jorge.fernandes, miguel.martins, moises.piedade}@inesc-id.pt

Abstract In this work we present a prototype circuit to harvest

energy from radio waves or through magnetic coupling based on

a stack of full-wave rectifiers with transistors working on sub-

threshold region. This circuit will use as an input a field-to-

voltage converter capable of outputting a 200mV waveform and

is able to self-start without any other energy sources. The circuit

presented here is a proof of concept energy-harvesting circuit

powering a low frequency ring oscillator which acts as the load.

The circuit is designed, simulated and tested in a standard

CMOS process, AMS CMOS 0.35 m.

I. INTRODUCTION

Recent trends and advances on circuits and systems

employing nano-devices, both CMOS and non-CMOS

devices, has increased the usage for silicon sensors. These are

expected to have a huge growth and to be used everywhere,

within electronic products, gadgets, and even medical and life

sciences [1].

To increase functionality new sensors include electronics

for processing and communications, and furthermore, wireless

sensors are looking for ways to be self- powered and extend

its autonomy and independence.

Batteries are the most used and led to this huge growth

market reality, however they are now limiting its continuing

growth since they can be expensive, bulky, they require

replacement and disposal, and in certain applications special

care has to be taken due to the chemicals inside. Ways to

recharge the batteries, or even better to replace them, using

energy harvesting techniques are being researched [2-3].

Most common energy harvesting techniques for low power

applications are to convert light, mechanical, or magnetic

energy into electric energy.

To convert light to electric energy it is necessary a

photovoltaic cell (commonly referred to as a solar cell if the

source is the sunlight) which are grouped into solar panels or

solar modules.

To convert mechanical energy into electrical energy

piezoelectric materials or micro electromechanical systems

(MEMS) are used to harvest energy from ambient vibrations

[4-5].

These two techniques have been useful for certain niche

applications with the drawback of combining different

technologies which limits cost reduction and integration.

Furthermore the light approach has the drawback of requiring

a larger area and to limit the use of the sensors in

environments with light, while in the MEMs approach it is

required that the sensor is not static.

An alternative is to harvest energy from radio waves [6],

which is the method used for powering RFID tags and has

become increasingly popular. In RFID applications it is used a

high energy source nearby, however the procedure can be

extended to harvest energy from radio waves emitted from TV

or radio transmitters, WiFi transmitters, cell-phone antennas,

or any other sources present in urban environments.

Many applications using sensors do not need a full time

working processing unit and a standard radio link to

communicate: they just require a very simple control and

processing unit with a low data-rate radio link, with low area

and low power where low-cost is the key feature, especially

for disposable units.

In this paper we present a prototype circuit to harvest

energy from radio waves or through magnetic coupling based

on a stack of full-wave rectifiers with transistors working on

sub-threshold region. Equivalent circuits exist for many years

(the authors traced it back to 1919, by Heinrich Greinacher) in

a context where high voltage values (kV) were used as input

and the circuits worked as ideal voltage doublers. More

recently several implementations of the full-wave rectifier has

been used (examples of it in [2-6]) as a way to rectify the

electric signal recovered by the input stage, either

piezoelectric or radio wave. Then, a larger voltage is generated

by the subsequent stages. The circuit presented here is a low

This work was supported by the Portuguese Foundation for Science and

Technology (FCT) through project ICONS (PTDC/EEA-ELC/68972/2006)

and the EU under project SE2A (ENIAC/12009/2009).

voltage energy-harvesting circuit, without further processing,

powering a low frequency ring oscillator which acts as the

load. The circuit is designed, simulated and tested in a

standard AMS 0.35 m CMOS process.

This paper is organized in six sections. In section II we

review the energy harvesting building blocks and present our

circuit main block. In section III we present a prototype circuit

with example simulations. In section IV and V we present the

test environment and the experimental results. Finally in

section VI we draw some conclusions.

II. ENERGY HARVESTING TECHNIQUES

Generally, energy harvesting circuits have to convert an

AC voltage into a DC voltage, store it and, in special cases,

multiply it. Well known techniques are to use a half- or full-

wave rectifier followed by a voltage regulator, which in its

simpler form can be just a capacitor. In case the DC voltage is

lower than the value needed, voltage doublers can be used to

obtain the necessary voltage. Most of these systems are used

with a battery that ensures that certain control mechanisms can

work on power-up, being the power harvesting circuit just a

way to recharge a battery and ensure it lasts longer.

Furthermore, they are usually considering the use of larger

voltage signals to accommodate diodes full conduction.

Here we try to use older techniques that do not require

switches and batteries. The system exploits a stack of full-

wave rectifiers with MOS transistors operating in sub-

threshold region that can be used to recover energy from radio

waves or through magnetic coupling. This circuit is intended

to be designed with a sensor that will act as a field-to-voltage

converter that is able to give a 200mV peak-to-peak amplitude

signal.

We are using MOS transistors from a 0.35m technology

with a threshold voltage on the order of 500mV well above the

available source voltage of 200mV. Therefore, we have the

transistors operating in the sub-threshold region where the

dependence between I

D

and V

GS

is exponential (weak

inversion) by [7],

exp 1 exp

.

GS M DS

D M

t t

V V V

I I

n

( | | | |

=

( | |

\ \

(1)

where I

M

is dependent on the technology and transistor

dimensions,

t

= kT/q is the thermal voltage, V

M

is a term

lower than the threshold voltage and n is a variable dependent

on technology and biasing that usually takes values from

1.2~1.8.

The main block used in our prototype is represented in

Fig. 1. It is important to notice that the input is going to be

obtained by a field-to-voltage converter which is not

grounded, therefore a reference voltage can be used (V

REF

)

which acts as a transformer secondary with middle point.

The circuit represented in Fig. 1 was simulated varying

several parameters to get a flavor of what are the absolute

values to be expected for such a circuit in these operating

conditions. The nominal values for the circuit are C=400fF,

M

1-4

have dimensions of 10(W/L)=10(25m/0.35m),

V

REF

=100mV, v

in+

-v

in-

= A sin (2 f t) being A=200mV,

f = 10kHz (note: the value of 10 kHz is used as a reference

value for transient simulation feasibility as the circuits are

simulated up to 40s to ensure final values). These values are

used to obtain the results described through tables 1 to 4

(highlight in grey background)) except for one which is

varied.

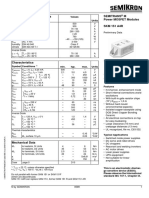

Figure 1. Full-wave rectifier with NMOS transistors.

TABLE I. VREF VARIATION

C=400fF, M1-4 =10(25m/0.35m), A=200mV f = 10kHz

VREF VOUT

0 V 100 mV

100 mV 197 mV

500 mV 574 mV

TABLE II. A VARIATION

C=400fF, M1-4 =10(25m/0.35m), VREF =100mV f = 10kHz

A VOUT

200 mV 197 mV

400 mV 343 mV

600 mV 491 mV

TABLE III. f VARIATION

C=400fF, M1-4=10(25m/0.35m), A=200mV, VREF=100mV

f VOUT

10 kHz 197 mV

100 kHz 196 mV

1 MHz 191 mV

10 MHz 166 mV

TABLE IV. W/L VARIATION

C=400fF, A=200mV, VREF=100mV, f = 10kHz

W/L VOUT

Rise time: 0 to 163 mV

10(1m/0.35m) 187mV

47.3 ms

10(5m/0.35m) 192 mV

21.5 ms

10(25m/0.35m) 197 mV

5.3 ms

10(125m/0.35m) 197 mV

1.6 ms

From Tables 1 and 2 we observe that the voltage drop on the

diode connected transistors reduce the maximum voltage

achievable on a full-wave rectifier and that its influence with

amplitude and reference voltage increases with these

parameters as expected from (1). Table 3 shows that as

frequency increases the voltage becomes smaller as expected

due to bandwidth limitations. Table 4 shows that transistor

dimensions influence more the time response of the circuit

than the final voltage to be obtained.

III. ENERGY HARVESTING PROTOTYPE

One common way to increase the DC voltage from a DC

source is to use a voltage doubler by stacking half- or full-

wave rectifiers. These techniques are very efficient to double

the voltage for each stage and are often called voltage

multipliers. This is not the case because the transistors used in

this work cannot be considered as ideal rectifiers as when used

with very high voltages. With the most simple models

commonly used for the MOS transistors (MOS models level

1~3) the transistors would be cutoff and the currents would be

considered zero. As we saw in section II the current below the

transistor threshold voltage has an exponential characteristic

with V

GS

, but having very low values. For the wanted

application we can consider having it harvesting the energy

for long time periods, store it, and then use for a short period

to send a small amount of data.

The prototype circuit is represented in Fig. 2 where each

full-wave rectifier output is connected to the above reference

input. We have targeted to have a circuit functioning at

400mV and to obtain such a voltage level with the present

technology we need 8 stages of full-rectifiers. We recall the

conclusions drawn in Section II from Table 1 and 2 to explain

why we need so many stages. These effects are shown in

Fig. 3 where it can be observed that as the V

REF

increase the

voltage difference between stages decrease, as expected.

The circuit in Fig. 2 has a 25pF internal capacitor and was

simulated with a 100pF external capacitor. Higher values are

obviously possible but they would increase the simulation

time accordingly. The ring oscillator is composed of three

gates, one NOR and two inverters, designed to have the

transfer characteristic center point adjusted to half the 400mV

wanted voltage. The NOR gate allows to turn on and off the

ring oscillator as wish for testing purposes. The circuit also

comprises an output stage for testing purposes, to drive larger

capacitances at higher frequencies.

In Fig. 4 we have the last stage voltage output, the oscillator

control voltage and the test ring oscillator which acts as a load.

The loading effect reduces with the capacitance increase but

so do the simulation time. Simulations that include Monte

Carlo analysis with process and mismatches variations showed

that the circuit behavior is maintained with variation on the

output voltage value. Further results are expected to be

obtained from the test chip.

The circuit was designed (shown in Fig. 5, with an area of

1890210 m

2

), extracted and simulated after extraction,

showing it is robust to parasitic capacitances which only add

to the existing ones improving the storage capability of the

circuit. The circuit does not require pads with protection

circuitry because the transistors are large; the pads are

connected to sources, and the voltage increase slowly to low

values. Extra observation points are left inside the circuit for

observation of the individual full-wave rectifiers output.

Being a prototype circuit, these test features allows the

circuit to be characterized beyond the scope of this

application, with larger values of capacitance or higher

frequencies. In these cases it is much simpler to characterize it

by testing than by simulation, where the combination of larger

values of frequency with larger values of capacitance make

transient simulations too long to be practical.

Figure 2. Prototype of an 8-stage power harvesting circuit with a test ring

oscillator in-chip.

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0

1

,

6

3

,

2

4

,

8

6

,

4 8

9

,

6

1

1

,

2

1

2

,

8

1

4

,

4

1

6

1

7

,

6

1

9

,

2

2

0

,

8

2

2

,

4

2

4

2

5

,

6

2

7

,

2

2

8

,

8

3

0

,

4

3

2

3

3

,

6

3

5

,

2

3

6

,

8

3

8

,

4

4

0

Figure 3. 8-stage power harvesting circuit outputs and the effect of loading

it with the test ring oscillator.

(a)

(b)

Figure 4. Power harvesting circuit and test ring oscillator outputs (a) during

2s (b) zoom of the oscillator output.

Figure 5. Prototype circuit (1890210 m

2

).

IV. TESTBENCH LAYOUT

As referred in Section II this circuit was developed to be

incorporated with a field-to-voltage converter which would

serve as the power source with an input voltage in the order

of 200 mV. For testing purposes in order to mimic this

system as well as isolate the circuit a transformer was

connected to each circuit input as shown in Fig. 6. This

circuit (Fig. 5) was tested with a function generator

(UNAOHM EM 193B) connected in parallel with the

transformers (Coilcraft PWB1010-1L) it was also included a

50 impedance matching circuit to adapt the transformers to

the function generator output impedance.

Figure 6. Testbench circuit

The output buffer is powered with an external DC source

(1.2 V) and the oscillator switch on (OSC

on

) is controlled by a

square wave generator. The primary winding of the 8-

Transformer Array is shorted to ground and the secondary

winding is connected to the circuit V

in-

and V

in+

. With this

setup we ensure circuit isolation and DC decoupling.

V. EXPERIMENTAL RESULTS

Figure 7 shows the rectifier output voltage when the circuit

is idle collecting energy from the energy source. The overall

results show that the circuit behaves better at 10 MHz where it

is closer to the simulated voltage values with 380 mV output

voltage with 350 mV input. These values are relatively lower

than expected, which is due to impedance mismatch between

the transformers and the function generator, and a higher

bonding inductance and encapsulating parasitics.

The preceding results show that: (1) the voltage stored by

each rectifying stage is below the input voltage because the

transistor operates at one third of the threshold voltage; (2)

operating in sub-threshold with higher v

t

technologies makes

imperative good isolation between rectifying stages for better

circuit performance; (3) the input stage of the circuit must

have a good impedance match to minimize losses; (4) the

cutoff voltage of this circuit is approximately 200 mV.

In Fig. 8 it is represented the oscillator circuit output (the

figure is obtained from a simulation of the full testbench in

Fig. 6, because it was not possible to take a snapshot of the

circuit working with the oscillator On). The ring oscillator

kicks-off when OSC

on

is low (zero Volts). The decrease in the

oscillating frequency in time is to be expected as the voltage

source of the ring oscillator decreases overtime with the

discharge of the external capacitor.

Figure 7. Output voltage at the 8

th

stage (experimental).

Figure 8. Oscillator Output with control signals (simulation).

The results show that the energy harvesting circuit, using a

standard CMOS process with v

t

as high as 600 mV and with

the transistor working in the sub-threshold region is able to

charge.an external capacitor, being then capable of powering a

small circuit (in this case a ring oscillator) for a short period of

time.

VI. CONCLUSIONS

We present a power harvesting circuit to be used in a low

cost self-powered sensor. The circuit uses a stack of full-wave

rectifiers as a common voltage multiplier and in this paper it is

evaluated its feasibility for low voltages below the transistors

threshold voltage. The circuit has no switches or any other

energy source as in more complex approaches and comprises a

ring oscillator to act as a load.

The full-wave rectifier is evaluated based on a sub-

threshold model and under parametric evaluation which leads

to the confirmation of the expected behavior and with the

absolute values obtainable giving the designer useful

guidelines.

Experimental results show that the circuit has an output

voltage of approximately 380 mV with 350 mV input and the

stored energy is enough to power a small circuit (ring

oscillator). The differences between the simulated and

experimental results are discussed.

REFERENCES

[1] Joseph Paradiso, Thad Starner, Energy Scavenging for Mobile

and Wireless Electronics, Pervasive Computing, pp. 18-27,

Jan. 2005

[2] Mingjie Guan and Wei-Hsin Liao, Comparative Analysis of

Piezoelectric Power Harvesting Circuits for Rechargeable

Batteries, IEEE International Conference on Information

Acquisition, pp. 243-246, June 2005.

[3] Dong Yuan,Wen Zhiyu, Liao Haiyang, Wen Zhongquan,

Power Self-Regulation Circuit of Piezoelectric Multi-Shaker

Micro-Generator, International Conference on Electronic

Measurement and Instruments, pp. 656-660, 2007.

[4] G. K. Ottman, H. F. Hofmann, and G. A. Lesieutre, Optimized

piezoelectric energy harvesting circuit using step-down

converter in discontinuous conduction mode, IEEE

Transactions on Power Electronics, vol. 18, no. 2, pp. 696-703,

2003.

[5] Yogesh K. Ramadass, Anantha P. Chandrakasan An Efficient

Piezoelectric Energy-Harvesting Interface Circuit Using a Bias-

Flip Rectifier and Shared Inductor, IEEE Int. Solid-State

Circuits Conference (ISSCC09), pp.296-298, May2009.

[6] Stephen ODriscoll, Ada S. Y. Poon, Teresa H. Meng A mm-

Sized Implantable Power Receiver with Adaptive Link

Compensation, IEEE Int. Solid-State Circuits Conference

(ISSCC09), pp.15-17, May2009

[7] Yannis Tsividis, Mixed Analog-Digital VLSI Devices and

Technology An introduction, McGraw-Hill 1995.

Você também pode gostar

- Trends of Power Electronics On Renewable Energy SystemDocumento8 páginasTrends of Power Electronics On Renewable Energy SystemsathishAinda não há avaliações

- Dubex Semina ProposalDocumento18 páginasDubex Semina Proposalannamichelle1001Ainda não há avaliações

- Progress in Electromagnetics Research, Vol. 132, 49-69, 2012Documento21 páginasProgress in Electromagnetics Research, Vol. 132, 49-69, 2012Sara TehraniAinda não há avaliações

- Minimization of Total Harmonic Distortion Using Pulse Width TechniqueDocumento12 páginasMinimization of Total Harmonic Distortion Using Pulse Width TechniqueIOSRjournalAinda não há avaliações

- Survey of CascadeDocumento10 páginasSurvey of Cascadesumiths32Ainda não há avaliações

- Wind ProjectDocumento11 páginasWind ProjectjyotiblossomsAinda não há avaliações

- Multistring Five-Level Inverter With Novel PWMDocumento13 páginasMultistring Five-Level Inverter With Novel PWMsandeepbabu28Ainda não há avaliações

- (ICCIP-2020) Available On: SSRN RF Energy Harvesting Using Efficient Power Management SystemDocumento8 páginas(ICCIP-2020) Available On: SSRN RF Energy Harvesting Using Efficient Power Management SystemAlice LiewAinda não há avaliações

- A 900Mhz RF Energy Harvesting Module: Taris Thierry, Vigneras Valérie Fadel LudivineDocumento4 páginasA 900Mhz RF Energy Harvesting Module: Taris Thierry, Vigneras Valérie Fadel Ludivinekavirasu1990Ainda não há avaliações

- Multilevel Converters For Single-Phase Grid Connected Photovoltaic Systems. An OverviewDocumento11 páginasMultilevel Converters For Single-Phase Grid Connected Photovoltaic Systems. An OverviewAnand RajkumarAinda não há avaliações

- 00707781Documento6 páginas00707781sandeepbabu28Ainda não há avaliações

- Power Harvester Design For Semi-Passive UHF RFID Tag Using A Tunable Impedance TransformationDocumento5 páginasPower Harvester Design For Semi-Passive UHF RFID Tag Using A Tunable Impedance TransformationM AAinda não há avaliações

- By Y.G.SAI RAGHU (124576) Under The Guidance of Dr. P. Sree Hari RaoDocumento26 páginasBy Y.G.SAI RAGHU (124576) Under The Guidance of Dr. P. Sree Hari RaosairaghubabuAinda não há avaliações

- GSM HarvesterDocumento17 páginasGSM HarvesterSarah HeadAinda não há avaliações

- Impact of Variable Switching Frequency Over Power Loss On Converter TopologiesDocumento6 páginasImpact of Variable Switching Frequency Over Power Loss On Converter TopologiesskrtamilAinda não há avaliações

- Final Project ReportDocumento43 páginasFinal Project Reportankit gangwarAinda não há avaliações

- 5716 4791 1 PB PDFDocumento8 páginas5716 4791 1 PB PDFJunika Purnama ZulkifliAinda não há avaliações

- Wireless Mobile ChargerDocumento87 páginasWireless Mobile ChargerADNAN NAJEEB PK100% (3)

- Electronics 08 01137 v2Documento14 páginasElectronics 08 01137 v2sigit kurniawanAinda não há avaliações

- Ambient RF Energy HarvestingDocumento5 páginasAmbient RF Energy HarvestingsuncollegeeceAinda não há avaliações

- Emi-Free DC-DC Buck Converter For AerospaceDocumento4 páginasEmi-Free DC-DC Buck Converter For AerospaceInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- PV Model 5Documento5 páginasPV Model 5ED-Daaif M'barkAinda não há avaliações

- Transformerless H6D2 InverterDocumento47 páginasTransformerless H6D2 InverterPinnam MallikarjunaAinda não há avaliações

- Design and Simulation of RF Energy Extracting Circuits and SystemDocumento28 páginasDesign and Simulation of RF Energy Extracting Circuits and SystemHaresh SinghAinda não há avaliações

- Design Optimization and Implementation For RF Energy Harvesting CircuitsDocumento10 páginasDesign Optimization and Implementation For RF Energy Harvesting CircuitsJoso LuchoAinda não há avaliações

- MSPWM Based Implementation of Novel 5-Level Inverter With Photovoltaic SystemDocumento9 páginasMSPWM Based Implementation of Novel 5-Level Inverter With Photovoltaic SystemIkram RidhoAinda não há avaliações

- Research Article: Investigation of RF Signal Energy HarvestingDocumento7 páginasResearch Article: Investigation of RF Signal Energy HarvestingrameshsophidarlaAinda não há avaliações

- 2006 Crte IV Curve Measurement PV SecDocumento5 páginas2006 Crte IV Curve Measurement PV Secmoussa1986Ainda não há avaliações

- 5.8Ghz Circularly Polarized Rectennas Using Schottky Diode and Ltc5535 Rectifier For RF Energy HarvestingDocumento4 páginas5.8Ghz Circularly Polarized Rectennas Using Schottky Diode and Ltc5535 Rectifier For RF Energy HarvestingNag ChallaAinda não há avaliações

- Reduction of Electromagnetic Interference in DC-DC Converter Using ChaosDocumento4 páginasReduction of Electromagnetic Interference in DC-DC Converter Using ChaosPrasenjit WakodeAinda não há avaliações

- A PV Module-Integrated Inverter Using A Ćuk Converter in DCM With Island Detection SchemeDocumento6 páginasA PV Module-Integrated Inverter Using A Ćuk Converter in DCM With Island Detection Schemegrasia77Ainda não há avaliações

- ArticleDocumento2 páginasArticleTaíla RodriguesAinda não há avaliações

- VIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFDocumento8 páginasVIZIMAX - CIGRE Toronto - Using A Controlled Switching Device For A Power Transformer PDFgeorge_cpp2Ainda não há avaliações

- Reconfigurable Antenna With Matching Network Final Project ReportDocumento44 páginasReconfigurable Antenna With Matching Network Final Project ReportDhruv ChaudharyAinda não há avaliações

- Multicarrier - Based PWM Control Strategies For Five - Level CMLIDocumento7 páginasMulticarrier - Based PWM Control Strategies For Five - Level CMLIDharani DeviAinda não há avaliações

- IEEE POWER ELECTRONICS 2015 Matlab Projectlist Mtech BeDocumento4 páginasIEEE POWER ELECTRONICS 2015 Matlab Projectlist Mtech BeKumar RajAinda não há avaliações

- A High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power TransmissionDocumento10 páginasA High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power Transmissionfelix_007_villedaAinda não há avaliações

- Rectenna Systems For RF Energy Harvesting and Wireless Power TransferDocumento24 páginasRectenna Systems For RF Energy Harvesting and Wireless Power TransferGeremu TilahunAinda não há avaliações

- 3-Phase PFC KolarDocumento7 páginas3-Phase PFC KolarJayant SalianAinda não há avaliações

- 130nm CMOS Technology Design of Passive UHF RFID Tag inDocumento4 páginas130nm CMOS Technology Design of Passive UHF RFID Tag inDuc DucAinda não há avaliações

- Signal Flow - Instrument Sensor Transducer PLC - jpg1653x483 56.9 KBDocumento7 páginasSignal Flow - Instrument Sensor Transducer PLC - jpg1653x483 56.9 KBsakthisriniAinda não há avaliações

- A 6.1-7.68 GHZ CMOS LC-Voltage Controlled Oscillators (VCO)Documento4 páginasA 6.1-7.68 GHZ CMOS LC-Voltage Controlled Oscillators (VCO)dhrubAinda não há avaliações

- ESPE03Documento9 páginasESPE03Karthi KeyanAinda não há avaliações

- Bannari Amman Institute of Technology: Prepared By: M.Selvaraj (3Documento11 páginasBannari Amman Institute of Technology: Prepared By: M.Selvaraj (3plcharumathiAinda não há avaliações

- Wireless Power Transmission For Charging MobilesDocumento6 páginasWireless Power Transmission For Charging Mobileszain abidiAinda não há avaliações

- Simple MOSFET-Based High-Voltage Nanosecond Pulse Circuit: Alton Chaney and Raji SundararajanDocumento6 páginasSimple MOSFET-Based High-Voltage Nanosecond Pulse Circuit: Alton Chaney and Raji SundararajanNikAinda não há avaliações

- Harvesting Wireless PowerDocumento13 páginasHarvesting Wireless PowerphithucAinda não há avaliações

- 1 5002033 PDFDocumento9 páginas1 5002033 PDFDmk ChaitanyaAinda não há avaliações

- Martina Calais Vassilios G. Agelidis: Pcalaism9Cc - Curtin.Edu - Au Vagelidis 9 Curtin. Edu. AuDocumento6 páginasMartina Calais Vassilios G. Agelidis: Pcalaism9Cc - Curtin.Edu - Au Vagelidis 9 Curtin. Edu. Auknighthood4allAinda não há avaliações

- Wireless Power Transfer Report: June 2015Documento12 páginasWireless Power Transfer Report: June 2015Ramesh Maurya MauryaAinda não há avaliações

- A Novel Topology and Control Strategy For Maximum Power Point Trackers and Multi-String Grid-Connected PV InvertersDocumento6 páginasA Novel Topology and Control Strategy For Maximum Power Point Trackers and Multi-String Grid-Connected PV Inverterswalidghoneim1970Ainda não há avaliações

- Universal Current SensorDocumento12 páginasUniversal Current SensorBhargav MushiniAinda não há avaliações

- 1982 National AN301 Conditioning ElectronicsDocumento13 páginas1982 National AN301 Conditioning ElectronicsTelemetroAinda não há avaliações

- Design and Simulation of an Inverter With High Frequency Sinusoidal PWM Switching Technique for Harmonic Reduction in a Standalone Utility Grid Harmonic Reduction in a Standalone Utility Grid Synchronized Photovoltaic SystemDocumento6 páginasDesign and Simulation of an Inverter With High Frequency Sinusoidal PWM Switching Technique for Harmonic Reduction in a Standalone Utility Grid Harmonic Reduction in a Standalone Utility Grid Synchronized Photovoltaic SystemS.m. FerdousAinda não há avaliações

- Dickson Voltage Multiplier With 1 To 6 Stages For Dual-Band Rectifiers (2.45/5.8 GHZ) With Low Input PowerDocumento8 páginasDickson Voltage Multiplier With 1 To 6 Stages For Dual-Band Rectifiers (2.45/5.8 GHZ) With Low Input PowerTELKOMNIKAAinda não há avaliações

- XMR AzDocumento9 páginasXMR AzbitconceptsAinda não há avaliações

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNota: 4.5 de 5 estrelas4.5/5 (2)

- Reconfigurable Microstrip Antennas: Chapter-2Documento51 páginasReconfigurable Microstrip Antennas: Chapter-2dhiwahar cvAinda não há avaliações

- A Tuned Rectifier For RF Energy Harvesting From Ambient RadiationsDocumento6 páginasA Tuned Rectifier For RF Energy Harvesting From Ambient RadiationsAppu ManiAinda não há avaliações

- 2010 Morley SpacePy A Python Based Lib of Tools For The Space SciencesDocumento7 páginas2010 Morley SpacePy A Python Based Lib of Tools For The Space SciencesJoão CunhaAinda não há avaliações

- Trainee's Project Report: DescriptionDocumento1 páginaTrainee's Project Report: DescriptionJoão CunhaAinda não há avaliações

- Media Anual KWH/M : Bilbao Santander León Gijón La Coruña Santiago de Compostela VigoDocumento1 páginaMedia Anual KWH/M : Bilbao Santander León Gijón La Coruña Santiago de Compostela VigoJoão CunhaAinda não há avaliações

- Pspice TutorialDocumento71 páginasPspice TutorialMarce CampanelliAinda não há avaliações

- Chapter 7 - Electricity (Teacher's Guide)Documento61 páginasChapter 7 - Electricity (Teacher's Guide)Liayana Che AliAinda não há avaliações

- The Importance of The Third Law ThermodynamicsDocumento8 páginasThe Importance of The Third Law ThermodynamicsTrisa Fadhillah0% (1)

- Electromagnetic Field Theory Solution BTETC501 - 1Documento19 páginasElectromagnetic Field Theory Solution BTETC501 - 1College use EducationAinda não há avaliações

- Chapter 2 Exercises Part2Documento2 páginasChapter 2 Exercises Part2Cedric MunlawinAinda não há avaliações

- Chapter 2 - Losses in Piping SystemsDocumento30 páginasChapter 2 - Losses in Piping SystemsNicholas EmildasAinda não há avaliações

- E&I QAP's - Submitted To Contractor HZADocumento33 páginasE&I QAP's - Submitted To Contractor HZASuraj ShettyAinda não há avaliações

- Fig. 1: Clap Switch Block DiagramDocumento26 páginasFig. 1: Clap Switch Block DiagramDiljot Singh 236Ainda não há avaliações

- Exercise 2Documento7 páginasExercise 2satrio weka0% (1)

- Seta KV-6 Viscosity BathDocumento2 páginasSeta KV-6 Viscosity BathAzimul Hasnat ChowdhuryAinda não há avaliações

- Operation & Service Manual: Supra 560, 660, 760, 860 & 960 With DIN Mount Cab DisplayDocumento114 páginasOperation & Service Manual: Supra 560, 660, 760, 860 & 960 With DIN Mount Cab DisplayElton Dos Santos100% (8)

- Problem Set 1Documento2 páginasProblem Set 1Lovedeep SinghAinda não há avaliações

- Sapphire Textile Mills LTD No 2: (70 DENIER)Documento19 páginasSapphire Textile Mills LTD No 2: (70 DENIER)Danish NawazAinda não há avaliações

- Physical Science Activity Sheet Quarter 2 - MELC 12 Week 5: Radio PulsesDocumento6 páginasPhysical Science Activity Sheet Quarter 2 - MELC 12 Week 5: Radio PulsesTonet Competente100% (1)

- ESD User Handbook Rev2Documento12 páginasESD User Handbook Rev2Amit B Kolekar100% (1)

- Ets 15Documento2 páginasEts 15abdalazeez20122013Ainda não há avaliações

- Unit 1 Force Systems PDFDocumento17 páginasUnit 1 Force Systems PDFpeter vanderAinda não há avaliações

- NPC Power System Protection PhilosophyDocumento60 páginasNPC Power System Protection PhilosophySellappan Muthusamy100% (3)

- Absolute Maximum Ratings Semitrans M Power MOSFET Modules SKM 151 A4RDocumento5 páginasAbsolute Maximum Ratings Semitrans M Power MOSFET Modules SKM 151 A4RChaovalit Jitsinthu100% (1)

- Alokaya 1Documento20 páginasAlokaya 1joker boyAinda não há avaliações

- Cuk Trainer ManualDocumento6 páginasCuk Trainer ManualShankar ArunmozhiAinda não há avaliações

- Chap 1 Types of TurbomachinesDocumento8 páginasChap 1 Types of TurbomachinesNorvinyeLorlortorYekoAinda não há avaliações

- SEN-30201: MAX31865 RTD-to-Digital Breakout Board, Multiple Cal OptionsDocumento8 páginasSEN-30201: MAX31865 RTD-to-Digital Breakout Board, Multiple Cal OptionsAchref NajjarAinda não há avaliações

- Error CodesDocumento10 páginasError CodesAlgie ReñonAinda não há avaliações

- WIZ SeriesDocumento4 páginasWIZ SeriesJon HamonAinda não há avaliações

- VTT Btuo45-041224Documento58 páginasVTT Btuo45-041224Khrystenn Mesias SerapioAinda não há avaliações

- US20190295733A1 - Pasma Compression Fusion DeviceDocumento8 páginasUS20190295733A1 - Pasma Compression Fusion DevicedaveklodavekloAinda não há avaliações

- RLC ExamplesDocumento25 páginasRLC ExamplesAbel LopezAinda não há avaliações

- Low Voltage CTS GB 2009 PDFDocumento66 páginasLow Voltage CTS GB 2009 PDFAkram Del RioAinda não há avaliações

- Thermowell PDFDocumento2 páginasThermowell PDFalisuseAinda não há avaliações

- Rojas 02-12-2023 20.08Documento17 páginasRojas 02-12-2023 20.08Juphil PletoAinda não há avaliações