Escolar Documentos

Profissional Documentos

Cultura Documentos

Carmix Metal Galante

Enviado por

rigoberto123456789Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Carmix Metal Galante

Enviado por

rigoberto123456789Direitos autorais:

Formatos disponíveis

CARMIX 3.5 T & 2.

5

360 series

CARGA, AMASA, TRANSPORTA Y DESCARGA EL HORMIGN DONDE USTED LO NECESITA

La autohormigonera autocargadora a la maxima potencia.

CARMIX reduce notablemente los costos de produccin del hormign. Elimina los desperdicios (tambin de tiempo) y racionaliza la ombra produciendo solo lo que se necesita y solo cuando requiere. La implantacin de fciles y intuitivos sistemas de dosificacin electrnicos asegura una calidad total del homign producido y hace de CARMIX el ideal para cualquier tipologa de construccin. (opcional) La nueva serie 360 incluye hoy en dia CARMIX 3.5 T4, CARMIX 3.5 T y CARMIX 2.5: 3 distintos modelos, una sola filosofa: garantizar hormign de calidad a costo reducio en cualquier tipo de ombra asegurando un excelente confort del operador y obtener una mayor productividad.

Haz de CARMIX el proveedor oficial de hormign de Vuestra obra: gracias a las tecnologas y soluciones adoptadas CARMIX se auto alimenta, produce, transporta y descarga mas de 100 m3 de hormign al da.

Cabina delantera para asegurar una perfecta visibilidad y un excelente confort del operador. Bombo giratorio 300 para facilitar la descarga del hormign en los 4 lados a una altura de ms de dos metros. Pala hidrulica articulada para una carga de los ridos optimal. Cuchara con apertura hydraulica para dosificacion volumetrica y evitar perdida de cemento. Motor transversal: fcil mantenimiento y chequeo. Peso igualmente distribuido. Frenos de disco mltiples en bao de aceite: ningn mantenimiento y fiabilidad total. Cuadro de distribucin con todos los instrumentos. Joymix ergonmico: un joystick servomanda todas las funciones principales. Sistema de pesaje electrnico con impresora para certificar la calidad del hormign al 100% (opcional). CARMIX selecciona los mejores proveedores para a segurar a sus clientes no solo la mejor calidad sino tambin para un servicio posventa a nivel mundial. Entre otros referimos PERKINS para los motores, HYDROMATIC REXROTH para la transmisin,DANFOSS para los motores hidrulicos, DANAHURTH para los ejes Y mas...

Lo que hace CARMIX N. 1

360 es el numero magico de la revolucion CARMIX. Es el ultimo desarrollo de una intuicion nacida hace 30 anos. Permite al operador con la simple presion de dos dedos descargar el hormigon alrede dor de los 4 lados de la CARMIX a mas de dos metros de altura sin ninguna maniobra.

Darnos los elementos y

CARGA

CARMIX...

Gracias a su pala articulada hidrulica CARMIX carga los ridos con una precisin excelente. La lama al interior de la cuchara permite romper los sacos de cemento evitando perdidas. De la cuchara todo el material pasa rpidamente al bombo a travs de la tolva.

MEZCLA

Una vez en el bombo ridos y cemento son perfectamente mezclados con agua bombeada desde los depsitos. La calidad de la mezcla y hormign esta asegurada por la doble hlice interna tipo T de 4 mm de espesor. (Sistema electrnico de pesaje disponible opcional). Ningn sitio es demasiado difcil para CARMIX. Las 4 ruedas motrices con transmisin hidrosttica y la ideal distribucin de los pesos permiten a CARMIX superar pendientes a plena carga de ms del 30%.

DISTRIBUCION

DESCARGA

La revolucin CARMIX! Con el bombo giratorio 300 el operador accionando el Joymix descarga hormign en los 4 lados del vehculo a una altura de dos metros. Ademas para una rpida y mejor descarga el bombo puede levantarse hidraulicamente. Tambien en este sentido CARMIX es unica!

30020 Noventa di Piave (Venice) Italy Tel.+39.042165191 - Fax +39.0421658838 info@carmix.com

www.carmix.com

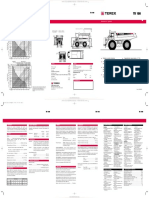

CARMIX 3.5 T4

MIXING UNIT: Drum Capacity 4.750 liters. Concrete output: 3,5 m3 per batch. Double mixing screws, cover for emergency unloading. Drum rotation by hydraulic motor and planetary reducers. Mixing and discharging speed independent from r.p.m. of diesel engine. Discharging by reversing drum. Quick discharge by drum tilting. The mixing unit is slewing nydraulically through 300 for high discharge over 2 m to the four sides of the vehicle. ENGINE: Diesel PERKINS 1104 C-44 TA Turbo, water-cooled, 4 cylinders. Rated power KW 80 (107 HP) set at 2300 rpm. Engine mounted transversal on the rear. TRANSMISSION: Hydrostatic, Hydromatic-Rexroth. Pump and motor are connected to the differentials through a 2 speed reducer (working and transfer). 4 wheel driving. SPEED: Working speed from 0 to 9 km/h, road transfer from 0 to 25 km/h. Electric servo control. DRIVING SEAT: Front cab on side of loading shovel. ROPS-FOPS type complete of double closing door. CHASSIS: Steel profile specially engineered for off-road operations. HYDRAULIC SYSTEM: Three circuits. 2 variable outlet pumps for hydrostatic transmission and drum rotation. 2 gear pumps for services. Inlet and outlet filter. Heat exchanger water/oil-air type. JOYMIX: All hydraulic functions of shovel and slewing drum controlled by a single fully servo controlled Joystick. LOADING SHOVEL: Capacity 540 liters. Complete with hydraulic opening gate. CHUTE: Slewing and nydraulically tilting. Fitted with two pins easily detachable to increase the discharge height. WATER SYSTEM: Self-contained. Hydraulic driven water pump, water meter, washing outlet. High pressure water pump. (On request) GRADIENT: Fully loaded 30%. BRAKES: Oil bath disc brakes inside differential axles. Twin independent circuits. Negative hydraulic parking brake. TYRES: Off road industrial type 16/70-20 PR 14. STEERING: Hydrostatic. (2 steering) Radius: internal mm. 2450, external mm. 5200. CARMIX 3.5 T4 (4 steering 3 ways) internal: mm. 1700, external mm 3.700. ELECTRIC SYSTEM: 12 Volt. 120 Ah battery for electric starter and road lighting. Safety battery cutoff. TANKS: Water: 2x400 liters. Diesel: 115 liters. Hydraulic oil: 80 liters. WEIGHT: About Kg. 7300. Equally distributed on both axles. SAFETY: Machine equipped with checking and block valves for maximum safety of the operator. Self Control avoids drum to slew if shovel's arm is lifted. CATALOGUES: The machine is equipped with Use and Maintenance and Spare Parts Manuals according to CE regulations.

CARMIX 2.5

MIXING UNIT: Drum capacity 3400 liters. Concrete output: 2,5 m3 per batch. Double mixing screws, cover for emergency unloading. Drum rotation by hydraulic motor and planetary reducers. Mixing and discharging speed independent from r.p.m. of diesel engine. Discharging by reversing drum. Quick discharge by drum tilting. The mixing unit is slewing hydraulically through 300 for high discharge at 1,9 m to the four sides of the vehicle. ENGINE: Diesel PERKINS 1104 C-44 water-cooled, 4 cylinders. Rated power KW 63 (85 HP) set at 2300 rpm. Engine mounted transversal on the rear. , TRANSMISSION: Hydrostatic, Hydromatic-Rexroth.Pump and motor areKyinected to the differentials through a 2 speed reducer (working and transfer). 4 wheel driving. SPEED: Working speed from 0 to 9 km/hi road transfer from 0 to 25 km/h. Electric servo control. DRIVING SEAT: Front cab on side of loading shovel. ROPS-FOPS type complete of double closing door. CHASSIS: Steel profile specially engineered for off-road operations. HYDRAULIC SYSTEM: Three circuits. 2 variable outlet pumps for hydrostatic transmission and drum rotation. 2 gear pumps for services. Inlet and outlet filter. Heat exchanger water/oil - air type. JOYMIX: All hydraulic functions of shovel and slewing drum controlled by a single fully servo controlled Joystick. LOADING SHOVEL: Capacity 400 liters. Complete with hydraulic opening gate. CHUTE: Slewing and hydraulically tilting. Fitted with two pins easily detachable to increase the discharge height. WATER SYSTEM: Self-contained. Hydraulic driven water pump. Water meter, washing outlet. High pressure water pump on request. GRADIENT: Fully loaded 30%. BRAKES: Oil bath disc brakes inside differential axles. Twin independent circuits. Negative hydraulic parking brake. TYRES: Off road industrial type 12.5-20 PR 12. STEERING: Hydrostatic. Radius: internal mm. 2400, external mm. 4850. ELECTRIC SYSTEM: 12 Volt. 120 Ah battery for electric starter and road lighting. Safety battery cutoff. TANKS: Water: 2x270 liters. Diesel: 105 liters. Hydraulic oil: 80 liters. WEIGHT: About Kg. 6000. Equally distributed on both axles. SAFETY: Machine equipped with checking and block valves for maximum safety of the operator. Self Control avoids drum to slew if shovel's arm is lifted. CATALOGUES: The machine is equipped with Use and Maintenance and Spare Parts Manuals according to CE regulations.

3230 4325

2915

3120

1670-1800

3000

3980

1450-1600

360

50

1550

2350 5600 7150

1700

1920 2310 2420

2100

1050

1400

2000 5100 6555

1700

1760 2085 2310 865

1840

Você também pode gostar

- Porgrama de MantenimientoDocumento1 páginaPorgrama de MantenimientoMilena Sahimara Campos AliagaAinda não há avaliações

- 323 ExcavadoraDocumento16 páginas323 ExcavadoraRossman MejicanosAinda não há avaliações

- Curso Compactacion Rodillo Compactador DynapacDocumento58 páginasCurso Compactacion Rodillo Compactador DynapacRodrigo Andre Valdivia PintoAinda não há avaliações

- Manual Operacion Familiarizacion Excavadora HidraulicaDocumento51 páginasManual Operacion Familiarizacion Excavadora HidraulicakevinAinda não há avaliações

- Hidraulica Semana 1Documento70 páginasHidraulica Semana 1MARCOSAinda não há avaliações

- 1315 C-48Documento2 páginas1315 C-48Raul Raul Sucuytana100% (1)

- Operacion de Motoniveladora 12Documento6 páginasOperacion de Motoniveladora 12Jerson Cuva100% (2)

- Dumpers Articulados 725Documento81 páginasDumpers Articulados 725Franklin TorresAinda não há avaliações

- 769D 04 Tren de PotenciaDocumento64 páginas769D 04 Tren de Potenciarigoberto123456789100% (1)

- VOLVO FMXDocumento4 páginasVOLVO FMXSaray Aljure Ospino100% (1)

- Curso de AutohormigoneroDocumento37 páginasCurso de Autohormigoneropercy MorenoAinda não há avaliações

- Catlogo Tractor D155AX 6 Espaol PDFDocumento20 páginasCatlogo Tractor D155AX 6 Espaol PDFHernan Bonifacio Pinto100% (1)

- Manual Ah02Documento128 páginasManual Ah02victor arias mezaAinda não há avaliações

- Test Caser250Documento16 páginasTest Caser250Manuel Castillo FernandezAinda não há avaliações

- Aslkla DDocumento18 páginasAslkla DBrayan Tapia100% (1)

- UNIC ES MINI GRÚAS - v3Documento12 páginasUNIC ES MINI GRÚAS - v3MarkCarstensAinda não há avaliações

- CARMIXDocumento20 páginasCARMIXsebastumorrowAinda não há avaliações

- Manipulador Telescopico Fijo Manitou Catalogo GamaDocumento8 páginasManipulador Telescopico Fijo Manitou Catalogo GamaMaquinzaAinda não há avaliações

- Exposicion Clientes Tractor 6403Documento49 páginasExposicion Clientes Tractor 6403Carlos Blanco100% (2)

- Codigo de Colores General 2005Documento128 páginasCodigo de Colores General 2005Daniel Pacheco LlantoyAinda não há avaliações

- Motosoldadora Lincol Vantage 500 DeutzDocumento2 páginasMotosoldadora Lincol Vantage 500 DeutzAugusto BellezaAinda não há avaliações

- Pautas de Mantecion Excavadora - Volvo Ec300Documento12 páginasPautas de Mantecion Excavadora - Volvo Ec300Edison FloresAinda não há avaliações

- Sandvik Range EspDocumento8 páginasSandvik Range EspRaul Apaza LujanAinda não há avaliações

- Muestra de Fluidos Autohormigonera Carmix 3.5tt-Ingenieria de ProyectosDocumento1 páginaMuestra de Fluidos Autohormigonera Carmix 3.5tt-Ingenieria de ProyectosIngemecpesantes0% (1)

- 12 La Nueva Generacion de Rodillos Autopropulsados UnlockedDocumento36 páginas12 La Nueva Generacion de Rodillos Autopropulsados UnlockedManuel CuencaAinda não há avaliações

- Excavadora Hidráulica PC4000Documento5 páginasExcavadora Hidráulica PC4000Juan TrianaAinda não há avaliações

- Cargador Frontal Arbeiro AmayaDocumento23 páginasCargador Frontal Arbeiro Amayaamaya1995Ainda não há avaliações

- WB93R eDocumento8 páginasWB93R eEdwin Olivario Taipe SuriAinda não há avaliações

- 18 Correa - Inspeccionar Ajustar Reemplazar PDFDocumento2 páginas18 Correa - Inspeccionar Ajustar Reemplazar PDFJonhAinda não há avaliações

- Especificaciones Excavadora 349-DL CatDocumento4 páginasEspecificaciones Excavadora 349-DL CathansAinda não há avaliações

- Ficha Tecnica Dieci Pegasus 38.16Documento2 páginasFicha Tecnica Dieci Pegasus 38.16B Quezada XkitaAinda não há avaliações

- Ficha Tecnica de MotoniveladoraDocumento7 páginasFicha Tecnica de MotoniveladoraLeika Mendoza0% (1)

- Tractores AgricolasDocumento20 páginasTractores AgricolasItzel Gómez Lorenzana100% (2)

- 1190E SP Servicio 733729Documento937 páginas1190E SP Servicio 733729Pedro Mollo Vara100% (1)

- Mantenimiento e Inspección 962m CatDocumento42 páginasMantenimiento e Inspección 962m CatWilmar Hancco100% (1)

- Manual de OperacionesDocumento315 páginasManual de OperacionesJean Carlo Cisneros HinostrozaAinda não há avaliações

- Lista de Productos Hidraulica SanfcoDocumento77 páginasLista de Productos Hidraulica SanfcoNaza PalomoAinda não há avaliações

- Curriculum Vitae Junior CondoriDocumento2 páginasCurriculum Vitae Junior CondoriAnthonyCruzYordanAinda não há avaliações

- CAT ICPneumatic3000 7000lbCapacityGas LP (GP15NM GP35NM) (Spanish)Documento12 páginasCAT ICPneumatic3000 7000lbCapacityGas LP (GP15NM GP35NM) (Spanish)ArmandoRodriguezAinda não há avaliações

- Catalogo Dumper Rigido Camion Minero Tr100 TerexDocumento2 páginasCatalogo Dumper Rigido Camion Minero Tr100 TerexjesusAinda não há avaliações

- Departamento de Desarrollo TecnicoDocumento37 páginasDepartamento de Desarrollo TecnicoEmmanuel Flores CoscoAinda não há avaliações

- Examen ProfesioDocumento2 páginasExamen Profesiocarlos velazquesAinda não há avaliações

- Catalogo de Piezas ST 1030Documento924 páginasCatalogo de Piezas ST 1030Gustavo A. Utreras FariasAinda não há avaliações

- EV. TEORICA VOLQUETE VOLVO FMX 6X4R - Contreras Pastor Sixto CastorDocumento6 páginasEV. TEORICA VOLQUETE VOLVO FMX 6X4R - Contreras Pastor Sixto CastorMoisesAinda não há avaliações

- A&R Brochure Retroexcavadora JCB 3CDocumento12 páginasA&R Brochure Retroexcavadora JCB 3CGustavo276Ainda não há avaliações

- Evaluacion Cargador Frontal 962H 1Documento5 páginasEvaluacion Cargador Frontal 962H 1Miguel Angel Ramirez LazoAinda não há avaliações

- Plano de Mantenimiento Ap 555e, Ext-02Documento1 páginaPlano de Mantenimiento Ap 555e, Ext-02Victor Hugo Huanca BartoloméAinda não há avaliações

- Catalogo Minicargador SK820 5 PDFDocumento12 páginasCatalogo Minicargador SK820 5 PDFEdwin CruzAinda não há avaliações

- Evaluacion Practica Volvo FMXDocumento1 páginaEvaluacion Practica Volvo FMXGustavoAinda não há avaliações

- Procedimento Seguro para Operación de Camión Articulado y Dumper v.1Documento13 páginasProcedimento Seguro para Operación de Camión Articulado y Dumper v.1omarAinda não há avaliações

- Volvo FMX 8X4 R Max E5: Evolucionamos Por TiDocumento2 páginasVolvo FMX 8X4 R Max E5: Evolucionamos Por TiVíctor Hugo Moreno SánchezAinda não há avaliações

- Tractores de CadenasDocumento33 páginasTractores de CadenasD.Figueroa50% (2)

- Competencia de Las Partes M& RDocumento11 páginasCompetencia de Las Partes M& RGianfranco EscobarAinda não há avaliações

- Camion Articulado Volvo eDocumento28 páginasCamion Articulado Volvo eGiovanni ManciniAinda não há avaliações

- Carmix 35TT EspDocumento2 páginasCarmix 35TT EspAllan Francisco Perez CordobaAinda não há avaliações

- Carmix 25 TTDocumento2 páginasCarmix 25 TTdavidbeju0% (1)

- Carmix 55xl EspDocumento2 páginasCarmix 55xl Esp987398739873100% (2)

- Catalogo Autohormigoneras Carmix 3 5ttDocumento2 páginasCatalogo Autohormigoneras Carmix 3 5ttcesarinAinda não há avaliações

- Mixkret 4Documento6 páginasMixkret 4Irlan Julcani Buendia50% (2)

- Maqmin 21 6 Equipos de Transporte para Minería deDocumento83 páginasMaqmin 21 6 Equipos de Transporte para Minería deJhonatan Franz Jurado TravezañoAinda não há avaliações

- Camion 797f CatDocumento24 páginasCamion 797f CatLuis Gonzalo Quispe Loayza100% (2)

- TornadoDocumento4 páginasTornadorigoberto123456789Ainda não há avaliações

- Huron 4Documento2 páginasHuron 4rigoberto123456789Ainda não há avaliações

- Carmix Metal GalanteDocumento4 páginasCarmix Metal Galanterigoberto123456789100% (1)