Escolar Documentos

Profissional Documentos

Cultura Documentos

Welding Procedure Specification Sample

Enviado por

Samer BayatiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Welding Procedure Specification Sample

Enviado por

Samer BayatiDireitos autorais:

Formatos disponíveis

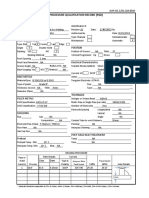

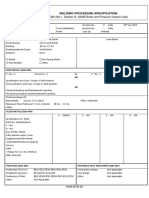

Welding Procedure Specification:- Example

Weld Procedure Number

30 P1 TIG 01 Issue A

Qualifying Welding Procedure (WPAR) WP T17/A Method Of Preparation and Cleaning: Manufacturer: National Fabs Ltd 25 Lane End Birkenshaw Leeds Workshop Parent Metal Specification: Parent Metal Thickness Pipe Outside Diameter Welding Position: Welding Progression: Machine and Degrease Grade 304L Stainless Steel 3 to 8mm Wall 25 to 100mm All Positions Upwards

Location:

Welding Process: Manual TIG Joint Type: Single Sided Butt Weld

Joint Design

Welding Sequences

Size Of Wire Current Voltage Type Of Travel Heat Run Process Filler Feed A V Current/Polarity Speed Input Metal Speed 1 TIG 1.2mm 70 - 90 DC2 And N/A N/A N/A N/A TIG 1.6mm 80 - 140 DCSubs Welding Consumables:Type, Designation Trade Name: Any Special Baking or Drying: Gas Flux: Gas Flow Rate - Shield: Production Sequence 1. Clean weld and 25mm borders to bright metal using approved solvent. 2. Position items to be

BS 2901 Part 2 : 308S92 No Argon 99.99% Purity 8 - 12 LPM

- Backing:

welded ensuring good fit up and apply purge Tungsten Electrode Type/ Size: 2% Thoriated 2.4mm Dia 3. Tack weld parts Details of Back Gouging/Backing: Gas Backing together using TIG, tacks to at least 5mm Preheat Temperature: 5C Min min length Interpass temperature: 200C Max 4. Deposit root run using 1.2mm dia. wire. Post Weld Heat Treatment Not Required 5. Inspect root run Time, temperature, method: internally Heating and Cooling Rates*: 6. Complete weld using 1.6mm dia wire using stringer beads as required. 7. 100% Visual inspection of completed weld Revision History Date Issue 26/11/2000 A First Issue

5 LPM

Changes

Authorization

Você também pode gostar

- WpsDocumento2 páginasWpsjsmargate100% (1)

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocumento1 páginaASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechAinda não há avaliações

- Sheet metal tolerance standards overviewDocumento2 páginasSheet metal tolerance standards overviewLee Chong EeAinda não há avaliações

- MR Zubair - NotesDocumento39 páginasMR Zubair - NotesAnjali Singh100% (1)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsDocumento11 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DareAinda não há avaliações

- Cswip - Section 09-Welding SymbolsDocumento14 páginasCswip - Section 09-Welding SymbolsNsidibe Michael Etim100% (1)

- FILL COURSE ENROLMENT FORMDocumento3 páginasFILL COURSE ENROLMENT FORMRaja Guru100% (1)

- NDT Exam PDFDocumento4 páginasNDT Exam PDFshyamkumar rakotiAinda não há avaliações

- PQR Is7307Documento1 páginaPQR Is7307Tridib Dey100% (1)

- JIMT Visual Inspection ReportDocumento1.913 páginasJIMT Visual Inspection Reportgomathyselvi100% (1)

- Astm A335 p91 PipeDocumento1 páginaAstm A335 p91 PipeBhagwati SteelageAinda não há avaliações

- Submerged Arc Welding Fluxes BasicityDocumento3 páginasSubmerged Arc Welding Fluxes Basicitylram70Ainda não há avaliações

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocumento13 páginasPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniAinda não há avaliações

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocumento6 páginasUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mAinda não há avaliações

- Welding Procedure Specification (WPS) : in The Outer TubeDocumento1 páginaWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaAinda não há avaliações

- Asme PQR DemoDocumento3 páginasAsme PQR DemoMuthusamy AyyanapillaiAinda não há avaliações

- GMAWDocumento12 páginasGMAWsushant47Ainda não há avaliações

- Cordon Off - 4 (00000003)Documento1 páginaCordon Off - 4 (00000003)Anonymous PlyxbQ3tAinda não há avaliações

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocumento1 páginaAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityAinda não há avaliações

- Api 577 Q&a PDFDocumento3 páginasApi 577 Q&a PDFElankumaran PeriakaruppanAinda não há avaliações

- Is 7310 RequirementsDocumento4 páginasIs 7310 RequirementsRavichandran Tirupattur SubramaniamAinda não há avaliações

- Procedure for Radiographic Testing of Welded Steel JointsDocumento30 páginasProcedure for Radiographic Testing of Welded Steel JointsG_ARVALIS8470Ainda não há avaliações

- PQR Saw ProcessDocumento1 páginaPQR Saw ProcessARUL ARON JOSEAinda não há avaliações

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocumento8 páginasA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- 03-Symbols Mock ExamDocumento5 páginas03-Symbols Mock ExamCRISTIAN SILVIU IANUC100% (1)

- ET NDT Sample Test Report FormatDocumento1 páginaET NDT Sample Test Report Formatanas dwiAinda não há avaliações

- CSWIP Module Re-ExamDocumento2 páginasCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- ASME 9 Calculator Approval RangesDocumento2 páginasASME 9 Calculator Approval RangesEmel Besir100% (1)

- P91 Profile WpsDocumento6 páginasP91 Profile WpsManzar KhanAinda não há avaliações

- 1035 03Documento2 páginas1035 03Anuj ShahiAinda não há avaliações

- Metrode - P92 WPS PDFDocumento3 páginasMetrode - P92 WPS PDFXing ChenAinda não há avaliações

- General Question Paper 1Documento5 páginasGeneral Question Paper 1indusampathAinda não há avaliações

- Ultrasonic Testing Report SummaryDocumento2 páginasUltrasonic Testing Report Summarymanjeev111Ainda não há avaliações

- WPQR6Documento3 páginasWPQR6Dimitris NikouAinda não há avaliações

- Mild Steel Welding ElectrodeDocumento12 páginasMild Steel Welding ElectrodeVĩnh NguyễnAinda não há avaliações

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocumento7 páginasCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248Ainda não há avaliações

- Hydrogen Cracking Causes and PreventionDocumento6 páginasHydrogen Cracking Causes and Preventionshahid khanAinda não há avaliações

- Welding Inspection Guide for SteelsDocumento132 páginasWelding Inspection Guide for SteelsfahreezAinda não há avaliações

- WPS 316 L PDFDocumento4 páginasWPS 316 L PDFIrinaAinda não há avaliações

- MCQS .... CSWIP Questions and AnswersDocumento67 páginasMCQS .... CSWIP Questions and AnswersAli Kashif100% (1)

- Cswip 3.1Documento2 páginasCswip 3.1Anna PariniAinda não há avaliações

- Acceptance CriteriaDocumento19 páginasAcceptance CriteriaAnonymous 5iv0i3cZAinda não há avaliações

- Destructive Test Report for Welding SamplesDocumento14 páginasDestructive Test Report for Welding SamplesMark AnthonyAinda não há avaliações

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 páginasWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEAinda não há avaliações

- Wps For Carbon Steel THK 7.11 GtawDocumento1 páginaWps For Carbon Steel THK 7.11 GtawAli MoosaviAinda não há avaliações

- Bolt Tightening Inspection FormatDocumento14 páginasBolt Tightening Inspection FormatAchmad SyaifulAinda não há avaliações

- Geometric shape welding imperfections causes and typesDocumento12 páginasGeometric shape welding imperfections causes and typesbipete69Ainda não há avaliações

- Phased Array Practical ExamDocumento2 páginasPhased Array Practical ExamMarcus AntoniusAinda não há avaliações

- Gta+sma PQRDocumento3 páginasGta+sma PQRRahul MoottolikandyAinda não há avaliações

- Wps Format Asme Sec - IxDocumento2 páginasWps Format Asme Sec - IxDeepu ChandranAinda não há avaliações

- Sample API 1104 WpsDocumento1 páginaSample API 1104 Wpsippon_osoto100% (1)

- WPS 2014-002 006 - 6G PipeDocumento3 páginasWPS 2014-002 006 - 6G PipejeswinAinda não há avaliações

- 1 5 1Documento5 páginas1 5 1daemsalAinda não há avaliações

- All Position Stainless Steel Welding ProcedureDocumento6 páginasAll Position Stainless Steel Welding ProcedureJaime PatrónAinda não há avaliações

- ASME P NumbersDocumento3 páginasASME P Numbersrajesh100% (1)

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- TIG Welding ProcedureDocumento1 páginaTIG Welding ProceduretexpectationsAinda não há avaliações

- Welding Procedure SpecificationsDocumento2 páginasWelding Procedure SpecificationsGerhard Kemp0% (1)

- Welding Procedure SpecificationDocumento101 páginasWelding Procedure SpecificationNhien ManAinda não há avaliações

- WPSDocumento1 páginaWPSNidhinkorothAinda não há avaliações