Escolar Documentos

Profissional Documentos

Cultura Documentos

Storm Copper Busbar Brochure

Enviado por

faberromeroDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Storm Copper Busbar Brochure

Enviado por

faberromeroDireitos autorais:

Formatos disponíveis

MANUFACTURING TO OEM SPECIFICATIONS AND SERVICE REQUIREMENTS

Inventory That Ensures Your Components Availability

We maintain a standing inventory of a million pounds of copper bar and sheet in a variety of widths and thicknesses, so we can respond quickly. That gives you more production flexibility.

Technology That Maximizes Your Efficiency

We continually re-evaluate our production processes, and we make investments in equipment to make us faster and more cost-effective. Our strategy is to ensure your component's quality first, then look for ways we can make your parts more cost effectively.

Custom shapes and sizes are produced quickly and accurately on our Trumph Punching Machines.

We maintain a million pounds of copper bar and sheet inventory at all times.

CONNECTIONS ARE OUR BUSINESS

Visit www.stormcopper.com for a complete description of our standard ground bar assemblies.

Layered conductors and insulators create custom Busbar laminations.

Our materials, processes, and finished components are engineered to meet, as needed, standards required by ASME, UL, CSA, Bellcore, and other testing/standards bodies. Since virtually every component we make is custom to a particular manufacturer or application, we have created a number of new cost effective techniques of producing connectors in both low and high volume production runs.

PRODUCTS

Our employees understand how to work a soft metal like copper and keep tolerances tight. Our 400 ton CNC busbar press is capable of making up to ten components at once. Modular tooling allows us to set up even complicated designs in a matter of a few minutes, with minimal tool cost.

Copper Fabrication

Storm Copper Components is one of the largest copper fabricators in the United States. Virtually all of our business is copper, and we offer a variety of metalworking capabilities, all based on CNC technology. Our equipment includes shears, presses, breaks, and punching machines.

Our employees understand the technicalities of working with copper, a softer metal than steel, and one that requires some extra care in fabrication. And our proto-typing capability can usually provide sample components for testing in a matter of days.

X-rays help us monitor plating thickness consistency.

Plating

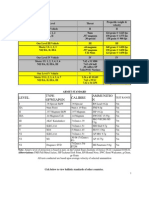

Storm Copper Components developed in-house plating capabilities so we could meet the delivery requirements of our key customers. Our original bright tin plating finish has been expanded to include tin/lead, lead and silver plating. Tin Lead Silver Tin/Lead

Cable Assembly

Storm produces a full line of cable assemblies for high current applications, with a variety of lug and connector options. This was our original business, and it's one that continues to grow today.

ONLINE SUPPORT GIVES YOU AN INSTANT CONNECTION WITH US

Storm Copper Components works closely with its customers, and our connection on the World Wide Web gives you easy access to critical information on electrical design, plus immediate access to our company. Our website includes conductivity tables, descriptions of our products, an inventory list of materials we have in stock, and other information that can help your procurement and scheduling.

Flexible Busbars allow for vibration and movement in high current applications.

Large capacitor bank assembly used in power generation.

Storm Copper Components Co. 240 Industrial Drive, P.O. Box 99 Decatur, TN 37322 1-800-394-4804 Fax: 423-334-3389 www.stormcopper.com

Você também pode gostar

- MANOBSDocumento479 páginasMANOBSBia239Ainda não há avaliações

- GOST R 58464-2019 Translation in EnglishDocumento1 páginaGOST R 58464-2019 Translation in EnglishVenads73Ainda não há avaliações

- Ar 190 11Documento122 páginasAr 190 11Kevin BravoAinda não há avaliações

- NFAA 5 Spot TargetDocumento4 páginasNFAA 5 Spot TargetFanni OkviasantiAinda não há avaliações

- Beoplay V1 - Into DetailsDocumento10 páginasBeoplay V1 - Into Detailskg_selvarajAinda não há avaliações

- Eta PRODocumento6 páginasEta PROAamir ayubAinda não há avaliações

- Bedmutha Copper BrochureDocumento4 páginasBedmutha Copper BrochuresanthoshAinda não há avaliações

- F-2-202, Sangam Sagar Aptts., Vinay Path, Todarmal Marg, Banipark, JaipurDocumento3 páginasF-2-202, Sangam Sagar Aptts., Vinay Path, Todarmal Marg, Banipark, JaipurArijit RoyAinda não há avaliações

- AR15 Improved Battle Sight ZeroDocumento3 páginasAR15 Improved Battle Sight ZeroMattGryderAinda não há avaliações

- Homebuilt Reloading Stand by Erik PrestmoDocumento18 páginasHomebuilt Reloading Stand by Erik Prestmopeter.gomes20087216Ainda não há avaliações

- WWW Scribd Com Document 435738955 Imo Olympiad Workbook 9Documento20 páginasWWW Scribd Com Document 435738955 Imo Olympiad Workbook 9Manish RathoreAinda não há avaliações

- Result Page: Description of EP2309028 Print Copy Contact Us CloseDocumento26 páginasResult Page: Description of EP2309028 Print Copy Contact Us CloseKaveri JainAinda não há avaliações

- Scan Doc0001Documento1 páginaScan Doc0001akms1982Ainda não há avaliações

- NationalTalentSearchExamination201510th 24 11 2015 PDFDocumento31 páginasNationalTalentSearchExamination201510th 24 11 2015 PDFankitagarg23Ainda não há avaliações

- Spectre 3x ManualDocumento2 páginasSpectre 3x Manualakms1982100% (1)

- Totalizer FT 100iDocumento6 páginasTotalizer FT 100iAgeng Firstyan BagaskoroAinda não há avaliações

- MOD 125 SniperDocumento3 páginasMOD 125 SniperCarlos EduardoAinda não há avaliações

- Paper Plane DragonflyDocumento3 páginasPaper Plane Dragonflylucky100% (5)

- Handbook of Ballistic and Engineering Data For Ammunition, Vol 1Documento261 páginasHandbook of Ballistic and Engineering Data For Ammunition, Vol 1Vlad VladAinda não há avaliações

- IMO Class 4 Paper 2018 Part 1Documento6 páginasIMO Class 4 Paper 2018 Part 1Prasenjit DasAinda não há avaliações

- Allen Precision Shooting Wildcat InformationDocumento9 páginasAllen Precision Shooting Wildcat Informationshwn_petersAinda não há avaliações

- Rapid Bolt Assembly InstuctionsDocumento1 páginaRapid Bolt Assembly Instuctionsgraham4877Ainda não há avaliações

- Report Gundriling AAMAstakhovDocumento27 páginasReport Gundriling AAMAstakhovGyörgy Murvai100% (1)

- Book of The Stoeger X10, X20, X50 v1.0Documento34 páginasBook of The Stoeger X10, X20, X50 v1.0Stephen Archer67% (3)

- Grade 6 Trees and Forrest SmallDocumento34 páginasGrade 6 Trees and Forrest Smallapi-183992607Ainda não há avaliações

- Basic Algoritham PDFDocumento84 páginasBasic Algoritham PDFRD ANF NORTHAinda não há avaliações

- IMO Class 2 Syllabus PDFDocumento1 páginaIMO Class 2 Syllabus PDFPrasad PawarAinda não há avaliações

- Rapid Field Target SpecsDocumento1 páginaRapid Field Target Specsgraham4877Ainda não há avaliações

- Main Areas ICT PHDDocumento8 páginasMain Areas ICT PHDTalib Hussain100% (1)

- IEO - Level2 - Mock SET 1 PDFDocumento16 páginasIEO - Level2 - Mock SET 1 PDFBBA- Big Bro Abbas BegAinda não há avaliações

- EES 007 Licensing of Cable Repair Facilities PDFDocumento16 páginasEES 007 Licensing of Cable Repair Facilities PDFMikhailAinda não há avaliações

- IGKO SetA Class5 PDFDocumento1 páginaIGKO SetA Class5 PDFG KumarAinda não há avaliações

- Class 5 Fa1 Worksheet 1Documento6 páginasClass 5 Fa1 Worksheet 1Kousika VijayakumarAinda não há avaliações

- Allen: Pre Nurture & Career Foundation DivisionDocumento4 páginasAllen: Pre Nurture & Career Foundation DivisionSindujaAinda não há avaliações

- National Foundation Phase Maths Olympiad Grade3 1.1Documento33 páginasNational Foundation Phase Maths Olympiad Grade3 1.1Guruji Smt Janani SairamAinda não há avaliações

- Bar ClampDocumento19 páginasBar Clampapi-200253170Ainda não há avaliações

- MBD Annular SectionDocumento4 páginasMBD Annular SectionCompra Venta De Maquinaria IndustrialAinda não há avaliações

- Bullet Mold EnlargementDocumento4 páginasBullet Mold Enlargementdannyjan5080100% (1)

- Philips Qfu1.1ela 312278519211 ChassisDocumento137 páginasPhilips Qfu1.1ela 312278519211 ChassisPittiplatschAinda não há avaliações

- 150 Office/Tech:: Rifle IndexDocumento42 páginas150 Office/Tech:: Rifle IndexStan BrittsanAinda não há avaliações

- Metric Tread DimensionDocumento22 páginasMetric Tread DimensionHanif MalekAinda não há avaliações

- Free PDF Paper TargetsDocumento2 páginasFree PDF Paper TargetsJillAinda não há avaliações

- Millett Long Range Scope (Lrs-1) Instructions and Operation ManualDocumento24 páginasMillett Long Range Scope (Lrs-1) Instructions and Operation ManualMiguel Angel Jimenez BlandinoAinda não há avaliações

- NSO (International Science Olympiad) Class 4 Paper 2018 Part 2 Download All The Papers For 2021 ExamDocumento5 páginasNSO (International Science Olympiad) Class 4 Paper 2018 Part 2 Download All The Papers For 2021 ExamSwaroop ChakravortyAinda não há avaliações

- Civil Service Reviewer: Analogy and LogicDocumento32 páginasCivil Service Reviewer: Analogy and LogicMaJoy OrbilloAinda não há avaliações

- Dbs22 enDocumento14 páginasDbs22 enmilivoj11Ainda não há avaliações

- Bisley CatalogueDocumento49 páginasBisley CatalogueMohamed TaamalliAinda não há avaliações

- NSTSE Class 4 Solved Paper 2010Documento23 páginasNSTSE Class 4 Solved Paper 2010Aloma FonsecaAinda não há avaliações

- Ballistic LevelDocumento4 páginasBallistic LevelJon KunbergerAinda não há avaliações

- M16a2 25m ZeroDocumento1 páginaM16a2 25m ZeroAlan Warren SnyderAinda não há avaliações

- UntitledDocumento218 páginasUntitledNikunj GokaniAinda não há avaliações

- Raman Spectroscopy of Graphene and GraphiteDocumento11 páginasRaman Spectroscopy of Graphene and Graphitenanda100% (1)

- Baselining of The 40 MM Family of AmmunitionDocumento18 páginasBaselining of The 40 MM Family of AmmunitionNORDBAinda não há avaliações

- English - Marigold - Class 3 PDFDocumento116 páginasEnglish - Marigold - Class 3 PDFshalusreejeshAinda não há avaliações

- JNV Class 6thDocumento2 páginasJNV Class 6thRamesh rajAinda não há avaliações

- Single Layer Winding of Three Phase Induction Motor: Enesi Asizehi YahayaDocumento6 páginasSingle Layer Winding of Three Phase Induction Motor: Enesi Asizehi YahayaHuong Thao Le LuongAinda não há avaliações

- Leading Manufacturers and Exporter of Electrical Components and Cable AccessoriesDocumento8 páginasLeading Manufacturers and Exporter of Electrical Components and Cable Accessoriesmultimet copperAinda não há avaliações

- SF 0011 0 Quality ZnAl WiresDocumento4 páginasSF 0011 0 Quality ZnAl WiresanandelectricalsAinda não há avaliações

- Nippon Steel Seamless CasingDocumento18 páginasNippon Steel Seamless Casingjohndo3Ainda não há avaliações

- Redd Iron PresentationDocumento29 páginasRedd Iron PresentationBAinda não há avaliações

- 002 DEW Warmarbeitsstahl GB PDFDocumento76 páginas002 DEW Warmarbeitsstahl GB PDFSinan Yıldız100% (1)

- Total Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedDocumento1 páginaTotal Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedfaberromeroAinda não há avaliações

- Acometida FullDocumento4 páginasAcometida FullfaberromeroAinda não há avaliações

- Ampacity Chart For Copper Bus Bar DesignDocumento2 páginasAmpacity Chart For Copper Bus Bar DesignfaberromeroAinda não há avaliações

- Copper Busbar Ampacity TablesDocumento2 páginasCopper Busbar Ampacity TablesfaberromeroAinda não há avaliações

- Ampacity Chart For Copper Bus Bar DesignDocumento2 páginasAmpacity Chart For Copper Bus Bar DesignfaberromeroAinda não há avaliações

- Marco Price List Specification Lighting 1-90Documento80 páginasMarco Price List Specification Lighting 1-90Alan MastersAinda não há avaliações

- 5.21.1 - Electrical Work PermitsDocumento17 páginas5.21.1 - Electrical Work PermitsMubasser Iqbal100% (1)

- AAPL Capability StatementDocumento41 páginasAAPL Capability StatementjsmnjasminesAinda não há avaliações

- Feasibility Analysis of A Grid-Connected PV System For Residential ApplicationDocumento2 páginasFeasibility Analysis of A Grid-Connected PV System For Residential ApplicationWayanSantikaAinda não há avaliações

- Sertif HMTGDocumento7 páginasSertif HMTGwandaAinda não há avaliações

- Embracing Change: Enhancing OpportunitiesDocumento46 páginasEmbracing Change: Enhancing OpportunitiesTohiroh FitriAinda não há avaliações

- Bhel ReportDocumento13 páginasBhel ReportAtul TripathiAinda não há avaliações

- AMI SOP 052021 v2Documento9 páginasAMI SOP 052021 v2Imran KhanAinda não há avaliações

- For Assistance Dial 1912 5616195: For Bill SMS BILL Pay Your Bill OnDocumento1 páginaFor Assistance Dial 1912 5616195: For Bill SMS BILL Pay Your Bill Ondevesh guptaAinda não há avaliações

- Solar Industry Članek InverterriDocumento3 páginasSolar Industry Članek InverterriAt YugovicAinda não há avaliações

- Causes of Boiler Slagging and FoulingDocumento9 páginasCauses of Boiler Slagging and FoulingAshiqAinda não há avaliações

- SIEMENSDocumento16 páginasSIEMENSHarika Shekapuram12Ainda não há avaliações

- Sealed Air PackTigerDocumento2 páginasSealed Air PackTigeropenblueAinda não há avaliações

- Report Mali ZvornikDocumento61 páginasReport Mali ZvornikSrbislav GenicAinda não há avaliações

- Posco DaewooDocumento6 páginasPosco DaewooAcero MariaAinda não há avaliações

- Rule 1020 New Establishment Registration (1) - 2Documento1 páginaRule 1020 New Establishment Registration (1) - 2Dustin NitroAinda não há avaliações

- Quality Standards PDFDocumento20 páginasQuality Standards PDFmudassarhussainAinda não há avaliações

- ExxonMobil 2009 Citizenship ReportDocumento52 páginasExxonMobil 2009 Citizenship ReportSohail Aamir100% (1)

- OriginDocumento4 páginasOriginefrenAinda não há avaliações

- Full Thesis PDFDocumento109 páginasFull Thesis PDFTanjib Rahman NiloyAinda não há avaliações

- L and TDocumento17 páginasL and TRaja Chowdary40% (5)

- Assignment On Project Management: MBA - II Section - ADocumento20 páginasAssignment On Project Management: MBA - II Section - Adilip_maniyaAinda não há avaliações

- Norme Deviz Instalatii Incalzire Gaze Indicator IDocumento310 páginasNorme Deviz Instalatii Incalzire Gaze Indicator Icereal killerlAinda não há avaliações

- Lockout Tagout TrainingDocumento26 páginasLockout Tagout TrainingAceel Fitch100% (2)

- Symphony LTD Launches Mobile Commercial Air Cooler Range - 'MobiCool' (Company Update)Documento3 páginasSymphony LTD Launches Mobile Commercial Air Cooler Range - 'MobiCool' (Company Update)Shyam SunderAinda não há avaliações

- Industrys Fast Mover AdvantageDocumento8 páginasIndustrys Fast Mover AdvantageRavi BabuAinda não há avaliações

- Magnetic Field Management Considerations For Underground Cable Duct Bank 01668529Documento7 páginasMagnetic Field Management Considerations For Underground Cable Duct Bank 01668529Gilberto MejíaAinda não há avaliações

- Energy ManagementDocumento47 páginasEnergy ManagementUnstraightable FingerAinda não há avaliações