Escolar Documentos

Profissional Documentos

Cultura Documentos

Heat Pipe

Enviado por

Marco BernardesDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Heat Pipe

Enviado por

Marco BernardesDireitos autorais:

Formatos disponíveis

Heat pipe

Heat pipe

A heat pipe or heat pin is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to efficiently manage the transfer of heat between two solid interfaces. The idea of heat pipes was first suggested by R.S.Gaugler in 1942. However, it was not until 1962, when G.M.Grover invented it, that its remarkable properties were appreciated and serious development began. At the hot interface within a heat pipe, which is typically at a very low pressure, a liquid in contact with a thermally conductive solid surface turns into a vapor A laptop heat pipe system by absorbing heat from that surface. The vapor then travels along the heat pipe to the cold interface, condenses back into a liquid, releasing the latent heat. The liquid then returns to the hot interface through either capillary action or gravity action where it evaporates once more and repeats the cycle. In addition, the internal pressure of the heat pipe can be set or adjusted to facilitate the phase change depending on the demands of the working conditions of the thermally managed system.

Structure, design and construction

A typical heat pipe consists of a sealed pipe or tube made of a material with high thermal conductivity such as copper (see: Copper in heat exchangers) or aluminium at both hot and cold ends. A vacuum pump is used to remove all air from the empty heat pipe, and then the pipe is filled with a fraction of a percent by volume of working fluid (or coolant) chosen to match the operating temperature. Alternatively, the pipe is heated until the fluid boils, and sealed while hot. Examples of such fluids include water, ethanol, acetone, sodium, or mercury. Due to the partial vacuum that is near or below the vapor pressure of the fluid, Diagram showing components and mechanism for a heat pipe some of the fluid will be in the liquid phase and some containing a wick will be in the gas phase. The use of a vacuum eliminates the need for the working gas to diffuse through any other gas and so the bulk transfer of the vapor to the cold end of

Heat pipe

the heat pipe is at the speed of the moving molecules. In this sense, the only practical limit to the rate of heat transfer is the speed with which the gas can be condensed to a liquid at the cold end.[2] Inside the pipe's walls, an optional wick structure exerts a capillary pressure on the liquid phase of the working fluid. This is typically a sintered metal powder or a series of grooves parallel to the pipe axis, but it may be any material capable of exerting capillary pressure on the condensed liquid to wick it back to the heated end. The heat pipe may not need a wick structure if gravity or some other source of acceleration is sufficient to overcome surface tension and cause the condensed liquid to flow back to the heated end.[citation needed] A heat pipe is not a thermosiphon, because there is no siphon. Thermosiphons transfer heat by single-phase convection. (See also: Perkins tube, after Jacob Perkins.) Heat pipes contain no mechanical moving parts and typically require no maintenance, though non-condensing gases (that diffuse through the pipe's walls, result from breakdown of the working fluid, or exist as impurities in the materials) may eventually reduce the pipe's effectiveness at transferring heat. This is significant when the working fluid's vapour pressure is low.[citation needed] The materials chosen depend on the temperature conditions in which the heat pipe must operate, with coolants ranging from liquid helium for extremely low temperature applications (24 K) to mercury (523923 K) & sodium (8731473 K) and even indium

This 100mm by 100mm by 10mm high thin flat heat pipe (heat spreader) animation, was created using high resolution CFD analysis, and shows temperature contoured flow [1] trajectories, predicted using a CFD analysis package, courtesy of NCI .

Cross section of a heat pipe for cooling the CPU of a laptop computer. Ruler scale is in millimeters.

Cut-away view of a 500 m thick flat heat pipe, with a thin planar capillary (aqua colored)

Heat pipe

(20003000 K) for extremely high temperatures. The vast majority of heat pipes for low temperature applications use some combination of ammonia (213373 K), alcohol (methanol (283403 K) or ethanol (273403 K)) or water (303473 K) as working fluid. Water, for instance, at low pressure will boil at just above 273 K (0 degrees Celsius) and so can start to effectively transfer latent heat at this low temperature. The advantage of heat pipes over many other heat-dissipation mechanisms is their great efficiency in transferring heat. They are fundamentally better at heat conduction over a distance than an equivalent Thin flat heat pipe (heat spreader) with remote heat sink and fan cross-section of solid copper (a heat sink alone, though simpler in design and construction, does not take advantage of the principle of matter phase transition). Some heat pipes have demonstrated a heat flux of more than 230 MW/m.[3] Active control of heat flux can be effected by adding a variable volume liquid reservoir to the evaporator section. Variable conductance heat pipes employ a large reservoir of inert immiscible gas attached to the condensing section. Varying the gas reservoir pressure changes the volume of gas charged to the condenser which in turn limits the area available for vapor condensation. Thus a wider range of heat fluxes and temperature gradients can be accommodated with a single design. A modified heat pipe with a reservoir having no capillary connection to the heat pipe wick at the evaporator end can also be used as a thermal diode. This heat pipe will transfer heat in one direction, acting as an insulator in the other.[citation needed]

Vapor Chamber or Flat heat pipes

Thin planar heat pipes (heat spreaders) have the same primary components as tubular heat pipes. These components are a hermetically sealed hollow vessel, a working fluid, and a closed-loop capillary recirculation system. Compared to a one-dimensional tubular heat pipe, the width of a two-dimensional heat pipe allows an adequate cross section for heat flow even with a very thin device. These thin planar heat pipes are finding their way into height sensitive applications, such as notebook computers, and surface mount circuit board cores. It is possible to produce flat heat pipes as thin as 0.5mm (thinner than a credit card).[citation needed]

Loop heat pipe

A loop heat pipe (LHP) is a two-phase heat transfer device that uses capillary action to remove heat from a source and passively move it to a condenser or radiator. LHPs are similar to heat pipes but have the advantage of being able to provide reliable operation over long distance and the ability to operate against gravity. They can transport a large heat load over a long distance with a small temperature difference.[][4] Different designs of LHPs ranging from powerful, large size LHPs to miniature LHPs (micro loop heat pipe) have been developed and successfully employed in a wide sphere of applications both ground based as well as space applications.

Heat pipe

Heat transfer

Heat pipes employ evaporative cooling to transfer thermal energy from one point to another by the evaporation and condensation of a working fluid or coolant. Heat pipes rely on a temperature difference between the ends of the pipe, and cannot lower temperatures at either end beyond the ambient temperature (hence they tend to equalise the temperature within the pipe). When one end of the heat pipe is heated the working fluid inside the pipe at that end evaporates and increases the vapour pressure inside the cavity of the heat pipe. The latent heat of evaporation absorbed by the vaporisation of the working fluid reduces the temperature at the hot end of the pipe. The vapour pressure over the hot liquid working fluid at the hot end of the pipe is higher than the equilibrium vapour pressure over A heat sink (aluminium) with heat pipe (copper) condensing working fluid at the cooler end of the pipe, and this pressure difference drives a rapid mass transfer to the condensing end where the excess vapour condenses, releases its latent heat, and warms the cool end of the pipe. Non-condensing gases (caused by contamination for instance) in the vapour impede the gas flow and reduce the effectiveness of the heat pipe, particularly at low temperatures, where vapour pressures are low. The speed of molecules in a gas is approximately the speed of sound, and in the absence of noncondensing gases (i.e., if there is only a gas phase present) this is the upper limit to the velocity with which they could travel in the heat pipe. In practice, the speed of the vapour through the heat pipe is limited by the rate of condensation at the cold end and far lower than the molecular speed.[citation needed] The condensed working fluid then flows back to the hot end of the pipe. In the case of vertically-oriented heat pipes the fluid may be moved by the force of gravity. In the case of heat pipes containing wicks, the fluid is returned by capillary action. When making heat pipes, there is no need to create a vacuum in the pipe. One simply boils the working fluid in the heat pipe until the resulting vapour has purged the non condensing gases from the pipe and then seals the end. An interesting property of heat pipes is the temperature over which they are effective. Initially, it might be suspected that a water charged heat pipe would only work when the hot end reached the boiling point (100 C) and steam was transferred to the cold end. However, the boiling point of water is dependent on absolute pressure inside the pipe. In an evacuated pipe, water will boil just slightly above its melting point (0 C). Thus the heat pipe can operate at hot-end temperatures as low as just slightly warmer than the melting point of the working fluid. Similarly, a heat pipe with water as a working fluid can work well above the boiling point (100 C), if the cold end is low enough in temperature to condense the fluid.[citation needed] The main reason for the effectiveness of heat pipes is the evaporation and condensation of the working fluid. The heat of vaporization greatly exceeds the sensible heat capacity. Using water as an example, the energy needed to evaporate one gram of water is 540 times the amount of energy needed to raise the temperature of that same one gram of water by 1 C. Almost all of that energy is rapidly transferred to the "cold" end when the fluid condenses there, making a very effective heat transfer system with no moving parts.[citation needed]

Heat pipe

Origins and research in the United States

The general principle of heat pipes using gravity (commonly classified as two phase thermosiphons) dates back to the steam age. The modern concept for a capillary driven heat pipe was first suggested by R.S. Gaugler of General Motors in 1942 who patented the idea.[5] The benefits of employing capillary action were independently developed and first demonstrated by George Grover at Los Alamos National Laboratory in 1963 and subsequently published in the Journal of Applied Physics in 1964.[6] Grover noted in his notebook:[7] "Heat transfer via capillary movement of fluids. The "pumping" action of surface tension forces may be sufficient to move liquids from a cold temperature zone to a high temperature zone (with subsequent return in vapor form using as the driving force, the difference in vapor pressure at the two temperatures) to be of interest in transferring heat from the hot to the cold zone. Such a closed system, requiring no external pumps, may be of particular interest in space reactors in moving heat from the reactor core to a radiating system. In the absence of gravity, the forces must only be such as to overcome the capillary and the drag of the returning vapor through its channels." Between 1964 and 1966, RCA was the first corporation to undertake research and development of heat pipes for commercial applications (though their work was mostly funded by the US government). During the late 1960s NASA played a large role in heat pipe development by funding a significant amount of research on their applications and reliability in space flight following from Grover's suggestion. NASAs attraction to heat pipe cooling systems was understandable given their low weight, high heat flux, and zero power draw. Their primary interest however was based on the fact that the system wouldnt be adversely affected by operating in a zero gravity environment. The first application of heat pipes in the space program was in thermal equilibration of satellite transponders. As satellites orbit, one side is exposed to the direct radiation of the sun while the opposite side is completely dark and exposed to the deep cold of outer space. This causes severe discrepancies in the temperature (and thus reliability and accuracy) of the transponders. The heat pipe cooling system designed for this purpose managed the high heat fluxes and demonstrated flawless operation with and without the influence of gravity. The developed cooling system was the first description and usage of variable conductance heat pipes to actively regulate heat flow or evaporator temperature.

Corporate R&D

Publications in 1967 and 1968 by Feldman, Eastman, & Katzoff first discussed applications of heat pipes to areas outside of government concern and that did not fall under the high temperature classification such as: air conditioning, engine cooling, and electronics cooling. These papers also made the first mentions of flexible, arterial, and flat plate heat pipes. 1969 publications introduced the concepts of the rotational heat pipe with its applications to turbine blade cooling and the first discussions of heat pipe applications to cryogenic processes. Starting in the 1980s Sony began incorporating heat pipes into the cooling schemes for some of its commercial electronic products in place of both forced convection and passive finned heat sinks. Initially they were used in tuners & amplifiers, soon spreading to other high heat flux electronics applications. During the late 1990s increasingly hot microcomputer CPUs spurred a threefold increase in the number of U.S. heat pipe patent applications. As heat pipes transferred from a specialized industrial heat transfer component to a consumer commodity most development and production moved from the U.S. to Asia. Modern CPU heat pipes are typically made from copper and use water as the working fluid.[8]

Heat pipe

Applications

Grover and his colleagues were working on cooling systems for nuclear power cells for space craft, where extreme thermal conditions are found. Heat pipes have since been used extensively in spacecraft as a means for managing internal temperature conditions. Heat pipes are extensively used in many modern computer systems, where increased power requirements and subsequent increases in heat emission have resulted in greater demands on cooling systems. Heat pipes are typically used to move heat away from components such as CPUs and GPUs to heat sinks where thermal energy may be dissipated into the environment.[citation needed]

Solar Thermal

Heat pipes are also being widely used in solar thermal water heating applications in combination with evacuated tube solar collector arrays. In these applications, distilled water is commonly used as the heat transfer fluid inside a sealed length of copper tubing that is located within an evacuated glass tube and oriented towards the sun.[citation needed]

Alaska pipeline support legs cooled by heat pipes to keep permafrost frozen.

In solar thermal water heating applications, an individual absorber tube of an evacuated tube collector can deliver up to 40% more efficiency when compared to more traditional "flat plate" solar water collectors. This is largely due to the vacuum that exists within the tube which slows down convective and conductive heat loss. Relative efficiencies of the evacuated tube system are reduced however, when compared to "flat plate" collectors because "flat plate" collectors have a larger aperture size and can absorb more solar energy per unit area. This means that while an individual evacuated tube has better insulation (lower conductive and convective losses) due to the vacuum created inside the tube, an array of tubes found in a completed solar assembly absorbs less energy per unit area due to there being less absorber surface area pointed toward the sun because of the rounded design of an evacuated tube collector. Therefore, real world efficiencies of both designs are about the same. Evacuated tube collectors reduce the need for anti-freeze additives to be added as the vacuum helps slow heat loss. However, under prolonged exposure to freezing temperatures the heat transfer fluid can still freeze and precautions must be taken in the design to ensure that the freezing liquid does not damage the evacuated tube. Properly designed solar thermal water heaters can be frost protected down to more than -3 C with special additives and are being used in Antarctica to heat water.[citation needed]

Permafrost cooling

Building on permafrost is difficult because heat from the structure can thaw the permafrost. To avoid the risk of destabilization, heat pipes are used in some cases. For example, on the Trans-Alaska Pipeline System residual ground heat remaining in the oil, as well as that produced by friction and turbulence in the moving oil could conduct down the pipe's support legs and melt the permafrost on which the supports are anchored. This would cause the pipeline to sink and possibly sustain damage. To prevent this each vertical support member has been mounted with 4 vertical heat pipes.[9] Heat pipes are also used to dissipate heat alongside parts of the QinghaiTibet Railway. The embankment and track absorb the Sun's heat. Vertical heat pipes either side of the formation prevent that heat spreading any further into the surrounding ground.

Heat pipe

Cooking

The first commercial heat pipe product was the "Thermal Magic Cooking Pin", developed by Energy Conversion Systems, Inc., and first sold in 1966. [10] The cooking pins used water as the working fluid. The envelope was stainless steel, with an inner copper layer for compatibility. During operation, the heat pipe is poked through the roast. One end of the pipe extends into the oven where it draws heat to the middle of the roast. The high effective conductivity of the heat pipe cut the cooking time for large pieces of meat to one-half of the usual period. [11] The principle has also been applied to camping stoves, transferring a large volume of heat at low temperature to allow baking of goods in camping-type situations, as well as cooking other dishes. An example of this is the Bakepacker system.[12]

Ventilation heat recovery

In heating, ventilation and air-conditioning systems, HVAC, heat pipes are positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the heat energy. The device consists of a battery of multi-row finned heat pipe tubes located within both the supply and exhaust air streams. Within the exhaust air side of the heat pipe, the refrigerant evaporates, taking its heat from the extract air. The refrigerant vapour moves towards the cooler end of the tube, within the supply air side of the device, where it condenses and gives up its heat. The condensed refrigerant returns by a combination of gravity and capillary action in the wick. Thus heat is transferred from the exhaust air stream through the tube wall to the refrigerant, and then from the refrigerant through the tube wall to the supply air stream. Because of the characteristics of the device, better efficiencies are obtained when the unit is positioned upright with the supply air side mounted over the exhaust air side, this allows the liquid refrigerant to flow quickly under gravity back to the evaporator. Generally, gross heat transfer efficiencies of up to 75% are claimed by manufacturers.[citation

needed]

Nuclear Reactor Cooling

Since the early 1990s, numerous nuclear reactor power systems have been proposed using heat pipes for transporting heat between the reactor core and power conversion system.[13] The first nuclear reactor to produce electricity using heat pipes, Demonstration Using Flattop Fission was first operated September 13, 2012. [14]

Limitations

Heat pipes must be tuned to particular cooling conditions. The choice of pipe material, size and coolant all have an effect on the optimal temperatures in which heat pipes work. When heated above a certain temperature, all of the working fluid in the heat pipe will vaporize and the condensation process will cease to occur; in such conditions, the heat pipe's thermal conductivity is effectively reduced to the heat conduction properties of its solid metal casing alone. As most heat pipes are constructed of copper (a metal with high heat conductivity), an overheated heatpipe will generally continue to conduct heat at around 1/80 of the original conductivity. In addition, below a certain temperature, the working fluid will not undergo phase change, and the thermal conductivity will be reduced to that of the solid metal casing. One of the key criteria for the selection of a working fluid is the desired operational temperature range of the application. The lower temperature limit typically occurs a few degrees above the freezing point of the working fluid. Most manufacturers cannot make a traditional heat pipe smaller than 3mm in diameter due to material limitations (though 1.6mm thin sheets can be fabricated). Experiments have been conducted with micro heat pipes, which use piping with sharp edges, such as triangular or rhombus-like tubing. In these cases, the sharp edges transfer the fluid

Heat pipe through capillary action, and no wick is necessary.[citation needed]

References

[1] http:/ / www. novelconceptsinc. com/ [3] Jim Danneskiold, Los Alamos-developed heat pipes ease space flight (http:/ / www. lanl. gov/ news/ releases/ archive/ 00-064. shtml). Los Alamos News Release, April 26, 2000. [7] Heat Pipe research at LANL (http:/ / www. lanl. gov/ orgs/ esa/ epe/ Heat_Pipe_Site/ ancient. shtml) [9] http:/ / www. alyeska-pipe. com/ InTheNews/ MonthlyNews/ 2004/ December/ dec2004_featurestory. asp [10] Midwest Research Institute, Heat Pipes (http:/ / ntrs. nasa. gov/ archive/ nasa/ casi. ntrs. nasa. gov/ 19750007248_1975007248. pdf), NASA Report NASA CR-2508, pg. 19, Jan 1, 1975.

External links

Frontiers in Heat Pipes (FHP) - An International Journal (http://www.thermalfluidscentral.org/e-journals/ index.php/Heat_Pipes) House_N Research (mit.edu) (http://architecture.mit.edu/house_n/web/resources/tutorials/House_N Tutorial Heat Pipes.htm) What is a Heat Pipe? (http://www.cheresources.com/htpipes.shtml) Heat pipe selection guide (pdf) (http://www.enertron-inc.com/enertron-resources/PDF/ How-to-select-a-heat-pipe.pdf)

Article Sources and Contributors

Article Sources and Contributors

Heat pipe Source: http://en.wikipedia.org/w/index.php?oldid=543086472 Contributors: 7severn7, Alphapage, Andrea.gf, Apoc2400, Arielco, Arnero, Audriusa, Bdentremont, Beefman, BenFrantzDale, BillAnderson71, Biscuittin, Bobblewik, Bragit, Buster2058, Cacycle, CanOfWorms, Cassnat, Charles Gaudette, Charles Matthews, ChrisJMoor, Conicer, Dan100, DeathMetalParrot, Delldot, Dr. Morbius, Drpixie, Duff-95SHO, Editore99, Enviromet, Everyking, Evil genius, Falcon8765, Firsfron, Foober, Fromeout11, Fuhghettaboutit, Fuzzform, Gameyer4, Gerriegijsen, Glenn, GliderMaven, Goldom, Gracefool, Grafen, Guy Macon, Hankwang, Hds619, Heatlord, Husond, Hustvedt, Iridescent, Isofilm, Jaganath, Jdpipe, Jesse Viviano, Jesuitson, Jlascar, JonHarder, Josh Parris, KDS4444, Kbrose, Ken g6, Khalid hassani, Kristoferb, Lepreshaun, Lexor, Lightmouse, LordZaylor, LorenzoB, Luce nordica, Maniago, Matt Smith4, Mikiemike, Mindmatrix, Mitch Ames, Mmeijeri, Moncrief, Newuy, NickFr, Old Guard, Omegatron, Other-thing, Pabouk, Pahazzard, Pce3, Pihmpdaddi, Psychofox, Quadell, RexNL, Rholton, Rich Farmbrough, Rjstott, Rjwilmsi, Roidroid, Roo72, Saga City, Sam Hocevar, Shaddack, Sharpinnovations, Sloggerbum, Snori, Sourpearpirate, Spinningspark, Srleffler, Ssd, Stephan Leeds, Sumone10154, Supak barua, Swaaye, TERdON, Theodore.cackowski, Tsemii, Twilight, Vanished user 5zariu3jisj0j4irj, Vertium, Whaa?, Wheels998, Wolfkeeper, Xaosflux, Yyash.vijay, ZeroOne, Zootalures, Zzedar, 166 anonymous edits

Image Sources, Licenses and Contributors

File:Laptop Heat Pipe.JPG Source: http://en.wikipedia.org/w/index.php?title=File:Laptop_Heat_Pipe.JPG License: Creative Commons Attribution-Sharealike 3.0 Contributors: Kristoferb (talk). Original uploader was Kristoferb at en.wikipedia File:Heat Pipe Mechanism.png Source: http://en.wikipedia.org/w/index.php?title=File:Heat_Pipe_Mechanism.png License: Creative Commons Attribution-Sharealike 2.5 Contributors: Original uploader was Zootalures at en.wikipedia Image:CFD IsoSkin Heat Pipe.gif Source: http://en.wikipedia.org/w/index.php?title=File:CFD_IsoSkin_Heat_Pipe.gif License: GNU Free Documentation License Contributors: Heatlord File:Laptop CPU Heat Pipe Cross Section.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Laptop_CPU_Heat_Pipe_Cross_Section.jpg License: Creative Commons Zero Contributors: User:Epbernard File:IsoSkin.png Source: http://en.wikipedia.org/w/index.php?title=File:IsoSkin.png License: Public Domain Contributors: User:Isofilm File:IsoSkin2.png Source: http://en.wikipedia.org/w/index.php?title=File:IsoSkin2.png License: Public Domain Contributors: User:Isofilm File:Heatsink with heat pipes.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Heatsink_with_heat_pipes.jpg License: Creative Commons Attribution-Sharealike 3.0 Contributors: Hustvedt File:Alaska Pipeline Closeup Underneath.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Alaska_Pipeline_Closeup_Underneath.jpg License: GNU Free Documentation License Contributors: Photo by and (c)2005 Derek Ramsey (Ram-Man)

License

Creative Commons Attribution-Share Alike 3.0 Unported //creativecommons.org/licenses/by-sa/3.0/

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Produced Water Pipeline: Trends EconomicsDocumento68 páginasProduced Water Pipeline: Trends EconomicsMarco BernardesAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Digital Weekly: EditionDocumento18 páginasDigital Weekly: EditionMarco BernardesAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Proceedings of Spie: Invited Paper Overview of Flow Dynamics in Gas-Assisted Laser CuttingDocumento9 páginasProceedings of Spie: Invited Paper Overview of Flow Dynamics in Gas-Assisted Laser CuttingMarco BernardesAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- New-Tsioli2011 Article AnExperimentalStudyOnTheVorticDocumento16 páginasNew-Tsioli2011 Article AnExperimentalStudyOnTheVorticMarco BernardesAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Digital Weekly: EditionDocumento18 páginasDigital Weekly: EditionMarco BernardesAinda não há avaliações

- Numerical Analysis of A Coaxial Impingement Jet and Application For A Laser Welding of AZ91 Magnesium Alloy With Shielding GasDocumento5 páginasNumerical Analysis of A Coaxial Impingement Jet and Application For A Laser Welding of AZ91 Magnesium Alloy With Shielding GasSamir BoseAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Ogjournal20220926 DLDocumento19 páginasOgjournal20220926 DLMarco BernardesAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Digital Weekly: EditionDocumento18 páginasDigital Weekly: EditionMarco BernardesAinda não há avaliações

- Digital Weekly: EditionDocumento19 páginasDigital Weekly: EditionMarco BernardesAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- Characteristics of Spiral Flow in Coanda NozzlesDocumento145 páginasCharacteristics of Spiral Flow in Coanda NozzlesMarco BernardesAinda não há avaliações

- An Experimental Study On The Vortical Structures and Behaviour of Jets Issuing From Inclined Coaxial NozzlesDocumento32 páginasAn Experimental Study On The Vortical Structures and Behaviour of Jets Issuing From Inclined Coaxial NozzlesMarco BernardesAinda não há avaliações

- A.C.H.E.O.N.: Aerial Coanda High Efficiency Orienting-Jet NozzleDocumento12 páginasA.C.H.E.O.N.: Aerial Coanda High Efficiency Orienting-Jet NozzleMarco BernardesAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Measurement of Forced Surface Convection in Directed Energy Deposition Additive ManufacturingDocumento14 páginasMeasurement of Forced Surface Convection in Directed Energy Deposition Additive ManufacturingMarco BernardesAinda não há avaliações

- Applications of The Coanda Effect OcrDocumento9 páginasApplications of The Coanda Effect OcrMarco BernardesAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- mhtl05 11Documento26 páginasmhtl05 11Marco BernardesAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- He Leadeth MeDocumento10 páginasHe Leadeth MeMarco BernardesAinda não há avaliações

- mhtl05 11Documento26 páginasmhtl05 11Marco BernardesAinda não há avaliações

- Effects of area-ratio on flow characteristics of inclined coaxial jetsDocumento25 páginasEffects of area-ratio on flow characteristics of inclined coaxial jetsMarco BernardesAinda não há avaliações

- mhtl05 11Documento26 páginasmhtl05 11Marco BernardesAinda não há avaliações

- Reverse Thermal Cloak Enables Local HeatingDocumento6 páginasReverse Thermal Cloak Enables Local HeatingMarco BernardesAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- CH 4Documento56 páginasCH 4Marco BernardesAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Transport PDFDocumento226 páginasTransport PDFMarco Bernardes100% (1)

- PIAB General Catalogue 2012 enDocumento531 páginasPIAB General Catalogue 2012 enMarco BernardesAinda não há avaliações

- A Concept of Heat Dissipation Coefficient For Thermal Cloak Based On EntropyDocumento8 páginasA Concept of Heat Dissipation Coefficient For Thermal Cloak Based On EntropyMarco BernardesAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- 8403 - PDF - CH07 - Cópia PDFDocumento28 páginas8403 - PDF - CH07 - Cópia PDFRichard De Medeiros CastroAinda não há avaliações

- BoundaryConditions Of41Documento133 páginasBoundaryConditions Of41Marco Bernardes100% (1)

- A Two-Phase Study Evaluating The Relationship Between Thimerosal-Containing Vaccine Administration and The Risk For An Autism Spectrum Disorder Diagnosis in The United States PDFDocumento12 páginasA Two-Phase Study Evaluating The Relationship Between Thimerosal-Containing Vaccine Administration and The Risk For An Autism Spectrum Disorder Diagnosis in The United States PDFMarco BernardesAinda não há avaliações

- Design and CFD Analysis of An Axisymmetric Supersonic Plug Nozzle For An Air-Air EjectorDocumento10 páginasDesign and CFD Analysis of An Axisymmetric Supersonic Plug Nozzle For An Air-Air EjectorMarco BernardesAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- 02 WholeDocumento268 páginas02 WholeMarco BernardesAinda não há avaliações

- 02 WholeDocumento268 páginas02 WholeMarco BernardesAinda não há avaliações

- Alok ResumeDocumento3 páginasAlok Resumealok choudharyAinda não há avaliações

- Cell City ProjectDocumento8 páginasCell City ProjectDaisy beAinda não há avaliações

- Montgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)Documento228 páginasMontgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)rebolavAinda não há avaliações

- Base para Detectores de Humo y Temperatura KIDDE KI-SBDocumento2 páginasBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaAinda não há avaliações

- Test Report OD63mm PN12.5 PE100Documento6 páginasTest Report OD63mm PN12.5 PE100Im ChinithAinda não há avaliações

- RHS NCRPO COVID FormDocumento1 páginaRHS NCRPO COVID Formspd pgsAinda não há avaliações

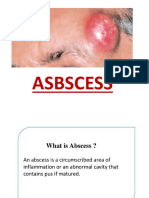

- ABSCESSDocumento35 páginasABSCESSlax prajapatiAinda não há avaliações

- Grade Eleven Test 2019 Social StudiesDocumento6 páginasGrade Eleven Test 2019 Social StudiesClair VickerieAinda não há avaliações

- PB PWR e R1 PDFDocumento8 páginasPB PWR e R1 PDFnallinikanth sivalankaAinda não há avaliações

- Scaffolding Control & MeasuresDocumento3 páginasScaffolding Control & Measuresviswamanoj100% (1)

- Junayed - 19 39800 1Documento11 páginasJunayed - 19 39800 1gurujeeAinda não há avaliações

- Female Reproductive System Histology IDocumento5 páginasFemale Reproductive System Histology ISolomon Seth SallforsAinda não há avaliações

- Wastewater Treatment Plant Design PDFDocumento68 páginasWastewater Treatment Plant Design PDFmostafa1alaahobaAinda não há avaliações

- wch13 01 Rms 20230817Documento24 páginaswch13 01 Rms 20230817halcieeschAinda não há avaliações

- 2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and ChildDocumento3 páginas2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and Childclint xavier odangoAinda não há avaliações

- Auditor General Insurance Regulation Dec 2011Documento23 páginasAuditor General Insurance Regulation Dec 2011Omar Ha-RedeyeAinda não há avaliações

- Urban Drainage Modelling Guide IUD - 1Documento196 páginasUrban Drainage Modelling Guide IUD - 1Helmer Edgardo Monroy GonzálezAinda não há avaliações

- To The OneDocumento8 páginasTo The OnePizzaCowAinda não há avaliações

- Consumer Behaviour: Group ProjectDocumento5 páginasConsumer Behaviour: Group ProjectAanchal MahajanAinda não há avaliações

- New930e-4se Ceam031503 930e4se Omm A31937 Up PDFDocumento273 páginasNew930e-4se Ceam031503 930e4se Omm A31937 Up PDFSergelen SakhyabazarAinda não há avaliações

- Heat Exchanger Sodium SilicateDocumento2 páginasHeat Exchanger Sodium SilicateChristopher BrownAinda não há avaliações

- Clinical Case Report No 2Documento11 páginasClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- Sub Erna RekhaDocumento2 páginasSub Erna Rekhasurabhi mandalAinda não há avaliações

- FileDocumento284 páginasFileJesse GarciaAinda não há avaliações

- Marketing-Aspect 4Documento10 páginasMarketing-Aspect 4Leiren RingorAinda não há avaliações

- Lease Practice QuestionsDocumento4 páginasLease Practice QuestionsAbdul SamiAinda não há avaliações

- December - Cost of Goods Sold (Journal)Documento14 páginasDecember - Cost of Goods Sold (Journal)kuro hanabusaAinda não há avaliações

- Live Performance Award Ma000081 Pay GuideDocumento48 páginasLive Performance Award Ma000081 Pay GuideDan LijndersAinda não há avaliações

- OilDocumento8 páginasOilwuacbekirAinda não há avaliações

- Rapid Cycling in Bipolar DisorderDocumento1 páginaRapid Cycling in Bipolar Disorderdo leeAinda não há avaliações

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNo EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (3)

- Coating and Drying Defects: Troubleshooting Operating ProblemsNo EverandCoating and Drying Defects: Troubleshooting Operating ProblemsNota: 5 de 5 estrelas5/5 (1)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceNo EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceAinda não há avaliações

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldNo EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldNota: 4 de 5 estrelas4/5 (289)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeNo EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeNota: 5 de 5 estrelas5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNo EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNota: 4 de 5 estrelas4/5 (146)