Escolar Documentos

Profissional Documentos

Cultura Documentos

6M HO Loop

Enviado por

นายโจ รักกาแฟDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

6M HO Loop

Enviado por

นายโจ รักกาแฟDireitos autorais:

Formatos disponíveis

M2 Antenna Systems, Inc.

Model No: 6M HO LOOP

SPECIFICATIONS:

Model ........................................ 6M HO LOOP Frequency Range ...................... 50 To 50.3 MHz Gain, Typical @ 11 ft. ................ 6.3 dBi @ 25 deg. Gain, 2 Stack @ 40 & 52 ft. ....... 10.3 dBi @ 6 deg. Polarity ...................................... Horizontal Impedance ................................. 50 Ohms, Unbalanced Power Handling. ........................ 800W, 1.5 kW stacked Feed Connector ......................... SO-239 Mounting .................................... 3/8-24 or 1-1/4-2 Vehicle Mounting Height ............ 30 or more Stacking Distance ..................... 9ft to 12ft Maximum Element Length ......... 29-1/2 Wind Area .................................. 0.1 sq ft. Weight ........................................ 2 lbs.

*Subtract 2.14 from dBi for dBd

FEATURES:

Our 6M HO Loop is the result of a continued development of reduced size, omni-directional horizontally polarized loop-style antennas. This new design is easy to match in any situation. Performance is better than anything in its class and its design makes it immune to nearly all weather conditions. Power handling is often a problem with small loops but this design can handle 800 watts with ease and a stacked pair can easily handle 1.5 kW. The patterns contained in the manual will give you a good idea of how well the 6M HO Loop will perform in your system. As with all horizontally polarized antennas, performance is usually tied to height above ground but even at ten feet the HO Loop yields an amazing 5.9 dBi at an angle of 27 degrees. Mounted on a vehicle at eleven feet above ground, the gain jumps to 6.3 dBi at 25 degrees. Stacked for base or portable use, twelve foot spacing is optimum. Note that the gain jumps over 3 dB for a stacked pair of these unique antennas, yielding as much as 10.3 dBi! Physically the HO Loop is 29.5 inches square with a wind area of just 0.1 square foot. The 3/8 diameter tubing keeps it light but plenty rugged for mobile operation. Our precision machined aluminum feed block is sealed and potted with silicon gel for extreme reliability and low loss. The feed block slides on the tubes for frequency adjustment and the shorting bar adjusts for a perfect match into 50 ohm feedline. Two HO Loops can be stacked using a coaxial power divider. Optional items include our line of lightweight aluminum mobile masts and our Big-Foot heavy duty magnetic base. We also offer coaxial power dividers and phasing cables for stacking HO Loops.

M2 Antenna Systems, Inc. 4402 N. Selland Ave. Fresno, CA 93722 Tel: (559) 432-8873 Fax: (559) 432-3059 Web: www.m2inc.com

2012 M2 Antenna Systems Incoporated

08/29/12 Rev.03

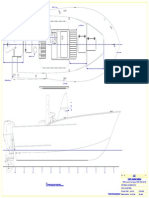

6M HO LOOP ASSEMBLY OVERVIEW

6M HO LOOP ASSEMBLY MANUAL

1

1. Slide on (1) support clamp and center it at 2-1/4 on to the white center insulator. Install a 1/4-20 X 1/4 set screw into support clamp block and tighten gently.

1. Insert the HO Loop tubes into the center insulator. Install screws and locknuts and tighten.

6M HO LOOP ASSEMBLY MANUAL

3

1. Install the 1/4-20 X 1/4 set screws in the feed block assembly and slide onto the tubes. Carefully align the HO Loop halves and tighten the set screws gently. 2. Install the 1/4-20 X 1/4 set screws in the shorting bar. Slide shorting bar on to HO Loop tubes and tighten the screws gently.

4

1. Position feed block assembly and shorting bar to the starting dimensions. Refer to the tuning detail page for more information.

6M HO LOOP ASSEMBLY DETAILS

5

1. Attach the second support clamp on one end of the 3/8 support tube. Install 6-32 screw, locknut and the 1/4-20 X 1 bolt on the support clamp block.

1. Connect the other end of the support tube to the other support clamp block with the 6-32 screw and locknut . 2. After final tuning attach the lower support clamp to the mast, adjust the loop to level position and tighten all hardware.

6M HO LOOP BASE MOUNTING DETAIL

6M HO LOOP TUNING DETAIL

For base station installations, objects such as towers, large diameter masts, trees, roofs or buildings near the HO Loop can cause some detuning. Be aware that some tuning of the HO Loop or HO Loops in their final position or under similar conditions may be necessary. For mobile installations, tune the HO Loop in its final position on your vehicle. When tuning multiple HO Loops in a stacked array, tune each HO Loop individually and recheck them in their final positions. After individual tuning and testing, add the phasing lines and power dividers and retest the complete system one final time, making fine adjustments as needed. Note: Be sure to reverse one feed block to account for the 180 phase shift in the 6M HO Loop 2 Port Power Divider. See Mounting and Stacking Options for more information. BASIC TUNING Be sure the feed block assembly is set to the starting dimension in figure 4. This dimension controls the FREQUENCY. Likewise, ensure the shorting bar is set to the starting dimension provided. The shorting bar position controls feed point IMPEDANCE, and also has a small effect on frequency. Tune the frequency first by adjusting the feed block assembly. Increasing the dimension will lower the HO Loop in frequency; decreasing it will raise the frequency. Once the HO Loop is at the desired frequency, make small adjustments to the shorting bar for best match. After tuning is complete attach the support tube as shown and tighten all hardware. REMEMBER: HORIZONTALLY POLARIZED ANTENNAS ARE AFFECTED BY THE GROUND SO THE HIGHER YOU GET YOUR HO LOOP, THE BETTER. The ground can be your friend as well, providing as much as 6 dB additional ground gain at some angles above the horizon. That angle is defined by the frequency and height above ground. At one wavelength (236 at 6 meters), the typical angle of maximum radiation will be about 14 degrees. At two wavelengths, the angle is 7 degrees and at four wavelengths the angle is 3.5 degrees. Net gain improves with height because the pattern hits the ground at a shallower angle, giving up less energy to the ground. In most mobile installations 10 to 11 feet is about the practical limit for most driving conditions. The HO Loop can be tuned to work as low as 18" above a vehicle roof with some compromise in performance. However, you will find more people to talk to and more DX if you can get the HO Loop up to at least the 10 foot level. POWER CONSIDERATIONS An HO Loop can handle up to 800 watts and a stacked pair can handle up 1.5 kW. Users often report long distance QSOs using HO Loops and modest power. We hope you enjoy your new HO Loop and please keep an ear out for those rare but wonderful 6 meter openings to other parts of the world!

M2 ANTENNA SYSTEMS, INC.

4402 N. SELLAND AVE. FRESNO, CA 93722 (559) 432-8873 FAX: 432-3059 www.m2inc.com Email: sales@m2inc.com

MAST MOUNTING OPTIONS

36 MOBILE MAST (SOLD SEPARATELY)

CUSTOMER SUPPLIED MAST (1-1/4 - 2 DIA.)

SINGLE 6M HO LOOP PERFORMANCE HEIGHT ABOVE GROUND 8 FT MOBILE 12 FT MOBILE 30 FT BASE STATION 50 FT BASE STATION GAIN 4.74 dBi 6.54 dBi 6.64 dBi 6.84 dBi ANGLE OF RADIATION 33 22 9 5

MOUNTING AND STACKING OPTIONS

SHOWN IS AN EXAMPLE OF A BASE STATION SYSTEM OF 2 STACKED AND PHASED 6M HO LOOPS

PARTS NEEDED: (2) 6M HO LOOPS 6M HO LOOP 2 PORT POWER DIVIDER (OMITTED FOR CLARITY)

Order online at http://www.m2inc.com

CUSTOMER SUPPLIED MAST (1-1/4 - 2 DIA.) NOTE: A 180 REVERSAL OF ONE FEED BLOCK IS NECESSARY TO ACCOMMODATE THE EXTRA HALF WAVE (/2) OF COAX IN THE LONG PHASING LINE OF THE 6M HO LOOP 2 PORT POWER DIVIDER.

2 STACKED 6M HO LOOP PERFORMANCE HEIGHT ABOVE GROUND 8 FT AND 18 FT 8 FT AND 20 FT 20 FT AND 32 FT 40 FT AND 52 FT GAIN 8.03 dBi 8.47 dBi 9.96 dBi 10.54 dBi ANGLE OF RADIATION 17 16 10 6

MOBILE MOUNTING OPTIONS

CAUTION: DEPENDING ON THE MAKE AND MODEL OF YOUR VEHICLE AND THE THICKNESS AND COMPOSITION OF THE VEHICLE BODY, ADDITIONAL GUYING OR SUPPORT MAY BE NECESSARY.

SHOWN IS AN EXAMPLE OF MOBILE HO LOOP MOUNTING (YOUR INSTALLATION MAY DIFFER)

PARTS NEEDED 6M HO LOOP 36 ALUMINUM MAST BIG-FOOT MAGNET MOUNT

Order online at http://www.m2inc.com

6M HO LOOP PARTS & HARDWARE

DESCRIPTION......................................................................................... QTY HOLOOP TUBE (BENT) 3/8 OD ............................................................. 2 SUPPORT TUBE, 3/8 ............................................................................ 1 FEED BLOCK ASSEMBLY ...................................................................... 1 SHORTING BAR, 1/2 X 1/2 X 2-1/2...................................................... 1 CENTER INSULATOR, 3/4 UHMW ........................................................ 1 SUPPORT CLAMP, 1/2 X 1 X 2-1/4 ..................................................... 2 HOLOOP UNIVERSAL MAST BRACKET ................................................ 1 UNI-CRADLE, (M2AMC0176) .................................................................. 2 U-BOLT, 2 HINDLEY............................................................................... 2 ASSEMBLY MANUAL .............................................................................. 1

HARDWARE: BOLT, 3/8-24 X 1, SS.............................................................................. 1 LOCKNUT, 3/8-24, SS ............................................................................. 1 BOLT, 1/4-20 X 1, SS.............................................................................. 1 BOLT, 1/4-20 X 3/4, FLAT HEAD PHILLIPS, SS .................................... 1 SET SCREW, 1/4-20 X 1/4, SS............................................................... 7 LOCKWASHER, 1/4, SS ......................................................................... 4 NUT, 1/4-20, SS ....................................................................................... 4 SCREW, 6-32 X 1-1/4, SS ...................................................................... 2 SCREW, 6-32 X 1, SS............................................................................. 2 LOCKNUT, 6-32, SS ................................................................................ 4 ALLEN WRENCH, 1/8............................................................................. 1

M2 ANTENNA SYSTEMS, INC.

4402 N. SELLAND AVE. FRESNO, CA 93722 (559) 432-8873 FAX: 432-3059 www.m2inc.com Email: sales@m2inc.com

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Honda CRF250L Wiring Diagram enDocumento1 páginaHonda CRF250L Wiring Diagram enนายโจ รักกาแฟ80% (5)

- Tokyohypower Hl110v ManualDocumento9 páginasTokyohypower Hl110v Manualนายโจ รักกาแฟAinda não há avaliações

- Hyg Dx77a ManualDocumento14 páginasHyg Dx77a Manualve7eoeAinda não há avaliações

- Downart WeldingDocumento11 páginasDownart Weldingนายโจ รักกาแฟAinda não há avaliações

- Pic18f2525 2620 4525 4620Documento390 páginasPic18f2525 2620 4525 4620api-19831863Ainda não há avaliações

- MACom CustomerPSG 082012Documento48 páginasMACom CustomerPSG 082012นายโจ รักกาแฟAinda não há avaliações

- Smith Marine Design: 9200 N. Lennox Ter, Citrus Springs, FL 34434 (352) 465-3123Documento1 páginaSmith Marine Design: 9200 N. Lennox Ter, Citrus Springs, FL 34434 (352) 465-3123นายโจ รักกาแฟAinda não há avaliações

- 302 01103 0 Mar 1SMDocumento2 páginas302 01103 0 Mar 1SMนายโจ รักกาแฟAinda não há avaliações

- Throttle BoosterDocumento1 páginaThrottle Boosterนายโจ รักกาแฟAinda não há avaliações

- 6M3 SSDocumento7 páginas6M3 SSนายโจ รักกาแฟAinda não há avaliações

- 4cx250 2mtr AmpDocumento15 páginas4cx250 2mtr Ampนายโจ รักกาแฟAinda não há avaliações

- Throttle BoosterDocumento1 páginaThrottle Boosterนายโจ รักกาแฟAinda não há avaliações

- 1 N 5365Documento3 páginas1 N 5365นายโจ รักกาแฟAinda não há avaliações

- Penguin B 3dDocumento1 páginaPenguin B 3dMohamed Ghazy Jr.Ainda não há avaliações

- 807 E. Parkridge Ave. - Corona, CA 92879 1-888-ACCU-372 - 951-479-0909 - Fax: 951-479-0305Documento12 páginas807 E. Parkridge Ave. - Corona, CA 92879 1-888-ACCU-372 - 951-479-0909 - Fax: 951-479-0305นายโจ รักกาแฟAinda não há avaliações

- Shimano Catalog 2012Documento144 páginasShimano Catalog 2012นายโจ รักกาแฟAinda não há avaliações

- 571188Documento28 páginas571188eka prasetiaAinda não há avaliações

- Cardiac Science G3 Pro Spec SheetDocumento2 páginasCardiac Science G3 Pro Spec Sheetcaseyatthebat1Ainda não há avaliações

- Interview Questions and AnswersDocumento2 páginasInterview Questions and AnswersvishwahAinda não há avaliações

- W 950Documento100 páginasW 950potatoAinda não há avaliações

- Assignment 2 Computer SkillsDocumento12 páginasAssignment 2 Computer SkillsMmonie MotseleAinda não há avaliações

- Introduction To Memory and Key Characteristics of MemoryDocumento17 páginasIntroduction To Memory and Key Characteristics of MemoryDev Rishi ThakurAinda não há avaliações

- 2009 Interactive Industry Report - 2009.06.29Documento210 páginas2009 Interactive Industry Report - 2009.06.29api-26238753Ainda não há avaliações

- Is DH1718 1Documento2 páginasIs DH1718 1dayshift5Ainda não há avaliações

- Practical 1 Dyna KitDocumento5 páginasPractical 1 Dyna KitHet PatelAinda não há avaliações

- Unit of Competency Learning Outcomes Learning Activities Methodologies Assessment Methods Nominal DurationDocumento8 páginasUnit of Competency Learning Outcomes Learning Activities Methodologies Assessment Methods Nominal Durationvanjoseph01Ainda não há avaliações

- NOWA Price ListDocumento2 páginasNOWA Price Listsunny_nsecAinda não há avaliações

- LR2000 Spanish Specsheet - CompressedDocumento2 páginasLR2000 Spanish Specsheet - CompressedYesica SantamariaAinda não há avaliações

- HP EliteDesk PDFDocumento112 páginasHP EliteDesk PDFKhuram s6Ainda não há avaliações

- Tia 568 C.1Documento42 páginasTia 568 C.1k1gabitzu9789Ainda não há avaliações

- Lab 7Documento5 páginasLab 7Desiree Mae IbonAinda não há avaliações

- 3 - Instruction DM1A-1Documento30 páginas3 - Instruction DM1A-1Ardhian Eka PAinda não há avaliações

- TM-CSIN-10001 Intro To Cospas-Sarsat PDFDocumento74 páginasTM-CSIN-10001 Intro To Cospas-Sarsat PDFhuyenquyet163Ainda não há avaliações

- Delta-Sks (En)Documento2 páginasDelta-Sks (En)maserrasAinda não há avaliações

- Clock GeneratorDocumento7 páginasClock GeneratorpurseyAinda não há avaliações

- Unit 3 Shell ProgrammingDocumento5 páginasUnit 3 Shell Programmingnavin_killerAinda não há avaliações

- Assembly LanguageDocumento7 páginasAssembly LanguageFranchezka YuAinda não há avaliações

- CTS-9006 CTS-9009 Operation Manual v1.4 ReleaseDocumento93 páginasCTS-9006 CTS-9009 Operation Manual v1.4 ReleaseRoberto Chang Palma100% (2)

- Konica Minolta Bizhub 654e PDFDocumento4 páginasKonica Minolta Bizhub 654e PDFanbvn99Ainda não há avaliações

- 2018-04 Skylake Dell 2018 Flyer SAP Business One HANADocumento47 páginas2018-04 Skylake Dell 2018 Flyer SAP Business One HANAMohammed AliAinda não há avaliações

- Add L900: Lte Hygiene ReportsDocumento38 páginasAdd L900: Lte Hygiene Reportsshashank.prajapati9389Ainda não há avaliações

- Panelview Plus 7 Performance Terminals: User ManualDocumento170 páginasPanelview Plus 7 Performance Terminals: User Manualzulfikar rochimAinda não há avaliações

- Manual de Instrucciones: Relevador para El Manejo de MotoresDocumento234 páginasManual de Instrucciones: Relevador para El Manejo de MotoresSamuel Ramos MondragónAinda não há avaliações

- U-Series V24 Int N00-502 R01Documento177 páginasU-Series V24 Int N00-502 R01nick_toma2004Ainda não há avaliações

- Oracle Database 10G - Automatic Sga Memory ManagementDocumento14 páginasOracle Database 10G - Automatic Sga Memory Managementapi-3848967Ainda não há avaliações

- Installation, Operation and Maintenance Manual: Part #452413 Canopy Type Kitchen HoodsDocumento40 páginasInstallation, Operation and Maintenance Manual: Part #452413 Canopy Type Kitchen HoodsmarcoelecAinda não há avaliações