Escolar Documentos

Profissional Documentos

Cultura Documentos

Harvesters: 703JH 753JH 759JH

Enviado por

rossini_danielDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Harvesters: 703JH 753JH 759JH

Enviado por

rossini_danielDireitos autorais:

Formatos disponíveis

JH

HARVESTERS

703JH | 753JH | 759JH

A powerful performer thats ready to go.

The smartly designed John Deere 700JH-Series Tracked Harvesters not only have the guts to get you into dense, challenging woods they seize the opportunity once youre there. Thats because each model boasts a fully integrated measuring system for plug-and-play Waratah heads powered by an efcient multifunctional hydraulic system. This new system knows when and where you need power to get the job done. Every feature of the JH models from the agile yet strong boom to the reputable heads enables superb harvesting performance.

2 3

With 17-percent more cutting swath, operators can make more cuts with less travel, maximizing cutting time and increasing your operations overall productivity. The new load-sensing hydraulic system allows for superior multifunctioning, giving performance and reliability a signicant boost. Streamlined and accessible hydraulic systems make service and maintenance a breeze, optimizing your uptime and lowering your operating costs. Each fully integrated harvester is factory conditioned for plug-and-play Waratah heads that will work reliably for you without the headaches that commonly come with non-factory installation.

703JH

PowerTech Engine Power Max Reach (With H480 Harvesting Head) Operating Weight (Without Attachment) Maximum Tractive Effort Best Applications Waratah Head Model 181 peak hp (135 kW) 27 ft. 9 in. (8.5 m) 50,960 lb. (23 110 kg) 57,600 lbf (256 kN) Thinning, regeneration, and swamp operations H270, H290, H480, HTH616, and HTH622B

753JH

241 peak hp (180 kW) 27 ft. 9 in. (8.5 m) 51,260 lb. (23 250 kg) 57,600 lbf (256 kN) Thinning, regeneration, and swamp operations H270, H290, H480, HTH616, and HTH622B

759JH

241 peak hp (180 kW) 27 ft. 9 in. (8.5 m) 59,000 lb. (26 760 kg) 57,600 lbf (256 kN) Thinning, regeneration, and steep ground operations H270, H290, H480, HTH616, and HTH622B

A powerful force in nature.

4 5

In the woods, there arent many forces as powerful as the new 700JH-Series. Its redesigned hydraulic system offers greater efciency and reliability, and improvements you can see and feel across functions. It starts with 17-percent higher ow to the head for improved delimbing pressure and feed speed. Plus 26-percent higher ow to the main circuits means more power and efciency across the board. Add in the 700JH-Series easy maneuverability and increased cutting swath, and youve got a force to be reckoned with.

3 2

Hydraulic system: With a faster hydraulic system, the multifunctioning JH-Series machines are the ringleaders of the industry. The new system architecture and hydraulic prioritization mean no waiting for power or oil. That means you can get more done, faster and with more precision. Plus, hydraulics run cooler and more efciently, making pumps last longer. Flexxaire fan system: An optional reverse-blower function clears debris from blocking airow, keeping the machine clean and cool. Cutting swath: The cutting swath has been increased by an impressive 17 percent, allowing operators to make a wide range of strategic and productive cuts with less tracking and traveling. Swing torque: Increased by 10 percent to 40,000 ft-lbs. The improved swing torque helps you harvest more efciently. Waratah head attachments: Choose one of ve top-of-the-line Waratah attachments.

The most comfortable seat in the woods.

Our machines are as impressive on the inside as they are on the outside. Among the most spacious in its class, the cab of this powerhouse is comfortable, well-appointed, and efciently arranged for maximum productivity. Loggers will appreciate the clear and expansive sight line, as well as the isolation mountings for a smoother and quieter ride.

AM/FM radio and standard air conditioning add to operator comfort. Storage is available behind the seat and in the door. Tinted polycarbonate windows with removable skylight enhance operator visibility for greater productivity. Powerview monitor has backlit gauges that make it easy to view engine coolant temp, fuel levels, hydraulic oil temps, tachometer, and more. Isolation mountings reduce noise and vibration for a quiet and comfortable cab. Fully adjustable suspension seat, armrests and backrest, easy access to pedals and levers, and joysticks located at the armrests for additional operator comfort.

6 7

1 2 3

Foot pedals: Rened shape and tension controls for improved operator heel-toe control. Controls: Low-effort controls with fully featured, backlit indicator lights. Powerview monitor: With its truly state-of-the-art diagnostic capabilities, your operators can maintain a high level of productivity at all times.

A perfect pair for the forest.

Our reputable Deere machines are Waratah-ready for built-to-work plug-and-play heads, making these integrated machines a force to be reckoned with. The factory pre-wired measuring system is designed specically for Waratah heads so these Deere machines can deliver the absolute best performance, productivity, and uptime in the industry. From processing at the landing to harvesting at the stump, you can reliably maximize jobsite production while getting the highest-value cut per stem.

H270 Height (With Rotator) Weight (Including Rotator and Link) Maximum Cutting Capacity Application 83 in. (2110 mm) 2,877 lb. (1305 kg) 25.6 in. (650 mm) Superior performance in late thinning and regeneration harvesting

H290 99 in. (2520 mm) 4,300 lb. (1950 kg) 29.5 in. (750 mm) Superior performance in late thinning and regeneration harvesting

H480 76 in. (1940 mm) 2,900 lb. (1315 kg) 25.6 in. (650 mm) Superior performance in late thinnings and regeneration harvesting, with an unbeatable power-to-weight ratio

HTH616 85 in. (2170 mm) 3,418 lb. (1550 kg) 24 in. (620 mm) Ideal for harvesting plantation operation Superior thinning and cut-to-length capabilities makes it perfect for processing small wood

8 9

All JH-Series Harvesters are factory engineered to be fully integrated plug-and-play with H480, HTH616 and HTH622B Waratah heads a harvesting package thats tough to beat. Waratah attachments are known for their durability, reliability, and precision all attributes that optimize your harvesting productivity and uptime. The John Deere carrier and Waratah head combo has gone through no-holds-barred testing to ensure compatibility and reliability in even the most challenging environments. The machines hydraulic system increases horsepower and ow (greater than 95 gpm) to the attachment, resulting in better grabbing pressure and faster speed.

HTH622B 126 in. (3200 mm) 4,770 lb. (2165 kg) 30 in. (760 mm) Ideal for big trees Tougher-than-nails design for continuous operation

Upper leveling: Shift-Tilt technology gives the JH-Series the industrys most stable platform for cutting on difcult slopes. Its four-way leveling system allows the upper structure to shift a full three feet forward, keeping the machines center of gravity up onto the steep inclines. Tractive effort: These powerful machines boast a proven tractive-effort-to-weight ratio to keep your operation going strong even in swampy or super-steep areas. Hydraulic system: The pressure-compensated, load-sensing hydraulics increase oil ow to improve function speeds in peak performance situations and increase the hydraulic systems lifespan. Plus, the hydraulics run cooler, making pumps last longer and keeping your equipment running smarter with much more time between repairs. Swing torque and acceleration: With 10-percent more swing torque, these machines move faster into position, ready and waiting for your operator to make the next cut. Effective power management: Make sure you have the right amount of power when and where you need it. The new hydraulic system prioritizes power loads, ensuring essential tasks like feed speed and multifunctioning always have enough dedicated ow. Not only do you get targeted maximum power, but moving parts arent starved for oil so youll have less downtime for maintenance, and cuts and cutting intervals can happen as fast as an operator wants.

10 11

Reliable machines and people.

The new 700JH-Series delivers the design, quality, reliability, and durability you expect of any John Deere machine. Backed by unmatched John Deere maintenance and parts programs and a world-class dealer network, these uninching machines follow through on maximum uptime whenever and wherever youre in the woods.

1 2 2

New service-door design for increased overall access to critical systems. Cleaner layout of hydraulics, with fewer parts for easier maintenance and less downtime. Common hydraulic reservoir internal components such as independent suction lines, case-drain ltration, and common return lters. Deck oor is clear of components, making it easier to clean. Optional platform counterweight with antislip edge for increased operator safety. A convenient ladder helps make service quick and easy. The optional Flexxaire system is a pneumatically actuated, variable-pitch fan, controlled by a timer and manual purge switch. At regular intervals the fan will reverse airow direction to blow debris out of the radiator. The operator can reverse the airow through the coolers manually at any time via a switch in the cab.

12 13

Cut timber and your costs down to size.

The eld-tested enhancements of the 700JH-Series Harvesters were designed for lower operating costs and easier service and maintenance. At the core of the JH-Series improved daily and long-term fuel efciency is a streamlined hydraulic system. Meanwhile, the optional Flexxaire fan system reduces debris buildup, ensuring cooler, more efcient hydraulics. And better service access and a cleaner hydraulic layout require fewer parts making service and maintenance a breeze.

Tracked Harvesters 703JH, 753JH, 759JH

703JH ENGINE Non-road emission standards Cylinders Engine displacement Peak power @ 2,000 rpm Net power (ISO 9249) @ 2,000 rpm Maximum net torque @ 1,400 rpm Additional features: Cooling fan Air cleaner 753JH / 759JH John Deere 6081H, Tier 2 John Deere 6081H, Tier 2 Complies with EPA Tier 2 regulations and CARB emissions 6 6 494 cu. in. 8.1 L 494 cu. in. 8.1 L 181 hp 135 kW 241 hp 180 kW 160 hp 119 kW 220 hp 164 kW 679 lbf. 920 Nm 907 lbf. 1230 Nm Suction type, belt driven Dual-stage dry type with safety element, aspirated 703JH / 753JH / 759JH HYDRAULICS Main pump: Maximum rated ow Main attachment pump: Maximum rated ow Oil ltration CYLINDERS Boom (1): Bore Rod diameter Stroke Closed length Arm (1): Bore Rod diameter Stroke Closed length Leveller (2): Bore Rod diameter Stroke Closed length UNDERCARRIAGE Track chain, heavy duty Travel speed, forward and reverse: High Low Tractive effort Additional features: Carrier slides (per side) Track rollers (per side) Track guides Track adjustment Travel brakes 8.0 in. 203.2 mm 02.4 mph 03.8 km/h 01.1 mph 01.8 km/h 57,600 lbf. 256 kN Two, bolt-on Eight, tractor type Integral, thick high-abrasion-resistant material: 1.0 in. 25 mm Hydraulic Sealed, wet, multi-disc, automatic application, integral with track-drive gearboxes 6.0 in. 152 mm 3.5 in. 89 mm 44.3 in. 1124 mm 64.7 in. 1643 mm 5.1 in. 130 mm 3.7 in. 95 mm 50.1 in. 1273 mm 72.4 in. 1838 mm N/A / N/A / 7.0 in. 178 mm N/A / N/A / 4.0 in. 102 mm N/A / N/A / 31.3 in. 795 mm N/A / N/A / 53.3 in. 1353 mm Variable-displacement axial piston pump 95 gpm 360 L/min. Dedicated axial piston pump 30 gpm 114 L/min. Two 10-micron return lters with bypass

14 15

703JH / 753JH / 759JH SWING MECHANISM Standard features: Rotation Swing speed Swing brake CAPACITIES Fuel tank Cooling system Engine lubrication, including lter Hydraulic reservoir capacity Swing-drive gearbox Track-drive gearbox (each) 154.0 gal. 584.0 L 10.2 gal. 38.5 L 7.4 gal. 28.0 L 36.0 gal. 136.0 L 1.2 gal. 4.5 L 1.3 gal. 4.8 L 703JH GROUND PRESSURE DATA As per SAE J1309, less attachment Double grouser, heavy duty: 24 in. 610 mm 30 in. 760 mm Single grouser, clipped corner, heavy duty: 24 in. 610 mm 28 in. 710 mm Triple grouser, heavy duty:* 36 in. 914 mm 7.3 psi 50.3 kPa 6.0 psi 41.1 kPa 7.3 psi 50.6 kPa 6.0 psi 41.3 kPa 8.4 psi 58.1 kPa N/A 753JH 759JH Continuous 360 deg. 7.0 rpm (maximum) Sealed, wet, multi-disc

7.2 psi 49.8 kPa 6.3 psi 43.3 kPa 5.1 psi 35.4 kPa

*Recommended for soft terrain only.

7.3 psi 50.1 kPa 6.3 psi 43.5 kPa 5.2 psi 35.6 kPa

8.4 psi 57.7 kPa 7.3 psi 50.0 kPa N/A

ELECTRICAL Voltage Number of batteries Alternator reading Work lights OPERATING WEIGHTS Approximate operating weight includes standard equipment, halffull fuel tank, all uids, and 175-lb. 80 kg operator, less attachment

24 volt Two 12 volt 80 amp 8 twin-power halogen lights (7 ood, 1 spot)

50,980 lb. 23 120 kg H270 H290

51,280 lb. 23 256 kg H480 HTH616

59,000 lb. 26 760 kg HTH622B

ATTACHMENT INFORMATION Maximum cutting capacity

25.6 in. 650 mm

29.5 in. 750 mm

Maximum delimbing capacity Feeding mechanism Dimensions: Width (arms open) Width (arms closed) Height (with rotator) Height (without rotator and link) Weight (without rotator and link) Weight (with rotator and link)

18.9 in. 480 mm N/A 65.4 in. 1660 mm 42.3 in. 1075 mm N/A 62.4 in. 1585 mm 2,513 lb. 1140 kg N/A

20.1 in. 510 mm N/A 77.6 in. 1970 mm 46.7 in. 1187 mm N/A 77.6 in. 1970 mm 4,079 lb. 1850 kg N/A

25.6 in. 650 mm 28 in. 710 mm (with SuperCut) 18.9 in. 480 mm N/A 65.0 in. 1650 mm 47.2 in. 1200 mm N/A 52.4 in. 1330 mm 2,646 lb. 1200 kg N/A

20.0 in. 508 mm

30.0 in. 762 mm

20.5 in. 520 mm

25.5 in. 647 mm

3 rollers, fully synchronized hydraulic drive 63.4 in. 1610 mm 55.1 in. 1400 mm 85.4 in. 2170 mm N/A N/A 3,418 lb. 1550 kg 68.6 in. 1742 mm 58.5 in. 1485 mm 126.0 in. 3200 mm N/A N/A 4,675 lb. 2120 kg

Saw equipped with automatic chain-tensioner system. See individual harvesting head brochures for more information.

8.0M 7.0M

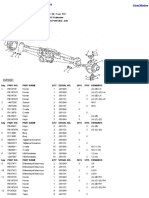

703JH / 753JH BOOM PERFORMANCE Maximum reach (to attachment pin): With standard boom Minimum reach (to attachment pin): With standard boom Lift capacity (bare pin @ full reach): With standard boom Lift capacity (bare pin @ 20 ft. 6.1 m): With standard boom DIMENSIONS A Overall height: Top of cab Top of boom B Overall track length C Track length (idler to sprocket) D Tail swing (from swing center): Short counterweight Long counterweight E Reach (to attachment pin): Maximum Minimum F Ground clearance: Single grouser Double grouser Triple grouser G Upperstructure width H Track gauge I Width over tracks: 24-in. 610 mm track shoes 28-in. 711 mm track shoes 30-in. 760 mm track shoes 36-in. 914 mm track shoes

G

6.0M 5.0M 4.0M 3.0M

27 ft. 10 in. 8.50 m 7 ft. 9 in. 2.36 m 8,780 lb. 3980 kg

2.0M 1.0M 0.0M -1.0M

GROUND LINE

10.0M 9.0M 8.0M 7.0M 6.0M 5.0M 4.0M 3.0M 2.0M 1.0M 0.0M

11,560 lb. 5240 kg

11 ft. 4 in. 3.45 m 14 ft. 2 in. 4.33 m 14 ft. 6 in. 4.41 m 11 ft. 1 in. 3.37 m 6 ft. 4 in. 1.93 m 7 ft. 2 in. 2.18 m 27 ft. 10 in. 8.50 m 7 ft. 9 in. 2.36 m 2 ft. 5 in. 730 mm 2 ft. 4 in. 700 mm 2 ft. 3 in. 685 mm 9 ft. 8 in. 2.94 m 7 ft. 6 in. 2.29 m / 8 ft. 5 in. 2.57 m 9 ft. 6 in. 2.90 m / 10 ft. 5 in. 3.18 m 9 ft. 10 in. 3.00 m / 10 ft. 9 in. 3.28 m 10 ft. 0 in. 3.05 m / 10 ft. 11 in. 3.33 m 10 ft. 6 in. 3.20 m / 11 ft. 5 in. 3.48 m

703JH / 753JH Tracked Harvesters

F H I B E C

Machine not exactly as shown. Illustrations for dimensioning purposes only.

16 17

CENTERLINE OF SWING

9.0M

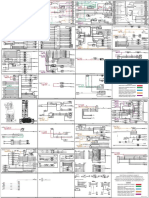

759JH BOOM PERFORMANCE Maximum reach (to attachment pin): With standard boom Minimum reach (to attachment pin): With standard boom Lift capacity (bare pin @ full reach): With standard boom Lift capacity (bare pin @ 20 ft. 6.1 m): With standard boom 27 ft. 10 in. 8.50 m 7 ft. 9 in. 2.36 m 8,780 lb. 3980 kg 11,560 lb. 5240 kg

8.0M 7.0M 6.0M 5.0M 4.0M 3.0M 2.0M 1.0M 0.0M -1.0M

GROUND LINE

10.0M 9.0M 8.0M 7.0M 6.0M 5.0M 4.0M 3.0M 2.0M 1.0M 0.0M

DIMENSIONS A Overall height: Top of cab Top of boom B Overall track length C Track length (idler to sprocket center) D Tail swing (from swing center): Short counterweight Long counterweight E Reach (to attachment pin): Maximum Minimum F Ground clearance: Single grouser Double grouser G Upperstructure width H Track gauge I Width over tracks: 24-in. 610 mm track shoes 28-in. 711 mm track shoes 12 ft. 11 in. 3.93 m 15 ft. 0 in. 4.57 m 14 ft. 6 in. 4.41 m 11 ft. 1 in. 3.37 m 6 ft. 4 in. 1.93 m 7 ft. 2 in. 2.18 m 27 ft. 10 in. 8.50 m 7 ft. 9 in. 2.36 m 2 ft. 6 in. 759 mm 2 ft. 5 in. 730 mm 9 ft. 8 in. 2.94 m 8 ft. 0 in. 2.44 m 10 ft. 0 in. 3.05 m 10 ft. 4 in. 3.15 m Levelling capability: Foward Rear Side-to-side

in. 30 mm) 2 (76

27 deg. (51% slope) 10 deg. (18% slope) 18 deg. (32% slope)

759JH Tracked Harvester

CENTERLINE OF SWING

9.0M

F H I B

Machine not exactly as shown. Illustrations for dimensioning purposes only.

E C

John Deere is the worlds leading designer,

manufacturer, and distributor of forest machines.

Our range of purpose-built forestry equipment

is without equal in the industry.

From thinning to regeneration harvesting,

for both cut-to-length and full-tree applications,

John Deere builds woods-tough equipment

with the logger in mind.

DKA703JH Litho in U.S.A. (08-09)

www.JohnDeere.com

Você também pode gostar

- Arctic Cat 2012 550 700 Service ManualDocumento154 páginasArctic Cat 2012 550 700 Service ManualImad Remi RamzaniAinda não há avaliações

- RT210 Parts ManualDocumento176 páginasRT210 Parts ManualPhilAinda não há avaliações

- John Deere Tractor 6403 and 6603 2WD or MFWD Repair Manual TM6024 PDFDocumento31 páginasJohn Deere Tractor 6403 and 6603 2WD or MFWD Repair Manual TM6024 PDFEquipment ManualsAinda não há avaliações

- Cat VibroDocumento16 páginasCat Vibrojheaszh100% (1)

- Mower GuideDocumento48 páginasMower GuidezexploAinda não há avaliações

- 053-1088 Jt4020at3rp - 3-0 Manual OperadorDocumento233 páginas053-1088 Jt4020at3rp - 3-0 Manual OperadorHector DiazAinda não há avaliações

- Yanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualDocumento349 páginasYanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualPer ForsbergAinda não há avaliações

- CASE 580 Super M Presentation PreliminaryDocumento6 páginasCASE 580 Super M Presentation PreliminaryDian SikumbangAinda não há avaliações

- VN70050788-3 Vicon RO-MDocumento161 páginasVN70050788-3 Vicon RO-MGolub Marko0% (1)

- Toro 518XI, 520XI, 522XI Owners ManualDocumento56 páginasToro 518XI, 520XI, 522XI Owners ManualKevins Small Engine and Tractor Service100% (1)

- Gleaner s8 Series BrochureDocumento72 páginasGleaner s8 Series Brochureapi-251664913Ainda não há avaliações

- Generic 7Sw: User Installation / Configuration Manual T150 Transmitter R170 ReceiverDocumento16 páginasGeneric 7Sw: User Installation / Configuration Manual T150 Transmitter R170 ReceiverVladimir Illich Pinzon BallenAinda não há avaliações

- BL61Documento12 páginasBL61dalibor_bogdan50% (2)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsAinda não há avaliações

- 210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionDocumento5 páginas210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionwilsonugshaAinda não há avaliações

- SWE25B Operator's ManualDocumento91 páginasSWE25B Operator's ManualIisakkiAinda não há avaliações

- New Holland B90B, B95B, B95BLR, B95BTC, B110B, B115B TIER 3 Loader Backhoe Service Repair ManualDocumento31 páginasNew Holland B90B, B95B, B95BLR, B95BTC, B110B, B115B TIER 3 Loader Backhoe Service Repair ManualggjjjjotonesAinda não há avaliações

- Magnum Manual Mmg155 PartsDocumento70 páginasMagnum Manual Mmg155 PartsFrancisco SandovalAinda não há avaliações

- John Deere - Parts Catalog - Frame 6Documento2 páginasJohn Deere - Parts Catalog - Frame 6tatasoyAinda não há avaliações

- 7 ReferencesDocumento6 páginas7 Referencessuneerav17100% (1)

- ASTEK ŁańcuchyDocumento610 páginasASTEK ŁańcuchyadasrafalskiAinda não há avaliações

- OMLVU10940Documento140 páginasOMLVU10940drwskatefilmsAinda não há avaliações

- SPC 10Documento3 páginasSPC 10Muhammad Ahsan AkramAinda não há avaliações

- Operator Manuals English Version 5.1Documento40 páginasOperator Manuals English Version 5.1Alberto Garcia OliverAinda não há avaliações

- CAT Antes de Usar TH460BDocumento4 páginasCAT Antes de Usar TH460Bmiguel0% (1)

- HarvestersDocumento132 páginasHarvestersLeTraitimbenletkAinda não há avaliações

- John Deere Product BrochureDocumento7 páginasJohn Deere Product Brochureapi-309873138Ainda não há avaliações

- OILGEAR-PVWH BombaDocumento22 páginasOILGEAR-PVWH BombaDiego CamachoAinda não há avaliações

- Ax Wagon LeafletDocumento40 páginasAx Wagon LeafletemmanolanAinda não há avaliações

- NH 48144035 PreviewDocumento61 páginasNH 48144035 Previewsergio astudilloAinda não há avaliações

- Service Manual: TractorDocumento41 páginasService Manual: TractorRulax MtzAinda não há avaliações

- Satco LTD: Satco 318 Setup & Testing ManualDocumento31 páginasSatco LTD: Satco 318 Setup & Testing ManualmarceloAinda não há avaliações

- D85EX-15E0 and Additional Models (JPN) EU SN 11001-UPDocumento130 páginasD85EX-15E0 and Additional Models (JPN) EU SN 11001-UPGustavo Enrique fontalvoAinda não há avaliações

- Manual Skidders John DeereDocumento16 páginasManual Skidders John Deererossini_daniel50% (2)

- Pub20021274 B Eng L20F L25FDocumento169 páginasPub20021274 B Eng L20F L25FJulio FernandoAinda não há avaliações

- FR 9040Documento61 páginasFR 9040Rulax Mtz0% (1)

- 277C, 287C, 297C MTL English PDFDocumento12 páginas277C, 287C, 297C MTL English PDFJuan n cadenaAinda não há avaliações

- WA380 7 BrochureDocumento24 páginasWA380 7 BrochureAvaa Amgaa100% (1)

- Ecr145c Eu EngDocumento20 páginasEcr145c Eu Engdalibor_bogdan100% (2)

- Ec360c Eu EngDocumento24 páginasEc360c Eu Engdalibor_bogdanAinda não há avaliações

- L350F 21D1002740Documento28 páginasL350F 21D1002740dalibor_bogdanAinda não há avaliações

- Toro Wheel Horse 268H Lawn and Garden Tractor Operators ManualDocumento44 páginasToro Wheel Horse 268H Lawn and Garden Tractor Operators Manualrop703406100% (1)

- A4 G930 - G960 Product Brochure enDocumento24 páginasA4 G930 - G960 Product Brochure endalibor_bogdanAinda não há avaliações

- Manual Motor MotocultorDocumento20 páginasManual Motor MotocultorRadu RacheriuAinda não há avaliações

- Catalogo Drive One 161110 PDFDocumento174 páginasCatalogo Drive One 161110 PDFIdiLab EmprendimientoAinda não há avaliações

- ECR28 ECR38 BrochureDocumento12 páginasECR28 ECR38 Brochuredalibor_bogdanAinda não há avaliações

- Caterpillar Electronic Technician 2011A v1.0 Status Report as of 1/17/2019Documento2 páginasCaterpillar Electronic Technician 2011A v1.0 Status Report as of 1/17/2019StevenAinda não há avaliações

- TimberRite HW Jan2006 BrazillDocumento7 páginasTimberRite HW Jan2006 BrazillmarceloAinda não há avaliações

- 777D Off-Highway Truck UpdatesDocumento54 páginas777D Off-Highway Truck UpdatesGabo Gabo100% (1)

- Massey Ferguson MF 1835 RectanGular Baler Parts Catalog ManualDocumento137 páginasMassey Ferguson MF 1835 RectanGular Baler Parts Catalog Manualandy habibiAinda não há avaliações

- L25 Electric: Volvo Electric Compact Wheel Loaders 5.1 - 5.3 TDocumento20 páginasL25 Electric: Volvo Electric Compact Wheel Loaders 5.1 - 5.3 TAndré Azevedo CorreiaAinda não há avaliações

- Wheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeDocumento4 páginasWheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeRalf MaurerAinda não há avaliações

- 580N 580SN 580SN WT 590SN With POWERSHUTTLEDocumento2 páginas580N 580SN 580SN WT 590SN With POWERSHUTTLEEl PerroAinda não há avaliações

- TO17VE-00 Operational PrincipleDocumento212 páginasTO17VE-00 Operational PrincipleArdi Heineken PradaAinda não há avaliações

- Rammax 1515 and 1510 Trench RollersDocumento12 páginasRammax 1515 and 1510 Trench RollersGustavoAinda não há avaliações

- Operation 31200354 09-19-11 ANSI EnglishDocumento150 páginasOperation 31200354 09-19-11 ANSI EnglishWilliam RoarkAinda não há avaliações

- Каталог Moffett LRDocumento151 páginasКаталог Moffett LRМаксимAinda não há avaliações

- Cat426a PDFDocumento90 páginasCat426a PDFJuan PenasAinda não há avaliações

- 721E & 821E Wheel Loaders Specs & FeaturesDocumento16 páginas721E & 821E Wheel Loaders Specs & FeaturesRaul E. Soli100% (1)

- Масла применяемые для КПП ZF TE-ML - 03 PDFDocumento13 páginasМасла применяемые для КПП ZF TE-ML - 03 PDFИгорь ТерещенкоAinda não há avaliações

- Masina Multifunctionala de Doborat ArboriDocumento16 páginasMasina Multifunctionala de Doborat ArboritwacacaAinda não há avaliações

- Feller John Deere 959KDocumento20 páginasFeller John Deere 959KJavierRivasNeiraAinda não há avaliações

- Pivot Part NumDocumento2 páginasPivot Part Numrossini_danielAinda não há avaliações

- Livro Irrigação ASABE - Capítulo 5Documento12 páginasLivro Irrigação ASABE - Capítulo 5rossini_danielAinda não há avaliações

- Livro Irrigação ASABE - Capítulo 1Documento32 páginasLivro Irrigação ASABE - Capítulo 1rossini_danielAinda não há avaliações

- Livro Irrigação ASABE - Capítulo 9Documento31 páginasLivro Irrigação ASABE - Capítulo 9rossini_danielAinda não há avaliações

- DS 1Documento23 páginasDS 1aayush bhatiaAinda não há avaliações

- Upto 62rd BPSC Mechanical Question BankDocumento140 páginasUpto 62rd BPSC Mechanical Question BankASHISH KUMAR SINGHAinda não há avaliações

- MD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Documento4 páginasMD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Huzzatul Islam NisarAinda não há avaliações

- ChuzaChen Hydroelectric Power ProjectDocumento13 páginasChuzaChen Hydroelectric Power ProjectkanabaramitAinda não há avaliações

- Accountability Report Ba CharityDocumento24 páginasAccountability Report Ba CharityBintang sonda sitorus PaneAinda não há avaliações

- Bing WorksheetDocumento3 páginasBing WorksheetFrutti MataniAinda não há avaliações

- GCMS-QF 15 - Calibration (IMTE) Form - MPSDocumento7 páginasGCMS-QF 15 - Calibration (IMTE) Form - MPSMobin Thomas AbrahamAinda não há avaliações

- Mouse Molecular Genetics Student Activity 2Documento7 páginasMouse Molecular Genetics Student Activity 2Jonathan ZhouAinda não há avaliações

- Phase-Field Models For The Evolution of Complex SystemsDocumento37 páginasPhase-Field Models For The Evolution of Complex SystemsMathis PlappAinda não há avaliações

- Chapter Six: Capital Allocation To Risky AssetsDocumento26 páginasChapter Six: Capital Allocation To Risky AssetsjimmmmAinda não há avaliações

- 2d3d Opal Card Vending Machine ManualDocumento40 páginas2d3d Opal Card Vending Machine ManualbsimonopalAinda não há avaliações

- Mobil Dynagear Series Performance ProfileDocumento2 páginasMobil Dynagear Series Performance ProfileXavier DiazAinda não há avaliações

- 5100 Series Gas Analyzer: Product Data SheetDocumento2 páginas5100 Series Gas Analyzer: Product Data SheetSai KamalaAinda não há avaliações

- Call For IPSF-EMRO Regional Working Group Subcommittees 2018-19Documento4 páginasCall For IPSF-EMRO Regional Working Group Subcommittees 2018-19IPSF EMROAinda não há avaliações

- To Signals and SystemsDocumento57 páginasTo Signals and SystemsMUHAMMAD HAFIZUDDINAinda não há avaliações

- Reformasi Birokrasi Di AustraliaDocumento54 páginasReformasi Birokrasi Di Australiazaky ahmadAinda não há avaliações

- A Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFDocumento7 páginasA Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFRomaric OuetchehouAinda não há avaliações

- Module 4 NotesDocumento20 páginasModule 4 NotesvijaykumaryadavAinda não há avaliações

- Bubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Documento7 páginasBubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Vikas PuniaAinda não há avaliações

- Filters in GeneralDocumento3 páginasFilters in GeneralJoseGarciaRuizAinda não há avaliações

- Cognitive TheoryDocumento18 páginasCognitive TheoryshaelynAinda não há avaliações

- Overhead Line Splices Automatic Copper: Splices For Metric ConductorDocumento27 páginasOverhead Line Splices Automatic Copper: Splices For Metric ConductorAzad RahmanAinda não há avaliações

- Alenar R.J (Stem 11 - Heliotrope)Documento3 páginasAlenar R.J (Stem 11 - Heliotrope)REN ALEÑARAinda não há avaliações

- Modelacion Fisicomatematica Del Transporte de Metales PesadosDocumento11 páginasModelacion Fisicomatematica Del Transporte de Metales PesadosdiegoAinda não há avaliações

- Academic SummaryDocumento4 páginasAcademic SummaryJacqui PendergastAinda não há avaliações

- 8th Grade GT Science SyllabusDocumento2 páginas8th Grade GT Science Syllabusapi-420198655Ainda não há avaliações

- Johnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartDocumento2 páginasJohnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartUlf NymanAinda não há avaliações

- CSAT 2019 Spe3D Duguid - Andrew PDFDocumento111 páginasCSAT 2019 Spe3D Duguid - Andrew PDFdocturboAinda não há avaliações

- Thrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Documento7 páginasThrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Muhammad RidwanAinda não há avaliações