Escolar Documentos

Profissional Documentos

Cultura Documentos

English Cipanun

Enviado por

BookMaggotDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

English Cipanun

Enviado por

BookMaggotDireitos autorais:

Formatos disponíveis

1.

INTRODUCTION

An aircraft could not fly when it is in bad condition. Bad condition is referred as unairworthy which means it is not safe to fly until rectification has been done. This project is carried out to rectify the problems on Cessna 310 aircraft to ensure that it meets the airworthiness requirements.

2.0

PROBLEMS

The Cessna 310 was the first twin-engine aircraft design from Cessna to enter production after World War II. The 310 first flew on January 3, 1953 with deliveries starting in late 1954. The sleek modern lines of the new twin were backed up by innovative features such as engine exhaust thrust augmentor tubes and the storage of all fuel in tip tanks in early models. In 1964, the engine exhaust was changed to flow under the wing instead of the augmentor tubes, which were considered to be noisy. The Cessna 310 was a common charter aircraft for the many air taxi firms that sprang up in the general aviation boom that followed World War II. The advantages to the Cessna 310 over its contemporaries, such as the Piper Aztec, were its speed, operating costs and after market modifications such as the Robertson STOL kits which made it popular world wide for its bush flying characteristics. It could access short fields while at the same time carrying a large useful load of 2000 lb. or more at high speeds for a twin engine piston aircraft.

2.2

Instruments A tachometer indicates a safe range of speeds at which the engine may be operated. Without tachometer, it is possible that the engine is used for a period that exceeds its limit and lead to engine failure. The manifold pressure gauge gives the pilot an approximation of the power the engine is producing. The aircraft flight manual includes charts showing the various combination s of r.p.m. and manifold pressure that produce desired engine performance. Altimeter is calibrated to indicate higher altitude with the decreases in pressure and usually referenced to sea level. Damaged altimeter will cause the instruments to give wrong altitude of aircraft especially if the weather is bad for the pilot will rely on this instrument as guidance. This can lead to engine failure and improper landing. All these three instruments mentioned are the problematic parts and very critical for an aircraft to fly in airworthy condition.

2.2.1

Missing Tachometer For this particular aircraft, the tachometer is missing. This problem is very critical which could cause the pilot unable to know whether the engine has exceeded its operation limit or not. If the engine operation limit has exceeded or used at long period at high speeds, this may causes excessive wear and other damage to engines. At last, the engine fails and aircraft crashes. The missing tachometer will absolutely cause the aircraft to be grounded until a new tachometer is placed. These

consequences cannot be avoided without a tachometer. (Refer to Figure 1)

Figure 1: Missing Tachometer Cases: On 16 June 2002 at 1942 hrs, the aircraft, Robinson R44, GSYTN was on a flight from Denham to a private landing site in

Leicestershire. Approximately 12 minutes after take-off, while cruising at 1,500 feet, the pilot noticed that the engine needle of the dual engine/rotor tachometer was indicating zero. He immediately confirmed that the throttle governor was on before putting the aircraft into what was described as an "urgent precautionary descent", which subsequently developed into an autorotative landing. During the landing, the tail boom was severed by a main rotor blade strike, immediately ahead of the tail rotor assembly. Neither occupant was injured during the event.

2.2.2

Uncalibrated Manifold Pressure Gauge An uncalibrated manifold pressure gauge would result in error when reading the power of the engine developing. This instrument has not been calibrated for a period since it was grounded. The manifold pressure gauge would certainly cause false reading of the engine power.

Figure 2: Uncalibrated Manifold Pressure Gauge Cases: On 24 June 2005, Robinson R22 Beta Helicopter CFQDQ crashed at Courtenay, British Columbia due to engine power loss. The pilot monitors the engine manifold pressure gauge to ascertain the power being produced but it fails to give proper reading and this leads to failure of maintaining the helicopters power.

2.2.3

Damaged Altimeter Without an altimeter, the correct altitude of an aircraft cannot be measured. As for this aircraft, the altimeter is in a error conditions. The glass is broken, the needle is not indicating the proper position of aircraft and the altimeter itself is not properly positioned. (Refer to Figure 2)

Figure 2: Damaged Altimeter Cases: The Ukrainian-built Antonov An-140 aircraft operated by the state-run Azerbaijani carrier crashed soon after takeoff on the evening of 23 December, killing all 18 passengers and five crew on board. The flight recorders have apparently shown that the altimeter failed immediately after takeoff. This meant that the pilots could not establish the aircraft's altitude.

3.0 OBJECTIVES

3.

Objective on Missing Tachometer The missing tachometer has to be replaced as soon as possible in order to help pilot in monitoring the safe range of speeds during flight.

3.

Objective on Uncalibrated Manifold Pressure Gauge For uncalibrated manifold pressure gauge, the uncalibrated gauge has to be replaced with a new calibrated manifold pressure gauge on the aircraft instrument panel

3.

Objective on Damaged Altimeter This particular defective instrument has to be removed and replace with a new altimeter.

4.0 SOLUTIONS 4.1 INSTRUMENTS There are three problems identified for this particular aircraft which is the missing of tachometer, uncalibrated manifold pressure gauge and damaged altimeter.

4.1.1

New Replacement Tachometer A new tachometer has to be replaced for the missing tachometer. The missing tachometer is replaced based on Cessna 310 Maintenance Manual in the aircraft hangar.

4.1.1.1 Removal of Tachometer For removal of missing tachometer, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to remove the tachometer. Tools and Equipments VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads. Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Removal

a.

Remove screws attaching instrument panel section, in which instrument is attached, to angle assembly.

b.

Remove nuts from upper portion of instrument panel section.

c.

Hinge instrument panel section aft on the lower shock mount.

d.

Tag and disconnect electrical wires and hoses from back of instrument being removed.

e.

Plug all hoses and cap fittings to prevent the entry of foreign matter.

f. g. NOTE:

Remove the connectors, nuts, and lockwashers. Remove lower attaching nuts and bolts. If the instrument is to be replaced, remove the hose fittings or electrical connector and install the replacement unit.

4.1.1.2 Installation of Tachometer For installation of missing tachometer, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to install the tachometer.

Tools and Equipments

VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads. Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Installation

NOTE: All straight threads must be lubricated with VV-P-236 petroleum; tapered threads with JAN-A-669 anti-seize compound. Apply lubricant to male threads only, omitting the first two threads. a. Instrument is positioned on back of instrument panel and it is secured with lower attaching bolts and nuts. b. Lighting fixtures and rubber washers are installed; they are secured with lockwashers and nuts. c. Connectors are attached to lighting fixtures. d. Hoses or electrical connecters are connected as tagged at removal. e. Instrument panel section is hinged forward on lower shock mounts and secured to stationary instrument panel with screws.

4.1.1.3 Flowchart

Removal of Tachometer

Installation

4.1.2 New Replacement Manifold Pressure Gauge The manifold pressure gauge for this particular aircraft is not calibrated and defective. It is decided that the safest method is to replace the old gauge with a brand new manifold pressure gauge.

4.1.2.1 Removal of Manifold Pressure Gauge For removal of manifold pressure gauge, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to remove the manifold pressure gauge. Tools and Equipments VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads. Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Removal

a.

Remove screws attaching instrument panel section, in which instrument is attached, to angle assembly.

b.

Remove nuts from upper portion of instrument panel section.

c.

Hinge instrument panel section aft on the lower shock mount.

d.

Tag and disconnect electrical wires and hoses from back of instrument being removed.

e.

Plug all hoses and cap fittings to prevent the entry of foreign matter.

f.

Remove the connectors, nuts, and lockwashers.

g.

Remove lower attaching nuts and bolts. NOTE: If the instrument is to be replaced, remove the hose fittings or electrical connector and install the replacement unit.

4.1.2.2 Send for Calibration For manifold pressure gauge, it is not allowed for a technician to calibrate this device. Therefore it is recommended that this instrument is sent to the manufacturer for calibration or it is

replaced with a new manifold pressure gauge. When comparing between these two options, it is better for the instrument to be replaced for the price is cheap and the instrument has not been replaced since its first operation. 4.1.2.3 Installation of Manifold Pressure Gauge For installation of manifold pressure gauge, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to install the manifold pressure gauge.

Tools and Equipments

VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads. Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Installation

NOTE: All straight threads must be lubricated with VV-P-236 petroleum;

tapered threads with JAN-A-669 antiseize compound. Apply lubricant to male threads only, omitting the first two threads. a. Instrument is positioned on back of instrument panel and it is secured with lower attaching bolts and nuts. b. Lighting fixtures and rubber washers are installed; they are secured with lockwashers and nuts. c. Connectors are attached to lighting fixtures. d. Hoses or electrical connecters are connected as tagged at removal. e. Instrument panel section is hinged forward on lower shock mounts and secured to stationary instrument panel with screws.

4.1.2.4 Flowchart

Removal of Manifold Pressure Gauge

Send for Calibration / New

Installation

4.1.3 New Replacement Altimeter The altimeter is in a very defective condition that the glass is broken, pointer is not functioning and the position of the instrument is not correct. This instrument is replaced according to appropriate procedures.

4.1.3.1 Removal of Altimeter For removal of altimeter, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to remove the altimeter. Tools and Equipments VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads. Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Removal

a.

Remove screws attaching instrument panel section, in which instrument is attached,

to b.

angle assembly. Remove nuts from upper portion of instrument panel section. c. Hinge instrument panel section aft on the lower shock mount. d. Tag and disconnect electrical wires and hoses from back of instrument being e. removed.

Plug all hoses and cap fittings to prevent the entry of foreign matter.

f. g.

Remove the connectors, nuts, and lockwashers. Remove lower attaching nuts and bolts.

NOTE: If the instrument is to be replaced, remove the hose fittings or electrical connector and install the replacement unit.

4.1.3.2 Installation of Altimeter For installation of altimeter, Cessna 310 Manual is referred. All the works are done in the hangar. It takes about half an hour to install the altimeter.

Tools and Equipments VV-P-236 petroleum to lubricate straight threads. JAN-A-669 anti-seize compound to lubricate tapered threads.

Rubber washers secured with lockwashers and nuts. Flat Head and Phillip Screwdriver. Torch light for proper lighting during maintenance. Socket and Wrench Set. Procedures of Installation

NOTE: All straight threads must be lubricated with VV-P-236 petroleum; tapered threads with JAN-A-669 anti-seize compound. Apply lubricant to male threads only, omitting the first two threads. a. Instrument is positioned on back of instrument panel and it is secured with lower attaching bolts and nuts. b. Lighting fixtures and rubber washers are installed; they are secured with lockwashers and nuts. c. d. Connectors are attached to lighting fixtures. Hoses or electrical connecters are connected as tagged at removal. e. Instrument panel section is hinged forward on lower shock mounts and secured to stationary instrument panel with screws. 4.1.3.3 Flowchart

Removal of Altimeter

Installation

5.0 COST 5.1 INSTRUMENTS PRICE LIST ITEMS Cessna Tachometer Cessna Altimeter

Manifold Pressure Gauge

PART NO. C668020 C661611-0105 C668001-0103

DESCRIPTION 1 Unit 1 Unit 1 Unit

COST (RM) 175.44 451.50 300.00

5.4

TOTAL COST

6.0 CONCLUSION

Você também pode gostar

- Vector Mechanics For Engineers-STATICSDocumento15 páginasVector Mechanics For Engineers-STATICSBookMaggot0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Why Choose MBA MSC BUSDocumento1 páginaWhy Choose MBA MSC BUSBookMaggotAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Understanding The Concept of The Gear Ratio: 1.27 Inches / 2 0.635 InchesDocumento1 páginaUnderstanding The Concept of The Gear Ratio: 1.27 Inches / 2 0.635 InchesBookMaggotAinda não há avaliações

- Seat Pitch Position On Two Seats, One Behind The Other - It Is NOT The Legrest Area As SomeDocumento3 páginasSeat Pitch Position On Two Seats, One Behind The Other - It Is NOT The Legrest Area As SomeBookMaggotAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- QuestionaireDocumento7 páginasQuestionaireBookMaggotAinda não há avaliações

- Typical Aircraft Charging CircuitDocumento1 páginaTypical Aircraft Charging CircuitBookMaggotAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Project p-37Documento2 páginasProject p-37BookMaggotAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Report Landing Gear Sek AkuDocumento3 páginasReport Landing Gear Sek AkuBookMaggotAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Aircraft PneumaticDocumento3 páginasAircraft PneumaticBookMaggotAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Ata Presentation Power PointDocumento9 páginasAta Presentation Power PointBookMaggotAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Retail Brochure 2011Documento176 páginasRetail Brochure 2011Oliver GunnellAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Nissan Qashqai J11. Instruction - Part 657Documento5 páginasNissan Qashqai J11. Instruction - Part 657Schalekis GeorgeAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Obrazac Za Narucivanje Upravljacke Jedinice-EngDocumento1 páginaObrazac Za Narucivanje Upravljacke Jedinice-EngkizonimeisterAinda não há avaliações

- Car AutomationDocumento2 páginasCar AutomationLuigi JamesAinda não há avaliações

- Specification Jumbo Drill Sandvik DD311D-40Documento4 páginasSpecification Jumbo Drill Sandvik DD311D-40Nathania Boas E SAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Retailer MRP List PDF FormatDocumento132 páginasRetailer MRP List PDF Formatshiva83% (6)

- A Comparative Study of The SuspensionDocumento7 páginasA Comparative Study of The SuspensionSivadanusAinda não há avaliações

- Mercedes Benz VitoDocumento366 páginasMercedes Benz Vitobmwscribd33% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Ch2 Solution2Documento385 páginasCh2 Solution2YoungCheon JungAinda não há avaliações

- Australian Motorcycle News - November 23, 2023 AUDocumento116 páginasAustralian Motorcycle News - November 23, 2023 AUOscar ValladaresAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Module1 - EV TechnologyDocumento40 páginasModule1 - EV TechnologyThiruvenkadam SrinivasanAinda não há avaliações

- Suzuki SV1000 '03 Service Manual Supplement PDFDocumento32 páginasSuzuki SV1000 '03 Service Manual Supplement PDFNikolas KarrerAinda não há avaliações

- Propulsion 1Documento64 páginasPropulsion 1jtradio13100% (1)

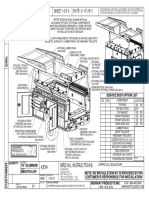

- Service Body 6212-001-AE: Sheet 1 of 6 DATE: 2/15/2011 P/NDocumento6 páginasService Body 6212-001-AE: Sheet 1 of 6 DATE: 2/15/2011 P/NmanutencaoseibAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Dailymobilecraneinspectionchecklist 140110014950 Phpapp02Documento2 páginasDailymobilecraneinspectionchecklist 140110014950 Phpapp02slamet4riadiAinda não há avaliações

- RentalDocumento8 páginasRentaldwi haryantoAinda não há avaliações

- Operations MotorDocumento203 páginasOperations MotorjohnAinda não há avaliações

- Aircraft Lighting RequirementsDocumento1 páginaAircraft Lighting Requirementsdonnal47100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Maglev TrainsDocumento11 páginasMaglev TrainsNeeraj SinghAinda não há avaliações

- Dodge Dakota 1997 - 2000 Fuse Box DiagramDocumento7 páginasDodge Dakota 1997 - 2000 Fuse Box DiagramDaniel herbas ramirezAinda não há avaliações

- Regal Raptor NAC Owner Manual PDFDocumento45 páginasRegal Raptor NAC Owner Manual PDFPAULO VILCHES0% (1)

- Modelguide 2014 TrucksDocumento36 páginasModelguide 2014 TrucksShawn PedersenAinda não há avaliações

- Me370sti 6tc 1989 OsaluetteloDocumento78 páginasMe370sti 6tc 1989 OsaluetteloMake100% (1)

- SEMINAR REPORT Railway BrakingDocumento21 páginasSEMINAR REPORT Railway BrakingAbhinay PandeyAinda não há avaliações

- VW Atlas - Body RepairsDocumento252 páginasVW Atlas - Body RepairsPaweł PaczuskiAinda não há avaliações

- CP CPS185Documento2 páginasCP CPS185Asad AijazAinda não há avaliações

- Vtu Mba Final Summer Project On Hyundai Part BDocumento31 páginasVtu Mba Final Summer Project On Hyundai Part Bvikash_thakur23100% (5)

- New Ceramic Products: Visit Us Online atDocumento5 páginasNew Ceramic Products: Visit Us Online atmiab1Ainda não há avaliações

- Vab - Mark IiDocumento2 páginasVab - Mark Iiabcmetum100% (1)

- Third Generation Montero Aftermarket Accesory Sheet - Sheet1Documento4 páginasThird Generation Montero Aftermarket Accesory Sheet - Sheet1Jose Luis Alcivar GuerraAinda não há avaliações