Escolar Documentos

Profissional Documentos

Cultura Documentos

Project Report 1

Enviado por

arunDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Project Report 1

Enviado por

arunDireitos autorais:

Formatos disponíveis

.

[ 1 ]

CHAPTER-1

1.1.0 INTRODUCTION

Agra is a major city on River Yamuna contributes about 90 MLD of sewage

with 18,000 kg. of BOD Load per day to river while the main part of the city is on the

western side of yamuna it has grown beyond the river on the eastern side which is

called trans-yamuna area while the original part of the city is called. The cis-yamuna,

a part of the city was severed and the collected waste water was pumped to a sewage

from beyond the city towards the south eastern part. However the system was not

functioning property and the waste water was following to the river through several

open drowns both in CIS and trans-yamuna areas. The respective quantities being

about 80 & 10 MLD. there are many city also that increase the Pollution like Mathura,

Vrindavan, Noida, Ghaziabad, Muzzaffar Nagar etc.

1.1.1 YAMUNA RIVER

River yamuna with a total length of around 1,370 Kilometers (851 ml) is the

largest tributary of the River ganga in northern India, Yamuna is consider to the most

sacred among all the rivers as per Hindu mythology its source is at yamunatri, in the

Uttarakhand Himalaya, in the Himalayan mountains, it flows through the states of

Delhi, Haryana and Uttar Padesh, before merging with the Ganges at Allahabad. The

cities of Delhi, Mathura and Agra lie on its banks.

Yamuna is one of the most polluted rivers in the world especially around

Delhi, which dumps about 57% of its waste in to the River. Delhi alone contributes

around 3,296 million litres per day of sewage in the River.

The main stream of the River Yamuna originated from the Yamunotri glaciar

near Bandar punch in the mussorie range of lover Himalaya in the district of uttar

Kashi in Uttar Pradesh, some say the source of the river is the saptarishi kund a

glacial lake.

1.1.2 POLLUTION IN YAMUNA RIVER

The yamuna river passing through 22 km in Delhi was once described as the lifeline

of the city, but today it has become one of the dirtiest rivers in the country. The

reason.

.

[ 2 ]

Delhi generates about 3,267 million litres per day (mld) of sewage while the

city's installed waste water treatment capacity is only 2,330 mld. More than 937 mld

of waste is not treated. Out of Delhi's 2,330 mld treatment capacity, 37 percent is

under-utilised and 1,270 mld of sewage is untreated and allowed to enter the river

everyday.

- The Yamuna's 22-km stretch in Delhi is barely 2 percent of the length of the

river, but contributes over 70 percent of the pollution load.

- Pollution levels in the Yamuna have risen, Biochemical oxygen demand

(BOD) load has increased by 2.5 times between 1980 and 2005- from 117

tonnes per day (TPD) in 1980 to 276 TPD in 2005.

- Delhi discharges about 3,684 MLD (million litres per day) of sewage into the

Yamuna.

- The faecal coliform count, which indicates the presence of disease causing

micro-organisms, is nearly 25,000 times more than the limit prescribed for

bathing.

- Delhi and Agra together account for 90 percent of the pollution in the river.

- The Capital has 16 drains discharging treated and untreated waste

water/sewage into Yamuna.

- The Najafgarh drain contributes to 60 percent of the total wastewater and 45

percent of the total BOD load being discharged from Delhi into the Yamuna.

The municipal wastewater has increased from 960 MLD in 1977 to 1,900

MLD in 1997.

- The capacity for treatment-increased from 450 MLD in 1977 to 1,270 MLD in

1997.

- A Central Pollution Control Board study on river water quality at the upstream

of Wazirabad shows dissolved oxygen (DO) level at 7.5 mg/l and BOD level

at 2.3 mg/l.

- At downstream Okhla, the DO level declined to 1.3 mg/l with the BOD at 16

mg/l indicating considerable deterioration in water quality due to discharge of

sewage and industrial effluents.

.

[ 3 ]

- The coliform count at Wazirabad is 8,506/100 ml whereas at Okhla, it

increases to 3,29,312/100 ml, as against the prescribed standard of 500/100

ml.

1.1.3 YAMUNA ACTION PLAN (YAP )

Government of India (GOI) in 12 towns of Haryana, 8 towns of Uttar Pradesh,

and Delhi under Yamuna Action Plan (YAP) which is

Sources : White Paper by the Ministry of Environment and Forests, Centre for

Science and Environment.

being implemented since 1993 by the National River conservat Directorate (NRCD)

of the Ministry of Environment and Forests. The

Japan Bank of International Coperation (JBIC) is participating in the

Yamuna Action Plan in 15 of the above 21 towns on the direction of the Supreme

Court of India with soft loan assistance of about Rs. 700 crore, while GOI is

providing the funds for the remaining 6 towns added later. The Indian government's

plans to repair sewage lines is predicted to improve the water quality of the river 90%

by the year 2010. The government has spent nearly $500 million trying to clean up the

river, most of it going to waste- treatment stations, yet pollution levels more than

doubled from 1993 to 2005 and continue to rise.

A total expenditure of Rs. 682 crore has been incurred under the first phase of

the Yamuna Action Plan (YAP). The phase which commenced in April 1993 was

completed in 2003 covering 21 towns of UP, Delhi & Haryana. The second Phase of

YAP commenced in December, 2004. Till september, 2009, an expenditure of Rs.

226.89 crore has been incurred under this phase. The projects taken up under YAP

include interception and diversion of raw sewage, setting up of Sewage Treatment

Plants, creation of low cost sanitation facilities, setting up of electric/improved wood

crematoria etc. Sewage treatment capacity of 753.25 mid has been created so far

under this Plan. Besides YAP, the Government of NCT of Delhi has taken up

sewerage and sewage treatment works under other schemes to fully address the

pollution load being discharged into Yamuna.

.

[ 4 ]

The water quality of Yamuna has not shown the desired improvement owing

to large gap between the demand and availability of sewage treatment capacity and

lack of fresh water in the river. This information was given by the Minister of State

for Environment and Forests (independent charge) Shri Jairam Ramesh in a written

reply to a question by Sh. Bhagat SinghKoshyari in Rajya Sabha November 23, 2009.

1.1.4 ECOLOGY

Yamuna supports a wide variety of plant and animal species. The river is

home to thousands of resident and migratory birds. The banks of the river are one of

the last refuges for the dwindling populations of blackbucks, Chitals and Nilgais etc.

1.1.5 MONITORING

The NRCD monitors the river at two places in Agra - upstream at Poiaghat,

(182 km from Okhla barrage towards Dayalbagh) and downstream behind the Taj

Mahal192 km from the Okhla barrage.

Sampling point of Yamuna River are :

1. Poiaghat - UP Stream of Agra (.182 km. from

okhala barrage towards, Dayalbagh)

2. Near Taj Mahal - down stream of Agra (192 km. from

okhla barrage)

River Yamuna is attached with the sewage line, like most Indian cities, Agra

metropolis is growing, the municipality, encompassing an area of 121.57 sq. km. had

a population as per 2001 census, of about 1.26 million by 2005, Thus had grown to

1.43 million with 2011 projected population estimated to touch 1.6 million. But Agra

designated as a world heritage site, faces a number of challenges in terms of water,

sewerage and financing municipal works, there is a bursting strain on the

infrastructure and services, both from the its own population.

1.1.6 EXPENDITURE ON RIVER CLEAN-UP

A comprehensive plan was prepared originally for Agra in 1917 at an

estimated cost of Rs 50 lakh. This included sewerage and storm water drainage, but

.

[ 5 ]

following a funds crunch it was never implemented. In 1945, this scheme was revised

for laying intercepting drains and sewers at an estimated cost of Rs 23.32 lakh.

However, it was only to be again revised in 1962 for construction of branch

sewers in the catchment of the main sewers (Mantola, Civil Line, Dholikhar, Mathura

road, Bhairon nala, Strand Road, Jama Masjid and Old Chhata sewers) at an estimated

cost of Rs 16.77 lakh.

Besides the numerous schemes and projects to improve sewerage the

government of India supported Agra with funds under YAP. However, this accounts

for just 14.5 per cent of the funds required for Agra's huge hardware plan. Till 2005,

Agra received Rs 77.75 crore under YAP. Another Rs 87.26 crore has already been

approved for the city under YAP-II.

Table :1.1.1 Investment to collect and treat sewage in Agra

Capital investment to clean Yamuna Rs. Crore

1962 sewerage scheme 0.167

Agra branch sewer scheme 0.10

1. YAP-I (spent in Agra) 69.91

2. YAP Extended (in Agra) 7.84

Tajganj sewerage scheme 43.57

JNNURM sewerage 763.13

JNNURM drainage 168.44

YAP-II allocated 87.26

Total 1140.42

Note : Under YAP-II Rs. 85.64 crore is for sewerage : Rs. 13 crore for YAP-III

project preparation in eight towns.

Sources :

1. Anon 2005 'MIS report of programmes under National River Conservation

plan Vol. II, MoEF, New Delhi, mimeo.

2. Anon 2002, 'Agra sewerage master plan', NEERI, Nagpur mimeo.

.

[ 6 ]

1.1.7 STATE OF THE RIVER

The two agencies monitoring water quality in Agra, the NRCD and the Agra

Jal Sansthan (AJS) do not seem to agree upon anything. NRCD's water quality

monitoring data shows high levels of DO in the Agra stretch during 1996-2005, when

the annual average DO level upstream of Agra increased from 10.65 mg/I to 11.60

mg/1.

At the same time data show that DO levels have also increased to 6.30 mg/I from

1.65 mg/I at the monitoring point downstream of Agra during 1996-2005. So after

receiving the city's treated, untreated and partially treated waste, the DO data, without

conviction deems the river water suitable for bathing. NRCD argues that the DO

levels have risen due to its efforts to clean up the river but the water supply board of

Agra- AJS - constantly complains that the water quality in the river at the water

supply intake is deteriorating.

The AJS says that DO levels touch zero several times in the year.43 In a

presentation on the Upper Ganga Water Supply scheme to supply drinking water to

Agra, the UPJN agrees with AJS and points out that minimum DO levels observed at

the AJS waterworks intake are always less than the 4-mg/level specified for a

drinking water source after conventional treatment.

1.2.0 SEWAGE OF AGRA

The liquid waste containing suspended colloidal and dissolved solid is called

sewage, so the sewage have the many type of water pollutants. it is required to reduce

the water pollution the process called sanitation.

The purpose of sanitation is to maintain such environment which do not effect

the public health. The correct sitting and proper orientation of buildings provide better

living for the inhabitants.

There is always the problem of generation of some undesirable matter,

especially that which is of excremental nature.

The development of Sanitary Engineering has contributed to the growth of

cities. Now the new of sanitation is very well realized in our country and every city is

now trying to have closed sewers and efficient disposal system of sewage, industrial

.

[ 7 ]

wastes and solid refuse. The efficient scheme can be partly financed from the cost

obtained from its products.

The 'Public Health Engineer' plays a major role in the field of control. The

methods have been developed by him for the treatment of water and sewage. He

should see that the effluent from any community does not pollute the natural water

supplies.

1.2.1 SANITARY ENGINEERING :

The branch of engineering which deals with the removal and disposal of the

sewage (liquid waste) without causing any nuisance to the community is called

Sanitary Engineering.

1.2.2 IMPORTANCE OF SANITARY ENGINEERING :

Sanitary Engineering deals with the removal and disposal of waste of the

entire city. Its importance is because it helps in :

(i) General developments of the city.

(ii) Protecting water supplies from pollution.

(iii) Collecting and disposing off the waste of the city.

(iv) Removing rain water from a town.

(v) Maintaining good environments for public

(vi) Preventing the pollution of natural streams etc.

(vii) Preventing the occurrence of disease e.g. malaria, typhoid etc.

1.2.3 Waste :

Anything which is not completely utilized and finally wasted in one or the other form

is called waste. The waste may be in any of the following states (i) Dry (ii) Semi

liquid (iii) Liquid

1.2.3 Dry Waste :

The waste which does not contain moisture is called dry waste. It is comprised

of the following items :

.

[ 8 ]

Fig. 1.2.1 : Flow Diagram of waste water system in Agra

(i) Rubbish : It means all sun-dry solid wastes as paper, leaves, grass, broken

furniture, pottery breakage, waste building materials etc. comparatively inert in

chemical action.

(ii) Ashes : These are the residues which remain after the combustion of coal,

coke, timber in the hearths and furnaces of industries and houses.

Sanitary

Engg.

Garbage House Drainage Industrial Storm Ventilation

Sewage water

Garbage Sullage Sewage Partial

Treatment

Combus Natural

Water

Course

Non Septic Dry weather Partial / Whole

Combustible Tank Flow

Filling Sewerage Natural water Course

Incineration

Sewage Sub Soil

Farm percolation

Sewage Treatment

works

Sludge Digestion Treatment units

Gases Effluent to Manure Effluent

natural water

course

Sewage Farming Land Filtration River

.

[ 9 ]

(iii) Garbage : It includes all types of semi-solid and solid waste food

products as vegetables, peelings of fruits, waste meat etc.

The dry-waste is never mixed with sewage. It is carried away from road-sides

by means of carts, trucks or tractor-trollys to safe places outside the city where it is

sorted into inflammable matter. The inflammable matter consists of sun-dried waste

such as paper, leaves, grass and broken furniture pieces. This is burnt in incinerators.

The non- inflammable matter consisting of ashes, buildings materials, vegetables,

peelings of fruits and waste meat are buried underground.

1.2.4 Semi-liquid waste : The semi-liquid waste is that waste which contains

organic matter. The semi-liquid waste i.e. human excreta or night soil is collected in a

separate pan in the same latrine from where it is removed through human agency. It is

then taken outside the town in closed cars, trucks or tanks mounted on the tractor-

trailors. The night- soil is buried in trenches and after 2-3 years it is converted into

good manure which can be used for growing crops.

1.2.5 Liquid Waste : It mainly consists of water and very less organic matter.

It is a discharge from the kitchens, bathrooms, washbasins and water-closets (flush

type latrines) and urinals.

1.2.5.1 Sullage : The liquid wastes from kitchens, bathrooms and wash-basins

is called sullage. It does not include discharge from hospitals, operation theatres and

slaughter-houses. It is only waste water and not very foul-smelling. It is carried in

open drains and is given no treatment before disposal. Amount of sullage is 100 kg. to

250 kg./ capita depending on the water supply allowance.

1.2.5.2 Sewage : it is liquid waste consisting of sullage, discharge from water closets,

urinal and hospitals including man and animal night- soil, it is easily decomposed and

creates foul-smelling gases and so it is conveyed in covered sewers.

1.2.6 TYPES OF SEWAGE :

(i) Sanitary Sewage

(ii) Storm Sewage

.

[ 10 ]

(i) Sanitary sewage is further divided into two classes :

(a) Domestic Sewage. It is liquid waste from kitchens and bathrooms and is

commonly known as sullage and excremental matter such as urine and

night-soil. This is from residential areas, offices and institutions.

(b) Industrial Waste. It is waste from industries and manufacturing

processes. This is also called trade waste in general.

The sewage consisting of the the above two classes (a) and (b) is called Dry

weather flow (D.W.F.). It does not contain any storm water i.e. rain water. The

quantity of D.W.F. is assumed same as water supply allowance per capita. In India an

average value is 150 litre per capita per day.

(ii) Storm Sewage. It is any surface water including rain water of the city, which may

be admitted into underground conduits.

1.2.7 SEWAGE TREATMENT :

The artificial process for changing or removing the objectionable constituents

present in sewage to make it less dangerous and offensive is called Sewage

Treatment.

Fig. 1.2.1 : Different states of water at Agra

WASTE

Dry State Semi Liquid State Liquid State

Rubbish Ashes Garbage

Human Excreta Hospital & Slaghter

House Waste

Sullage Sewage Storm Water

Sanitary Sewage Storm Sewage

Domestic Sewage Industrial Waste

.

[ 11 ]

1.2.8 OBJECTS OF SEWAGE TREATMENT :

- To reduce the strength of sewage, so that it may not pollute the receiving

water.

- To reduce its volume in general.

- To destroy the pathogens i.e. bacteria content.

- To recover its industrial value.

- To enable its safe and satisfactory disposal.

Like most Indian cities, Agra metropolis is growing. The municipality,

encompassing an area of 121.57 sq km had a population, as per 2001 census, of about

1.26 million. By 2005, this had grown to 1.43 million, with 2011 projected population

estimated to touch 1.6 million. But Agra, designated as a world heritage site, faces a

number of challenges in terms of water, sewerage and financing municipal works.

There is a bursting strain on the infrastructure and services, both from its own

population and from the regular onslaught of visiting tourists, estimated at 1.80

million every year.

1.2.9 AGRA CITY WASTE PROFILES:

Money Invested is Rs. 77.75 crore under YAP (Sept. 2005), Here is Capacity

Created : 90.25 MLD (STPs) And Untreated waste : 104.85-206.75 MLD (41-80 percent

of waste generated)

In the city, Agra Jal Sansthan (AJS) is in charge of operation and maintenance,

and revenue collection in supplying water, while all capital works related to water

supply and sanitation are undertaken by Agra Jal Nigam (AJN).

1.2.10 SEWAGE TREATMENT CAPACITY :

Three STPs with a combined capacity of 90,25 mld have been set-up under

YAP. While 78 mld (Dhandupura) and 2.25 mld (Burhi ka nagla) facilities were set-

up to deal with waste of Cis Yamuna, a solitary 10 mld STP was set-up at Peela Khar

to deal with the waste of trans-yamuna.

.

[ 12 ]

Figure :1.2.3 Diagram of a typical sewage treatment plant

The sewage network has been expanded to feed them, but the

infrastructure remains inadequate and the river remains dirty. Agra's sewerage system

is in shambles. Spread over 1,400 ha it is devoid of proper connections with most

sewage flowing into open drains. While the system is largely silted several lines

remain choked and damaged at a number of places. This has made the disposal of

sewage into nalas (open drains) a common affair. For example, the sewage arriving at

Dhandupura STP is partly from the small population connected to the sewerage

system, with the rest arriving from the 17 intercepted open drains. On the other hand,

incoming sewage at Burhi ka Nagla and Peela Khar STP arrives from intercepted

open drains. Notably, a major part of Agra, 8,300 ha remains unsewered.

Preliminary

treatment

(ii) Grit Chamber or deterious tank

(To remove heavy particles)

eq. grit, sand, ashes etc.

Raw

Sewage

Influent

(i) Screens (to remove floating

e.g. cloth wood)

(iii) Skimming tanks (to remove

lighter & greasy) matter

(iv) Clarifiers or

(sedimentation

tanks)

Application to

land

Irrigation Land filtratiuon

To natural

waters

Activated

sludge

Trickling

filter

E

F

L

U

E

N

T

Biological treatment

(to remove bacteria)

Secondary

treatment

(to remove)

colloidal

fines)

.

[ 13 ]

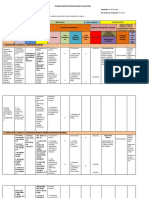

Table 1.2.1 : Monthly information of STP Established at Agra

Name

of City

Name of

STP

Capaciy

(MLD)

Average

received

effluent

of one

month

at STP

(MLD)

Influent Effluent Disposal

method

of

Effluent

River/

Earth

Daily

electric

problem

(hr/day)

Performance

Evaluation (%)

Flow

Loadin

g

Monthly

Average

TSS

(mg/l)

Average

BOD of

1 month

Average

TSS

(mg/l)

Average

BOD

(mg/l)

TS BOD

Agra

Dhandhu

-Pura

(U.A.S.B

. Type)

78 46.06 487.40 218.11 48.57 29.70 Earth 1.54 90.03 86.38 -

Burhi ka

Nagla

(W.S.P.

Type)

2.25 2.76 456.33 201.67 48.0 31.0 River 2.24 89.48 84.63

Over

Loadin

g

Peela

-Khar

(W.S.P.

Type)

10 9.75 475.0 206.0 48.0 30.0 River 2.15 89.85 85.43 -

Source : U.P.P.C.B. Agra

.

[ 14 ]

1.2.11 WATER SUPPLY :

According to the AJS, the total water demand of the city is 320 million litres

per day (mid), which includes the demand for bulk supply, estimated at 75 mld. The

water demand as estimated for the 1.42 million-population in 2005 was 245 mld,

which was calculated on a 170 litres per capita daily (Ipcd) standard. For this, the city

has two water treatment plants with a capacity to treat 410 mld in entirety.

1.2.12 WASTE GENERATION :

According to CPCB's Status of sewage treatment in India report of February

2006, the city generated 211 mid sewage in 2001. This is based on a sewage

generation factor of 168 Ipcd (or a UPJN estimates show that the water demand has

shot up from 284 mld to 320 mld leading to an increased wastewater discharge. But

how much is actually used is unknown. UPJN while reviewing YAP has estimated the

wastewater discharge in 2003 to be 152.15 mld. This assumes the water supply to be

107 Ipcd. This is far lower that the water supply estimates provided by AJS. R P S

Sanghu, chief chemist AJS says, "Per capita water supply is set at 135 Ipcd." This

difference in data will definitely affect the waste planning for the city.

The most recent estimates, however, have been collated by CPCB in its 2005-

06 annual report stating the flow in all drains to be 254 mld. This points to a 100 mld

rise in waste water generated over since UPJN's last estimate 3 years back.

1.2.13 FUTURE PLANS :

Now, Rs 124.13 crore has been sanctioned under YAP-II for UP and Agra

seems to be benefiting the most. The focus is on laying 41-km of sewers in the

western districts along with a 40 mld STP at Bijpuri and 33-km sewer in the northern

district with a 14-mld STP at Dayalbagh. However, the southern and eastern districts

have been completely ignored. I .N. Tyagi, project manager Yamuna pollution control

unit, UPJN Agra says: "Besides repairing the existing sewage systems promoting

citizen's participation have been envisaged." According to YAP-II Agra should have

an additional capacity of 54 mld enabling the city to treat 144.25 mld of its waste by

2009. But as per 2006 waste generation estimates this will still be inadequate.

.

[ 15 ]

Under JNNURM the COP of Agra has set aside more money for sewerage. Rs

763.13 crore out of Rs 7,854.64 crore has been allotted for laying new sewer lines,

STPs and SPS. Statistically speaking, this shall result in the creation of 1,028 km of

sewer lines, 264 mld treatment capacity, and 19 major and 36 minor pumping stations.

If this plan is implemented within the set time frame, Agra will have a sufficient

treatment capacity, and as a result lesser pollution loads will be discharged into the

river. However, until then the river will have to linger for respite while Agra plans to

go through with stopgap measures such as the Ganga jal project.

1.3.0 STRUCTURE OF THE INDUSTRY :

It is estimated that there are as many as 500 units in this industry, each one

employing on an average 6persons thus leading to a direct employment of almost

3000 persons. Besides, another 1000 persons are dependent on the related enterprises

and trading activities of the industry. A classification of these units according to a

geographical area in Agra district is given as under :

Table-1.3.1 Geographical Distribution of the Working Industry

Place Number of Units

Noorie Darwaja 380

Sheetla Gali 50

Bagh Muzzafar Khan 40

Chippitola 10

Moti Katra 20

Total 500

The working industry and businesses can be broadly classified as:

- Big Groups having their own production units or shops. They supply their

products to different cities and have even started exporting sweets.

- Medium groups having their own production units, shop etc but they supply

their product to commission agents and not directly to markets in different

cities.

.

[ 16 ]

- Very small groups having their own production unit but they are dependent

upon the commission agents even for the raw material and marketing of the

product.

- Commission Agents who have no production units of their own but are

involved in trading activity. The structure of the industry has an upside down

pattern of different categories of units according to their turnover.

1.3.1 INDUSTRIAL EFFLUENT OF AGRA :

The city of Agra enjoys a world-fame because of the Taj Mahal, which is why

one can find tourist inflow. Here throughout the year. In the industrial map of India,

Agra is famous for its leather shoe Manufacturing. Petha manufacturing and even

generator production. Due to pollution related problems, most of the industries are

being shifted to the outskirts of the City. Wastewaters obtained from industries are

generally much more polluted than the domestic or even commercial wastewaters.

Still, however, several industrialists try to discharge their effluents into our natural

river streams, through unauthorised direct discharges. Such a tendency on the part of

the industries may pollute the entire river water to a grave extent, thereby making its

purification almost an impossible task. Sometimes, the industries discharge their

polluted wastewaters into municipal sewers, there by making the task of treating that

municipal sewage, a very difficult and a costly exercise.

The industries are, therefore, generally prevented by legal laws, from

discharging their untreated effluents. It, therefore, becomes necessary for the

industries to treat their wastewaters in their individual treatment plants, before

discharging their effluents either on land or lakes or rivers, or in municipal sewers, as

the case may be.

Agra Economy is mainly based on industries which include Tannery, Petha,

dairy etc.

1.3.2 PETHA INDUSTRY :

The Petha cluster in Agra is more than a century old. Currently, 35 tonnes of

organic petha waste is produced per day and it uses coal for cooking purposes. The

oldest firm, in business since 1885, is Bhimsain's. The latest and perhaps the most

popular is Panchi. Petha here refers to a form of sweet that is made from Ash-

.

[ 17 ]

Pumpkins. A decade ago there were just two varieties of petha. But changing times

have brought in additional flavors; chocolate, cherry, mango, orange, stuffed petha,

coconut petha and even sandwich pethas. Wholesome and nutritive, it is known to act

like a blood coagulant and is used in treatment of peptic ulcers and obesity. The

delicious sweet preparations made from it are used for the treatment of tuberculosis,

weakness of the heart and anemia Most of Petha manufacturing units are located at

Nurie Darwaza in Agra. At present there are about 500 units that are producing Petha

sweet in Agra. However, only three or four of them are working efficiently and have

adopted canning technology to export their products in the international markets

Environmental degradation caused by effluents let out by the manufacturing unties

has been worrying the State Government. The waste water from Petha manufacturing

units has higher content of BOD (Biological Oxygen Demand) and COD (Chemical

Oxygen Demand) and also contains some suspended solids, dissolved solids etc. This

waste-water is usually let out in the river Yamuna that makes the water unusable and

unsafe. The State Government is planning to shift all the Petha manufacturing units at

Kalindi Vihar where a common waste waster treatment plant has been establishes, but

most of the manufactures are not keen on shifting their units because of lack of other

infrastructure facilities there. Besides, the small manufacturers lack the purchasing

power to buy their own piece of land.

Oriented work as not much mechanization has been done as yet. Easy &

cheaper processing and easy loan system through commission agents has lead to sub

contracting of production. Many workers after receiving experience of 2-3 years have

started running their own units with a small working capital investment, which too is

easily available from commission agents, Environmental degradation caused by

effluents let out by the manufacturing unties has been worrying the State Government.

The waste water from Petha manufacturing units has higher content of BOD.

(Biological Oxygen Demand) and COD (Chemical Oxygen Demand) and also

contains some suspended solids, dissolved solids etc. This waste-water is usually let

out in the river Yamuna that makes the water unusable and unsafe. The State

Government is planning to shift all the Petha manufacturing units at Kalindi Vihar

where a common waste water treatment plant has been establishes, but most of the

manufacturers are not keen on shifting their units because of lack of other

.

[ 18 ]

infrastructure facilities there. Besides, the small manufacturers lack the purchasing

power to buy their own piece of land.

1.3.3 DAIRY INDUSTRY :

Dairy industry soctor is big as its is surrounded by many village like Kiroli,

Fatehpursikri, Acchnera, Fatehabad, Kheragarh etc. Many tonnes of milk and milk

products (skimmed milk, cheese, Ghee, curd, buttermilk, ice creams) are supplied to

nearby cities like Dehli, Noida, Gurgoan. The main dairies of Agra are Shanti Dairy,

Neeraj Dairy, Milan food products, Universal food products (Creambell), Bhola Baba

Dairy and a large number of uncountable small dairy running at small shops and

houses. The effluent from these dairies contains a high quantity of oils,

Microorganisms, enzymes, solid waste which is discharged to Yamuna after being

flowing in the drains.

With increase in demand for milk and milk products, many dairies of different

sizes have come up in different places. These dairies collect the milk from the

producers, and then either simply bottle it for marketing, or produce different milk

foods according to their capacities. Large quantity of waste water originates due to

their different operations. The organic substances in the wastes comes either in the

form in which they were present in milk, or in a degraded form due to their

processing's. As such, the dairy wastes, though biodegradable, are very strong in

nature.

1.3.4 EFFECTS OF THE DAIRY WASTES ON THE RECEIVING STREAMS/

SEWERS :

As observed from the above table the waste is basically organic in nature. This

is also slightly alkaline when fresh. When these wastes are allowed to go into the

stream without any treatment, a rapid depletion of the dissolved oxygen content of the

stream occurs, along with growth of sewage fungi covering the entire bottom of the

stream and the submerged parts of the hydraulic structures within it. The waste is said

to carry, occasionally, the bacteria responsible for tuberculosis. Though alkaline in

fresh condition, the milk waste becomes acidic due to the decomposition of Lactose

into lactic acid under anaerobic condition, particularly after complete oxygen

depletion of the stream. The resulting condition precipitates casein from the waste,

.

[ 19 ]

which decompose further into a highly odourous black sludge. At certain dilutions the

dairy waste is found to be toxic to fishes also.

As the dairies are usually situated in rural areas or in small towns, the question

of discharging the dairy waste into the sewers does not arise. In large cities, combined

treatment of domestic sewage and dairy waste may be considered if the latter

constitutes only 10% in volume of the former. In that case the dairy waste should be

discharged in a fresh condition, as a putrefied waste may cause corrosion of the

sewers.

1.3.5 TANNERY INDUSTRY :

The tannery industry of Agra is significant source source of pollution. In

particular waste water from the sector contains strong alkalis, bio-waste and high

concentration of heavy metals such as chromium, if not treated properly, his possess a

significant risk to human health and environment. Skins typically arrived at the

tannery dried stiff and dirty with soil and gore. First the ancient tanners would soak

the skins in water to clean and soften them. Then they would pound and scour the skin

to remove any remaining flesh and fat. Next the tanner needed to remove the hair

fibers from the skin. This was done by either soaking the skin in urine, painting it with

an alkaline lime mixture, or simply letting the skin putrefy for several months then

dipping it in a salt solution. After the hair fibers were lossened the tanners scraped

them off with a knife and the effluent goes to rivers, oceans and other water bodies.

The tanning industry is one of the oldest industries in India. Usually the

tannery wastes are characterised by strong colour, high BOD, high pH and high

dissolved salts. Disposal of these wastes into water courses or onto land, with or

without prior sedimentation, was not a problem perhaps decades ago. But in the recent

years, the concentrated growth of this industry in certain localities has shown how the

waste from this industry can cause irreversible damage to the water environment in

the vicinity. In view of its peculiar pollution potential, and the increasing demand for

good quality of water, both for domestic and other industrial purposes, it has become

essential to treat the waste to a certain degree prior to its disposal.

.

[ 20 ]

1.3.6 EFFECTS OF THE TANNERY WASTE-ON RECEIVING WATERS

AND SEWERS :

As stated earlier the tannery wastes are characterized by high BOD, high

suspended solids, and strong colour. These wastes when discharged as such

deplete the dissolved oxygen of the stream very rapidly, due to both chemical

and biological oxidation of sulphur and organic compounds. A secondary

pollution of the stream may occur due to the deposition of solids near the

discharge point and its subsequent putrefaction. The gas evolved during this

process has got a typical foul odour. Usually chlorides are refractory to water

treatment processes; as such, chloride in excess of tolerance limits (usually 500

mg/l when used as raw water for domestic purposes) render the water unsuitable

for future use. The chromium is toxic to aquatic life and inhibits the growth of

fish in the stream. However most of chromium is precipitated in the combined

tannery waste when mixed with spent lime liquor.

1.3.7 METHODS OF TREATING INDUSTRIAL WASTEWATERS :

Industrial wastewaters, as pointed out above, usually contain several

chemical pollutants and toxic substances in too large proportions. The

characteristics of the produced wastewater will usually vary from industry to

industry, and also vary from process to process even in the same industry. Such

industrial waste waters cannot always be treated easily by the normal methods of

treating domestic wastewaters, and certain specially designed methods or

'sequence of methods' may be necessary.

Figure 1.3.1 : Digram for the Treatment of the Combined Waste from a

Industry

The increase of velocity becomes prohibitive due to the increased velocity

head and frictional losses. The velocity of flow plays another important role in the

Raw

Waste Primary Setting

Tank

Anaerobic

Lagoon

Aerated

Lagoon

Effluent

BOD=

190 mg/l

Sludge to Sand

Drying Bed

COD=2900 mg/l Screen

BOD 1500 mg/l

(Detention time = 10 days) (Detention time = 6 days)

Screenings

.

[ 21 ]

design of U-tube aeration tanks. The aeration unit should be supplied with sufficient

amount of air. But the maximum air water ratio in the aeration unit practicable is a

function of the velocity. Higher velocity is needed for a desired higher air water ratio.

The air requirement in U-tube aeration system is much smaller than that in the

conventional aerobic biological reactors, because of the greater solubility and hence

greater oxygen transfer rate at the very high hydrostatic pressure. It has been found

that a maximum of 20% air-water ratio can be achieved at a velocity of 1.2 m/sec.

Higher velocity in the range of 1.8 m/sec to 2.4 m/sec is required for attaining an air-

water ratio of around 25%. It may be noted that surging occurs in the aeration tube,

when maximum practicable air water ratio is exceeded.

The velocity of flow within the aeration tube usually ranges from 1 to 2 m/sec,

and an oxygen transfer rate up to 3 kg/hr/m

3

can be achieved.

The power requirement depends on the oxygen requirement, oxygen transfer

efficiency and the depth of the air-injector. Higher the depth, higher will be the power

consumption. But higher depths are required to generate higher density difference

between the downflow and upflow sections, for circulation. The air injector depth

ranges in between 20 m and 40 m. The resulting power economy ranges from 4.5 to

3.0 Kg of oxygen per KWH.

The inherent efficiency of the U-tube aeration system and the associated economy in

land and power consumption in its use, will soon establish its position in the field of

biological treatment of domestic and even strong industrial wastes. As the U-tube

aeration units are capable of handling a very large volume of waste occupying

comparatively very small area, the system may be employed where there is no room

for installation of a conventional treatment system, particularly for the treatment of

wastes at the sea out-fall. Releasing to Yamuna by industrial effluent and Sewerline.

1.4.0 SIGNIFICANCE OF THE STUDY :

(i) It is Recently Research work on the sewage, Industrial effluent and

water of River Yamuna so it will help to have knowledge about the

qualitative characteristics of waste water and water of River Yamuna at

Agra.

.

[ 22 ]

(ii) Cause of waste water many deseases can effect the humans and

animals so it will help to aware human being Protect Yourself and

animals.

(iii) Waste water of any city in the major Problems. Thease day everyone

wants to have knowledge about Polluted water so they can obtain by

This research work.

(iv) River Yamuna is the holy river of the Hindu's Puran and shastra. That's

why they take bath on holy festivals and many dons so they can take

about polluted before worship water and may avoid it.

(v) The human being can save them animals to avoid river water as

drinking water to animals.

(vi) Sewers are very polluted and thease are very dangerous for human

being if a person have knowledge about harmfulness then they could

make a distance of Agra's sewer line and they can protect their health.

(vii) Citizens of Agra may aware about polluted water with the help of this

research work and they may be started sanitary work.

.

[ 23 ]

CHAPTER 2

OBJECTIVES OF STUDY

1. To determine and comparison after ETP and before ETP colour, odour, pH,

TSS, TDS, TS, BOD, COD, oil and grease in the effluents of Petha, Tannery

and dairy industries at Agra.

2. To determine and comparison pH, TDS, TSS, TS, BOD and COD in the

sewage before STP and after polishing pond of sewage treatment plants (STP)

at Agra.

3. To determine and comparison colour, Odour, turbidity, temperature, EC, pH,

BOD, COD, l C , MPN of TC and FC in the water of upstream and down

stream of river Yamuna at Agra.

4. To compare the final outlet of sewage, final outlet of selected industrial

effluents with the standards prescribed by U.P.P.C.B.

.

[ 24 ]

CHAPTER 3

3.0.0 INTRODUCTION

Related literature acts as the back bone for a researcher. Infact the researcher

who undertakes a research project with systematic reviewing of other studies and

writings related to the problem, completes successfully the research. It is obviously

imprudent and wasteful to proceed in any study without knowing what was gone

before? The competent physician must keep constantly abreast of the latest

discoveries in the field of medicine. The successful lawyer must be readily able to

locate information pertinent to the case in hand obviously a careful student of

technology, the research worker should become familiar with the location and use of

the sources of Environmental information. Bearing this in mind a comprehensive

survey of the related literature was made.

Study of the related literature implies location, reading and evaluating reports

of researches as well as report of casual observations and opinion that are related to

the individual's planned research project.

3.1.0 SIGNIFICANCE OF THE REVIEW RELATED LITERATURE

Mc Garth and Watson (1954) have asserted that a review of the literature and

related research report is almost as important component in beginning a research

project.

When a new research project is launched the researcher has to construct its

background with the previous work done by others. We learn from experience of

others and our own experience. By reviewing the literature related to the problem the

researcher not only becomes aware about history of research problem but also

establishes a link between past and present. Review of research studies serves a

buckle, between the old and new, between the known and unknown and between the

already investigated and to be investigated. It develops researcher's insight and

establishes his intellectual superiority over others. It removes misgivings and

miscronceptions about the problem. Defining and delimiting the problem is not at all

possible without review of related literature.

The significance of review of related literature displayed in the following

diagram :

.

[ 25 ]

Fig. 3.1.1: Schematic representation of significance of Review of Literature

3.2.0 SOURCES OF RELATED LITERATURE

There are several sources of review of related literature in which some source

are reliable and some unreliable. The reliable sources have an important place in

research but sometimes unreliable sources play an important role in research.

Unreliable sources give clues and insight to researches. So both types of the sources

have their own importance. It is necessary to review thoroughly both types of the

sources. There are several sources of review of related literature in periodicals,

indices, abstracts, books and text books, monographs, year books, bulletins and

survey reports, educational research information centers, microfilms, dissertations and

thesis, newspapers etc. These sources can be divided in two parts : (i) Primary sources

(ii) Secondary sources

Primary source is a description of the study by the individual who actually

observes or wishes the accurance can carries it out.

Secondary source materials in education include publication in the events

described. These materials comprise text, books, encyclopedia. So both type sources

have their own importance. It is necessary to the researcher to review thoroughly both

types of sources.

The significant source of literature which can be exposed by the novice

researcher are exhibited as following :

.

[ 26 ]

Fig. 3.1.2: Showing the significant sources of Related Literature

Thus it can be concluded that review of literature is the foundation of research

work. Keeping in view the importance of related literature before the actual work on

the problem investigation made survey of the related literature.

3.3.0 SOME RECENT RELATED INDIAN STUDIES

Contaminated and polluted water now kills more people than all forms of

violence including wars, according to a United Nations report released on March 22,

2010 on World Water Day that calls for turning unsanitary wastewater into an

environmentally safe economic resource. According to the report titled "Sick Water"

90 percent of wastewater discharged daily in developing countries is untreated,

contributing to the deaths of some 2.2 million people a year from diarrheal diseases

caused by unsafe drinking water and poor hygiene. At least 1.8 million children

youngerthan 5 die every year from water related diseases.

Fully 80 percent of urban waste in India ends up in the country's rivers and

unchecked urban growth across the country combined with poor government

oversight means the problem is only getting worse. A growing number of bodies of

water in India are unfit for human use, and in the River Ganga, holy to the country's

82 percent Hindu majority, is dying slowly due to unchecked pollution.

New Delhi's body of water is little more than a flowing garbage dump, with

fully 57 percent of the city's waste finding its way to the Yamuna. It is that three

billion liters of waste are pumped into Delhi's Yamuna (River Yamuna) each day.

.

[ 27 ]

Only 55 percent of the 15 million Delhi residents are connected to the city's sewage

system. The remainder flush their bath water, waste water and just about everything

else down pipes and into drains, most of them empty into the Yamuna. According to

the Centre for Science and Environment, between 75 and 80 percent of the river's

pollution is the result of raw sewage. Combined with industrial runoff, the garbage

thrown into the river and it totals over 3 billion liters of waste per day. Nearly 20

billion rupees, or almost US $500 million, has been spent on various clean up efforts.

3.3.1 MAHARASHTRA HAS THE MOST POLLUTED RIVERS IN INDIA

That Mithi river has been reduced to a filthy nullah is well-known. However,

now a report of the Central Pollution Control Board (CPCB) shows that Maharashtra

has the largest number of polluted rivers in the country. The CPCB draws up a list of

polluted river stretches in the country on the basis of what it calls "water quality

monitoring". It has identified 26 such rivers in Maharashtra with 28 polluted stretches.

Mula and Mutha in Pune, Kalu and Bhatsa in Thana and Mithi river in Mumbai are

among these.

Environmental experts are worried that it is not only industrial pollution,

which is responsible for degrading the quality of water in state rivers. The rapid

urbanisation across the state is a major culprit as well. "Domestic sewage is a source

of pollution besides industrial and other sources," said an official from the Union

ministry of environment and forests. So even a river like Kundalika, which flows

through the Sahyadris in Raigad, now house a polluted stretch. Similarly, Nira a

tributary of Bhima in Solapur, and Kanhan, a rive flowing through Nagpur have been

polluted because of industrial and domestic effluence.

The CPCB has marked 1.50 polluted river stretches in India, which includes

almost all the major rivers. After Maharashtra, Gujarat has the most polluted rivers,

showing that industrial activity is a major source of pollution.

The National River Conservation Programme (NRCP) is the nodal central

government plan to fight river water pollution. However, it covers only 38 rivers in 20

states. Of these, the clean-up of just four rivers in Maharashtra Panchganga, Tapi,

Krishna and Godavari is getting funds under NCRP. But CPCB data shows that

even small rivers and tributaries in the state are polluted. This means a lot of effort

will have to be made by the state and local authorities to clean them up.

Magsaysay Award winnde Rajendra Singh, who has revived several dying

rivers in Rajasthan, said, "I have seen Mula and Mutha rivers when they were

.

[ 28 ]

absolutely clean. Today they only carry industrial discharge. As long as the

government allows factories and individuals to keep flouting environmental

guidelines, nothing will change" "If rivers are to be saved, pollution abetment

schemes must be taken up urgently. These include interception, diversion and

treatment of sewage, lowcost sanitation works on river banks as well as electric

crematoria," said another expert.

The most polluted rivers in the state are Bhima, Godavari, Mula & Mutha,

Pawana, Panchganga, Patalganga, Indrayani, Koyna, Kundalika, Kalu, Kanhan, Kolar,

Mithi, Tapi, Girna, Nira, Wainganga, Wardha, Krishna, Purna, Nira, Chandrabhaga,

Venna, Ulhas, Rangavali and Bhatsa.

3.3.2 THE MOST POLLUTED PLACES IN INDIA

Vapi in Gujarat and Sukinda in Orrisa in among the world's top 10 most

polluted places, according to the Blacksmith Institute, a New York-based nonprofit

group.

Vapi : Potentially affected people : 71,000 Pollutants : Chemicals and heavy

metals due to its industrial estates.

Sukinda : Potentially affected people : 2,600,000. Pollutants : Hexavalent

chromium due to its Chromite mines.

3.3.3 TOP 20 CRITICALLY POLLUTED PLACES IN INDIA

We list the TOP 20 places from this infamous record. ANKLESHWAR

Pollution score: 88.5/ 100

Ankleshwar in the Bharuch district of Gujarat takes the top spot in the

'critically polluted places' with a score of 88.5.

Ankleshwar is known for its industrial township called GIDC (Gujarat

Industrial Development Corporation), which is one of the biggest in Asia. Ankleshwar

also has an office of the ONGC (Oil and Natural Gas Corporation Limited). Today,

Ankleshwar has over 5000 big and small chemical plants. These chemical plants

produce products such as pesticides, pharmaceuticals, specialty chemicals, and paint.

VAPI Pollution score: 88.09/ 100

Located in the in Valsad district of Gujarat, for Vapi, the cost of growth has

been severe: levels of mercury in the city's groundwater are reportedly 96 times

higher than WHO safety levels, and heavy metals are present in the air and the local

produce.

.

[ 29 ]

The industrial township of Vapi holds its place of importance on the

"industrial" map and it is the largest industrial area in Asia in terms of small-scale

industries, dominated by chemical industry plants, along with their unfortunate

hazards. Vapi has also been listed in the Top 10 most polluted places in the world by

the US-based Blacksmith Institute.

GHAZIABAD Pollution score: 87.37/ 100

The industrial city of Ghaziabad, Uttar Pradesh, has industries that

manufacture railway coaches, diesel engines, bicycles, tapestries, glassware, pottery,

paint and varnish, heavy chains, etc. Also It has ordinance factory (Muradnagar) &

Bharat electronics ltd. for manufacturing defense products.

CHANDRAPU Pollution score: 83.88/ 100-Chandrapur in Maharashtra is very rich

in mineral wealth such as iron ore, limestone and coal and this boon has been its bane.

Many cement factories are located in this region. Due to large number of coal mines

present around the city, the city is also known as City of Black Gold. The mammoth

coal mines in an around the city also contribute to the heavy industrialization of the

city.

KORBA Pollution score: 83/ 100

This city in Chattisgarh, is the Power Capital of Central India with the NTPC's

Super Thermal Power Plant in Korba is working at 90% Plant Load Factor. There are

huge coal reserves in the vicinity, offering cheap pithead power generation

opportunities and there is enough water from the State's largest reservoir of Hasdeo

Bango. 84% of India's cool is in Chhattisgarh and two other States. Korba is also the

site of an aluminium facility operated by Bharat Aluminium Company (BALCO).

BHIWADI Pollution score: 82.91/ 100

Located in the Alwar district of Rajasthan, Bhiwadi has around 1,000 tiny,

small, medium, large, industries and including MNC industrial units manufacturing

various types of products. They include all types of industries like steel, furnace,

electronics, engineering, textiles, pharmaceuticals, printing, cables, rolling mills, food

processing, herbal care etc.

ANGUL TALCHER Pollution score: 82.09/ 100

Angul district is located in the center of the state of Orissa.

Source : The Central Pollution Control Board (CPCB) in conjunction with IIT-Delhi recently (28 June,

2010) surveyed 88 industrial clusters around the country, and found 43"critically polluted"

(score above 70 on a 100 point scale) while 32 were "severely polluted" score (60-70).

.

[ 30 ]

Even though Angul district is blessed with rich natural resources, it is the

hottest district in India where maximum temperature goes up to 50C during summer.

Many blame the Orissa government for destroying the natural greens of the district.

And yet the industrialization of the district has not stopped in spite of the public anger

for destroying jungles. The state government in its way to setup more and more

mines, plants in the district.

VELLORE-Pollution score: 81.79/ 100

This city in Tamil Nadu is considered to be one of the oldest surviving cities

in South India. The city, along with its nearby industrial towns has witnessed a

consistent industrial growth, followed by the implementation of South Asia's second

railway track between Chennai, Royapuram and Walajah. The Golden Quadrilateral

road; has significantly improved the region's industrial activities. This city is a hub for

leather industries, chemical industries as well as automobile and mechanical

industries.

SINGRAULI Pollution score: 81.73/ 100

Singrauli in Uttar Pradesh is fast emerging as an energy hub of India,

especially for electric power and coal. The total installed capacity of all power plants

at Singaruli is around ten percent of total installed capacity of India (as of 10

November 2006).

LUDHIANA-Pollution score: 81.66/ 100

This city in Punjab is also known as the 'Manchester of India' because it is the

industrial hub of Punjab, Ludhiana has been reputed to be the most polluted city on

Punjab. It is home to 8 large integrated knitwear factories, roughly 6,000 small to

medium sized knitwear factories, 10 big hosiery yarn mills and 150 small- to medium-

sized worsted and woollen yarns mills, factories of bicycles like Hero Cycles, Avon

Cycles, and a number of machine tools, sewing machines, generators, diesel engines,

tyres & tubes factories.

Industry is the main cause of water and air pollution in the city. Now a sewage

treatment plant is being set up at Ludhiana to control pollution of surface water under

the Satluj Action Plan.

NAJAFGARH DRAIN BASIN Pollution score: 79.54/ 100

Najafgarh drain basin in East Delhi (including Anand Parvat, Naraina, Okhala

and Wazirpur which are industrial hubs) is in the eleventh place in the over all list.

Najafgarh drain basin is also the biggest polluter to Yamuna.

.

[ 31 ]

NOIDA Pollution score: 78.90/ 100

This suburb of Delhi is a major hub for automobile ancillary units, with

companies like Escorts, Honda-SIEL and New Holland Tractors operating from the

city's SEZ.

DHANBAD Pollution score: 78.63/ 100

Located in Jharkhand, Dhanbad is also known as the 'Coal Capital of India'

and is 79th among the fastest growing cities of the world. Dhanbad is famous for its

coal mines and industrial establishments; it has 112 coal mines with a total produce of

27.5 million tonnes. Many sponge iron factories and ceramic factories are located in

the Dhanbad district.

DOMBIVLI Pollution score: 78.41/ 100

Dombivli as the 14th most polluted city in the country and second in the state

of Maharashtra. Dombivll is an industrial township in Thane district of Maharashtra.

Any taxi driver can point it out to you from a distance. This small town with a big

industrial estate, comprising some 50 chemicals units manufacturing dye

intermediaries, is perpetually engulfed in smog. For the 100,000 residents, life is

worse than hell. "The factories emit gases at night. They discharge effluents openly

into the drain passing through our colony. Any complaint against them will only mean

that we lose our jobs," laments Saroj Panicker, a resident of Dombivli, whose father

works in a chemicals factory.

KANPUR Pollution score: 78.09/ 100

The nineth most populous city in India, Kanpur is located on the banks of the

river Ganga and is an important industrial centre. The city is famous for its leather

products and cotton wears. Unfortunately, because of the heavy industrialization,

Kanpur is also famous for its pollution.

Kanpur went into decline after the 1960s; many industries shut down or left

the city, and those that remained -- like the tanneries acquired a bad reputation

because they were so polluting.

CUDDALORE Pollution score: 77.45/ 100

Cuddalore in Tamil Nadu has a large number of industries including one

industrial pocket -SIPCOT - which has secured it a place in the dubious club of global

toxic hotspots owing to the area's high levels of pollution. A report for the Tamil

Nadu Pollution Board by the Nagpur-based National Environmental Engineering

Research Institute found that residents of the SIPCOT area of Cuddalore were at least

.

[ 32 ]

2000 times more likely to contract cancer in their lifetimes due to their exposure to

high levels of toxic gases from chemical industries in the region.

AURANGABAD Pollution score: 77.44/ 100

This city in Maharashtra is surrounded with many historical monuments,

including the Ajanta Caves and Ellora Caves, which are UNESCO World Heritage

Sites. Many renowned Indian and MNCs have established themselves in the Industrial

Estates of Aurangabad including Videocon, Skoda Auto, Wockhardt, Siemens, Bajaj

Auto, Goodyear etc. Many firms have their manufacturing bases in Aurangabad, in

the sectors of automotive and auto components, pharmaceuticals and breweries,

consumer durables, plastic processing, aluminium processing, agriculture and biotech.

FARIDABAD Pollution score: 77.07/ 100

Faridabad's residential and industrial areas are in the grip of severe air

pollution. The air in the Delhi suburb is full of deadly elements like carbon dioxide,

carbon monoxide, sulphur dioxide and nitrogen oxide along with dust particles.

It is a major industrial city home to many units manufacturing tractors,

motorcycles, switch gears, refrigerators, shoes and tyres. Numerous brick kilns

located around Faridabad have emerged as one of the greatest air pollutants and use

rubber tyres and other high polluting materials to bake mud bricks.

The result of the large scale environmental pollution is that public health has

taken a severe beating. In many parts of Faridabad people suffer from diseases like

asthma, cancer, skin problems etc.

AGRA Pollution score: 76.48/ X00

The city of the Taj, has expanded rapidly without much planning, leading to

residential and business areas that lack civic amenities. Diesel generators, diesel

vehicles and numerous tanneries add to high levels of air pollution.

As it flows into Agra, the river Yamuna is hugely contaminated -- because 80

percent of the city's sewage flows into it. Choked drains and piled up garbage are

common sights.

3.3.4 INDIA'S 10 MOST POLLUTED INDUSTRIAL HUBS

Pollution level in ten major industrial hubs in the country, including some in

Gujarat and Uttar Pradesh has reached to a 'very alarmingly' level, according to a

study.

The hubs in the top ten list are located in Ankleshwar and Vapi in Gujarat,

Ghaziabad and Singrauli in Uttar Pradesh, Korba in Chhattisgarh, Chandrapur

.

[ 33 ]

(Maharashtra), Ludhiana in Punjab. Vellore in Tamil Nadu, Bhiwadi in Rajasthan

and Angul Telcher in Orissa.

"Many of these areas have already exhausted their capacity. We might put on

hold new approvals in these ten polluted hotspots till their environmental health is

restored," said Environment Minister Jairam Ramesh after releasing a report on

'Comprehensive environmental assessment of industrial clusters' in New Delhi.

The study, a first of its kind, has been prepared by IIT-Delhi along with the

Central Pollution Control Board, ranking the 88 industrial clusters across the country

on Comprehensive Environment Pollution Index (CEPI) on the basis of water, land

and air pollution.

The clusters have been ranked on a scale of 0-100, based on their sensitivity

towards the environment with ten of them topping the infamous list by scoring above

80 indicating the high level of metals and effluent discharged by them in the nearby

rivers and region.

Thirty-three industrial hubs have scored about 70-80 and categorised as

'critically' polluted, at least 32 others scored around 60-70 and tagged as 'seriously'

polluted clusters, while 10 in the score of 50-60 are in the 'warning' zone

The idea is to identify them in order to take concerted action and to centrally

monitor them at the national level to improve the current status of their environmental

components such as air and water quality," Ramesh said.

Subsequently, the CPCB along with State PCBs have been asked to prepare an

action plan for the 43 industrial clusters including ten 'very alarmingly' and 33 'most

severely' polluted areas within next three months, he said.

Such environmental assessment will be done once in a two year.

The scientists who have developed yardsticks have assessed all available data

on issues like water and air pollution, biodiversity conservation, land degradation,

ecological damage and waste management.

"I will soon approach the Finance Commission for fund for clean-up

programmes in these clusters," Ramesh said, adding that efforts are also on to study

the health impact from such critically polluted clusters.

3.4.0 WORLD WIDE RELATED STUDIES

To present study the present chapter embodies a brief review of reseaches

done in the area related to this investigation.

Sources : Tags : Central Pollution Control Board, Jairam Ramesh, Uttar Pradesh, Angul Telcher,

Finance Commission

.

[ 34 ]

Researcher tried to search all related literature from all possible sources to get

acquainted with different problems of desired area methods and techniques relevant to

the selected problem and to have clear concept of the work itself, keeping in view the

importance of related literature before started the actual work out the problem the

researcher survey of related literature in relation to the variables of the study.

To have clear understanding of literature available studies have been

categorized broadly in two sections according to the need of studies. Some relevant

studies undertaking by the researcher are categorized into two major heads :

1. Researches carried out at International level

2. Researches carried out at National level

So the review of related literature of present investigation can be depicted in

following manner:

3.4.1 RESEARCHES CARRIED OUT AT INTERNATIONAL LEVEL

FOREIGN STUDY

Clark michael, Tobin Lucas (1999) did work on the Torrens river at the river

banks of Adelaide city (Australia) and he found. That the down stream of river more

polluted as physical and chemical characteristics than up stream.

Scientist reported about industrial effluents and sewage outflow increase the pollution

of the river torrens at Adelaide city. So they suggested to pollution control board that

sewage treatment plants (STP) and Effluent Treatment plants (ETP) should be more

effected.

Kluivert Edwin, Bommel Van Mark (2001) found that amsel river at

Amsterdam (Netherlands) is less polluted compare with down stream of the city. The

physical characteristics of River as TDS, TSS and turbidity be reduced by the city

outfall.

So they reported significant information about the water system of the city.

They reported that the water of city dilute the pollutants of the river Ansel at

Amsterdam city (Netherlands). So the result was very significant about the sewage of

city.

Sedki Hamada (2001) released significant report about Nile River (Egypt). He

called sample at two point and he choosed Alexandaria (Egypt) and the second

.

[ 35 ]

sampling point was cairo (Egypt) and he found cairo is more polluted than

Alexandaria.

According to Recber and Hiddink (2003) Kazil river of turkey at the river

bank of Ankara (Turkey) was found more polluted compare with down stream of the

city as chemically. They collect sample at down stream and upstream of the city and

found the water of upstream is more polluted than water of down stream. So the result

was negative about the city outfall to river kazil.

Prapakamal Chareon (2003) reported by his research work that the industrial

effluent of Bangkok is being more polluted the water of river Chao Paraya. He called

the sample of various point of the down stream and up stream and the sampling

process was composite sampling method.

He found after comparison the water of down stream is physically and

chemically. More polluted than the water of up stream. That mean the waste water of

city is not treating proper.

Karim and Jassim (2004) have done research work on the sewage of Basra

(Iraq). They found the sewage of North Basra is more polluted than the sewage of

South Basra. They done work about the basis of pH, TDS, TSS, BOD and COD.

They found pH, TDS, BOD and COD of North Basra is so high than South

Basara and they also reported that the STP of north Basara many times suffer as

overloading. The average waste water of North Basara is high than the capacity of

STP.

Bierhoff et al. (2004) choose the Bonn (Germany) for the study of pollutants

in sewages and the industrial effluents.

He collected composite samples of various industry at the bonn city of

Germany and the same city sewage samples also and he compared the pH, TSS, TDS,

BOD, COD, oil and grease and heavy metals (Cr, Zn, Ni, Fe, Pb, Cd) and he found

industrial effluent is rich in pollution than the sewage before treatment.

Egervari and Bozsik (2005) checked the efficiency of Budapest (Hungary)

sewage treatment plants (STP) and he found that the efficiency of every plant is

different and it also affected by the dilution of waste water various part of city.

The efficiency of North STP is better than the south. So he conclused about

the various factor effect the efficiency STP.

.

[ 36 ]

Vazguez et al. (2000) determined the efficiency of potable water treatment

plant at Buenos Aires (Argentina) and he reported about the efficiency of treatment

plant. He found the potable water treatment plant's efficiency nearby 95.0%.

Lifang Wen (2003) found about the sewage of canton city of China going to

river si-kiang is out of standards.

He analysis the pH, TSS, TDS, BOD, COD and found more polluted than

standards. The total suspended solid and COD was very high and its not acceptable to

river canton.

Advocaat Dick and Onopko (2006) checked the pH, COD BOD and Oil and

grease of leningrad (Russia) sewage.

This study was based after STP and before STP analysis and the comparison

both and evaluate the efficiency of STP. The efficiency of STP was appreciable and

the water which was going towards the river Neva also in standards.

Gere Richards (2004) analysed the physical, chemical and biological

characteristics of the river Hudson at riverbank of New York (U.S.A.) and he also

sampling point of New orleans (U.S.A) and he found the water of river Hudson

slightly in the better position than the water of river mississippi at New orleans.

Kawamoto and Shimomura (2007) determined the efficiency of STP and ETP

and compared its also. The efficiency of sewage treatment plants is better than the

efficiency of effluents treatment plants.

They analysed on the basis of parameter pH, colour, TDS, TSS, BOD, COD

and the heavy metals. They found the efficiency of STP is appreciable than the

efficiency of ETP.

Zoff and Cannavaro (2005) have done research work on the industrial effluent

and sewage of the Rome city (Italy). He wanted about the qualitative characteristics of

industrial effluent and the sewage after treatment process and he found the waste

water of industries are out of standards and the water of sewage after treatment is

under standards.

Krug and Loth (2006) did work on the Vistula river at the riverbank of warsaw

(Poland) he determined the bacteriological characteristics of river vistula. The

sampling point was after city and the before city of Warsaw and they result was the

bacteriological contamination increased due to city water.

.

[ 37 ]

3.4.2 RESEARCH CARRIED OUT AT NATIONAL LEVEL

Indian study

Khurana and Mehta (2004) have done comparison study of the water of river

Yamuna and the Chambal river near at Agra. They collected water at Pinhat (Agra) of

river Chambal and near Taj Mahal at Agra. They made object pH, Temperature, EC,

DO, turbidity and found that the river Yamuna is very polluted than the Chambal river

and every parameters was better of river Chambal.

Shuri and Sharma (2008) checked the efficiency of Burhi Ka Nagla (STP) at

Agra. He took the analysed characteristics, colour, odour pH, TSS, TDS and found

about 90% efficiency of this treatment plant.

Garg et al. (2004) analysed the Yamuna river at Delhi. They took the sample

from various point at river bank of Delhi and comparison. This with down stream of

Delhi. The difference was too much the before city water was very clean with the

comparison of Delhi.

So he found that the Delhi is being very polluted to river Yamuna. Srivastava

(2006) have done comparison study of river Ganga. He choosed sampling point of

Haridwar and Kanpur and he implemented the composite sampling method. He found

the water of river Ganga at Haridwar is many times better than Kanpur.

The BOD, COD, TSS, TDS and odour, colour and TC and FC was study

parameters and the physical, chemical and biological characteristics of river Ganga

was compared each other. The study conclusion occurred. The water of river Ganga

from Haridwar to Kanpur carry many sewages and other type pollutants and been

very polluted.

Sharma et al. (2005) reported about the Uttangan river at Arnota (Agra) is

qualitative fruitful than the river Yamuna at Bateshwar (Agra). The study parameters

was physical and chemical and the sampling method used as grab sampling. First he

studied the physical parameters colour, odour, turbidity, specific conductivity and the

chemically examine as TDS, TSS, BOD, COD,

Cl , pH and DO.

The Uttangan river at Arnota was in better condition compare with Yamuna

river at Bateswar. The cause was found that the many sewage and other waste water

fall in river yamuna through the various city and the Uttangan faces less problems at

this type in the way.

.

[ 38 ]

Subramanyam and Krishnamurti (2003) have shown by report about Vapi

(Gujarat) is among the word's top ten most polluted places, according to them

research.

They did work on sewage and the industrial effluents of Vapi and found, the

waste water was very polluted as chemicals and heavy metals due to its industrial

estates. They used composite sampling method in his research and found high range

pollutants in the waste water of Vapi in Gujarat.

Kshirsagar (2002) according to is report, the up stream of Gomti river is better

than the down stream. He examined the river water and evaluate by the physical,

chemical and biological characteristics and he found. The waste water of city being

more polluted to river Gomti at Lucknow due to its heavy polluted sewages he chosen

the different sampling point before city and after city of Lucknow and extract this

result.

Raghwan and Koshik (2008) found, Sukinda in Orrissa is the very polluted

place in India. They did our research on waste water and obtain. The waste water of

Sukinda (Orrisa) have the pollutants as hexavalent chromium (Cr

6

) due to its chromite

mines.

Gupta and Srivastava (2006) found in his study. They did comparison study of

river Chambal. They compared the biological and chemical characteristics of river

Chambal at Kota and near the Udi bridge (Etawah) and they reported comparison of

the chemical and biological characteristics of river Chambal at Kota and Etawah is

nearby equal.

In other words "The comparison study of the river Chambal at both places

have no more qualitative difference so and the cause was found; in the way from Kota

to Etawah river Chambal did not face, critical circumstances due to waste water. So

water found in better position after the long way.

.

[ 39 ]

Chapter-4

4.0.0 INTRODUCTION

This chapter is a mapping strategy and the index of the whole work. It is

essentially a statement of the object of the inquiry and the strategies for collecting the

evidence, analyzing the evidence and reporting the findings. Thus, research design is

the statement of the object of the inquiry and how a satisfactory culmination is to be

effected. Moreover, design is the process of making decisions before the situation

arises in which the decision has to be carried out. It is a process of deliberate

anticipation directed towards bringing an expected situation under control.

According to Claire Seltiz and other [1962], a research design is the