Escolar Documentos

Profissional Documentos

Cultura Documentos

Stitch Length Effect

Enviado por

Faruk Zaman FahadDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Stitch Length Effect

Enviado por

Faruk Zaman FahadDireitos autorais:

Formatos disponíveis

Journal of American Science, 2011;7(8)

http://www.americanscience.org

The influence of stitch length of weft knitted fabrics on the sewability

Z. M. Abdel Megeid1, M. Al-bakry2 and M. Ezzat1

2

Textile Research Division, National Research Centre, Cairo, Egypt Faculties of Specific Education, Home Economics, Mansoura University Z_algory@yahoo.com

Abstract: The sewing needle penetration force, the feed of the sewing material, sewing needle size are very important parameters during the sewing of knitted fabric. This paper is studying the effect stitch length, yarn count, and needle size on the penetration force which indicates the fabric sewability. Some physical and mechanical properties of these fabrics were also tested. From the results of this study obtained, we can conclude that, the sewability (which is indicated by penetration force) of 100% cotton single jersey fabric is inversely proportional to its stitch length. In the same time the fabric with coarser yarn count gives the higher penetration force. Also we can conclude that, fabrics with coarser yarn counts and shorter stitch length have better functional performance characteristics. [Z. M. Abdel Megeid, M. Al-bakry, and M. Ezzat, The influence of stitch length of weft knitted fabrics on the sewability. Journal of American Science 2011;7(8):610-617]. (ISSN: 1545-1003). http://www.americanscience.org.

Key Words: stitch length-weft knitted fabric-sewability- abrasion resistance- Air Permeability

1. Introduction: Knit fabrics are having wider use in time since they can be produced more easily for a lower cost, and they are more flexible .However, knit fabrics are less than woven fabrics since they are produced with low twist yarn and have a slack construction, as a result of which they have a low abrasion resistance. Abrasion resistance and pilling performance are two of the most important mechanical characteristics of fabric. The resistance of a fabric against the force of friction is known as the abrasion resistance. [1] There are many factors, such as yarn spinning system, fabric construction and finishing processes that affect in the abrasion resistance. With certain precautions taken in fabric production, the abrasion resistance of knit fabrics can be developed positively. [1] In the case of weft knitting, the dimensional properties of staple weft knitted fabrics depend mainly on the average loop length. In an earlier work, many attempts were made by researchers to analyze the relationships among the dimensions of knitted fabrics, the properties of the constituent yarns and the variable factors in knitting. It was noticed that the dimensional and weight related properties of knitted in relaxed state were determined uniquely by length of yarn in the stitch [2]. T. Ogulata and S. Mavruz have shown that the fabric with the lowest course count per cm and yarn count in Tex has the highest air permeability values. Moreover, increasing the loop length produced a looser surface in the fabric and decreased air permeability. As the yarn gets thinner and the pores between loops gets larger, the air permeability will 610 increase accordingly. According to some formulations, when the stitch density, stitch length or yarn diameter increase, pore size values decreases. [3]. The sewing needle penetration force, sewing thread tension the feed of the sewing material, as well as selection of the sewing thread, sewing needle size and shape of the sewing needle point are very important parameters during the sewing of knitted fabric. Sewing thread plays an influential role in seam design; it should be stretchable since knitted fabric has elastic properties in the direction of courses and Wales .The size of the needle eyelet and thread thickness should be mutually adjusted in order for the thread to pass through the eyelet with as little friction as possible. The quality of a sewn seam depends on these two factors, therefore it is necessary to match the thickness and density of the knitted fabric with the fineness of sewing thread and needle. The penetration force of a sewing needle is mostly based on the friction occurring between the sewing work pieces and sewing needle, and the highest penetration force of the sewing needle occurs at the moment when the sewing needle penetrates the sewing material, which should be taken into consideration, especially with knitted fabrics.(4) The sewing needle penetration force is one of the most significant technical parameters in the sewing process affected by various factors such as: type, number of layers of the sewing material, and needle size [4].

Journal of American Science, 2011;7(8)

http://www.americanscience.org

The stitch length for each fabric was calculated as the ratio of course length to the number of needles [5]. Doyle and Hurd (1953) found that the stitch density of plain knitted fabrics in the dry relaxed state is dependent only on the loop length, and independent of other yarn and knitting variables [6]. This paper is studying the effect of stitch length, yarn count, and needle size on the penetration force which indicates the fabric sewability 2- Experimental work: 1-The knitted fabric samples were made of 100% cotton. Produced 9 sample fabrics from single jersey, machine (circular knitting) gouge 24 Diameter of cylinder 26/inch by using combed cotton with 3 English counts 20/1, 24/1, 30/1 at different stitch length (1.3 -1.8 -2.7mm) and rate of feeding 135, 155, 175 - The physical properties test: - Fabric weight/g square meter according to ASTM D3776 - Air permeability/ Cm3/cm2/sec according to ASTM D 737-96 -Thickness/ mm according to ASTM according to ASTM D1777-96 -stitch length using Huttra course length tester according to ASTM D 3887.

The mechanical properties test: The L&M sew ability tester:

Fig 1 The L+M sewability Tester 8,9 Testing fabric sewing properties, US patent 3979951, 1976), a device used in many studies on needle penetration force. This equipment simulates a sewing machine by penetrating the tested fabric with an unthreaded needle, at a rate of 100 penetrations per min., with needle count 70, 80. -Abrasion resistance / cycle according to ASTM D 4966 -Burst strength/ Kg/cm2 according to ASTM D 378601 The physical and mechanical properties of these fabrics were tested under standard condition. 3-Result and discussion: The results of tested samples are shown in table (1).

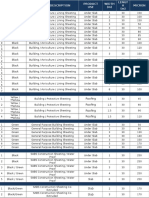

Table (1) The Average results for Tested Samples Sewability/N Air permeability Thickness/ mm S.L/ / Cm3/cm2/sec S Ne mm N70 N80 1 2 3 4 5 6 7 8 9 20 20 20 24 24 24 30 30 30 1.3 1.8 2.7 1.3 1.8 2.7 1.3 1.8 2.7 38 36 18 32 26 8 7 6 6 55 26 12 27 14 7 11 8 5 58 62 63 56 60 54 59 89 79 23.8 54.3 112.0 52.90 107.9 118.4 126.6 136.7 272.6

Abrasion / cycle 410.0 350.0 300.0 290.0 175.0 193.3 123.3 163.3 124.0

Weight/g 240.4 212.4 207.1 199.7 177.5 155.0 150.6 128.2 118.4

Burst Kg/cm2 11.00 9.20 9.00 8.40 7.70 6.40 7.70 6.30 5.93

S Ne S.L Sew ability N

: Sample number : Count 20 24 30 : stitch length :Sewing needle penetration force/N : needle number 70-80

611

Journal of American Science, 2011;7(8)

http://www.americanscience.org

3.1. Effect of stitch length on Sewability: a. Sewing needle penetration force; Sewability (for needle number N70):

Fig (1) The Relation between Stitch Length and Sew ability (N70) for Different Yarn Counts From figure (1) it is observed the relation between stitch length and sewability by using (Needle 70) that stitch length of 100% cotton single jersey fabric is inversely proportional to its sewability. In the same time the fabric with coarser yarn count gives the higher penetration force and vise versa. This result may be explained by the fabric thickness and tightness factor which are decreased with the finer count and longer stitch length which allows the needle to penetrate easily.

b. Sewing needle penetration force; Sewability (for needle number N80):

Fig (2) The Relation between Stitch Length and Sew ability (N80) for Different Yarn Counts

612

Journal of American Science, 2011;7(8)

http://www.americanscience.org

3.2. Effect of stitch length on some fabric Properties:

a. Fabric thickness:

Fig (3) the Relation between Stitch Length and Fabric Thickness for Different Yarn Counts Figure (3) shows the relation between stitch lengths and the fabric thickness, which indicates that stitch length, is inversely proportional to its measured thickness. In the same time the fabric with coarser yarn count gives the higher fabric thickness and vise versa.

b. Fabric weight:

Fig (4) the Relation between Stitch Length and Fabric Weight for Different Yarn Counts

613

Journal of American Science, 2011;7(8)

http://www.americanscience.org

Figure (4) shows the relation between stitch lengths and the fabric weight, which indicates that stitch length, is inversely proportional to its measured weight. In the same time the fabric a. Fabric Air Permeability:

with coarser yarn count gives the higher fabric weight and vise versa.

Fig (5) the Relation between Stitch Length and Air Permeability for Different Yarn Counts Figure (5) shows the relation between stitch lengths and the fabric air permeability, which indicates that stitch length, is directly proportional to its measured air permeability. In the same time the fabric with finer yarn count gives the higher fabric air permeability. This result may be explained by the tightness factor which is decreased with the finer count and longer stitch length which allows the air flow to penetrate easily thru the fabric.

b. Fabric abrasion resistance:

Fig (6) the Relation between Stitch Length and Fabric Abrasion for Different Yarn Counts

614

Journal of American Science, 2011;7(8)

http://www.americanscience.org

Figure (6) shows the relation between stitch lengths and the fabric abrasion resistance, which indicates that stitch length, is inversely proportional to its measured abrasion resistance. In the same time

the fabric with coarser yarn count gives the higher fabric abrasion resistance.

c. Fabric bursting strength:

Fig (7) the Relation between Stitch Length and Fabric bursting strength for Different Yarn Counts

Table (2) quality factors of the fabrics under study Bursting Abrasion Air Sewability Sewability Strength Strength permeability N80 N70 Ne 20, SL 1.3mm Ne 20, SL 1.8mm Ne 20, SL 2.7mm Ne 24, SL 1.3mm Ne 24, SL 1.8mm Ne 24, SL 2.7mm Ne 30, SL 1.3mm Ne 30, SL 1.8mm Ne 30, SL 2.7mm 100 92 91 88 85 79 85 79 77 100 93 87 85 71 74 65 70 65 98 71 60 72 61 60 59 58 54 55 60 71 59 68 86 73 81 100 58 58 67 59 62 88 93 100 100

Quality Factor 82.2 74.7 75.1 72.8 69.3 77.1 74.9 77.6 79.3

Figure (7) shows the relation between stitch lengths and the fabric bursting strength, which indicates that stitch length, is inversely proportional to its measured bursting strength. In the same time the fabric with coarser yarn count gives the higher fabric bursting strength.

3.3. Assessment of fabric quality with different stitch lengths and yarn counts: An assessment approach to the quality of fabrics under study was carried out to indicate the overall quality level of the fabrics based on the performance characteristics of these fabrics when manufactured as knitwear.

615

Journal of American Science, 2011;7(8)

http://www.americanscience.org

This assessment is done by recalculating the measured values of these quality attributes according to a new dimensionless scale between 0 and 100. This way helps to compare between different samples. Figure (8) shows radar chart of each fabric, and table (2) shows their quality factors.

Ne 20, SL 1.3mm

Bursting Strength Bursting Strength

From these figures and table we can conclude that, fabrics with coarser yarn counts and shorter stitch length have better functional performance characteristics, while fabrics with finer yarn counts and longer stitch length have better sewability characteristics.

Ne 20, SL 1.8mm

Bursting Strength

Ne 20, SL 2.7mm

100 80 60 40 20 0

100 50

Sewability N70 Abrasion Strength Sewability N70

100 80 60 40 20 0

Abrasion Strength

Sewability N70

Abrasion Strength

Sewability N80 Sewability N80 Air permeability

Air permeability Sewability N80 Air permeability

Ne 24, SL 1.3mm

Bursting Strength Bursting Strength

Ne 24, SL 1.8mm

Bursting Strength

Ne 24, SL 2.7mm

100 80 60 40 20 0

Sewability N70

100 80 60 40 20 0

Abrasion Strength

Sewability N70

100 80 60 40 20 0

Abrasion Strength

Sewability N70

Abrasion Strength

Sewability N80

Air permeability

Sewability N80

Air permeability

Sewability N80

Air permeability

Ne 30, SL 1.3mm

Bursting Strength Bursting Strength

Ne 30, SL 1.8mm

100 80 60 40 20 0

Bursting Strength

Ne 30, SL 2.7mm

100 80 60 40 20 0

Sewability N70

100 80 60 40 20 0

Abrasion Strength

Sewability N70

Abrasion Strength

Sewability N70

Abrasion Strength

Sewability N80

Air permeability

Sewability N80

Air permeability

Sewability N80

Air permeability

Fig (8) the Radar charts of the nine fabrics with different Stitch Lengths and Yarn Counts Conclusion: From results we can conclude that, the sewability (which is indicated by penetration force) of 100% cotton single jersey fabric is inversely proportional to its stitch length. In the same time the fabric with coarser yarn count gives the higher penetration force. Also we can conclude that, fabrics with coarser yarn counts and shorter stitch length have better functional performance characteristics. 616

Coresponding author Z. M. Abdel Megeid Textile Research Division, National Research Centre, Cairo, Egypt Z_algory@yahoo.com

Journal of American Science, 2011;7(8)

http://www.americanscience.org

References: 1-Fiber&textiles in Eastern Europe 2009, pilling performance and abrasion characteristics of selected basic weft knitted fabrics vol.18 no 2 pp51-54 2-Manonmani G &Vigneswaran chettier, 2010. Suitability of compact yarn for manufacturing of ECO-Friendly processed weft knitted fabrics, JTATM, 6(3) pp1-18 3-Ogulata, R.T., Mavruz, S. 2010 investigation of porosity and air permeability values of plain knitted fabrics, fibers and textiles in Eastern Europe , vol. 18, no.5, pp71-75. 4-Ujevic D., Kartal M., Sajatovic B.B.; impact of sewing needle and thread on the technological process of sewing knitwear. Fibers Textiles in Eastern Europe 2008, vol.16, no.4 (69) pp.85-89 5-M Badal, R Unmar& S Rosunee, (2010) Development of predictive model for setting stitch

length value of single jersey cotton fabrics. Indian journal of fiber& textile research .vol.35, June, pp.172-173 6-C.Prakash and K. Thangamani, 2010) Establishing the effect of loop length on dimensional stability of single jersey knitted fabric made from cotton /lycra core spun yarn. Indian journal of science and technology vol.3no3 (mar, pp.287 7-Manal elbakry, ahmed salman and baha raft, The Effect of the different of Practical Methods for Knitting Fabric on the Characteristic of Functional of Final Product (2005 / 2004). 8-The L+M Sewability Tester (BS EN ISO 9002 certificate no.2739. 9-Ayca Gurarda and Binnaz Meric, Sewing needle penetration force and Elastane fiber damage during the Sewing of cotton/Elastane woven fabrics

6/12/2011

617

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Turn in Order Rotating BookcaseDocumento7 páginasTurn in Order Rotating BookcasexXAlbert10Xx100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Henriques, Julian - Sonic Bodies. Reggae Sound Systems, Performance Techniques and Ways of Knowing (2011)Documento389 páginasHenriques, Julian - Sonic Bodies. Reggae Sound Systems, Performance Techniques and Ways of Knowing (2011)Cecilia100% (1)

- Frill Seeker by Yumiko Watanabe PDFDocumento2 páginasFrill Seeker by Yumiko Watanabe PDFcsilla100% (4)

- Upstream Pre B1 Test 1ADocumento4 páginasUpstream Pre B1 Test 1ABiljana Nestorovska100% (1)

- Route To Academic SpeakingDocumento150 páginasRoute To Academic SpeakingBull3asaur100% (3)

- ChristiesDocumento158 páginasChristiesAtreyee Gupta100% (2)

- History of Architecture Periods and StylesDocumento16 páginasHistory of Architecture Periods and StylesMons DelmendoAinda não há avaliações

- Visions of The Apocalypse - Beatus Manuscripts and 13th Century Apocalypse ManuscripsDocumento15 páginasVisions of The Apocalypse - Beatus Manuscripts and 13th Century Apocalypse Manuscripsalice85aliceAinda não há avaliações

- Henry Schein Orthodontics Catalog - ElastomericsDocumento12 páginasHenry Schein Orthodontics Catalog - ElastomericsOrtho OrganizersAinda não há avaliações

- Where Great Writers Are MadeDocumento11 páginasWhere Great Writers Are Madejondotli100% (1)

- Router Table - RTA300: Supercedes Earlier Model RTA300 - July 2002Documento2 páginasRouter Table - RTA300: Supercedes Earlier Model RTA300 - July 2002j_abendstern4688Ainda não há avaliações

- CHS 1999 Yearbook - TextDocumento322 páginasCHS 1999 Yearbook - TextDCG CandyAinda não há avaliações

- Resale: Honey, I'm HomeDocumento1 páginaResale: Honey, I'm HomeSarahMagedAinda não há avaliações

- Pang-Araw-Araw Na Tala Sa Pagtuturo: Paaralan Baitang/Antas II Guro Asignatura MAPEH Petsa/Oras Markahan UNA (WEEK 3)Documento5 páginasPang-Araw-Araw Na Tala Sa Pagtuturo: Paaralan Baitang/Antas II Guro Asignatura MAPEH Petsa/Oras Markahan UNA (WEEK 3)Jhoya Gutierrez HeleraAinda não há avaliações

- ColourDocumento2 páginasColourapi-305963468Ainda não há avaliações

- Fashion Design QuotesDocumento5 páginasFashion Design QuotesArilandrinAinda não há avaliações

- Study On Rapier Weaving Mechanism.Documento11 páginasStudy On Rapier Weaving Mechanism.Naimul HasanAinda não há avaliações

- Précis On Simon Goldhill's The Great Dionysia and Civic IdeologyDocumento1 páginaPrécis On Simon Goldhill's The Great Dionysia and Civic IdeologyNana SmithAinda não há avaliações

- Portrait of An Artist (Pool With Two Figures)Documento4 páginasPortrait of An Artist (Pool With Two Figures)danaAinda não há avaliações

- Worksheet WoodDocumento2 páginasWorksheet WoodEva MAinda não há avaliações

- ScriptDocumento8 páginasScriptgynecologistcobra83% (6)

- Copyright LawDocumento21 páginasCopyright LawBelle MadreoAinda não há avaliações

- 3D Cardboard & Duct Tape Deer Head Trophy With Template: Food Living Outside Play Technology WorkshopDocumento35 páginas3D Cardboard & Duct Tape Deer Head Trophy With Template: Food Living Outside Play Technology WorkshopLinoAinda não há avaliações

- 2020 Petit Collage CatalogDocumento52 páginas2020 Petit Collage CatalogJayAinda não há avaliações

- The Beauty of Everyday ObjectsDocumento10 páginasThe Beauty of Everyday ObjectsShiko shikoAinda não há avaliações

- Spiro Omr SheetDocumento2 páginasSpiro Omr Sheetsmart prabhuAinda não há avaliações

- Hadrians Villa Igcse LanguageDocumento2 páginasHadrians Villa Igcse LanguageShriya JagwayanAinda não há avaliações

- Ikorodu HistoryDocumento4 páginasIkorodu HistoryBashorun MosesAinda não há avaliações

- The Translation of Advertisements From Adaptation To LocalizationDocumento8 páginasThe Translation of Advertisements From Adaptation To LocalizationAnas Khalfaoui HassaniAinda não há avaliações

- Detailed LP in ArtsDocumento7 páginasDetailed LP in ArtsIrish Melonie PobladorAinda não há avaliações