Escolar Documentos

Profissional Documentos

Cultura Documentos

Marking Out Tools Information Sheets Mel02inf4436+v1.2

Enviado por

youngfpDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Marking Out Tools Information Sheets Mel02inf4436+v1.2

Enviado por

youngfpDireitos autorais:

Formatos disponíveis

Page 1 of 3

Competenz - N Z Engineering Food & Manufacturing Industry Training Organisation Inc.

MARKING-OUT INFORMATION SHEETS MEL02INF4436 v1.2 HEALTH & SAFETY REQUIREMENTS RECORDING REQUIREMENTS: Record the results of your work on Task Worksheet MEL02TWS01 v1.3 REFERENCES: This document relates in part to the requirements of Unit Standard 4436 v5 MARKING OUT The purpose of marking-out is to; Define the shape of an article Indicate position of holes and other features Provide alignment and machining marks Minimize material wastage Marking-out techniques include the use of datum, pitch circle diameters (PCD) and templates. Marking-out is usually done on a firm, flat work surface or vertically using marking-out tools on a surface table. Marking-out Using Datums Effective marking-out requires clean edges and faces on the work piece, and uses a combination of at least two primary reference points such as Datum Points, Datum Lines and Datum Edges.

Odd-leg calipers Dividers

Tools Commonly Used for Marking-out Tasks

Steel Rule Scriber Engineers Square

Center and Dot-Punches Combination Set

Angle Plates

Scribing Block Height Gauge Vee Blocks

Surface Table

Marking-out using datums can be done using either;

Simple hand tools such as a ruler, scriber, square

and odd-leg calipers, or

Vertical marking-out tools such as an angle plate,

scribing block or vernier height gauge situated on a marking-out table

Parallels

IP! When finish ed, re the to turn ol to i ts sto box, t rage ool ca binet marke or the d plac e on t works he hop sh adow board .

SMAR TT

Marking Hole Positions Along a Centerline

Brush a thin layer of marking blue onto the surface of the metal bar to highlight the lines.

Use odd-leg calipers to find and scribe the centerline along the bar using one edge as the datum.

Use a rule, scriber and square to mark the hole positions along the centerline working from the datum at one end of the bar.

Use a rule to re-check the marked position. Center punch the location of each hole ready for drilling.

Marking Hole Positions on a Pitch Circle Diameter (PCD)

Use an engineers square and odd-leg calipers to mark the position of the PCD centerlines from the datum edges.

Center punch the PCD center-point and use a pair of dividers to scribe the pitch circle. Trammels are required for scribing larger PCDs.

Calculate the hole positions and use dividers to step-out and scribe the positions around the PCD.

Recheck the scribed positions. If OK, center punch the location of each hole ready for drilling.

s osition d by; Hole p lculate a c e b ence can cumfer r i c Marking Shapes and Hole Positions Using Templates e h er gt e numb dividin h t y b PCD Templates are commonly made of sheet metal, plastic and wood and shaped to of the s or, represent the finished article. Templates can be simple geometric shapes or of hole ing jig-bor g detailed profiles used for fabricating complex structures. in s u by les. ate tab Hole positions in the template are marked on the work-piece surface using transfer punches. coordin

HANDY HINT; to ensure clean marking out, check the caliper, divider and center punch tips are not worn or damaged.

TIP! SMART on a PCD

Use an a square, odd-leg calipers, a rule and a scriber to lay-out the template

Locate the template on the alignment marks. Clamp in place if necessary.

HANDY HINT; templates are a useful time-saver when marking-out repetitive fabrication work.

Use a scriber to mark-out the template profiles. Use transfer punches to mark the locations of the holes ready for drilling. Use a rule to recheck the profiles and hole positions.

Marking-out Using a Combination Set

A scriber and a combination set protractor can be used for marking-out virtually any angle from a datum face.

A scriber and a combination try-square can be used for marking-out at 90 and 45 to a datum face.

A combination set center-finder is used for scribing intersecting lines to establish the center of a round bar or circular shape.

Marking-out On a Table Work requiring accuracy to within 0.15 mm can be done using a scribing block.

Accuracy to within 0.02 mm can be achieved by using a vernier height gauge.

Vee blocks are used to support and clamp round work pieces during marking out with a vernier height gauge. The round bar should be supported on the angled faces of the vee block.

An angle plate can be used to hold larger work pieces while marking-out vertical distances using a vernier height gauge. Smaller, less accurate marking-out can be done using a scribing block.

Marking-out Using Spirit Levels and Plumb-bobs

Check for a true right-angle using an Engineers Square or a Rafter Square.

T TIP! Check t he tool for any damage or fault s such as worn, b roken o r missin parts, e g xpired calibrat or the t io n ool not zeroing Report . any pro blems t your su o pervisor .

SMAR

Use a scriber to mark the final position prior to riveting, bolting-up or welding. Use a spirit-level to check and adjust the position of a horizontal structural component. A protractor can be used to establish the correct angle of a horizontal beam in respect to a vertical component. Plumb-lines provide a datum when positioning vertical components in larger structures. When positioned vertically, the horizontal distance between the plumb-line and the vertical component will be the same at the top and the bottom. HANDY HINT; increasing the vertical distance between the measuring points on a vertical plumb-line will improve the accuracy of the setup. Steel beam

The glass or plastic vial on a spirit level is usually marked in 1-degree increments. A small air bubble sits central to the vial when the level is placed on a horizontally true surface.

Plumb-bob

Flat and true machined surface.

Você também pode gostar

- Sheet Metal Duct Layout BookDocumento40 páginasSheet Metal Duct Layout BookRyan Murray77% (13)

- The Home Handyman - May 2016 PDFDocumento68 páginasThe Home Handyman - May 2016 PDFzvezdelina100% (1)

- (Metalworking) Welding and MachiningDocumento1.767 páginas(Metalworking) Welding and MachiningEugeneAinda não há avaliações

- Ryo Yoshida BJD Making Guide English TranslationDocumento61 páginasRyo Yoshida BJD Making Guide English TranslationChe Jael Flaviano100% (4)

- Engineering Drawing NotesDocumento81 páginasEngineering Drawing NotesAnonymous OFP2ygPIdAinda não há avaliações

- Wood & Wood ProductsDocumento33 páginasWood & Wood ProductsPatricia Erika ArgusAinda não há avaliações

- Screw Threads and Assembly Drawing Class NotesNotesDocumento17 páginasScrew Threads and Assembly Drawing Class NotesNotesRay NjorogeAinda não há avaliações

- Microsoft PowerPoint - G D & T 17.11Documento96 páginasMicrosoft PowerPoint - G D & T 17.11vijaykkhal100% (1)

- Lettering and DimensionsDocumento23 páginasLettering and DimensionsMujtaba AbbasAinda não há avaliações

- International ShippingDocumento17 páginasInternational ShippingyoungfpAinda não há avaliações

- Verification and Validation Guidelines For High Integrity SystemsDocumento198 páginasVerification and Validation Guidelines For High Integrity SystemsyoungfpAinda não há avaliações

- Roundness IDocumento13 páginasRoundness Ibalasubramani_srinivAinda não há avaliações

- Chapter 12 Working DrawingDocumento63 páginasChapter 12 Working DrawingLhen Mediante AsuncionAinda não há avaliações

- Marine Offshore Safety Sign PDFDocumento9 páginasMarine Offshore Safety Sign PDFyoungfpAinda não há avaliações

- Your Source For GD&T Training and MaterialsDocumento6 páginasYour Source For GD&T Training and Materialskharsh23Ainda não há avaliações

- Cold Ironing and Onshore Generation For Airborne Emission ReductionsDocumento34 páginasCold Ironing and Onshore Generation For Airborne Emission ReductionsyoungfpAinda não há avaliações

- 2-4 Basic Engineering Drawing and CAD I PDFDocumento233 páginas2-4 Basic Engineering Drawing and CAD I PDFsmendoza100% (2)

- Planer MachineDocumento46 páginasPlaner Machinepoohru puru100% (15)

- CE102-W5-Wood and Its PropertiesDocumento43 páginasCE102-W5-Wood and Its PropertiesRomel BernardoAinda não há avaliações

- Chapter7 Demtol1 - Dimensioning StandardsDocumento100 páginasChapter7 Demtol1 - Dimensioning Standardsapi-265554570Ainda não há avaliações

- Drafting and Dimensioning StandardsDocumento30 páginasDrafting and Dimensioning StandardskrristinAinda não há avaliações

- Laboratory Report 2 - de LunaDocumento7 páginasLaboratory Report 2 - de LunaAgent PAinda não há avaliações

- Drill JigsDocumento195 páginasDrill JigsArun PeriyasamyAinda não há avaliações

- Setting OutDocumento8 páginasSetting OutSuranga Gayan100% (1)

- DJF - Model Question PaperDocumento6 páginasDJF - Model Question PaperMohammedRafficAinda não há avaliações

- Vernacular Terms in Philippine ContructionDocumento3 páginasVernacular Terms in Philippine ContructionClaro III TabuzoAinda não há avaliações

- JJ 103 Fitting ReportDocumento12 páginasJJ 103 Fitting ReportNasrul Haziq Murad55% (20)

- XH7126 CNC Milling MachineDocumento2 páginasXH7126 CNC Milling MachineMUHAMMAD NAUMANAinda não há avaliações

- ME 114 - Engineering Drawing II: SectioningDocumento31 páginasME 114 - Engineering Drawing II: SectioningTemmy Candra WijayaAinda não há avaliações

- MSP - Week 7 8Documento7 páginasMSP - Week 7 8John MarkAinda não há avaliações

- Chapter 2 - Dimensioning - EGE4Documento162 páginasChapter 2 - Dimensioning - EGE4bmyertekinAinda não há avaliações

- Jigs and FixturesDocumento85 páginasJigs and FixturesNithin Mathew Eyyalil100% (2)

- Sample Multiple Choice Questions (MCQ) : Unit - IDocumento22 páginasSample Multiple Choice Questions (MCQ) : Unit - IDaveed stark100% (1)

- Projection of Points and PlanesDocumento30 páginasProjection of Points and PlanesAnonymous p8bHAAxAinda não há avaliações

- Lecture 2 - Introduction To Tool DesignDocumento18 páginasLecture 2 - Introduction To Tool DesignPratik PatelAinda não há avaliações

- Engg Drawing Viva QuestionsDocumento8 páginasEngg Drawing Viva Questionsmahdzia0% (1)

- MarkingouttoolsDocumento24 páginasMarkingouttoolsOmar EzzatAinda não há avaliações

- 02 - Workshop-Machine Shop o GDocumento17 páginas02 - Workshop-Machine Shop o Gsakali aliAinda não há avaliações

- Unit 9 Tools For Basic Layout: StructureDocumento7 páginasUnit 9 Tools For Basic Layout: StructureAkash Kumar DevAinda não há avaliações

- Machining FixedDocumento512 páginasMachining FixedstephendixAinda não há avaliações

- Manufacturing Engineering 2Documento7 páginasManufacturing Engineering 2Study SuccessAinda não há avaliações

- Marking OutDocumento2 páginasMarking OutOladimeji TaiwoAinda não há avaliações

- Basic Workshop CH 2 & 3 and Projects ASTUDocumento14 páginasBasic Workshop CH 2 & 3 and Projects ASTUandu habshaAinda não há avaliações

- Benchwork and Fitting: Linear Measurements Angular Measurements Surface MeasurementDocumento8 páginasBenchwork and Fitting: Linear Measurements Angular Measurements Surface MeasurementJohn smithAinda não há avaliações

- Production Technology: Department of Mechanical EngineeringDocumento17 páginasProduction Technology: Department of Mechanical Engineeringrahul bhattAinda não há avaliações

- Tecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctDocumento40 páginasTecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctAnkush NayarAinda não há avaliações

- Nomenclatures of Single Point Cutting Tool Using Tool Makers MicroscopeDocumento7 páginasNomenclatures of Single Point Cutting Tool Using Tool Makers Microscopeविशाल पुडासैनीAinda não há avaliações

- Toolpaths: Ste P Toolpath CommentsDocumento11 páginasToolpaths: Ste P Toolpath CommentsuzeyirAinda não há avaliações

- 3) Marking Tools Used in FittingDocumento5 páginas3) Marking Tools Used in FittingKrako Tram100% (1)

- Basic Marking Out and Measuring InstrumentsDocumento70 páginasBasic Marking Out and Measuring Instrumentsbonganishiba594Ainda não há avaliações

- Gear CuttingDocumento3 páginasGear CuttingBarun DeAinda não há avaliações

- Marking ToolsDocumento14 páginasMarking ToolsFabian NdegeAinda não há avaliações

- Contouring and TurningDocumento9 páginasContouring and Turning123anthonyAinda não há avaliações

- Session 09Documento59 páginasSession 09etaAinda não há avaliações

- Dial Indicator: The Premier Source of Parts and Accessories For Mini Lathes and Mini MillsDocumento2 páginasDial Indicator: The Premier Source of Parts and Accessories For Mini Lathes and Mini MillsAmin UviantoAinda não há avaliações

- Metalwork Notes NEWDocumento49 páginasMetalwork Notes NEWJudeAinda não há avaliações

- Design of Machine Elements ProjectDocumento43 páginasDesign of Machine Elements ProjectGirish ChandankarAinda não há avaliações

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDocumento34 páginasBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDeepti KanadeAinda não há avaliações

- Kiran Universal CouplingDocumento10 páginasKiran Universal CouplingMurali SiddarthAinda não há avaliações

- Dr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDocumento12 páginasDr. Richard E. Link U.S. Naval Academy Department of Mechanical Engineering 590 Holloway Road Annapolis, MD 21402-5042 All Rights ReservedDaveB2008Ainda não há avaliações

- SMEA1304Documento164 páginasSMEA1304y2k405 kaosAinda não há avaliações

- Line and Grade PresentationDocumento35 páginasLine and Grade PresentationRick Pongi100% (1)

- Common Terms and Definitions: Basic DimensionDocumento9 páginasCommon Terms and Definitions: Basic Dimensionswap dAinda não há avaliações

- Dimensioning ME DrawingsDocumento50 páginasDimensioning ME DrawingsLuis NunesAinda não há avaliações

- CAM-CIM Manual - M.tech - Jan 2022Documento46 páginasCAM-CIM Manual - M.tech - Jan 2022KUNAL SHIMPIAinda não há avaliações

- m2 U6 Recessing and RadiusingDocumento13 páginasm2 U6 Recessing and RadiusingViệt Đặng XuânAinda não há avaliações

- Bezel Bezel Lock: Rotate The Bezel To Zero The Needle. Tighten To Lock The Bezel in PlaceDocumento2 páginasBezel Bezel Lock: Rotate The Bezel To Zero The Needle. Tighten To Lock The Bezel in PlaceAmin UviantoAinda não há avaliações

- Lab Report ME3Documento8 páginasLab Report ME3Hassan Iftekhar AhmedAinda não há avaliações

- 5.EMM Lab ManualDocumento38 páginas5.EMM Lab ManualRakeshkumarcegAinda não há avaliações

- Different Measuring ToolsDocumento2 páginasDifferent Measuring Toolsanon_449620137Ainda não há avaliações

- Light Signal Alarm System LSAS BrochureDocumento5 páginasLight Signal Alarm System LSAS BrochureyoungfpAinda não há avaliações

- Light Signal Alarm System LSAS Brochure PDFDocumento6 páginasLight Signal Alarm System LSAS Brochure PDFyoungfpAinda não há avaliações

- Symbols For Triangular LightsDocumento1 páginaSymbols For Triangular LightsyoungfpAinda não há avaliações

- Cable Selection Guide For Process InstrumentationDocumento3 páginasCable Selection Guide For Process InstrumentationyoungfpAinda não há avaliações

- BNWAS Le Guardian 2025 English Brochure PDFDocumento6 páginasBNWAS Le Guardian 2025 English Brochure PDFyoungfpAinda não há avaliações

- DNV GUIDANCE Emergency Stop SystemsDocumento13 páginasDNV GUIDANCE Emergency Stop SystemsyoungfpAinda não há avaliações

- IACS Joint Safety StatementDocumento3 páginasIACS Joint Safety StatementyoungfpAinda não há avaliações

- Dead Man Alarm DMA English BrochureDocumento6 páginasDead Man Alarm DMA English BrochureyoungfpAinda não há avaliações

- Sulzer Zv40/48 Zgoda Crankshaft Replacement & In-Place MachiningDocumento2 páginasSulzer Zv40/48 Zgoda Crankshaft Replacement & In-Place MachiningyoungfpAinda não há avaliações

- Wartsila Seals Bearings Portable CBMDocumento2 páginasWartsila Seals Bearings Portable CBMyoungfpAinda não há avaliações

- Becker Intelligent Monitoring System BIMS PDFDocumento4 páginasBecker Intelligent Monitoring System BIMS PDFyoungfpAinda não há avaliações

- Information On Detention and Action Taken Rev5Documento12 páginasInformation On Detention and Action Taken Rev5youngfpAinda não há avaliações

- Amendments To SOLAS PDFDocumento2 páginasAmendments To SOLAS PDFyoungfpAinda não há avaliações

- CNC TURNING MachineDocumento14 páginasCNC TURNING MachineFaiz AhmedAinda não há avaliações

- GDS PQDocumento108 páginasGDS PQSaad AkramAinda não há avaliações

- Consumable Stock June 2021Documento497 páginasConsumable Stock June 2021isser150Ainda não há avaliações

- Advanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedDocumento57 páginasAdvanced Cutting and Routing Techniques Using The Festool MFS Fence System ReducedxanderAinda não há avaliações

- Victorian PlayhouseDocumento12 páginasVictorian Playhousepierre van wykAinda não há avaliações

- Bamboo-Based Biocomposite: Application For A Sustainable Naval ArchitectureDocumento11 páginasBamboo-Based Biocomposite: Application For A Sustainable Naval ArchitectureNimna ZakariaAinda não há avaliações

- Veneer and LaminatesDocumento14 páginasVeneer and Laminates1DC20AT025 Ganesh AkshayAinda não há avaliações

- 2.4 MM Mandible Trauma and Locking Reconstruction.J9499ADocumento3 páginas2.4 MM Mandible Trauma and Locking Reconstruction.J9499AprincaroAinda não há avaliações

- Following Is The 27 Page Instruction Manual For The Microlux 7 X 14 High-Precision Heavy-Duty LatheDocumento31 páginasFollowing Is The 27 Page Instruction Manual For The Microlux 7 X 14 High-Precision Heavy-Duty LatheRichard BedellAinda não há avaliações

- The WoodcutterDocumento1 páginaThe WoodcutterBaobab DramatherapyAinda não há avaliações

- WIPDocumento3 páginasWIPAris SusantoAinda não há avaliações

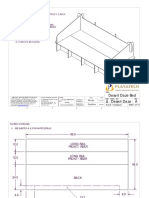

- Desert Daze Bed Desert Daze: Sunshine WristyDocumento10 páginasDesert Daze Bed Desert Daze: Sunshine WristycformnemAinda não há avaliações

- Lecture 5 - Canned Cycle-TurningDocumento11 páginasLecture 5 - Canned Cycle-TurningAditya RatleyAinda não há avaliações

- Manuale 43631P000Documento20 páginasManuale 43631P000kinkywoodesignAinda não há avaliações

- Project For Mechanical DrawingDocumento19 páginasProject For Mechanical DrawingMoh AmmAinda não há avaliações

- 2 - First Rate CatalogueDocumento32 páginas2 - First Rate CatalogueMarcelo VisintinAinda não há avaliações

- Grinding Eqipment: Product CatalogueDocumento32 páginasGrinding Eqipment: Product CataloguePablo OlórtigaAinda não há avaliações

- Introduction To Plywood IndustryDocumento9 páginasIntroduction To Plywood IndustryShakeel AhamedAinda não há avaliações

- MCF VTU Question BankDocumento6 páginasMCF VTU Question BankRAKSHITH MAinda não há avaliações

- 9 Types of Wood Framing To KnowDocumento19 páginas9 Types of Wood Framing To KnowMarion LauritoAinda não há avaliações

- Wood JointsDocumento22 páginasWood JointsRaju RoyAinda não há avaliações

- AA Revised Instructions Connectors 9-25-14 BC 7-15-16Documento3 páginasAA Revised Instructions Connectors 9-25-14 BC 7-15-16mohamed hamedAinda não há avaliações

- English FP4MEDocumento2 páginasEnglish FP4MEHossein TomariAinda não há avaliações

- Smaw 9 Summative Test Q1Documento2 páginasSmaw 9 Summative Test Q1Jose Intraboy Arais Tabugoc Jr.Ainda não há avaliações