Escolar Documentos

Profissional Documentos

Cultura Documentos

Popular Mechanics - Replacing Your Water Pump

Enviado por

diemnganDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Popular Mechanics - Replacing Your Water Pump

Enviado por

diemnganDireitos autorais:

Formatos disponíveis

Popular Mechanics - Replacing Your Water Pump

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=Popu...

SAVE THIS | EMAIL THIS | Close

REPLACING YOUR WATER PUMP

BY BOB FREUDENBERGER Illustrations by Russell J. von Sauers and Ron Carboni

Published on: July 1, 2000

Bombing down the interstate, you glance at the odometer and realize you've just reached an automotive milestone: 100,000 miles with no major repairs. Time was a car that had passed its belly over that much real estate was considered pretty much used up, but yours still runs great and looks practically new. Amazing how technology has advanced. Then you notice the temperature gauge. Holy smokes--pegged! You put it in neutral, coast off onto the shoulder and shut her down. There's that maple-syrup-spilled-on-the-radiator odor again--you've smelled it before, but filed it under "things to think about later." Sooner would've been better--now you're walking. Seal Deal The biggest change in water pump design occurred decades ago when the spring-loaded mechanical seal was adopted. However, its rubber parts may disintegrate if the engine overheats, and its polished sealing faces can wear and warp if the engine is run dry. Typically, pumps will start leaking catastrophically shortly after a boil-over. This kind of failure can be worse than it sounds. Besides the vastly expensive internal engine damage that running without coolant may cause, a leaking seal can wash away the shaft bearing's lubricant, perhaps resulting in a snapped shaft, and a flying fan or belt pulley can destroy the radiator or even dent the hood. So, leakage is the No. 1 failure. Noise is second, and is always indicative of a terminal condition. While service literature on water pumps often will show a picture of a badly eroded impeller that contributes to overheating, technicians say that's not as common as it once was. Another possible problem with the same consequences is an impeller that's come loose from its shaft. Erosion of the inside surfaces of the pump chamber caused by cavitation (a weak cap or a chronically low level, perhaps?) can open up the working space and reduce flow, as can corrosion from too little antifreeze in the coolant mix.

This is an easy one, because it's near the top. Your job would be a lot tougher if the pump were near the bottom.

With the engine warm enough to open the thermostat, but not hot enough to pressurize the system, look

1 of 4

29/08/2006 2:23 PM

Popular Mechanics - Replacing Your Water Pump

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=Popu...

Evidence Gathering If you start to smell the distinctive odor of engine coolant, or you notice that the level in the overflow bottle is dropping rapidly, it's time for a careful exam. (If you're lucky, it may be just a leaky hose connection, but look the radiator over, too. If the smell is strong in the passenger compartment and the windshield tends to steam up, think about the heater core. In cases where none of the above is the culprit, better check out the water pump.) First, use an inspection mirror and a good light to view the vent hole that's at the bottom of the pump casting's nose. Or, support the front of the car safely on jackstands and look up from underneath. All seals are supposed to weep slightly (a little coolant is needed to lube the faces), but drips mean you'd better go shopping for an estimate. Next, grasp the fan or water pump pulley and see if it rocks from side to side. If there's anything but slight movement, the bearing is on its way out. Also, you can remove the belt and see how the bearing feels as you rotate the pump shaft. Roughness isn't acceptable. A low-flow situation that results in hot running can be hard to diagnose. Drain the level down to the top of the radiator tubes, get the engine hot, and then shut it off for 10 minutes and let it heat soak to make sure the thermostat is wide open. Now, fire it up again and run it at 3000 rpm. On cars using the radiator fill neck on the top tank, look down into it with a flashlight and you should see strong circulation. Another possibility is to squeeze the upper hose to feel for flow, but that's pretty subjective. Unfortunately, there's no good way for the do-it-yourselfer to differentiate a weak pump from a clogged radiator.

for vigorous flow at 3000 rpm.

Major Undertaking? On some front-wheel drives the job is a horror story. Make sure you resist the temptation to get into this repair if you're not prepared to invest the time required. Find out the flat-rate hours by asking a local garage owner or dealer service manager. Or, look it up on your PM CD-ROM. It's a job that could take several hours, depending on what you drive. The first steps in removing any water pump are to let the engine cool off completely, and then drain the cooling system by either opening the radiator petcock or disconnecting the bottom radiator hose. Next, do whatever is necessary to remove the accessory drivebelts. If the car has a longitudinally mounted engine as found in every rwd and some front-drivers, remove the air shrouds (in some cases, the radiator, too), and then the fan and its clutch, which bolt to the front of the water pump shaft. Now you can start on the pump by disconnecting the hoses. Those for the heater will probably be stubborn, so you may need to split their ends with a utility knife (if they're long enough, you might be able to trim them off square and

Wet liquid seeping from the weep hole signifies the end of the service life of the seals in your pump.

Almost any radial play in the water pump shaft is grounds for immediate pump replacement before something

2 of 4

29/08/2006 2:23 PM

Popular Mechanics - Replacing Your Water Pump

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=Popu...

reuse them). Extract the pump-to-engine bolts and keep them and any accessory brackets they retain in strict order or you'll regret it at assembly. There may be hidden bolts, so take a look at a diagram. The pump should come off with a good tug. If not, make sure you didn't miss any bolts, and then tap on the inlet or outlet neck with a mallet or a block of wood and a hammer. Don't use a screwdriver to pry the seam open or you'll make a nick that the gasket may not seal. Pumps seal against the engine or backing plate with a gasket, an O-ring or RTV silicone. Get the mating surface clean with a scraper. If you must use silicone sealer, use one rated for automotive use. It should also be labeled low-volatility. Outgassing from the curing sealant can poison oxygen sensors--so leave the bathtub caulk with your plumbing tools. We should mention a potential problem. Suppose you're installing a water pump on a car with a serpentine belt. Engines on many older models were equipped with a regular V-belt, but the water pump for the old model may fit physically on the new one. Can you guess the possible mistake? Think about direction: The serpentine belt might drive the impeller in the opposite direction from that of the V-belt, so you could end up installing a pump that runs backward, causing a seemingly incurable overheating situation. Make sure you get exactly the right part, and compare the impellers. Also, heed that routing diagram. After everything is buttoned up, figure out how much coolant your system holds. This should be in your owner's manual, or in the shop manual. Using the appropriate manufacturer's coolant, add half that amount and then top off with water. This will give you a 50-50 mix. Be sure to follow the service procedure for bleeding the air bubbles out of the system.

fails.

Vehicles with serpentine belts have a belt routing diagram under the hood somewhere. Read and obey.

HOW IT WORKS: Water Pump Shaft Seals

Two perfectly flat rings, one stationary and the other rotating with the pump shaft, are pressed together by means of a coil spring. The rings may be made of carbon or may be ceramic, phenolic, porous bronze, cast iron, etc., in any combination. This allows only enough seepage to keep the elements lubricated. It has a weak link, however, in the form of its rubber partsthe bellows that seals the spring and the rubber seat cup between the rotating element and the shaft. If the engine is ever run dry, the temperature of the pump is apt to rise far beyond what the rubber can survive, and a leak occurs. Another possibility is warpage of the sealing

3 of 4

29/08/2006 2:23 PM

Popular Mechanics - Replacing Your Water Pump

http://hearst.corp.printthis.clickability.com/pt/cpt?action=cpt&title=Popu...

elements, also from overheating. Theres conflicting evidence on whether silicates and phosphates from antifreeze, or other hard particles such as casting core sand, can actually damage the seal faces. Engineers have told us the running clearance is way too small to admit solids of any appreciable diameter. Since cars are lasting longer than they used to, and since weve become such a litigious society, carmakers are working harder than ever to make water pumps last. After all, when a pump goes youve got to get out and walk, which exposes you to dangers that horrify auto company lawyers. So, there has been a push for water pump seals that will rarely, if ever, fail. One design that looks promising is from Michael Ostrowski and John Crane International, the leading supplier of conventional water pump seals. Called the Advanced Metal Diaphragm seal, it uses a flexible stainless steel diaphragm that acts as both the spring and the bellows, and incorporates an improved method of mounting the seal faces.

Links referenced within this article

Find this article at:

http://www.popularmechanics.com/automotive/sub_care_sat/1272366.html SAVE THIS | EMAIL THIS | Close Uncheck the box to remove the list of links referenced in the article.

4 of 4

29/08/2006 2:23 PM

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Seismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineerDocumento16 páginasSeismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineercivilsadiqAinda não há avaliações

- Section 4 DrainageDocumento30 páginasSection 4 DrainageomarizaidAinda não há avaliações

- En 1993 1 12 2007 PDFDocumento11 páginasEn 1993 1 12 2007 PDFRajan SteeveAinda não há avaliações

- En 1998 - Eurocode 8 Design of Structures Design of Structures For Earthquake Resistance For Earthquake ResistanceDocumento214 páginasEn 1998 - Eurocode 8 Design of Structures Design of Structures For Earthquake Resistance For Earthquake Resistancenahan_khanehe_delAinda não há avaliações

- D10TDocumento2 páginasD10TjoseluisyalicoAinda não há avaliações

- 13-1 Introduction: Earth Is Presented in Section 13-7. Slurry Trench Walls, Specially Constructed Concrete Walls BuiltDocumento15 páginas13-1 Introduction: Earth Is Presented in Section 13-7. Slurry Trench Walls, Specially Constructed Concrete Walls BuiltRajesh KhadkaAinda não há avaliações

- Hilti Bolt Design For CanadaDocumento120 páginasHilti Bolt Design For Canadadeepteck00Ainda não há avaliações

- Rammed EarthDocumento116 páginasRammed EarthGuillermoValeroLozano100% (5)

- Catalogo de Peças Scania - 2015Documento433 páginasCatalogo de Peças Scania - 2015João Paulo Gonçalves100% (2)

- Grouting ProcedureDocumento7 páginasGrouting ProcedureArbiAinda não há avaliações

- Petronas TowersDocumento22 páginasPetronas TowersMiti Agarwal100% (2)

- Grand Rapid Art MuseumDocumento16 páginasGrand Rapid Art Museummonderoglu100% (1)

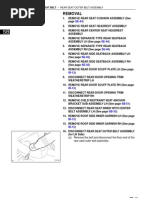

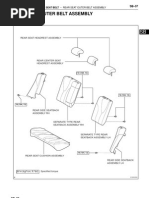

- Installation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHDocumento3 páginasInstallation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHdiemnganAinda não há avaliações

- Removal: Seat Belt - Rear Seat Inner Belt AssemblyDocumento2 páginasRemoval: Seat Belt - Rear Seat Inner Belt AssemblydiemnganAinda não há avaliações

- Reassembly: Seat - Front Seat Assembly (For Power Seat)Documento5 páginasReassembly: Seat - Front Seat Assembly (For Power Seat)diemnganAinda não há avaliações

- FRONT SEAT ASSEMBLY (For Power Seat) : ComponentsDocumento4 páginasFRONT SEAT ASSEMBLY (For Power Seat) : ComponentsdiemnganAinda não há avaliações

- Rear Seat Assembly: ComponentsDocumento6 páginasRear Seat Assembly: ComponentsdiemnganAinda não há avaliações

- Disposal: Seat Belt - Front Seat Outer Belt AssemblyDocumento5 páginasDisposal: Seat Belt - Front Seat Outer Belt AssemblydiemnganAinda não há avaliações

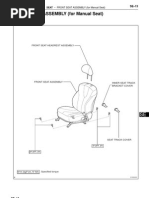

- FRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsDocumento3 páginasFRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsdiemnganAinda não há avaliações

- Removal: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchDocumento4 páginasRemoval: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchdiemnganAinda não há avaliações

- Front Seatback Heater: ComponentsDocumento2 páginasFront Seatback Heater: ComponentsdiemnganAinda não há avaliações

- Removal: Seat Belt - Rear Seat Outer Belt AssemblyDocumento4 páginasRemoval: Seat Belt - Rear Seat Outer Belt AssemblydiemnganAinda não há avaliações

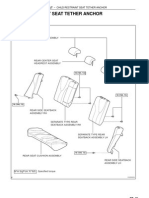

- Child Restraint Seat Tether Anchor: ComponentsDocumento3 páginasChild Restraint Seat Tether Anchor: ComponentsdiemnganAinda não há avaliações

- Seat Heater System: PrecautionDocumento2 páginasSeat Heater System: PrecautiondiemnganAinda não há avaliações

- Front Seat Cushion Heater: ComponentsDocumento2 páginasFront Seat Cushion Heater: ComponentsdiemnganAinda não há avaliações

- Rear Seat Outer Belt Assembly: ComponentsDocumento3 páginasRear Seat Outer Belt Assembly: ComponentsdiemnganAinda não há avaliações

- Removal: Seat - Front Seat Assembly (For Power Seat)Documento2 páginasRemoval: Seat - Front Seat Assembly (For Power Seat)diemnganAinda não há avaliações

- Rear Seat Inner Belt Assembly: ComponentsDocumento3 páginasRear Seat Inner Belt Assembly: ComponentsdiemnganAinda não há avaliações

- Lumbar Support Adjuster Assembly: ComponentsDocumento2 páginasLumbar Support Adjuster Assembly: ComponentsdiemnganAinda não há avaliações

- Removal: Seat - Front Seat Assembly (For Manual Seat)Documento2 páginasRemoval: Seat - Front Seat Assembly (For Manual Seat)diemnganAinda não há avaliações

- Seat Heater Switch: ComponentsDocumento4 páginasSeat Heater Switch: ComponentsdiemnganAinda não há avaliações

- Front Power Seat Lumbar Switch: ComponentsDocumento2 páginasFront Power Seat Lumbar Switch: ComponentsdiemnganAinda não há avaliações

- Removal: Seat - Front Power Seat Lumbar SwitchDocumento2 páginasRemoval: Seat - Front Power Seat Lumbar SwitchdiemnganAinda não há avaliações

- Child Restraint Seat Anchor Bracket: ComponentsDocumento2 páginasChild Restraint Seat Anchor Bracket: ComponentsdiemnganAinda não há avaliações

- Removal: Seat - Front Seat Cushion HeaterDocumento2 páginasRemoval: Seat - Front Seat Cushion HeaterdiemnganAinda não há avaliações

- Power Seat Switch: ComponentsDocumento2 páginasPower Seat Switch: ComponentsdiemnganAinda não há avaliações

- Diagnosis System: CG SG SIL CanhDocumento2 páginasDiagnosis System: CG SG SIL CanhdiemnganAinda não há avaliações

- Front Seat Frame With Adjuster: InspectionDocumento2 páginasFront Seat Frame With Adjuster: InspectiondiemnganAinda não há avaliações

- System Diagram: E55 Seat Heater SwitchDocumento2 páginasSystem Diagram: E55 Seat Heater SwitchdiemnganAinda não há avaliações

- Removal: Seat - Front Seatback HeaterDocumento2 páginasRemoval: Seat - Front Seatback HeaterdiemnganAinda não há avaliações

- System Diagram: Driver SideDocumento2 páginasSystem Diagram: Driver SidediemnganAinda não há avaliações

- Seat Belt Warning System: PrecautionDocumento2 páginasSeat Belt Warning System: PrecautiondiemnganAinda não há avaliações

- Henry Dee Taking Off Beme For Office Building of 40m October 2016Documento257 páginasHenry Dee Taking Off Beme For Office Building of 40m October 2016Henry DiyokeAinda não há avaliações

- Administrative Order No. 23 Compliance Report TemplateDocumento7 páginasAdministrative Order No. 23 Compliance Report TemplateVILMA BASEAinda não há avaliações

- Yakmach KharanDocumento3 páginasYakmach KharanMunir HussainAinda não há avaliações

- Timber DistortionDocumento14 páginasTimber DistortionThomas SmithAinda não há avaliações

- FHWA Design and Construction of Stone Columns Vol.1 ExtraDocumento46 páginasFHWA Design and Construction of Stone Columns Vol.1 ExtranoordenAinda não há avaliações

- Lead-In: in Tree It More - : and - They To It From Home I Is Own:"-In The To: It The /!Documento1 páginaLead-In: in Tree It More - : and - They To It From Home I Is Own:"-In The To: It The /!Gabriela FlorentaAinda não há avaliações

- Rimska ArhitekturaDocumento11 páginasRimska ArhitekturadebbronnerfilesAinda não há avaliações

- DTC P0299 Chevrolet Sonic 2014Documento7 páginasDTC P0299 Chevrolet Sonic 2014miguelAinda não há avaliações

- MOJAVE Single Wide Proof 2014Documento16 páginasMOJAVE Single Wide Proof 2014Donnarose DiBenedettoAinda não há avaliações

- Vertical Vessel AISCDocumento9 páginasVertical Vessel AISCRajveer SinghAinda não há avaliações

- LubricationDocumento4 páginasLubrication1680808054731Ainda não há avaliações

- BPA Englisch 2016Documento63 páginasBPA Englisch 2016Carlos RojasAinda não há avaliações

- ED & HJ W.H.HagerDocumento9 páginasED & HJ W.H.Hagerjamjam75Ainda não há avaliações

- Puc 6004 BuyDocumento16 páginasPuc 6004 BuyJuanAinda não há avaliações

- NAF Unex Butterfly 4141 GB PDFDocumento8 páginasNAF Unex Butterfly 4141 GB PDFganeshanAinda não há avaliações

- POLYTHERM Price List 190404Documento6 páginasPOLYTHERM Price List 190404MEPAinda não há avaliações

- Experimental Tests On Steel Storage RackDocumento83 páginasExperimental Tests On Steel Storage RackMarina LatinovićAinda não há avaliações

- Ajiya - 2017 - Catalogue A - Rev41 (Final Copy)Documento12 páginasAjiya - 2017 - Catalogue A - Rev41 (Final Copy)pincer-pincerAinda não há avaliações