Escolar Documentos

Profissional Documentos

Cultura Documentos

Diesel Engine Maintenance Checklist

Enviado por

johnnybe51Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Diesel Engine Maintenance Checklist

Enviado por

johnnybe51Direitos autorais:

Formatos disponíveis

TM 5-692-1

CHAPTER 3 DIESEL ENGINES

3-1.

Minimum maintenance activities for diesel engines

The tables located at the end of this chapter indicate items that must be performed to maintain the diesel engines at a minimum level of operational readiness. Due to the many variations in engine age and design that may be encountered, not all of the items listed will be applicable for all facilities. All maintenance must be performed in accordance with the engine manufacturer's published maintenance schedule and procedures for the specific engine installed. Maintenance actions are included in this chapter for various modes of operation, subsystems, or components. Table 3-1 provides maintenance information for diesel engines in standby mode. Table 3-2 provides maintenance information for diesel engines operating in short-term activities. Short-term activities are those scheduled maintenance activities with a frequency of 1,000 hours run time or less. Table 3-3 provides maintenance information for diesel engines operation in long term activities. Long-term activities are those scheduled maintenance activities with a frequency greater than 1,000 hours run time. 3-2. Major equipment maintenance for diesel engines Any maintenance procedure that requires disassembly of the engine or removal of components is considered major maintenance. Personnel performing any of the major maintenance procedures listed in this chapter must be trained diesel engine mechanics. In addition, the timing of the maintenance schedule for major maintenance items can vary significantly based on the engine design and speed. All maintenance must be performed in accordance with the engine manufacturer's published maintenance schedule and procedures for the specific engine installed. 3-3. Diesel engine performance trend analysis Trend analysis is a valuable tool in predicting maintenance requirements and shall be used to determine impending problems and to schedule maintenance. Trend analysis consists of recording significant operating data and plotting that data versus engine hours and then analyzing the graphs for significant changes in performance. Operating data should be obtained under the same load and general operating conditions each time it is recorded. Data shall be taken at intervals not to exceed 250 hours (100 hours is preferred). Any significant change in recorded data should be verified by obtaining a second set of data. Various commercial software packages are available to aid in the planning of maintenance and analysis of malfunctions. These systems use field instrumentation to constantly monitor the status of the engine health. By storing this monitored data in a database during periods of normal operation, the system can identify changes in the operating behavior of the engine over long periods of time. Necessary adjustments and maintenance work can thus be planned on the basis of the engine condition. As a minimum, the following data shall be obtained and plotted. a. Cylinder compression pressures b. Cylinder firing pressures c. Fuel pump/injector rack or governor power piston position

3-1

TM 5-692-1

d. Cylinder exhaust temperature e. Crankcase pressure (or vacuum) f. Lube oil pressure at engine inlet or header

g. Air inlet manifold pressure h. Lube oil added to engine sump in the last 100 hours. Do not include oil changes. i. Lube oil analysis results, especially for trace metals

3-2

TM 5-692-1

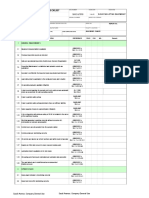

Table 3-1. Diesel engine standby mode Diesel Engine Standby Mode Action Frequency

WARNING! THE MAINTENANCE PROCEDURES OUTLINED IN THIS SECTION MAY OR MAY NOT REQUIRE REMOVING AN ENGINE FROM ITS READY STANDBY STATE SO THAT THE ENGINE DOES NOT AUTOMATICALLY START IF A POWER FAILURE OCCURS. WHEN NECESSARY, OBTAIN CLEARANCE FROM OPERATOR AND VERIFY THAT CONTROLS AND ENGINE STARTING DEVICES ARE PROPERLY LOCKED OUT TO PREVENT POSSIBLE AUTOMATIC STARTUP OF ENGINE.

Check and verify operation of pre-lube pump. Check and verify operation of keep warm system. Check and verify operation of starting air compressors or battery charger. Check and verify starting air pressure is correct or batteries are charged. Verify that control power is available to the control system and all controls are in the proper position to allow automatic starting of the engines. Check for fuel oil and lube oil leaks. Check for cooling leaks. Check day tank area for leaks. Check lube oil level; add if required. Inspect air filter; clean/replace if required. Check starting air lubricator; fill if required. Check oil level in governor; add if required. Check coolant level in expansion tank. Record and report any discrepancies. 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs week week week week week week

3-3

TM 5-692-1

Table 3-2. Diesel engine operating mode, short term activities Diesel Engine Operating Mode, Short Term Activities Action Frequency

WARNING! THE MAINTENANCE PROCEDURES OUTLINED IN THIS SECTION MAY OR MAY NOT REQUIRE REMOVING AN ENGINE FROM ITS READY STANDBY STATE SO THAT THE ENGINE DOES NOT AUTOMATICALLY START IF A POWER FAILURE OCCURS. WHEN NECESSARY, OBTAIN CLEARANCE FROM OPERATOR AND VERIFY THAT CONTROLS AND ENGINE STARTING DEVICES ARE PROPERLY LOCKED OUT TO PREVENT POSSIBLE AUTOMATIC STARTUP OF ENGINE.

Inspect engine and listen for any unusual noise. Check for fuel oil, lube oil, and coolant leaks. Note and record any excessive vibration in the turbocharger or blower. Check and record the data indicated on the engine instrument panel. Note any unusual readings and investigate. Check lube oil level in engine crankcase or sump. Check coolant level in expansion tank. Check oil level in governor. Check fuel strainers for water; drain if required. Check fuel level in day tank Check color and smoke level of exhaust gas. Check lube oil and fuel filter pressure drop; change filters as required. Inspect air filters; replace as required. Check pH of engine coolant; add conditioner as required to meet manufacturer's recommendations. Take lube oil sample for test and analysis; change lube oil if indicated by test results or provide additives if recommended by lube oil supplier. Verify proper operation of all safety shutdown controls and alarms; immediately repair any defective items. Change fuel oil filters; filters should be changed based on maximum recommended pressure differential. hr hr hr 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs 8 hrs day day 250 hrs1 250 hrs1 1K hrs2 1K hrs2

3-4

TM 5-692-1

Table 3-2. Diesel engine operating mode, short term activities Diesel Engine Operating Mode, Short Term Activities Action Clean and inspect centrifugal lube oil filters if provided. Grease/lubricate auxiliary pump bearings. ___________________ 1 Every Month for Standby Units 2 Every Six Months for Standby Units

(continued)

Frequency 1K hrs2 1K hrs2

3-5

TM 5-692-1

Table 3-3. Diesel engine operating mode, long term activities Diesel Engine Operating Mode, Long Term Activities Action Frequency

WARNING!

THE MAINTENANCE PROCEDURES OUTLINED IN THIS SECTION MAY OR MAY NOT REQUIRE REMOVING AN ENGINE FROM ITS READY STANDBY STATE SO THAT THE ENGINE DOES NOT AUTOMATICALLY START IF A POWER FAILURE OCCURS. WHEN NECESSARY, OBTAIN CLEARANCE FROM OPERATOR AND VERIFY THAT CONTROLS AND ENGINE STARTING DEVICES ARE PROPERLY LOCKED OUT TO PREVENT POSSIBLE AUTOMATIC STARTUP OF ENGINE. Inspect valves and check valve clearance; adjust as required. On two-cycle engines, inspect and clean inlet and exhaust ports. Check injector timing; adjust as required. Verify proper operation of all instrumentation. Inspect blower drive and timing gears if applicable. Inspect aftercooler; clean if required. Inspect and clean turbocharger if required. Change governor oil. On two-cycle engines, inspect pistons, rings, inlet and exhaust ports, and cylinder liner. Remove and inspect one cylinder head, piston, liner, and connecting rod. Measure all surfaces subject to wear, and record data for use in determining overhaul intervals. Inspect all oil passages and water side surfaces for obstructions and deposits. Check foundation bolts for tightness. Where engine and driven equipment are mounted on a skid with spring isolators, inspect spring isolators for proper clearance. Drain and flush cooling system. Replace coolant. Inspect all thermostatic valves or regulators. Inspect all engine-driven pumps. Inspect aftercooler and lube oil cooler; clean if required. Inspect all gears and/or chain drives for driven components and auxiliaries for wear; adjust if appropriate. Check alignment of engine and driven equipment. 2K hrs 2K hrs 2K hrs 2K hrs 4K hrs 4K hrs 4K hrs 4K hrs

8K hrs 8K hrs 8K hrs 8K hrs 8K hrs 8K hrs 8K hrs

3-6

Você também pode gostar

- Generator Faults and RemediesDocumento7 páginasGenerator Faults and Remediesemmahenge100% (2)

- Malfunction and Troubleshooting For Diesel EngineDocumento10 páginasMalfunction and Troubleshooting For Diesel Engineعبدالله عمر0% (1)

- Diesel Engine OverhaulingDocumento163 páginasDiesel Engine OverhaulingRobert Agapito100% (2)

- Maintenance Interval ScheduleDocumento3 páginasMaintenance Interval Scheduleashish_ismdhanbadAinda não há avaliações

- How Diesel Engine WorksDocumento26 páginasHow Diesel Engine WorksAbdul Shukur89% (9)

- Sub: Multipurpose Hall - Lusail Sports Club - Package 2Documento12 páginasSub: Multipurpose Hall - Lusail Sports Club - Package 2Seyed IbrahimAinda não há avaliações

- Diesel Generator LogsheetDocumento2 páginasDiesel Generator Logsheetcoleiro100% (6)

- Alignment PDFDocumento12 páginasAlignment PDFVictor Nunez100% (1)

- Engine Alignment DetailsDocumento13 páginasEngine Alignment DetailsNaufal HilmiAinda não há avaliações

- Prediction of Repair & Maintenance Costs of Diesel EngineDocumento7 páginasPrediction of Repair & Maintenance Costs of Diesel EngineAnonymous pKuPK3zUAinda não há avaliações

- Genset Startup and Commissioning Checklist C 175Documento13 páginasGenset Startup and Commissioning Checklist C 175Dwi Mulyanti DwimulyantishopAinda não há avaliações

- Diesel Generator Overhauling Procedure-21-22 Best PracticeDocumento15 páginasDiesel Generator Overhauling Procedure-21-22 Best PracticeMarcos Fernandez100% (2)

- EGB-1P and EGB-2P Governor - ActuatorDocumento68 páginasEGB-1P and EGB-2P Governor - ActuatorMiguel SoteloAinda não há avaliações

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocumento65 páginasMaintenance Intervals: Operation and Maintenance Manual ExcerptmedescalanteAinda não há avaliações

- How To Inspect A GearboxDocumento9 páginasHow To Inspect A Gearboxroberto_perracini100% (1)

- Sudhir Gensets Training FileDocumento47 páginasSudhir Gensets Training FileabhishekAinda não há avaliações

- Induction Motor Starting MethodsDocumento4 páginasInduction Motor Starting Methodsعلي عايد عبدالشهيدAinda não há avaliações

- Section C, Exhibit 1 - Example Equipment Inspection ChecklistsDocumento5 páginasSection C, Exhibit 1 - Example Equipment Inspection ChecklistsArturo Ramos AlvezoAinda não há avaliações

- Hydraulic System MaintenanceDocumento4 páginasHydraulic System MaintenanceMohamed IbrahimAinda não há avaliações

- Generator Operation & MaintenanceDocumento39 páginasGenerator Operation & Maintenancejuanfer_arevalo3681Ainda não há avaliações

- Main Seawater Pump Overhaul ReportDocumento7 páginasMain Seawater Pump Overhaul ReportPrakhyati RautAinda não há avaliações

- CatDocumento36 páginasCatnagananda_ar100% (1)

- Mainternal Interval 3406Documento3 páginasMainternal Interval 3406Sandy Sanjaya100% (1)

- Vm-10 (Diesel Generator Overhauling Report)Documento1 páginaVm-10 (Diesel Generator Overhauling Report)catalin67% (3)

- Approximate Generator Fuel Consumption ChartDocumento1 páginaApproximate Generator Fuel Consumption Chartankur yadavAinda não há avaliações

- Diesel Generator (DG) Operation Standard ProcedureDocumento2 páginasDiesel Generator (DG) Operation Standard ProcedureMdrahaman MithuAinda não há avaliações

- DG Maintenance Scope MKDocumento9 páginasDG Maintenance Scope MKBahati ValerianAinda não há avaliações

- Centrifugal Pump Report PDFDocumento1 páginaCentrifugal Pump Report PDFandrew rachmanAinda não há avaliações

- Overhauling Procedure and Report of Generator 12Documento7 páginasOverhauling Procedure and Report of Generator 12Swaroop MohapatraAinda não há avaliações

- NPT Operation and Maintenance Manual For Gas GeneratorDocumento60 páginasNPT Operation and Maintenance Manual For Gas GeneratorJORGE LUIS MENDOZA SANCHEZ100% (1)

- Product Doc 1 en 180Documento6 páginasProduct Doc 1 en 180Fredy Mauricio Diaz VargasAinda não há avaliações

- Bauer Air CompressorDocumento46 páginasBauer Air CompressorEdward FernandezAinda não há avaliações

- Duetz 1011 & 2011 CE246Documento8 páginasDuetz 1011 & 2011 CE246PaulFoote100% (1)

- Bevel Gear ManualDocumento8 páginasBevel Gear ManualPiort ZelaskiAinda não há avaliações

- Diesel Engine ProblemsDocumento27 páginasDiesel Engine ProblemsStephen Musarurwa75% (4)

- XGC80 I PDFDocumento14 páginasXGC80 I PDFDIBNESH PANDITAAinda não há avaliações

- Maintenance On Unit 5Documento10 páginasMaintenance On Unit 5Mazhar UddeenAinda não há avaliações

- Fuel Injector AdjustmentDocumento5 páginasFuel Injector AdjustmentpaballaysAinda não há avaliações

- Maintenance Schedule Engine Mitsubishi S16RDocumento3 páginasMaintenance Schedule Engine Mitsubishi S16Randi100% (1)

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocumento35 páginasMaintenance Intervals: Operation and Maintenance Manual Excerpt08088338100% (1)

- Preventive Maintenance Engineer C.VDocumento4 páginasPreventive Maintenance Engineer C.VDIJUAinda não há avaliações

- Scheduling A Top End OverhaulDocumento3 páginasScheduling A Top End OverhaulVictor NunezAinda não há avaliações

- Front Loader Maintenance PlanDocumento2 páginasFront Loader Maintenance PlanScribdTranslationsAinda não há avaliações

- Caterpillar 3408C and 3412C Marine Generator Sets Service Manual (PDF, EnG, 1 MB)Documento43 páginasCaterpillar 3408C and 3412C Marine Generator Sets Service Manual (PDF, EnG, 1 MB)Tudor virgil33% (3)

- Basic Process of Overhaul For Diesel Power Generating SetDocumento4 páginasBasic Process of Overhaul For Diesel Power Generating SetMarcos Fernandez100% (1)

- 03 Features 1KD, 2KD PDFDocumento2 páginas03 Features 1KD, 2KD PDFCarlos QuispeAinda não há avaliações

- Equipment Maintenance Management in Cape Verde Porto Da Praia - PDFDocumento72 páginasEquipment Maintenance Management in Cape Verde Porto Da Praia - PDFAmel Abbas Abbas AbbakerAinda não há avaliações

- Caterpillar 3406Documento6 páginasCaterpillar 3406api-224431410Ainda não há avaliações

- Daily Inspection Report PC1250Documento8 páginasDaily Inspection Report PC1250Rois HananAinda não há avaliações

- Fuel Injection NotesDocumento37 páginasFuel Injection Notessachin0311Ainda não há avaliações

- Preventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForDocumento2 páginasPreventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForAndrewAinda não há avaliações

- DG Maintenance Manual PDFDocumento39 páginasDG Maintenance Manual PDFvij200950% (2)

- Repair and Field Service BrochureDocumento4 páginasRepair and Field Service Brochurecorsini999Ainda não há avaliações

- Instruction Manual For Gear Pump: Daito Kogyo Co., LTDDocumento15 páginasInstruction Manual For Gear Pump: Daito Kogyo Co., LTDMoreno NuevoAinda não há avaliações

- Greaves Non-Automotive Engines BrochureDocumento6 páginasGreaves Non-Automotive Engines BrochureRicardo TurlaAinda não há avaliações

- Cat 3516Documento2 páginasCat 3516muhammad arif100% (1)

- Engine Maintenance For Gas Turbine AssignmentDocumento7 páginasEngine Maintenance For Gas Turbine AssignmentMuhamad AimanAinda não há avaliações

- SID97-3C ADJUSTMENT of Continental Fuel InjectionDocumento41 páginasSID97-3C ADJUSTMENT of Continental Fuel InjectionTito Teixeira100% (1)

- ARIEL Maint intervalSEK PDFDocumento7 páginasARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- AWS - Welding SymbolsDocumento1 páginaAWS - Welding SymbolsAli Saifullizan IsmailAinda não há avaliações

- Plate Heat Exchanger Cleaning ProcedureDocumento20 páginasPlate Heat Exchanger Cleaning Procedurejohnnybe51Ainda não há avaliações

- Training Manual For Refrig Service TechsDocumento127 páginasTraining Manual For Refrig Service Techsjohnnybe51Ainda não há avaliações

- Maintenance Tips For Heat ExchangerDocumento4 páginasMaintenance Tips For Heat ExchangerMONAAinda não há avaliações

- Hydraulic DefinitionsDocumento39 páginasHydraulic Definitionsjohnnybe51100% (2)

- Glossary of Electrical TermsDocumento20 páginasGlossary of Electrical Termsjohnnybe51Ainda não há avaliações

- Guide To Compact Heat Ex Changers - Plate Heat ExchangerDocumento65 páginasGuide To Compact Heat Ex Changers - Plate Heat ExchangerFrank ChoiAinda não há avaliações

- Cable Installation ManualDocumento95 páginasCable Installation Manualjohnnybe510% (1)

- Chilled Water System FundamentalsDocumento14 páginasChilled Water System Fundamentalsjohnnybe51Ainda não há avaliações

- Connecting To The Grid PDFDocumento68 páginasConnecting To The Grid PDFHarish KumarAinda não há avaliações

- E Book PDF) Cooking Coca Cola RecipesDocumento8 páginasE Book PDF) Cooking Coca Cola Recipesjulfoo0% (2)

- 10 Secrets High School Test PDFDocumento171 páginas10 Secrets High School Test PDFOlimpiu AntAinda não há avaliações

- Vxdiag Multi Diagnostic Tool User Manual Vxdiagshop - 2018111401903117Documento18 páginasVxdiag Multi Diagnostic Tool User Manual Vxdiagshop - 2018111401903117Jhon Jairo BernalAinda não há avaliações

- Shafer Vs Judge Nov 14, 1988Documento2 páginasShafer Vs Judge Nov 14, 1988Alvin-Evelyn GuloyAinda não há avaliações

- MR Lube Case StudyDocumento2 páginasMR Lube Case StudyWillie Cientos Gantia100% (1)

- Ariel JGE JGH JGK JGT Manual - 231029 - 233805Documento203 páginasAriel JGE JGH JGK JGT Manual - 231029 - 233805Daniel LatorreAinda não há avaliações

- ACEA Preliminary CO2 Baseline Heavy-Duty VehiclesDocumento12 páginasACEA Preliminary CO2 Baseline Heavy-Duty VehiclesHUGO VILLANUEVAAinda não há avaliações

- Dorcas P.PDocumento10 páginasDorcas P.POrbital TechAinda não há avaliações

- Bi0068130001 - Manual de PartesDocumento677 páginasBi0068130001 - Manual de PartesMiguel angel Guerra Briceño100% (1)

- Catalogo Cummins Serie s8.3gDocumento46 páginasCatalogo Cummins Serie s8.3gAlexis Sanchez0% (1)

- XC-G Series Servo BrochureDocumento3 páginasXC-G Series Servo Brochurejohnsuca81100% (1)

- 785C Truck Electrical System: 1HW1-UPDocumento2 páginas785C Truck Electrical System: 1HW1-UPJuan MAinda não há avaliações

- Stagecoach East Midlands: (PB0001484, PF0001611, PF0007038)Documento18 páginasStagecoach East Midlands: (PB0001484, PF0001611, PF0007038)Nathan AmaizeAinda não há avaliações

- ABS Parts New Product Circular July-21Documento4 páginasABS Parts New Product Circular July-21ishan jainAinda não há avaliações

- The Right Spark Plug For Every Application: The ComprehensiveDocumento2 páginasThe Right Spark Plug For Every Application: The ComprehensiveMAIRIAinda não há avaliações

- Supra 6xx - 7xx Mod 99 (62-10483) PDFDocumento33 páginasSupra 6xx - 7xx Mod 99 (62-10483) PDFj_gabrielflores100% (2)

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBADocumento3 páginas216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 3 UBAubaldo caraballoAinda não há avaliações

- Citation CJ4 - Checklist Working TitleDocumento3 páginasCitation CJ4 - Checklist Working TitlePhilippe MagnoAinda não há avaliações

- mm0888 WebDocumento216 páginasmm0888 WebArturiano BandalhoAinda não há avaliações

- Government College of Engineering and Leather Technology: Sub: Industrial Management Assignment (Ca2)Documento8 páginasGovernment College of Engineering and Leather Technology: Sub: Industrial Management Assignment (Ca2)rohon alamAinda não há avaliações

- Al-Si Centrifugalni Lijev LMMDocumento8 páginasAl-Si Centrifugalni Lijev LMMMarija MusaAinda não há avaliações

- Digital MarketinggDocumento14 páginasDigital Marketinggtanya singhAinda não há avaliações

- Swift Sedan 2013 InduoDocumento428 páginasSwift Sedan 2013 InduoHN PARTES SuzukiAinda não há avaliações

- 2011 Dealer Book OrbeaDocumento260 páginas2011 Dealer Book OrbeaJOelAinda não há avaliações

- Electrical Circuit Diagram Mazak VCU 500ADocumento144 páginasElectrical Circuit Diagram Mazak VCU 500AMichael Naím Dévora Quintanar100% (8)

- Saic-U-7010 - Side Boom Tractor-Cranes-2023Documento8 páginasSaic-U-7010 - Side Boom Tractor-Cranes-2023محمد ممدوحAinda não há avaliações

- International HX Wiring DiagramsDocumento482 páginasInternational HX Wiring DiagramsNathan CrestaniAinda não há avaliações

- Service Manual SWE210: Hunan Sunward Intelligent Machinery Co., LTDDocumento172 páginasService Manual SWE210: Hunan Sunward Intelligent Machinery Co., LTDKo Zay92% (12)

- Opel HistoryDocumento47 páginasOpel Historylen_tia@yahoo.com100% (5)

- NIOSH 2001-109 Preventing Injuries and Deaths of Workers Who Operate or Work Near ForkliftsDocumento12 páginasNIOSH 2001-109 Preventing Injuries and Deaths of Workers Who Operate or Work Near ForkliftsAndres PAinda não há avaliações

- Alarm List: Arbiter Sensor Time Process StepDocumento4 páginasAlarm List: Arbiter Sensor Time Process Stepphankhoa83-1Ainda não há avaliações

- NB80460T3 ON Semiconductor Product Details: Part Number: Worldway Part #: Category: Manufacturer: ApplicationsDocumento3 páginasNB80460T3 ON Semiconductor Product Details: Part Number: Worldway Part #: Category: Manufacturer: ApplicationsÃkshay JainAinda não há avaliações