Escolar Documentos

Profissional Documentos

Cultura Documentos

Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connection

Enviado por

mhel_almoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connection

Enviado por

mhel_almoDireitos autorais:

Formatos disponíveis

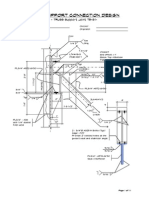

REAN'S BUILDING Angle plate design: Framed beam connection

Bearing type

4-21

5/24/2002

lh Q lv 3"spacing

Notes: Rbs = = = = Where : Av = At = Fu = dh = lh = lv = n= s= H= Q= Given: Beam = H= tf = tw = A36, Fy = A36, Fu = lv = lh = Q= Beam reaction, P = A325-X Bolt dia. h = Hole dia.,dh = n= (1.) Bolt Shear : Area of 3/4 Fv = Single shear capacity.,Sv = No. of bolt req'd.;r =

Bolt shear adequacy: Allowable load for 3/4" A325x =

Resistance to block shear, kips 0.03AvFu + 0.50AtFu {(0.30lv + 0.50lh)+0.30[(n-1)(s- h)- h/2]- h/4}xFut (K1+K2)Fu tw Net shear area, sq. in. Net tension area, sq. in. Specified min. tensile strength, ksi dia. of hole ( dia. of fastener + 1/16"), in. distance center of hole to beam end, in. distance of center of hole to edge of web , in. number of fasteners Fastener spacing, in. Depth of beam Coped dist. in. W14 x 38 14.1 0.515 0.310 36 58 ? 2 1/2 3/4 47.44 3/4 13/16 ? bolt, Ab = 21.6 AbFv P/(Sv*2) Use n = 13.3

in. in. in. ksi ksi in. in. in. kips in. in. ps 0.442 ksi 9.54 2.49 4 k > 9.54 k sq.in. k/bolt pcs pcs OK

Bolt strength at bolt holes on beam:

fv act. = fv act. =

(P/2n)/Ab 13.42

> 21.6 ksi 2.00 2 2/8 1.69 3.00

OK in. in. in. in.

(2.) Bolt Spacing: Minimum spacing = 2 2/3d = Prefferd spacing = 3d To satisfy bearing on web: Spacing = (2P/Fut)+d/2 Use standard, s

(3.) Edge distance : Minimum distance in the direction of raective force : lv = 2P/Futw 0.53 Use 1 1/2 (4.) Check Shear & Tension (Block shear) lv = lh = n-1 = s-dh = dh = 1.50 2.50 3 2.19 0.81 dh/2 = dh/4 = Fu = tw =

0.3lv = 0.5lh = (.3*lv+.5lh) = (0.3((n-1)(s-dh)-dh/2))-dh/4= Futw =

in. in.

0.41 0.10 58 0.95 0.45 1.25 1.7 1.75 55.1

Allowable block shear, Rbs = 0.03AvFu + 0.50AtFu = {(0.30lv + 0.50lh)+0.30[(n-1)(s- dh)- dh/2]- dh/4}xFutw Rbs = 189.84 kips > P OK Gross area of web plate = (H-(Q+tf))tw Net area of web plate,Anet = (H-(Q+tf+(dh*n)))tw = = 3.98 2.97 sq.in. sq.in.

Shear plate thickness for Block shear (Web): H' = net length of plate H' = (H-(Q+tf+(dh*n)) fv = 0.4Fy fv = P/Anet Required tw due to shear = 0.34 in.

9.59 Anet=twH' < 0.5 "

in. OK

Net tension in web plate,T = lh Q lv S=3" H' M T

T = Tension in web plate due to Vert. Moment, M M = from baseframe analysis (staad result) M= 0.16 k-ft 1.92 k-in. M= T * H'/2 T= 2M/H' T= 0.40 kips ft = Reqr'd tw due to mom. = 0.5Fy 0.002 ft =T/(twH') tw =T/(ft*H') in. < 0.5"

OK

(5.) Connection Angles: width width thk. Try 2L 5 5 1/2 Allowable bearing : From Tabl I-F, for Fu = 58 ksi, lv = 1 1/2" allowble load = 43.5 kips/hole R= 174 kips > P OK

length 12.32

A36

Shear on plane through fasteners: allowble shear = 0.40Fy = 14.40 on gross area 0.30Fu = 17.4 on net area net area governs when (d + 1/16")>L/6n L= 12.32 in. n= 4 (d+1/16")= 0.81 in. L/6n = 0.513 in. Net area = 2t[L-n(d+1/16)] Net area, An = 9.07 sq.in. fv = P/An fv = 5.23 ksi < 0.3Fu OK USE 2L - 5" x 5" x 1/2" x 12.32" Connection angle

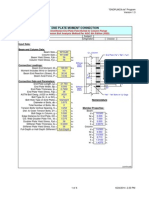

REAN'S BUILDING Beam bearing plate design:

5/24/2002

N+2.5k k

k1 B AISC - ASD R = DL + LL = W 14 X 53 k1 = bf = Allowable stresses:

k1

33.17

fc = Fy = k= tf = 27 1.05 31.59 1 7/16 0.66 ksi ksi sq.in. mm in. in. mm mm ksi in.

3 36 tw = h=

ksi ksi 3/8 13.92

15/16 8.06

Fb = 0.75fy Fp = o.35f ' A = R/Fb = Let B = bf = 8.06 204.72 N= A/B use N =

say Actual bearing pressure : fp = R/(BxN) 0.343 n = (B/2)-k1 3.0925 Calculate plate thikness: t = ((3fpn^2/Fb))^.5 t= 0.604 15.33 say 16 USE BEARING PLATE : 205 x 305 x 16 mm

3.919 12 304.8 305

in. mm mm

Check web crippling on Lenght (N+2.5k) @ Reaction: R/(N+2.5k)tw < or = .75fy R= 33.17 in. N= 12.00 in. 2.5k = 3.59 in. tw = 0.38 in. R/(N+2.5k)tw = 5.67 <27 ksi OK Check web crippling @ interior load: N= 0.00 in. Rn = 47.44 k Rn = (N+5k)(Fyw)(tw) Fyw = Rn/(N+5k)(tw) Fyw = 17.60 <27 ksi OK

EUGENIO BUILDING Flange Thickness design: Notation T= B= Q= Fy = O= a= a', b, b' = d= d' = p= t= n= Ft = A=

5/2/2002

factored applied tension per bolt, excluding initial tightening, kips design tensile strength of bolt factored prying force per bolt at design load, kips yield strength of flange resistance factor dimension shown in figure but to be takenin the analysis at not more than 1.25b dimension shown in figure diameter of bolt width of bolt hole parallel to stem of tee length of flange, parallel to stem, tributary to area of bolt thickness of flange of tee number of bolts bolt capacity section area of 1 bolt

M2 M1 M2 M1

2T

a a'

b b' d

2T

T+Q T+Q Q Given: T= V= Fy = N= 32.4 0 36 12 kip-ft kip ksi in. T+Q Q For W14 X 53 h= 13.92 bf = 8.06 tf = 0.66 tw = 0.38 Q

in. in in in

SELECTION OF T-STUB Force in T-STUB, F = Try n = 4 O= T 3/4 0.75 = 32.40 90 0.442 8.10 29.82 6 2.5 kips sq.in. kips kips in. in

dia.Bolt,Ft = A= T= F/n = B= OFtA = p= N/2 = assuming b'=

From equation: t = ((2tb')/(OFyp))^.5

t= Check Thickness: b' = a' = 2.5 3.8425

0.46

in.

11.59

mm

in in >1.25b

1.25b = 3.59375 b= 2.875 a = 4.2175

in. in in

= (a'/b')((B/T)-1) = 4.12 >1 use = 1 d' = 0.81

t^2 = (4.44Tb')/(pFy[1+ (1-(d'/p))]) 4.44Tb' = 89.91 pFy = 216.00 1-(d'/p) = 0.87 t= 0.47 in. > 0.66 actual thikness OK t= 12.00 mm. reqrd. thickness say 12 mm.

REAN'S BUILDING 5/24/2002 Angle plate design: Framed beam connection Notation T = Applied tension per bolt, excluding initial tightening & prying force, kips Q = Prying force per bolt at design load, kips B = Allowable tension per bolt, kips tc = Flange or angle thickness required to develop B in bolts with no prying action, in. = 8Bb' pFy

Fy = p= a= d= d' = b' = a' = = n= Ab = N= L= dx = = = '=

Yield strength of flange material, ksi length of flange, parallel to stem or leg, tributary to each bolt, in. Distance from bolt centerline to edge of tee flange or angle leg more than 1.25b , in. Bolt diameter, in. width of bolt hole parallel to stem tee stem or angle leg, in. b-(d/2), in. a+(d/2), in. b'/a' number of bolts section area of 1 bolt Fitting length, in. Length of angle plate Bolt location, in. (0< <1.0) ratio of moment at bolt line to mement at stem line M2/ M1 Value of for which required thickness (treq'd) is a minimum or allowable applied tension per bolt (Tall) is a maximum. = Ratio of net area (at bolt line) and a gross area (at the face of the stem or angle leg) = 1-d'/p

M2 M1

M2 M1

2T

a a' Web member

b b' d

2T

T+Q T+Q Q T+Q Q Q

Given:

From block shear calculation: Connection Angles: width width Try 2L 5 5 M= 0.16 kip-ft V= 47.44 kip Fy = 36 ksi L =N = 12.32 in. d= 3/4 in. lh Q lv 3"spacing L

thk. 1/2 L= dx = tf = tw =

length 12.32 12.32 5 0.5 0.5

A36 in. in in in

SELECTION OF T-STUB M= (L/2)*F Force in T-STUB, F = 0.31 B= 19.4 n= T/B = 0.02 use n = 4 3/4 T= F/n Bolt strength at bolt hole for tension: ftall. = B/Ab = 43.91 b = (dx-tw)/2 = a = [(2w+tw)-dx]/2 check 1.25b use b' = (b-d/2) a' = (a+d/2) p= L/2 = d' = d+1/16 = 1-d'/2 = b'/a' Calculate

Ab = 0.08 ftact. = > 2.25 2.75 2.81 2.75 1.88 3.13 6.16 0.8125 0.59 0.60

0.442 <B T/Ab 0.2 >1.25 >a

kip kips pcs sq.in. OK ksi OK in. in. in. in. in. in. in. in.

if if use use

= 1/ ((B/T)-1) > 1 set ' = 1 < 1 set ' = lesser of 1/ (( = 413.28 '= 0.00 '= -1.69

/1-

)) and 1

Calculate Thickness, t required =

tc =

8Tb' pFy(1+ 1.17 221.76 0.00 0.07 1.84 2mm

')

8Tb' = pFy = '= t= t= say Considering prying force: tc =

< 0.5

OK

8Tb' pFy 0.07 < 0.5 OK

tc =

= 1/ [((T/B)/(t/tc)^2)-1] < 0 set = 0 1/ = 1.68 T/B = 0.00 (t/tc)^2 = 47.43 = -1.68 use = 0.00 if Q= Q= B 0.00 (t/tc)^2 kips

Você também pode gostar

- Simple Bracing ConnectionDocumento33 páginasSimple Bracing ConnectionRohit SinghAinda não há avaliações

- Beam ConnectionDocumento3 páginasBeam ConnectionLeonardo PimentelAinda não há avaliações

- Beam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryDocumento1 páginaBeam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña Velasquez100% (1)

- SIM BoxingDocumento2 páginasSIM Boxingkrishnakant_75Ainda não há avaliações

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocumento361 páginasUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Documento22 páginasFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXAinda não há avaliações

- Example J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Documento2 páginasExample J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Martin VenichAinda não há avaliações

- Gordon NovelDocumento50 páginasGordon NovelNic Hotep100% (2)

- Kito Electric Hoist CatalogueDocumento36 páginasKito Electric Hoist CatalogueADITYA_PATHAKAinda não há avaliações

- BraceconnectionDocumento10 páginasBraceconnectionLeonardo PimentelAinda não há avaliações

- CompositeFloorBeam 2014 OK VIGUETA W16x40 L 9.55mDocumento6 páginasCompositeFloorBeam 2014 OK VIGUETA W16x40 L 9.55mValiente ImperatorAinda não há avaliações

- Anchor Bolt Design Apdx D ACI318 05Documento4 páginasAnchor Bolt Design Apdx D ACI318 05Mohammed HanafiAinda não há avaliações

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Documento3 páginasHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariAinda não há avaliações

- Beam To Column'S Flange Fixed Connection - Bcff-3: Design DataDocumento6 páginasBeam To Column'S Flange Fixed Connection - Bcff-3: Design DataAchmad RifaiAinda não há avaliações

- AISC ASD Base Plate Thickness V2016-2Documento9 páginasAISC ASD Base Plate Thickness V2016-2yusuf_jtAinda não há avaliações

- AISC Tension MemberDocumento3 páginasAISC Tension Membermodulor3dAinda não há avaliações

- A23.3-04 CorbelsDocumento3 páginasA23.3-04 CorbelsDivyesh MistryAinda não há avaliações

- Design Basis For Steel Connection of Standard Drawing - Rev Ad PDFDocumento5 páginasDesign Basis For Steel Connection of Standard Drawing - Rev Ad PDFvijaystructuralAinda não há avaliações

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocumento11 páginasRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalAinda não há avaliações

- LRFD Beam Column DesignDocumento242 páginasLRFD Beam Column DesignChristian FTAinda não há avaliações

- Double Angle ConnectionDocumento8 páginasDouble Angle ConnectionrunkirAinda não há avaliações

- Evo Design - Structural Design: Calculation SheetDocumento4 páginasEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaAinda não há avaliações

- Petrofac International LimitedDocumento33 páginasPetrofac International LimitedHanafiahHamzahAinda não há avaliações

- Design of FoundationDocumento66 páginasDesign of FoundationShaikh Muhammad Ateeq100% (2)

- BOLTGRP13Documento33 páginasBOLTGRP13NEOAinda não há avaliações

- End Plate Connection Design Per AISCDocumento5 páginasEnd Plate Connection Design Per AISCAdam Michael GreenAinda não há avaliações

- Brace Frame Connection ECBFDocumento48 páginasBrace Frame Connection ECBFleonid48Ainda não há avaliações

- Under Ground SumpDocumento7 páginasUnder Ground SumpMariappan .PAinda não há avaliações

- Base Plate & BoltsDocumento3 páginasBase Plate & BoltsarvnndAinda não há avaliações

- Structural Calcs SHEDDocumento24 páginasStructural Calcs SHEDvtalexAinda não há avaliações

- Client: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSDocumento28 páginasClient: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSOMARB26Ainda não há avaliações

- Base Plate For Tension1Documento7 páginasBase Plate For Tension1maheshbandhamAinda não há avaliações

- Vibration - Electrical or Mechanical - EASADocumento3 páginasVibration - Electrical or Mechanical - EASAGilbAinda não há avaliações

- Anchor Bolt As Per BS CodeDocumento16 páginasAnchor Bolt As Per BS Codesuvodip khanAinda não há avaliações

- Anchor Bolt (CSA) Rev1.1Documento10 páginasAnchor Bolt (CSA) Rev1.1coolkaisyAinda não há avaliações

- Seated ConnectionDocumento5 páginasSeated ConnectionMcsSelvaAinda não há avaliações

- Base Plate and Blot Design-UploadDocumento6 páginasBase Plate and Blot Design-UploadygguptaAinda não há avaliações

- Design of Brace Connection: Input InformationDocumento6 páginasDesign of Brace Connection: Input InformationJonatas PrandiniAinda não há avaliações

- D 2510 - 94 R98Documento3 páginasD 2510 - 94 R98David Cazorla100% (1)

- DG Consulting EngineersDocumento8 páginasDG Consulting EngineersThakshayani SellavelAinda não há avaliações

- Beam - Deflection CheckDocumento8 páginasBeam - Deflection ChecksharanekkmAinda não há avaliações

- Truss Support Connection Design T5-S1Documento11 páginasTruss Support Connection Design T5-S1rajedmaglinteAinda não há avaliações

- Base Plate (Template)Documento3 páginasBase Plate (Template)li yongzhongAinda não há avaliações

- Brace TR W6X25Documento6 páginasBrace TR W6X25mihai_serban13Ainda não há avaliações

- RAM Connection Input With CommentsDocumento6 páginasRAM Connection Input With CommentsAhmed Saeed OokaAinda não há avaliações

- End Plate Moment ConnectionDocumento4 páginasEnd Plate Moment Connectionmahhor82_635643838Ainda não há avaliações

- Cleat Connection For PlatformsDocumento29 páginasCleat Connection For PlatformsRajveer SinghAinda não há avaliações

- Beam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataDocumento5 páginasBeam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataAchmad RifaiAinda não há avaliações

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Documento184 páginasFin Plate-Beam To Beam Inside (AISC-LRFD)AshishAinda não há avaliações

- Epmc Extended LRFD Asd Aisc New 28-10-2013Documento10 páginasEpmc Extended LRFD Asd Aisc New 28-10-2013tamerragaaAinda não há avaliações

- A Sample of Wet Soil Has A Volume of 0Documento8 páginasA Sample of Wet Soil Has A Volume of 0eph0% (1)

- Moment Connection - Beam SpliceDocumento3 páginasMoment Connection - Beam SpliceSh MNAinda não há avaliações

- Pad Eye Connected To Bottom PieceDocumento7 páginasPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- 3 5mDocumento8 páginas3 5mSanjay sharmaAinda não há avaliações

- HSS Flange Plate Moment Connection - Temporary SteelDocumento9 páginasHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteAinda não há avaliações

- V.K Jain-Advanced Machining Processes-Allied Publications PDFDocumento370 páginasV.K Jain-Advanced Machining Processes-Allied Publications PDFMayank Vyas100% (1)

- The Flexural and Shear Design of Deep Beam: Input DataDocumento6 páginasThe Flexural and Shear Design of Deep Beam: Input DataManal ElkasabyAinda não há avaliações

- Moment ConnectionsDocumento15 páginasMoment ConnectionsHector Aguana100% (1)

- UB254 To UB457Documento7 páginasUB254 To UB457ihpeterAinda não há avaliações

- Design of Beam To Beam Connection Using Web CleatDocumento2 páginasDesign of Beam To Beam Connection Using Web CleatAnonymous UUAriPf8KqAinda não há avaliações

- Seismic Modification Factor Calculation As Per UBC97Documento1 páginaSeismic Modification Factor Calculation As Per UBC97RigonDECAinda não há avaliações

- CivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFDocumento9 páginasCivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFhemantcabhaleAinda não há avaliações

- Weld Group 01Documento11 páginasWeld Group 01Sneyder NeyAinda não há avaliações

- Entrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12Documento2 páginasEntrance B: 1008 72 CHS 559x25 (S355) 80.64 1314 72 CHS 610x28 (S355) 105.12suman_civilAinda não há avaliações

- AISC 13th Slip Critical Bolt Capacity ASDDocumento1 páginaAISC 13th Slip Critical Bolt Capacity ASDdantevariasAinda não há avaliações

- Base Plate Very EccentricityDocumento2 páginasBase Plate Very EccentricityJetn SrisuthumAinda não há avaliações

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocumento9 páginasPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCНемања КараклајићAinda não há avaliações

- End Plate Conn 01 - Finite ElementDocumento4 páginasEnd Plate Conn 01 - Finite Elementrodriguez.gaytanAinda não há avaliações

- RCP 1Documento1 páginaRCP 1mhel_almoAinda não há avaliações

- Midterm Exam-Hoa 4Documento1 páginaMidterm Exam-Hoa 4mhel_almoAinda não há avaliações

- Rafter 3Documento1 páginaRafter 3mhel_almoAinda não há avaliações

- Crestley Oneway Slab Design S1Documento3 páginasCrestley Oneway Slab Design S1mhel_almoAinda não há avaliações

- Basic Microcomputer DesignDocumento25 páginasBasic Microcomputer Designmhel_almoAinda não há avaliações

- Masters WIC PDFDocumento1 páginaMasters WIC PDFmhel_almoAinda não há avaliações

- Pipes & Tubings: in in MM in MM LB/FT KG/FT KG/MDocumento5 páginasPipes & Tubings: in in MM in MM LB/FT KG/FT KG/Mmhel_almoAinda não há avaliações

- Basement 916 GRND 848 2nd 875 3rd 875 4th 875 Deck 875 5264 52640Documento1 páginaBasement 916 GRND 848 2nd 875 3rd 875 4th 875 Deck 875 5264 52640mhel_almoAinda não há avaliações

- Purlins: Bundle Purlins Size Weight in 6000Mm LengthDocumento1 páginaPurlins: Bundle Purlins Size Weight in 6000Mm Lengthmhel_almoAinda não há avaliações

- Column DesignDocumento10 páginasColumn Designmhel_almo100% (1)

- C E I L I N G Area 30: Petronne Petronne PetronneDocumento1 páginaC E I L I N G Area 30: Petronne Petronne Petronnemhel_almoAinda não há avaliações

- EM 1110-2-2902 - Conduits, Culverts, and Pipes - WebDocumento87 páginasEM 1110-2-2902 - Conduits, Culverts, and Pipes - WebPDHLibraryAinda não há avaliações

- Midterm Exam-Hoa 4Documento1 páginaMidterm Exam-Hoa 4mhel_almoAinda não há avaliações

- 701.ssvseat 1.04Documento2 páginas701.ssvseat 1.04Cosmin MuscaluAinda não há avaliações

- EM230 BR BM3 Fitting InstructionsDocumento2 páginasEM230 BR BM3 Fitting InstructionsRoman BabaevAinda não há avaliações

- Oracle Jrockit Mission Control Lab GuideDocumento17 páginasOracle Jrockit Mission Control Lab GuideashuhegdeAinda não há avaliações

- Efficia Infant WarmingDocumento8 páginasEfficia Infant WarmingNurhidayat MursalinAinda não há avaliações

- Le22a1321 AocDocumento130 páginasLe22a1321 AocEchefisEchefisAinda não há avaliações

- SinxbyxDocumento9 páginasSinxbyxGreeshmaAinda não há avaliações

- Chapter 19A ConcreteDocumento10 páginasChapter 19A ConcreteMofasa EAinda não há avaliações

- JDE ApplicationDocumento642 páginasJDE ApplicationAnonymous cputyzAinda não há avaliações

- Cbse PMT 2012Documento33 páginasCbse PMT 2012Vishal RamakrishnanAinda não há avaliações

- Hot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19Documento2 páginasHot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19حسين محمد مطرود كاظمAinda não há avaliações

- Advanced Cooling System - EMD00253ENDocumento4 páginasAdvanced Cooling System - EMD00253ENnarayanan_anoob0% (1)

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDocumento29 páginas1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B EAinda não há avaliações

- S09 Power TrainDocumento90 páginasS09 Power TrainPLANEAMIENTO MDRILLAinda não há avaliações

- Unit-II Some PPT NetDocumento2 páginasUnit-II Some PPT NetbandisaidaiahAinda não há avaliações

- VLE Lactic Acid Ethyl Lactate Esterification PDFDocumento7 páginasVLE Lactic Acid Ethyl Lactate Esterification PDFAseem Kashyap0% (1)

- Internship Report May 2016Documento11 páginasInternship Report May 2016Rupini RagaviahAinda não há avaliações

- Jerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransDocumento1 páginaJerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransSabrina BrennanAinda não há avaliações

- Ecc Mech Sharq 22 016 Rev 01Documento6 páginasEcc Mech Sharq 22 016 Rev 01Muthu SaravananAinda não há avaliações

- GMP Male BearingDocumento3 páginasGMP Male BearingMahdi HajizadehAinda não há avaliações

- CovestroDocumento2 páginasCovestroRonaldo CamargoAinda não há avaliações

- BM 81004 MuvDocumento52 páginasBM 81004 MuvHamza Abbasi AbbasiAinda não há avaliações

- Honeywell P7640B1032 Differential Pressure Sensors PDFDocumento2 páginasHoneywell P7640B1032 Differential Pressure Sensors PDFMarcello PorrinoAinda não há avaliações

- WDU 2.5 enDocumento14 páginasWDU 2.5 enAhmadBintangNegoroAinda não há avaliações