Escolar Documentos

Profissional Documentos

Cultura Documentos

05 Modeling Dynamic and Static Behavior of Chemical Processes

Enviado por

Asrul SaniDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

05 Modeling Dynamic and Static Behavior of Chemical Processes

Enviado por

Asrul SaniDireitos autorais:

Formatos disponíveis

Modeling Dynamic and Static

Behavior of Chemical Processes

Cheng-Liang Chen

PSE

LABORATORY

Department of Chemical Engineering

National TAIWAN University

Chen CL 1

State Variables and State Equations

State Variables:

A set of fundamental dependent quantities whose values

will describe the natural state of a given system

(temperature, pressure, ow rate, concentration )

State Equations:

A set of equations in the state variables above which

will describe how the natural state of a given system

changes with time

Chen CL 2

Principle of Conservation of A Quantity S

S =

_

_

total mass

mass of individual components

total energy

momentum

Chen CL 3

accumulation of S

within a system

time period

=

ow of S

in the system

time period

ow of S

out the system

time period

+

amount of S generated

within the system

time period

amount of S consumed

within the system

time period

Chen CL 4

Total Mass Balance:

d(V )

dt

=

i:inlet

i

F

i

j:outlet

j

F

j

Mass Balance on Component A:

dn

A

dt

=

d(c

A

V )

dt

=

i:inlet

c

A

i

F

i

j:outlet

c

A

j

F

j

rV

Total Energy Balance:

dE

dt

=

d(U +K +P)

dt

=

i:inlet

i

F

i

h

i

j:outlet

j

F

j

h

j

QW

s

Chen CL 5

Mathematical Model

A Stirred Tank Heater

Mathematical model of a process

= state equations with associated state variables

Chen CL 6

Total mass in tank: V = Ah

Total energy of liquid in tank:

E = U +K +P

dU

dt

dH

dt

;

dK

dt

=

dP

dt

= 0

H = Ahc

p

_

T T

ref

_

State variables: h, T

Total mass balance:

d(Ah)

dt

= F

i

F

=c

A

dh

dt

= F

i

F

Chen CL 7

Total energy balance:

d

_

Ahc

p

_

T T

ref

_

dt

= F

i

c

p

_

T

i

T

ref

_

Fc

p

_

T T

ref

_

+Q

T

ref

=0

A

d(hT)

dt

= F

i

T

i

FT +

Q

c

p

A

d(hT)

dt

= Ah

dT

dt

+T A

dh

dt

..

=F

i

F

= F

i

T

i

FT +

Q

c

p

Ah

dT

dt

= F

i

(T

i

T) +

Q

c

p

Chen CL 8

Summary: State equations

A

dh

dt

= F

i

F

Ah

dT

dt

= F

i

(T

i

T) +

Q

c

p

Summary: variables

state variables: h, T

output variables: h, T

disturbances: T

i

, F

i

manipulated variables: Q, F

parameters: A, , c

p

Chen CL 9

Mathematical Model

A Stirred Tank Heater (cont)

Assumed initial steady states:

0 = A

dh

dt

= F

i,s

F

s

0 = Ah

dT

dt

= F

i,s

(T

i,s

T

s

) +

Q

s

c

p

Chen CL 10

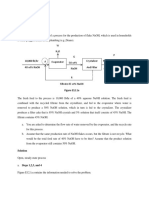

Temperature response to a step decrease in inlet temperature:

Dynamic response to a step decrease in inlet ow rate:

Chen CL 11

Additional Element:

Transport Rate Equations

Transport Rate Equations:

To describe rate of mass, energy, and momentum transfer between

a system and its surroundings

Example: a stirred tank heater

heat supplied by steam:

Q = UA

t

(T

st

T)

Chen CL 12

Additional Element:

Kinetic Rate Equations

Kinetic Rate Equations:

To describe rates of chemical reactions taking place in a system

Example: a 1st-order reaction in a CSTR

reaction rate equation:

r = k

0

e

E/RT

c

A

Chen CL 13

Additional Element:

Reaction and Phase Equilibrium Relationships

Reaction and Phase Equilibrium Relationships:

To describe equilibrium situations reached during a chemical

reaction or by two or more phases

Example: a ash drum

temperature of liquid phase

= temperature of vapor phase

pressure of liquid phase

= pressure of vapor phase

chemical potential of component i

in liquid phase =

chemical potential of component i

in vapor phase

Chen CL 14

Additional Element:

Equations of States

Equations of States:

To describe the relationship

among intensive variables

describing the

thermodynamic state

of a system

Example: a ash drum

Ideal gas law for vapor phase:

pV

vapor

= (moles of A + moles of B)RT

=

mass of A + mass of B

average MW

RT

=

mass of A + mass of B

y

A

M

A

+y

B

M

B

RT

vapor

=

mass of A + mass of B

V

vapor

= [y

A

M

A

+y

B

M

B

]

p

RT

liquid

= (T, x

A

)

Chen CL 15

Dead Time

Dead Time:

Whenever an input variable of a system changes

there is a time interval (short or long) during which

no eect is obsrved on outputs of the system

dead time, transportation lag, pure delay,

distance-velocity lag

Chen CL 16

Example: liquid through a pipe

A: temperature of inlet changes

B: temperature of outlet response

dead time: d

d =

volume of pipe

volumetric ow rate

=

A L

A U

av

=

L

U

av

T

out

(t) = T

in

(t d)

Chen CL 17

Modeling Diculties

Poorly understood processes

Imprecisely known parameters

Size and complexity of a model

Chen CL 18

Additional Examples of Mathematical Modeling

Continuous Stirred Tank Reactor (CSTR)

Exothermic Rx: A B

Chen CL 19

Total Mass Balance:

d(V )

dt

=

i

F

i

F 0

=c

=

dV

dt

= F

i

F

Mass Balance on Component A:

(r: rate of reaction per unit volume)

dn

A

dt

=

d(c

A

V )

dt

= c

A

i

F

i

c

A

F rV

V

dc

A

dt

+c

A

dV

dt

..

=F

i

F

= c

A

i

F

i

c

A

F k

0

e

E/RT

c

A

V

dc

A

dt

=

F

i

V

_

c

A

i

c

A

_

k

0

e

E/RT

c

A

Chen CL 20

Total Energy Balance:

total energy E = U +K +P = U H(T, n

A

, n

B

) (enthalpy)

dE

dt

=

dU

dt

dH

dt

=

i

F

i

h

i

(T

i

) Fh(T) Q (1)

also

dH

dt

=

H

T

..

V c

p

dT

dt

+

H

n

A

..

H

A

(T)

dn

A

dt

+

H

n

B

..

H

A

(T)

dn

B

dt

note

dn

A

dt

=

d(c

A

V )

dt

= c

A

i

F

i

c

A

F rV

dn

B

dt

=

d(c

B

V )

dt

= c

B

i

F

i

. .

=0

c

B

F +rV

dH

dt

= V c

p

dT

dt

+

H

A

_

c

A

i

F

i

c

A

F rV

_

+

H

B

_

c

B

F rV

(2)

Chen CL 21

(1) = (2) V c

p

dT

dt

=

H

A

_

c

A

i

F

i

c

A

F rV

_

H

B

_

c

B

F rV

+F

i

i

h

i

(T

i

)

. .

i

h

i

(T)

. .

c

A

i

H

A

(T)

+

i

c

p

i

(T

i

T)

F h(T)

. .

c

A

H

A

(T)+c

B

H

B

(T)

Q

=

H

A

c

A

i

F

i

. .

(i)

+

H

A

c

A

F

. .

(ii)

+

H

A

rV

+

H

B

c

B

F

. .

(iii)

H

B

rV +F

i

c

A

i

H

A

. .

(i)

+F

i

i

c

p

i

(T

i

T) Fc

A

H

A

. .

(ii)

Fc

B

H

B

. .

(iii)

Q

=

_

H

A

H

B

_

. .

H

r

rV +F

i

i

c

p

i

(T

i

T) Q

=

i

,c

p

=c

p

i

= V

dT

dt

= F

i

(T

i

T) +

(H

r

)

c

p

. .

J

rV

Q

c

p

Chen CL 22

Summaries:

state var.s: V, c

A

, T

state eqn.s:

dV

dt

= F

i

F

dc

A

dt

=

F

i

V

_

c

A

i

c

A

_

k

0

e

E/RT

c

A

dT

dt

=

F

i

V

(T

i

T) +Jk

0

e

E/RT

c

A

Q

c

p

V

output var.s: V, c

A

, T

input var.s: c

A

i

, F

i

, T

i

, Q, F

manip. var.s: Q, F

disturbances: c

A

i

, F

i

, T

i

const. par.s: , c

p

, (H

r

), k

0

, E, R

Chen CL 23

Additional Examples of Mathematical Modeling

An Ideal Binary Distillation Column

Chen CL 24

Assumptions:

constant vapor holdup:

equal molar heats of vaporization for A and B

negligible heat loss

constant relative volativility

100% tray eciency

V = V

1

= = V

N

y

i

=

x

i

1 + ( 1)x

i

neglect dynamics of condenser and reboiler

neglect momentum balance for each tray

leaving liquid = L

i

= f(M

i

), i = 1, , N

liquid holdup = M

i

Chen CL 25

State Equations (1): feed tray (i = f)

total mass:

dM

f

dt

= F

f

+L

f+1

+V

f1

L

f

V

f

= F

f

+L

f+1

L

f

comp A:

d(M

f

x

f

)

dt

= F

f

c

f

+L

f+1

x

f+1

+V

f1

y

f1

L

f

x

f

V

f

y

f

Chen CL 26

State Equations (2): top tray (i = N)

total mass:

dM

N

dt

= F

R

+V

N1

L

N

V

N

= F

R

L

N

comp A:

d(M

N

x

N

)

dt

= F

R

x

D

+V

N1

y

N1

L

N

x

N

V

N

y

N

Chen CL 27

State Equations (3): bottom tray (i = 1)

total mass:

dM

1

dt

= L

2

L

1

+V V

1

= L

2

L

1

comp A:

d(M

1

x

1

)

dt

= L

2

x

2

+V y

B

L

1

x

1

V

1

y

1

Chen CL 28

State Equations (4): ith tray (i = 2, , N 1; i = f)

total mass:

dM

i

dt

= L

i+1

L

i

+V

i1

V

i

= L

i+1

L

i

comp A:

d(M

i

x

i

)

dt

= L

i+1

x

i+1

L

i

x

i

+V

i1

y

i1

V

i

y

i

Chen CL 29

State Equations (5): reux drum

total mass:

dM

RD

dt

= V

N

F

R

F

D

comp A:

d(M

RD

x

D

)

dt

= V

N

y

N

(F

R

+F

D

)x

D

Chen CL 30

State Equations (6): column base

total mass:

dM

B

dt

= L

1

V F

B

comp A:

d(M

B

x

B

)

dt

= L

1

x

1

V y

B

F

B

x

B

Chen CL 31

Relationships:

equilibrium relationships:

y

i

=

x

i

1 + ( 1)x

i

i = 1, , f, , N; B

hydraulic relationships: (Francis weir formula)

L

i

= f(M

i

) i = 1, , f, , N

State Variables:

liquid holdups:

M

1

, M

2

, , M

f

, , M

N

; M

RD

, M

B

liquid concentrations:

x

1

, x

2

, , x

f

, , x

N

; x

D

, x

B

Chen CL 32

Summaries:

2N + 4 nonlinear dierential equations (state eqn.s)

2N + 1 algebraic equations (equilibrium and hydraulic)

example: N = 20 trays

2N + 4 = 2(20) + 4 = 44 nonlinear di. eqn.s

2N + 1 = 2(20) + 1 = 41 algebraic equations

Chen CL 33

Modeling Considerations

for Control Purposes

State-variables model

input-output model (convenient for control)

Degrees of freedom ( df) inherent in the process

extent of control problem to be solved

Chen CL 34

Input-Output Model:

output = f(input variables)

y

i

= f(m

1

, , m

k

; d

1

, , d

t

) i = 1, , m

Chen CL 35

Example: Input-Output Model for CSTR

Assumptions: F

i

= F dV/dt = 0

Chen CL 36

Total Energy Balance:

V

dT

dt

= F

i

(T

i

T) +

Q

c

p

Q = UA

t

(T

st

T)

dT

dt

+

_

F

i

V

+

UA

t

V c

p

_

. .

a1/+K

T =

F

i

V

..

1/

T

i

+

UA

t

V c

p

. .

K

T

st

dT

dt

+aT =

1

T

i

+KT

st

SS: 0 +aT

s

=

1

T

i,s

+KT

st,s

d(T T

s

)

dt

+a (T T

s

)

. .

T

=

1

(T

i

T

i,s

)

. .

T

i,s

+K (T

st

T

st,s

)

. .

T

st

dT

dt

+aT

=

1

i

+KT

st

T

(t) = c

1

e

at

+

_

t

0

_

1

i

+KT

st

_

dt

initial: T

(t = 0) = 0 c

1

= 0

T

(t) =

_

t

0

_

1

i

+KT

st

_

dt

Chen CL 37

Block Diagram: inputs (T

i

(t), T

st

(t)) output (T

(t))

This example: output variables = state variables

Chen CL 38

Distillation: output variables = state variables!

State variables:

liquid holdups:

M

1

, M

2

, , M

f

, , M

N

; M

RD

, M

B

liquid concentrations:

x

1

, x

2

, , x

f

, , x

N

; x

D

, x

B

Output variables:

distillate rate and composition: F

D

, x

D

bottom rate and composition: F

B

, x

B

Chen CL 39

DOF: Degree of Freedom

Degrees of Freedom (DOF):

# of independent variables that must be specied in order to dene

a process completely

DOF = (# Var.s) (# Indep. Eq.s)

Chen CL 40

Example: stirred tank heater

mathematical model: # of eq.s = 2

A

dh

dt

= F

i

F

Ah

dT

dt

= F

i

(T

i

T) +

Q

c

p

# of variables = 6 (h, T

i

, T, F, F

i

, Q)

DOF = 6 - 2 = 4

specify T

i

, F

i

, F, Q h(t), T(t)

in order to specify a process completely

the # of DoF should be zero

Chen CL 41

Example: binary distillation column

DOF = (4N + 11) (4N + 5) = 6

Chen CL 42

Degrees of Freedom of A Process

f = DOF = V E = (# Var.s) (# Indep. Eq.s)

Case 1: DOF = 0

unique values of the V variables

the process is exactly specied

Case 2: DOF > 0

multiple solutions result from the E equations

can specify arbitrarily f of the V variables

the process is underspecied by f equations

Case 3: DOF < 0

no solution to the E equations

the process is overspecied by f equations

Chen CL 43

DOF and Process Controllers

An under-specied process with DOF = f > 0

Q: how to reduce DOF to zero

to specify system completely with unique behavior ?

from external world: disturbances

to add control loops

Control loop:

additional equation between MV and CV

additional variable: set-point

same: DOF

dierence: specify MV specify set-point

Chen CL 44

Example: stirred tank heater with two control loops

DOF = 4 DOF = 0 if we specify

T

i

, F

i

from external world ( disturbances)

set-points of the two controllers

Chen CL 45

Example: binary distillation column ( DOF = 6)

specication of disturbances (external world):

feed rate (F

f

) and feed composition (c

f

)

DOF = 6 DOF = 4

specication of control objectives ( set-points):

(I) for products:

x

D

: distillate composition

x

B

: bottom stream composition

(II) for operational feasibility:

M

RD

: liquid holdup in reux drum

M

B

: liquid holdup at base of column

four control loops

DOF = 6 DOF = 4 DOF = 0

Chen CL 46

Note: other alternative control objectives

(1) keep at desired F

D

, x

D

, M

RD

, M

B

(2) keep at desired F

B

, x

B

, M

RD

, M

B

Você também pode gostar

- HimmelblauDocumento17 páginasHimmelblauadilla nitaaAinda não há avaliações

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsAinda não há avaliações

- Vapor/Liquid Equilibrium: Vle by Modified Raoult'S LawDocumento16 páginasVapor/Liquid Equilibrium: Vle by Modified Raoult'S LawAby JatAinda não há avaliações

- Analysis of The Adsorption Process and of Desiccant Cooling SystemsDocumento155 páginasAnalysis of The Adsorption Process and of Desiccant Cooling SystemsRajesh VyasAinda não há avaliações

- 12.A.4 Quenchingof A Steel Billet. A Cylindrical Steel Billet 1ft in Diameter and 3Documento2 páginas12.A.4 Quenchingof A Steel Billet. A Cylindrical Steel Billet 1ft in Diameter and 3Delyana RatnasariAinda não há avaliações

- CN2116 HW11 Solution (XJP - 2012) FinalDocumento9 páginasCN2116 HW11 Solution (XJP - 2012) FinalPrimus OngAinda não há avaliações

- CSTRDocumento12 páginasCSTRRuri Agung WahyuonoAinda não há avaliações

- 06 Chapter 12 (Compiled) PDFDocumento80 páginas06 Chapter 12 (Compiled) PDFHaziq KhairiAinda não há avaliações

- Transport Phenomenon NotesDocumento7 páginasTransport Phenomenon Notesvishakha goelAinda não há avaliações

- Heat Capacity of Liquids - Critical Review and Recommended ValuesDocumento404 páginasHeat Capacity of Liquids - Critical Review and Recommended ValuesDoris AngAinda não há avaliações

- Example 6Documento5 páginasExample 6Dewi AnggreniAinda não há avaliações

- Lab 3Documento16 páginasLab 3Paen Zulkifli100% (1)

- MATLAB ProjectsDocumento2 páginasMATLAB ProjectsNidhi ChauhanAinda não há avaliações

- Design of Cooling Tower With IotDocumento4 páginasDesign of Cooling Tower With IotAnonymous kw8Yrp0R5rAinda não há avaliações

- Drying of Process MaterialDocumento30 páginasDrying of Process MaterialsehagendutAinda não há avaliações

- Applied Mathematics in Chemical EngineeringDocumento1 páginaApplied Mathematics in Chemical EngineeringVikram R RavikumarAinda não há avaliações

- Successful Design of Catalysts: Future Requirements and DevelopmentNo EverandSuccessful Design of Catalysts: Future Requirements and DevelopmentAinda não há avaliações

- Evaluation of The Spitzkasten Classifier in Terms of Hydraulic Velocity and Mass RecoveryDocumento41 páginasEvaluation of The Spitzkasten Classifier in Terms of Hydraulic Velocity and Mass RecoveryAllen DimayugaAinda não há avaliações

- Kinetics and Mechanism of Urea FormaldehydeDocumento5 páginasKinetics and Mechanism of Urea FormaldehydeDessy A. SariAinda não há avaliações

- Frequency Domain Analysis of Dynamic Systems: Jos E C. GeromelDocumento43 páginasFrequency Domain Analysis of Dynamic Systems: Jos E C. Geromelblister_xbladeAinda não há avaliações

- Chemical Reactors: FoglerDocumento34 páginasChemical Reactors: FoglerMike PoulinAinda não há avaliações

- Unit-10 Methanol To OlefinDocumento19 páginasUnit-10 Methanol To OlefinDurgesh Dev TripathiAinda não há avaliações

- Dynamics of ThermometerDocumento12 páginasDynamics of ThermometerSaumya Agrawal100% (1)

- Something Related To Catalysts.Documento2 páginasSomething Related To Catalysts.Deepro BhattacharyaAinda não há avaliações

- A Mixture Containing Equimolar Amounts of BenzeneDocumento1 páginaA Mixture Containing Equimolar Amounts of BenzeneFranciskus Peri0% (1)

- Chemical Reactor ControlDocumento19 páginasChemical Reactor ControlJetulio JetulinoAinda não há avaliações

- Chemical Reactor Design++ PDFDocumento72 páginasChemical Reactor Design++ PDFKiran Patil0% (1)

- AllDocumento9 páginasAllswarhiliAinda não há avaliações

- Thermo Homework 6Documento7 páginasThermo Homework 6Danny BoyleAinda não há avaliações

- 5 Heated Tank PDFDocumento34 páginas5 Heated Tank PDFNguyễn ÁnhAinda não há avaliações

- Drying Operation: Meika Syahbana RusliDocumento69 páginasDrying Operation: Meika Syahbana RusliFrida GinaAinda não há avaliações

- Symbols and Units: Script Fonts Are Used For Physical Quantities and in Bold FontDocumento127 páginasSymbols and Units: Script Fonts Are Used For Physical Quantities and in Bold FontSingh AnujAinda não há avaliações

- CRE Notes 13-A Methanol ReactorDocumento11 páginasCRE Notes 13-A Methanol ReactorjoeAinda não há avaliações

- Kopp Rules Heat Capacity Solid PDFDocumento134 páginasKopp Rules Heat Capacity Solid PDFMouad ArradAinda não há avaliações

- Types of SteamDocumento13 páginasTypes of SteamDuy Nguyen Duc100% (1)

- XI Chemistry Target Paper 2023 (Sir Nasim Zulfiqar)Documento5 páginasXI Chemistry Target Paper 2023 (Sir Nasim Zulfiqar)adeel mehmoodAinda não há avaliações

- PDF (All-In-One) MK Perancangan Pabrik Kimia (Copyright - R.Turton and J. Shaeiwitz 2012) PDFDocumento564 páginasPDF (All-In-One) MK Perancangan Pabrik Kimia (Copyright - R.Turton and J. Shaeiwitz 2012) PDFSaputra Purnawan0% (1)

- Tugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Documento8 páginasTugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Putra MaulanaAinda não há avaliações

- Dewpoint Calculation For A Multicomponent Mixture PDFDocumento4 páginasDewpoint Calculation For A Multicomponent Mixture PDFsandeep lal100% (1)

- Control Structure Design For Methanol ProcessDocumento91 páginasControl Structure Design For Methanol ProcessAdegunju Adedayo SulaimonAinda não há avaliações

- BACKUPUASPENGPRODocumento47 páginasBACKUPUASPENGPRONadhira SyifaAinda não há avaliações

- Tugas Termo II (Rani Nainggolan S1-C 2014) PDFDocumento4 páginasTugas Termo II (Rani Nainggolan S1-C 2014) PDFRani NainggolanAinda não há avaliações

- Process Control 128Documento60 páginasProcess Control 128Gagan SharmaAinda não há avaliações

- FullDocumento33 páginasFullEja RotiKeju100% (2)

- Kinetic Modeling of Methanol To Olefins (MTO) Process On SAPO-34 CatalystSAPO PDFDocumento5 páginasKinetic Modeling of Methanol To Olefins (MTO) Process On SAPO-34 CatalystSAPO PDFKim Lloyd A. BarrientosAinda não há avaliações

- 7.0 Fabric Filter & ScrubberDocumento78 páginas7.0 Fabric Filter & ScrubberohoreyAinda não há avaliações

- Chapter 2 LLE-part 2 - 18nov2020Documento22 páginasChapter 2 LLE-part 2 - 18nov2020CaratsSVTAinda não há avaliações

- Separacion Mecanica de FasesDocumento36 páginasSeparacion Mecanica de FasesIvan MarmilichAinda não há avaliações

- Destilasi MultikomponenDocumento22 páginasDestilasi MultikomponenAgudaAinda não há avaliações

- Absorption Chemical ReactionDocumento5 páginasAbsorption Chemical ReactionSundar SkAinda não há avaliações

- TPDocumento82 páginasTPVirginia SitompulAinda não há avaliações

- Optimalisasi Kompresor SentrifugalDocumento27 páginasOptimalisasi Kompresor SentrifugalDea Amelia100% (1)

- Week 7. Design For Single ReactionDocumento20 páginasWeek 7. Design For Single ReactionYuni ApriyaniAinda não há avaliações

- Convergence Hints (Aspen)Documento13 páginasConvergence Hints (Aspen)Saurabh GuptaAinda não há avaliações

- Makalah Termodinamika IIIDocumento33 páginasMakalah Termodinamika IIIdata laptop asusAinda não há avaliações

- P11 2aDocumento7 páginasP11 2aFachri MunadiAinda não há avaliações

- Fuels - Higher and Lower Calorific ValuesDocumento3 páginasFuels - Higher and Lower Calorific Valuesjohn100% (1)

- Chap 02 SMDocumento116 páginasChap 02 SMCarla MedeirosAinda não há avaliações

- Optimally Economic Design of Flare Systems PDFDocumento5 páginasOptimally Economic Design of Flare Systems PDFMedaculoAinda não há avaliações

- Infrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFDocumento2 páginasInfrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFPedro AluaAinda não há avaliações

- Preparation and Characterization of Activated Carbon From Palm Shell by Chemical Activation With K CODocumento5 páginasPreparation and Characterization of Activated Carbon From Palm Shell by Chemical Activation With K CODiego MontenegroAinda não há avaliações

- Modern Chemistry Chapter 1 PowerPointDocumento46 páginasModern Chemistry Chapter 1 PowerPointLaurie Gardner100% (8)

- Lecture 1 - ThermochemistryDocumento40 páginasLecture 1 - ThermochemistryMARITHE ROJIANNE MERCADOAinda não há avaliações

- Subject ChemistryDocumento13 páginasSubject ChemistryWinki MansonAinda não há avaliações

- Factors Affecting SolubilityDocumento25 páginasFactors Affecting Solubilitynona wayne dela peñaAinda não há avaliações

- QUESTIONSDocumento5 páginasQUESTIONSkanyakuarAinda não há avaliações

- 17bec0026 Physics Da-1Documento47 páginas17bec0026 Physics Da-1gautamAinda não há avaliações

- B. Tech. in Metallurgical Materials Engineering PDFDocumento29 páginasB. Tech. in Metallurgical Materials Engineering PDFSahil RajAinda não há avaliações

- Principles of Organic Synthesis 2th EditionDocumento643 páginasPrinciples of Organic Synthesis 2th Editionminh leAinda não há avaliações

- Butadieno A04 431-1Documento16 páginasButadieno A04 431-1Tasneem MAinda não há avaliações

- Cathodic Protection Guidelines - 8Documento27 páginasCathodic Protection Guidelines - 8Noli OtebaAinda não há avaliações

- Lesson 1.2 Writing and Naming of Compounds-Group UploadDocumento60 páginasLesson 1.2 Writing and Naming of Compounds-Group UploadMike MarquisAinda não há avaliações

- Annual Exam - Class 11 - Chemistry Question PaperDocumento4 páginasAnnual Exam - Class 11 - Chemistry Question PaperADITIYAAinda não há avaliações

- Aspects of Alumina ProductionDocumento11 páginasAspects of Alumina ProductionNebojsa VasiljevicAinda não há avaliações

- Agrale 2013 ARLADocumento1 páginaAgrale 2013 ARLASamuel SouzaAinda não há avaliações

- Ishihara2019 MPCDocumento11 páginasIshihara2019 MPCKrisna MertaAinda não há avaliações

- Abstraction From PrecipitationDocumento28 páginasAbstraction From PrecipitationChristian LozadaAinda não há avaliações

- PPTDocumento36 páginasPPTPARUL KUMAR SHARMAAinda não há avaliações

- Chapter Nine Heat Integration: 9.1. Synthesis of Heat-Exchange Networks (Hens)Documento47 páginasChapter Nine Heat Integration: 9.1. Synthesis of Heat-Exchange Networks (Hens)Catlinhbk08Ainda não há avaliações

- AP Chem: Chapter 4 Practice Multiple Choice QuestionsDocumento6 páginasAP Chem: Chapter 4 Practice Multiple Choice QuestionsRohit DhakaAinda não há avaliações

- Dehydrobromination of Meso-Stilbene DibromideDocumento8 páginasDehydrobromination of Meso-Stilbene DibromideMo MlAinda não há avaliações

- 133 1 132 1 10 20110530 PDFDocumento11 páginas133 1 132 1 10 20110530 PDFMurali DarenAinda não há avaliações

- Airlift CFD SimulationDocumento7 páginasAirlift CFD Simulationlrodriguez_892566Ainda não há avaliações

- Acids and Bases Weebly FileDocumento5 páginasAcids and Bases Weebly Fileapi-240469044Ainda não há avaliações

- ASTM D2386-15e1 PDFDocumento5 páginasASTM D2386-15e1 PDFAndres Muñoz AguirreAinda não há avaliações

- Component 1 MA 06 (MC)Documento6 páginasComponent 1 MA 06 (MC)Zareen KidwaiAinda não há avaliações

- ChE Reviewer 2014 (PART I)Documento7 páginasChE Reviewer 2014 (PART I)jantskieAinda não há avaliações

- Photoelectric Effect: Dual Nature of Matter and RadiationsDocumento21 páginasPhotoelectric Effect: Dual Nature of Matter and RadiationsVishesh SheraAinda não há avaliações

- Types of Chemical Reaction PDFDocumento31 páginasTypes of Chemical Reaction PDFDanica ZunichiAinda não há avaliações