Escolar Documentos

Profissional Documentos

Cultura Documentos

ABB Slip-Ring Motors

Enviado por

idontlikeebooksDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ABB Slip-Ring Motors

Enviado por

idontlikeebooksDireitos autorais:

Formatos disponíveis

Brochure

Slip-ring motors for heavy-duty and critical applications Reliable and efficient solutions to drive your operations

We provide motors and generators, services and expertise to save energy and improve customers processes over the total lifecycle and beyond

2 ABB Motors and Generators | Slip-ring motors for heavy-duty and critical plants

Join forces with the technology leader Choose ABB efficiency and quality

The most innovative technology for motors and drives. Forward-looking products based on more than a century of experience.

A global leader in power and automation technology, ABB designs and manufactures a comprehensive range of motors and generators for all applications. We have more than 100 years of experience in supplying low and high voltage AC motors for use in almost all industries. Our resources and extensive R&D program have enabled us to become a technology leader in our chosen fields, and ensure we are well-placed to maintain our edge in the future. We utilize the most advanced design and manufacturing technologies to optimize the reliability and efficiency of the solutions we supply. Our motors are often used in critical applications where downtime must be avoided, so it is vital that they are backed by effective and responsive support. Our global network of service facilities enables us to respond quickly and support our customers wherever they are located in the world. These advantages - our experience, resources, technological leadership and worldwide sales and service network have helped us to become the preferred supplier to leading players in a wide range of industries. Slip-ring motors, ideal for heavy load inertia applications or weak network conditions: - high starting torque, high inertia low starting current - high torque over the entire speed range - suitable for starting in weak networks - can be adapted for use with VSDs (variable speed drives) Our design experience and application expertise have made us a leading manufacturer of high voltage slip-ring induction motors. These motors are widely used in applications requiring high starting torque or low starting current, including mill drives, cement plants, mines, utilities, water works and many more.

Slip-ring motors are known as wound rotor induction motors in certain markets.

These rugged motors with fully braced and vacuum pressure impregnated windings are made for heavy-duty operation. Their high efficiency level is mainly achieved through sophisticated motor design software, the effective use of high quality materials, and advanced ventilation technology. High efficiency means substantial energy savings over the life of the motor. Compliance with major standards worldwide - IEC - NEMA - GOST - CSA - BS, ANSI, IEEE, VDE, EN

In addition to our comprehensive range of motors designed to meet international IEC standards, we now have a full range of NEMA compliant motors. ABB premium quality - high efficiency - low noise - long lifetime - VPI (vacuum pressure impregnation) insulation system - advanced design - over 100 years of experience in motors and generators - global ABB service network - ISO 9001 quality certification - ISO 14000 environmental certification

Slip-ring motors for heavy-duty and critical plants | ABB Motors and Generators 3

Wide product range Slip-ring motors to suit all requirements

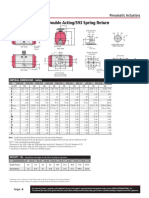

Output in kW 50 Hz, 11 kV

KW 19000 18000 17000 16000 15000 14000 13000 12000 11000 10000 9000 8000 7000 6000 5000 4000 3000 2000 1000 0

4p 1500 rpm 6p 1000 rpm 8p 750 rpm 10p 600 rpm 12p 500 rpm

Air/Water Air/Air

Main features: - Output power: 300 to 18,000 kW at 50 Hz - Output power: 400 to 15,000 HP at 60 Hz - Voltage range: 380 to 13,800 V - Shaft heights: 400 to 1,120 mm - Standards: IEC, NEMA, BS, ANSI, IEEE, VDE, EN

4 ABB Motors and Generators | Slip-ring motors for heavy-duty and critical plants

High quality components for top performance Putting advanced technology to work

The bearings The bearings are designed to deliver a long operating life with easy maintenance. Various types of bearings are available, including cylindrical, self-aligning and sleeve versions, with the optimum choice depending on the size, operating characteristics and type of motor. Antifriction bearings are designed for a 100,000 hour working life, and are structured to minimize the noise level and prevent dust penetration. The rotor When a motor is operated in difficult conditions - in harsh environments or with demanding operating cycles - vibrations occur that can reduce the useful life of the rotor. ABB motors feature rotors made of materials selected to withstand these conditions, ensuring low vibration levels through their solid structure and perfect balancing of each component. The rotor shaft is built to match the challenges imposed by the motors specific operating cycles and conditions, and the rotor itself is dynamically balanced at the maximum operating speed. Each weld is made according to rigorous procedures and undergoes several quality checks, while the windings are produced using techniques to minimize vibrations. A rigid wrapping also prevents the windings from exposure to distorting centrifugal forces.

The stator The stator is designed and built from the first welded joints onwards - to produce a compact and uniform system that can deliver a long operating life, even in difficult conditions. Ventilation is optimized by the use of special radial ducts. The lamination is insulated from the stator core by means of a heat-resistant inorganic resin (Class F), while the windings and connections are insulated by means of mica-based tapes. Once the winding is complete, the whole stator is vacuum pressure impregnated to form a single block that will keep its rigidity over the entire life of the motor. The terminal boxes are designed to make cable connection easier and reduce installation time.

1 Stator | 2 Rotor 1 2

Slip-ring motors for heavy-duty and critical plants | ABB Motors and Generators 5

Engineered for a long operating lifetime Reliable slip rings and efficient cooling solutions

Advanced slip-ring unit Slip-ring motors can be supplied with: - permanent contact brushes, or - brush-lifting gear. In both cases, the slip rings are mounted at the N-end and enclosed in a separate housing from the motor. This arrangement provides easy access and maintenance, and keeps carbon dust out of the motor. It also makes it possible to have different cooling methods for the slip rings and motor. Replacement machines with an internal slip-ring compartment are available on request. Slip rings with permanent contact brushes The slip rings are manufactured from highly corrosion resistant Cu-Sn-Ni alloy and are helical grooved as standard. Slip rings with brush-lifting gear Manufactured from stainless steel, these slip rings have a smooth, non-grooved surface. After the motor has achieved full speed, the brush-lifting and slip-ring short-circuiting gear (BLG) first short-circuits the rotor winding and then raises the brushes from the slip rings. Effective cooling for safe, reliable operation Internal air circulation is provided by a shaft mounted fan or separate blower. In air-to-air cooled motors, the external cooling air is circulated by a shaft mounted fan or separate blower. Standard versions are always self-ventilated.

In weather protected motors, the cooling air is drawn through the motor by a shaft mounted fan. Protection is provided by a weatherproof cover which also serves as a silencer. Uniform and efficient cooling of the stator is ensured by radial air ducts in the stator core and spacers between the coil ends. The stator frame construction is designed to facilitate an efficient flow of cooling air. Slip-ring units with permanent contact slip-ring brushes are equipped with a heat exchanger or protective cover similar to that on the motor. A shaft mounted fan circulates cooling air through the slip-ring unit, filter, and upper cover. This cooling system is isolated from the motors cooling system, thus providing easy maintenance and inspection.

Cooling systems

Water-air cooled IP55 IC81W TEWAC

Air-to-air cooled IP55 IC611 TEAAC

Weather protected IP23/IPW24 IC01 WPI/WPII

6 ABB Motors and Generators | Slip-ring motors for heavy-duty and critical plants

Straightforward connections Designed for easy installation

The standard terminal box offers plenty of space for easy cable fitting and connection. Other types of connection box can be provided on request, with the following types available: - phase separated - phase segregated - phase insulated Different types of cable connections, such as Raychem termination or Elastimold , are available. The box is turnable by 90 to provide cable entry from any direction.

Terminal box big size

Terminal box small size

Phase separated terminal box

Phase segregated terminal box

Slip-ring motors for heavy-duty and critical plants | ABB Motors and Generators 7

Contact us

modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Ltd. does not accept any responsibility whatsoever for potential errors or possible lack of information in this document. We reserve all rights in this document and in the subject matter and illustrations contained herein. Any reproduction, disclosure to third parties or utilization of its contents - in whole or in parts - is forbidden without prior written consent of ABB Ltd. Copyright 2011 ABB. All rights reserved.

604498/001 - 06/2011 - Printed in Italy - 1.000 - CAL

www.abb.com/motors&generators

We reserve the right to make technical changes or

Você também pode gostar

- WEG Three Phase Induction Motors M Line 50019089 Brochure EnglishDocumento12 páginasWEG Three Phase Induction Motors M Line 50019089 Brochure Englishhossein447Ainda não há avaliações

- GAVE 099CA00567.05EN - LowDocumento32 páginasGAVE 099CA00567.05EN - LowRahmat Nur IlhamAinda não há avaliações

- Brochure Industrial SolutionsDocumento12 páginasBrochure Industrial SolutionsGab_SandovalR7175Ainda não há avaliações

- (HG) Relay (HGMP) Catalog en 1904-NewDocumento32 páginas(HG) Relay (HGMP) Catalog en 1904-NewAnas AjAinda não há avaliações

- The Switchboard That Your Installation Deserves: BloksetDocumento12 páginasThe Switchboard That Your Installation Deserves: Bloksetmumi87Ainda não há avaliações

- Modeling and Simulation of Reverse PowerDocumento6 páginasModeling and Simulation of Reverse PowergusgifAinda não há avaliações

- IAS28P4Documento8 páginasIAS28P4anexi01Ainda não há avaliações

- Volume 3 - Scope of Works, Technical SpecificationsDocumento79 páginasVolume 3 - Scope of Works, Technical Specificationsmudassir mAinda não há avaliações

- Sabre Vacuum Circuit Breaker Ring Main Unit Up To 24kV: With Automation and Remote Control OptionsDocumento16 páginasSabre Vacuum Circuit Breaker Ring Main Unit Up To 24kV: With Automation and Remote Control OptionsArlone ManaladAinda não há avaliações

- BahraTBS Busway AE CatalogueDocumento66 páginasBahraTBS Busway AE Catalogueمعاذ كروبينAinda não há avaliações

- VCB 06 (1) .07.07 PDFDocumento56 páginasVCB 06 (1) .07.07 PDFrazvansasuAinda não há avaliações

- Sf6 & VCB PDFDocumento11 páginasSf6 & VCB PDFAnonymous SkU7PyAinda não há avaliações

- User Manual Ecu Test Bench 2020Documento24 páginasUser Manual Ecu Test Bench 2020jhoan maestreAinda não há avaliações

- White Paper - Resistive Load Banks: AESPL - Ahuja Engineering Services Pvt. LTDDocumento10 páginasWhite Paper - Resistive Load Banks: AESPL - Ahuja Engineering Services Pvt. LTDsinanbalbanAinda não há avaliações

- BloksetDocumento3 páginasBloksetabdilAinda não há avaliações

- H 2Documento181 páginasH 2Adrián Elías GuzmánAinda não há avaliações

- Automation and Power KLGDocumento20 páginasAutomation and Power KLGKumud GoelAinda não há avaliações

- 7SA87Documento64 páginas7SA87Selva Kumar100% (1)

- C Ais e 1901 PDFDocumento44 páginasC Ais e 1901 PDFTuan DuongAinda não há avaliações

- Catalog Cba-30 enDocumento12 páginasCatalog Cba-30 enRizkiary RamadhanAinda não há avaliações

- Submittal Rev 2Documento264 páginasSubmittal Rev 2Haythamberg AhmedAinda não há avaliações

- Catalog of Dpe-12ntf&24ntf (Dongwoo)Documento2 páginasCatalog of Dpe-12ntf&24ntf (Dongwoo)Minh VienAinda não há avaliações

- Cableeye Catalog W PricesDocumento32 páginasCableeye Catalog W PricesgersonfreireAinda não há avaliações

- R1 Prevention Knowledge and PracticesDocumento123 páginasR1 Prevention Knowledge and PracticesFG SummerAinda não há avaliações

- Interfacing DEIF Equipment, Application Notes 4189340670 UK - 2013.10.04Documento49 páginasInterfacing DEIF Equipment, Application Notes 4189340670 UK - 2013.10.04Luis Jesus50% (2)

- MCC-UniGear ZVC Catalogue RevF.Documento123 páginasMCC-UniGear ZVC Catalogue RevF.Anonymous cOYX3GRdRBAinda não há avaliações

- LV SwitchgearS-GEDocumento8 páginasLV SwitchgearS-GEJuan E Torres MAinda não há avaliações

- MVControllers 1500 Sg001 en PDocumento48 páginasMVControllers 1500 Sg001 en PricardoqqAinda não há avaliações

- Solution Guide: High Dependability and Low Voltage SwitchboardDocumento46 páginasSolution Guide: High Dependability and Low Voltage SwitchboardLaura Daniela GavrilasAinda não há avaliações

- GCP 30Documento4 páginasGCP 30wagner_guimarães_10% (1)

- Sabre Range Brochure WebDocumento64 páginasSabre Range Brochure WebKadirou BigstarAinda não há avaliações

- Caja Modeada - Hyundai - Serie HGP 2015Documento128 páginasCaja Modeada - Hyundai - Serie HGP 2015Matias Soto BilbaoAinda não há avaliações

- Record PlusDocumento250 páginasRecord PlusDixie VictoriaAinda não há avaliações

- NEX 24KV CatalogueDocumento42 páginasNEX 24KV CatalogueThức VõAinda não há avaliações

- La-101914 31136 105 PDFDocumento4 páginasLa-101914 31136 105 PDFAnonymous TrDuMhMvAinda não há avaliações

- Gavr 15aDocumento2 páginasGavr 15aduaAinda não há avaliações

- PPS 1005Documento6 páginasPPS 1005Boom08Ainda não há avaliações

- AVR GAVR 15data Leiras - 2Documento2 páginasAVR GAVR 15data Leiras - 2Argee PadauanAinda não há avaliações

- GTG 1328sc Sw50 50bargeDocumento4 páginasGTG 1328sc Sw50 50bargewidyo saptotoAinda não há avaliações

- Current RatingsDocumento4 páginasCurrent RatingsJove MultisystemsAinda não há avaliações

- ABB Disconnector GW54 1YVA000105 RevA enDocumento8 páginasABB Disconnector GW54 1YVA000105 RevA enDenis SăndicăAinda não há avaliações

- B503DSL Series Solar Photovoltaic Pump Controller Instruction ManualDocumento36 páginasB503DSL Series Solar Photovoltaic Pump Controller Instruction Manualم. هاني الحطامي100% (1)

- CG Power Systems Canada Eng EnglishDocumento6 páginasCG Power Systems Canada Eng EnglishpitambervermaAinda não há avaliações

- Inverter, Storage and PV System Technology Industry Guide 2013Documento100 páginasInverter, Storage and PV System Technology Industry Guide 2013ahmetgumus1903Ainda não há avaliações

- P12x Ent f65Documento518 páginasP12x Ent f65Adip Chy100% (1)

- Oil+Immersed+Transformer 1311 PDFDocumento24 páginasOil+Immersed+Transformer 1311 PDFPrabodh ChandimaAinda não há avaliações

- Advance Tech Guide - Power MV GearDocumento48 páginasAdvance Tech Guide - Power MV GearNiraj SrivastavaAinda não há avaliações

- 001 - SAREL SYSclad Switchboard CatalogueDocumento16 páginas001 - SAREL SYSclad Switchboard Cataloguemohd aizat mohd sayuthiAinda não há avaliações

- SIRIUS Datasheet P-1Documento100 páginasSIRIUS Datasheet P-1madhan_22Ainda não há avaliações

- Howell Energy Systems PVT LTDDocumento13 páginasHowell Energy Systems PVT LTDvenkatesh rao100% (1)

- Job No: GA13011 Name of Project 109MW Main HFO Power Plant Project - Bangladesh Title 132kV Metering Panel Revision: 00Documento18 páginasJob No: GA13011 Name of Project 109MW Main HFO Power Plant Project - Bangladesh Title 132kV Metering Panel Revision: 00MeenakshiAinda não há avaliações

- Deswed106022en HDDocumento16 páginasDeswed106022en HDmumi87Ainda não há avaliações

- Catalog HYUNDAI HGM MCCBDocumento168 páginasCatalog HYUNDAI HGM MCCBKostas TressosAinda não há avaliações

- ABB VD4 Circuit Breaker InstructionsDocumento100 páginasABB VD4 Circuit Breaker InstructionsKunwar SinghAinda não há avaliações

- C&S Pricelist July2017 PDFDocumento124 páginasC&S Pricelist July2017 PDFVasudev AgrawalAinda não há avaliações

- gc2000 ManualDocumento269 páginasgc2000 ManualthuanAinda não há avaliações

- ABB Synchronous MotorsDocumento20 páginasABB Synchronous Motorsidontlikeebooks0% (1)

- GE Large Induction MotorsDocumento8 páginasGE Large Induction MotorsidontlikeebooksAinda não há avaliações

- Medium & High Voltage and High Speed Motors PDFDocumento16 páginasMedium & High Voltage and High Speed Motors PDFSandeep SinghAinda não há avaliações

- Water Safety Risk Assessment Guide v1.0Documento4 páginasWater Safety Risk Assessment Guide v1.0idontlikeebooksAinda não há avaliações

- Psar35 m5 Rescue V December 2022Documento37 páginasPsar35 m5 Rescue V December 2022idontlikeebooksAinda não há avaliações

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocumento2 páginasAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksAinda não há avaliações

- Bronze Medallion (BM) Theory Questions (Assessment Task 1)Documento23 páginasBronze Medallion (BM) Theory Questions (Assessment Task 1)idontlikeebooksAinda não há avaliações

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocumento2 páginasAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksAinda não há avaliações

- Gold Medallion Assessors Guide v1.2 2023Documento9 páginasGold Medallion Assessors Guide v1.2 2023idontlikeebooksAinda não há avaliações

- SMPC Delivery and Assessment Guide v1 June 2022Documento37 páginasSMPC Delivery and Assessment Guide v1 June 2022idontlikeebooksAinda não há avaliações

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocumento2 páginasAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksAinda não há avaliações

- NL48Documento1 páginaNL48idontlikeebooksAinda não há avaliações

- 2023 State Age Championships Final Event Information 1Documento10 páginas2023 State Age Championships Final Event Information 1idontlikeebooksAinda não há avaliações

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocumento2 páginasAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksAinda não há avaliações

- Lime Slaking 101 Whitepaper 4-06-22Documento8 páginasLime Slaking 101 Whitepaper 4-06-22idontlikeebooksAinda não há avaliações

- STT Vertimill Retrofit 03282022Documento2 páginasSTT Vertimill Retrofit 03282022idontlikeebooksAinda não há avaliações

- CA6 ContactorsDocumento36 páginasCA6 ContactorsAbhishek mishraAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- Memo 2023 Age Championships Water Safety RosterDocumento3 páginasMemo 2023 Age Championships Water Safety RosteridontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- TeSys Giga Contactors - LC1G225KUENDocumento5 páginasTeSys Giga Contactors - LC1G225KUENidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocumento1 páginaWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksAinda não há avaliações

- WEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishDocumento8 páginasWEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishidontlikeebooksAinda não há avaliações

- Emmission Reduktion at VWDocumento8 páginasEmmission Reduktion at VWAlin DanielAinda não há avaliações

- Service: Audi 100 1991Documento156 páginasService: Audi 100 1991Dávid DupkalaAinda não há avaliações

- Crawler Crane ChecklistDocumento2 páginasCrawler Crane ChecklistAnuraj100% (1)

- Automatic Transfer Switch ATS Between Two Low-Voltage Utility SuppliesDocumento4 páginasAutomatic Transfer Switch ATS Between Two Low-Voltage Utility SuppliesSebastianCicognaAinda não há avaliações

- Cub Cadet Parts Manual For Model 2185 Tractor SN 1a031g and AfterDocumento6 páginasCub Cadet Parts Manual For Model 2185 Tractor SN 1a031g and Afterthomas100% (30)

- POLY GIM Swiss Type CNC Auto Lathe Diamond II&III SERIES Maintenance ManualDocumento274 páginasPOLY GIM Swiss Type CNC Auto Lathe Diamond II&III SERIES Maintenance ManualALEX JHONNY MUESES PIAUM67% (3)

- Trane - Education MaterialsDocumento14 páginasTrane - Education MaterialsFawaaz KhurwolahAinda não há avaliações

- Moteur 400 500cc Geopolis - SatelisDocumento72 páginasMoteur 400 500cc Geopolis - SatelisGeorge BaltzAinda não há avaliações

- Crane Cams-Hydraulic Lifter AdjustmentDocumento2 páginasCrane Cams-Hydraulic Lifter Adjustmentlambjabibi100% (2)

- Carmix - 3 5TTDocumento2 páginasCarmix - 3 5TTZola1stAinda não há avaliações

- Vauxhall Workshop A13dtc Torque Guide ValuesDocumento6 páginasVauxhall Workshop A13dtc Torque Guide ValuesBernardo RamirezAinda não há avaliações

- Small Biogas Engine Conversion Kit Rural ApplicationDocumento43 páginasSmall Biogas Engine Conversion Kit Rural Applicationgkarthikeyan100% (1)

- Emerson IF80 0471Documento16 páginasEmerson IF80 0471Tekos7Ainda não há avaliações

- H and P Unit I II III MQCDocumento36 páginasH and P Unit I II III MQCSuryakant LadAinda não há avaliações

- Massey PartsDocumento54 páginasMassey PartsOhioBound100% (1)

- Ata 37 - VacuumDocumento13 páginasAta 37 - VacuumPapa Bebe FamilyAinda não há avaliações

- QCD Fire Pump Check ListDocumento3 páginasQCD Fire Pump Check ListAnoirAinda não há avaliações

- Stator MotorDocumento8 páginasStator MotorMPENDULO MABILAAinda não há avaliações

- Installation, Operation: Horizontal Electric Steam BoilerDocumento12 páginasInstallation, Operation: Horizontal Electric Steam Boilerpatricia cebajosAinda não há avaliações

- Valmet 611 DSLDocumento57 páginasValmet 611 DSLagrodostavaAinda não há avaliações

- Frame and Covers 17887-2 Atlas Copco Construction Tools ABDocumento52 páginasFrame and Covers 17887-2 Atlas Copco Construction Tools ABВадим БалабанAinda não há avaliações

- SSP 344 Audi A6 Avant 2005 PDFDocumento40 páginasSSP 344 Audi A6 Avant 2005 PDFFabian Henao Calle100% (1)

- Flowserve TurbinesDocumento8 páginasFlowserve TurbinescanscotAinda não há avaliações

- Six Months Industrial Automation SyllabusDocumento9 páginasSix Months Industrial Automation SyllabusWilliam SmithAinda não há avaliações

- Bergen B Gas Engine: ... The Power of ExperienceDocumento16 páginasBergen B Gas Engine: ... The Power of ExperienceKarim Sowley DelgadoAinda não há avaliações

- Caterpillar 320 ELDocumento2 páginasCaterpillar 320 ELSantiago GuayasamínAinda não há avaliações

- Ford Modular Engine - WikipediaDocumento5 páginasFord Modular Engine - WikipediaDanivie CorderoAinda não há avaliações

- quadramaticPGEI 5329 PDFDocumento67 páginasquadramaticPGEI 5329 PDFFehr RiveraAinda não há avaliações

- Manual Tecnico Actuador Neumatico Bray S92 93 PDFDocumento1 páginaManual Tecnico Actuador Neumatico Bray S92 93 PDFlcs2006mvAinda não há avaliações

- WORKSHOP MTE PROJECT B16 - 36 and B16 - 53Documento18 páginasWORKSHOP MTE PROJECT B16 - 36 and B16 - 53Rishabh Kumar SinghAinda não há avaliações