Escolar Documentos

Profissional Documentos

Cultura Documentos

Scope of Work

Enviado por

64104641Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Scope of Work

Enviado por

64104641Direitos autorais:

Formatos disponíveis

SCOPE OF WORK Safety Audit shall be undertaken as per IS 14489, rules 68 j (9) (ii) of the Gujarat factory rules

1963 and latest amendments in FA 1948, Gujarat Safety Rules. INTRODUCTION: Safety Audit is an important & useful technique for Industrial management, whereby one can obtain a systematic critical appraisal of the effectiveness of company/plants safety program that is undertaken with a view to suggest improvements & up gradation. Safety Audit is tool for ensuring that the plant operations & maintenance procedures match the design intent and standards .It keeps operating personnel alert to the process hazards; reviews operating procedures for necessary revisions; seeks to identify equipment or process changes that could have introduced new hazards; initiates application of new technology to existing hazards; and reviews adequacy of maintenance & safety inspections. OBJECTIVES The audit has the following objectives: Identify the potential fire, safety & health hazards. Study the exiting organizations & control measures in above areas. Recommend proper measures & procedures for controlling the hazards identified Recommend measures for improving the effectiveness of the existing organization, program & procedures in above areas. METHODOLOGY The Safety Audit is mainly divided into 3 steps as Pre-audit activities Audit Activity Post Audit Activities 1. 2. 3. 4. 5.

The Technical Scope of Safety Audit would also include:PROCESS/OPERATIONAL SAFETY Field review of plant installation, which involves all equipments MECHANICAL SAFETY Review of maintenance procedure i.e. system of work & procedure of taking out the equipment from active service for maintenance and inspection. 2. Review of piping maintenance and testing including yard piping 3. Breakdown and preventive maintenance system 4. Maintenance of critical equipments. 5. Records and history card system 6. Review of machine safety installation 7. Routine and vulnerable spares procurement and planning system 8. Compliance with statutory requirements ELECTRICALS Review of instrumentation system of the process from the process safety angle including the emergency relief arrangements 2. Study of in-built safety guard of instrumentation with the help of P & I diagram.(Not HAZOP) 3. Review of critical interlock, emergency trips etc. 4. Review of functioning and maintenance schedule of various safety devices in plant sensor, smoke detector, fire system etc., INSPECTION Review of maintenance system such as testing of pressure vessel, NDT, online monitoring inspection and piping inspection. 2. Inspection and maintenance of tools, Gaskets etc., and testing of lifting machines and tackles ,lift and hoist etc., 3. Review of record keeping procedure. 4. Review of corrosion prevention Programmed exits in the complex and suggestion for its effective working. 5. Review of technique utilized of the asses the corrosion exist in installation. CENTRAL ENGINEERING SERVICES 1. 2. 3. TANK 1. Review of the piping network i.e. underground and above ground maintenance system Review of pipeline modification undertaken recently, also Review of pipeline modification procedures Review of road conditions for general traffic safety point of view and for the movement of mobile cranes FARMS 1. 1. 1.

Review of fire fighting system, fire protection system installed at tank farm as well as control room fire or gas Release warning system and survival system. 2. Review of maintenance system for the fire fighting equipments/Tenders/pumps 3. Review of Training imparted to employees released to fire fighting . GENERAL SAFETY 1. Review of safety Organization 2. Review of Adequacy, Suitability and Availability of personal protective equipments 3. Review of maintenance system for various safety gadgets provided in plans. 4. Review of safety work permit system 5. Review of safety training to all level of employees. 6. Review of on/off site emergency planning and its effectiveness 7. Review of display board /hoarding in plant area and display of documents in control room. 8. Review of system available in safety unit for statutory compliance. FIRE PROTECTION & FIRE FIGHTING SYSTEMS LEGAL & DOCUMENTATION REVIEW/VERIFICATIONS EXCLUSIONS: 1. All information, maps, data shall be made available to GCI, free of costs. 2. Any other studies or modification of the scope shall be carried out with extra costs. 3. Client will provide To & Fro from Vadodara to site and Lodging & Boarding at your guest-house to our Experts REPORTS: Draft Report-1 set & Final Reports- 2 sets each.

TIME FRAME: General Schedule 10 days (In plant & Office)

Você também pode gostar

- Safety Audit MethodologyDocumento5 páginasSafety Audit MethodologyLalit Kumar Das MohapatraAinda não há avaliações

- Plant and Equipment Management ProcedureDocumento8 páginasPlant and Equipment Management ProcedureEkum EdunghuAinda não há avaliações

- Hazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)Documento11 páginasHazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)IJRASETPublicationsAinda não há avaliações

- Project (APOT)Documento43 páginasProject (APOT)Alaa RajabiAinda não há avaliações

- Chlorine CylinderDocumento9 páginasChlorine Cylinderjoseph_mscAinda não há avaliações

- Msds of Argon GasDocumento6 páginasMsds of Argon GasQilah KamarudinAinda não há avaliações

- 2000 Rigsafe Air Booster CompressorDocumento2 páginas2000 Rigsafe Air Booster CompressorLauren'sclub EnglishBimbel Sd-sma100% (1)

- Safety Alert Space HeatersDocumento2 páginasSafety Alert Space HeatersRamadan KareemAinda não há avaliações

- Section 4 - Grave Emergency ShutdownDocumento19 páginasSection 4 - Grave Emergency ShutdownHammad MasoodAinda não há avaliações

- Cooling TowersDocumento4 páginasCooling TowersosamaAinda não há avaliações

- Safety, Health & EnvironmentDocumento60 páginasSafety, Health & EnvironmentGopalakrishnanAinda não há avaliações

- Hazard IdentificationDocumento1 páginaHazard IdentificationMohamad Zakwan Zach ZakariaAinda não há avaliações

- M. RPK. Environmental Incident Investigation and Reporting MARCH 2021Documento57 páginasM. RPK. Environmental Incident Investigation and Reporting MARCH 2021randell vasquezAinda não há avaliações

- Sop For Chlorine Cylinder&TonnerDocumento1 páginaSop For Chlorine Cylinder&Tonnersaikumar selaAinda não há avaliações

- Checklist For Concept Note For Chlorine Storage and HandlingDocumento4 páginasChecklist For Concept Note For Chlorine Storage and Handlingjkhan_724384Ainda não há avaliações

- Job Description: Senior OperatorDocumento3 páginasJob Description: Senior OperatorhamdibouhajarAinda não há avaliações

- Allbright Industries (M) SDN BHD: Doc No.: RevDocumento10 páginasAllbright Industries (M) SDN BHD: Doc No.: RevMaint100% (1)

- Training Session 2011: Training Subject: Training RoomDocumento17 páginasTraining Session 2011: Training Subject: Training RoomSrikanth0% (1)

- 0 EDOPEC Fire FightingDocumento16 páginas0 EDOPEC Fire FightingocayliAinda não há avaliações

- R-1Copy of Guidelines For Safe Transportation of Chlorine TonnersDocumento40 páginasR-1Copy of Guidelines For Safe Transportation of Chlorine Tonnersrddesai63Ainda não há avaliações

- Service FormatDocumento1 páginaService FormatMadhan MohanAinda não há avaliações

- Vehicle Log - MC 148 Al Ghadeer Phase 2 - 4Documento1 páginaVehicle Log - MC 148 Al Ghadeer Phase 2 - 4Sajid ShahAinda não há avaliações

- Preservation Program Works For Outages From One Month To Several YearsDocumento4 páginasPreservation Program Works For Outages From One Month To Several Yearse.vicente.caballeroAinda não há avaliações

- Cold Work PermitDocumento11 páginasCold Work PermitMuneeb Ur Rehman100% (1)

- Sop Installing PumpDocumento4 páginasSop Installing Pumpilham100% (1)

- Method Statement Hot InsulationDocumento14 páginasMethod Statement Hot InsulationSaleem AkhtarAinda não há avaliações

- Ocp For Oil Handling-ModiDocumento3 páginasOcp For Oil Handling-ModiRaja RamAinda não há avaliações

- Basics of Industrial Heat TransferDocumento12 páginasBasics of Industrial Heat TransferPinaiAinda não há avaliações

- K-FLEX HVAC Applications Installation ManualDocumento63 páginasK-FLEX HVAC Applications Installation ManualMohammad TaheriAinda não há avaliações

- Introduction of Turcomp - WhyDocumento100 páginasIntroduction of Turcomp - WhyMohd NoorAinda não há avaliações

- Inspectation Test PlanDocumento1 páginaInspectation Test Planazimr157Ainda não há avaliações

- Dust Explosion in CFBC BoilersDocumento5 páginasDust Explosion in CFBC BoilersS V NAGESHAinda não há avaliações

- Have You Been SET-UP? A Brief Discussion On Job Hazard Analysis (Jha)Documento30 páginasHave You Been SET-UP? A Brief Discussion On Job Hazard Analysis (Jha)Ian KoAinda não há avaliações

- Portable Ventilator Fan Operation ManualDocumento2 páginasPortable Ventilator Fan Operation ManualAbdul RachmanAinda não há avaliações

- Sop Inert GasDocumento5 páginasSop Inert GasvinodsnAinda não há avaliações

- Job Safety Analysis (Jsa)Documento9 páginasJob Safety Analysis (Jsa)MohdHuzairiRusliAinda não há avaliações

- PSE Alert - VCE Incident - BP RefineryDocumento4 páginasPSE Alert - VCE Incident - BP RefineryOsedebamen IraborAinda não há avaliações

- A-One Consultant - Methanol & Other LicensesDocumento12 páginasA-One Consultant - Methanol & Other LicensesWasim PathanAinda não há avaliações

- Preservation Procedure For Material Under Stand StillDocumento7 páginasPreservation Procedure For Material Under Stand StillsvvsnrajuAinda não há avaliações

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Documento70 páginasLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoAinda não há avaliações

- Atex Guide PDFDocumento6 páginasAtex Guide PDFSELVARAJAinda não há avaliações

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaDocumento67 páginasOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILAinda não há avaliações

- Disaster Aniversaries PDFDocumento40 páginasDisaster Aniversaries PDFHarold Fernando Guavita ReyesAinda não há avaliações

- KHATIB ABDUL RAHIM CV... HDocumento4 páginasKHATIB ABDUL RAHIM CV... HAbdulrahimAinda não há avaliações

- Manual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18Documento32 páginasManual of - Installation - Operation - Maintenance Dual Fuel Burners L.P.G. - Light Oil HS5 HS10 HS18AlvaroValdebenitoValenzuelaAinda não há avaliações

- Standard Operating ProcedureDocumento4 páginasStandard Operating ProcedureJAY BHAVSARAinda não há avaliações

- Boiler O&M ManualDocumento1.669 páginasBoiler O&M ManualLeonardo CoronadoAinda não há avaliações

- AOD Isolation Risk Assessment Rev D2Documento17 páginasAOD Isolation Risk Assessment Rev D2api-3745449Ainda não há avaliações

- 20120502-47 De-Oiling Removal of Flammable Liquids From PipelinesDocumento2 páginas20120502-47 De-Oiling Removal of Flammable Liquids From Pipelinesnice guyAinda não há avaliações

- Manual: Procedure Titel: HSE-ManualDocumento11 páginasManual: Procedure Titel: HSE-ManualGeetha_jagadish30Ainda não há avaliações

- JMS-STS-PIP - JMS Latest FormatDocumento2 páginasJMS-STS-PIP - JMS Latest Formatmohd as shahiddin jafriAinda não há avaliações

- Working Height +1105: Pit Dimension: 2300L X 2600W X - 160DDocumento2 páginasWorking Height +1105: Pit Dimension: 2300L X 2600W X - 160DDeepak kumarAinda não há avaliações

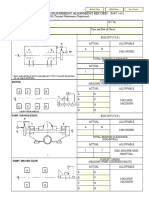

- Horizontal Rotating Equipment Alignment Record: Save Data... Email Data... Reset DataDocumento5 páginasHorizontal Rotating Equipment Alignment Record: Save Data... Email Data... Reset DataGovind Jha100% (1)

- Working From Heights Wooden PolesDocumento31 páginasWorking From Heights Wooden PolesJose OrtegaAinda não há avaliações

- Ayoki Safety Monthly Initiative 27.11.21slideDocumento19 páginasAyoki Safety Monthly Initiative 27.11.21slideAltafAinda não há avaliações

- Materi Hazard - IdentificationDocumento61 páginasMateri Hazard - IdentificationRatna CahyaningtyasAinda não há avaliações

- Work Permit Safety Standard Training PackDocumento24 páginasWork Permit Safety Standard Training PackAtma Prakash Sinha100% (1)

- Eil Permit For Energy Isolation & De-IsolationDocumento1 páginaEil Permit For Energy Isolation & De-IsolationAvesh ChauahanAinda não há avaliações

- DM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)Documento5 páginasDM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)kevinAinda não há avaliações

- Heater Tube InspectionDocumento129 páginasHeater Tube Inspectionuniquepp100% (2)

- Safety in Oil and Gas IndustryDocumento239 páginasSafety in Oil and Gas Industry64104641Ainda não há avaliações

- Scope of Electrical AuditDocumento5 páginasScope of Electrical Audit6410464167% (3)

- 0036 Kitchen Fires - tcm3171-645582Documento2 páginas0036 Kitchen Fires - tcm3171-64558264104641Ainda não há avaliações

- Scope of Safety AuditDocumento1 páginaScope of Safety Audit64104641Ainda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Research PaperDocumento154 páginasResearch Paperleo lokeshAinda não há avaliações

- Bei 076 III II AntenamarksDocumento8 páginasBei 076 III II Antenamarksshankar bhandariAinda não há avaliações

- CS Lewis - The Discarded ImageDocumento4 páginasCS Lewis - The Discarded Imagejscavani100% (2)

- Data Migration To HadoopDocumento26 páginasData Migration To Hadoopkrishna100% (2)

- Nhóm 1- Tấm CámDocumento12 páginasNhóm 1- Tấm CámNguyễn NgọcAinda não há avaliações

- Org BehaviourDocumento16 páginasOrg BehaviourKARTHIK14550% (4)

- دور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفDocumento18 páginasدور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفWshiar Omer100% (1)

- RRL ResearchDocumento4 páginasRRL ResearchRamel PaglanganAinda não há avaliações

- 2a Three Types of LightingDocumento14 páginas2a Three Types of LightingMarcus MasangkayAinda não há avaliações

- Sediment Transport Flo2DDocumento22 páginasSediment Transport Flo2DJoshua Xilo MoronAinda não há avaliações

- Seminar - Write-Up FormatDocumento8 páginasSeminar - Write-Up Formatd.orreenselcouthAinda não há avaliações

- DAAD WISE Summer Internship ReportDocumento2 páginasDAAD WISE Summer Internship ReportVineet Maheshwari100% (1)

- ECSE 221 Midterm W11Documento9 páginasECSE 221 Midterm W11Eliran HalfonAinda não há avaliações

- Agri Mapping UEGISDocumento17 páginasAgri Mapping UEGISnarockavAinda não há avaliações

- Noun in English Grammar With Examples With PDFDocumento9 páginasNoun in English Grammar With Examples With PDFhemisphereph2981Ainda não há avaliações

- Chapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsDocumento20 páginasChapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsAdrian ToaderAinda não há avaliações

- Technical Note - Measurement MicrophonesDocumento4 páginasTechnical Note - Measurement MicrophonesWillFonsecaAinda não há avaliações

- Constructivist Approach To Teaching and LearningDocumento2 páginasConstructivist Approach To Teaching and LearningLen-Len CobsilenAinda não há avaliações

- Utm EnglishDocumento23 páginasUtm Englishapi-240506461Ainda não há avaliações

- Theories in NursingDocumento22 páginasTheories in NursingChrisgr8Ainda não há avaliações

- A Survey of Cross-Infection Control Procedures: Knowledge and Attitudes of Turkish DentistsDocumento5 páginasA Survey of Cross-Infection Control Procedures: Knowledge and Attitudes of Turkish Dentistsbie2xAinda não há avaliações

- Briefings To University of Minnesota Board of Regents On Markingson CaseDocumento288 páginasBriefings To University of Minnesota Board of Regents On Markingson CaseMarkingsonCaseAinda não há avaliações

- Portable Centre Pivot Irrigation System With Advanced Control Through Sensors A ReviewDocumento4 páginasPortable Centre Pivot Irrigation System With Advanced Control Through Sensors A ReviewEditor IJTSRDAinda não há avaliações

- World Hub Indonesia-TurkeyDocumento2 páginasWorld Hub Indonesia-TurkeyJihan ZahraAinda não há avaliações

- Jurnal PEMELIHARAAN IKAN BAUNG (Hemibagrus Nemurus) DENGAN Padat Tebar Yang Berbeda Pada Sistem Budidaya BosterDocumento14 páginasJurnal PEMELIHARAAN IKAN BAUNG (Hemibagrus Nemurus) DENGAN Padat Tebar Yang Berbeda Pada Sistem Budidaya Bosterdesi sukmawatiAinda não há avaliações

- NCERT Solutions For Class 12 English Flamingo Chapter 8Documento3 páginasNCERT Solutions For Class 12 English Flamingo Chapter 8AKASH KUMARAinda não há avaliações

- Perraillon Marginal Effects Lecture Lisbon 0Documento65 páginasPerraillon Marginal Effects Lecture Lisbon 0Meseret ZerihunAinda não há avaliações

- Van GenuchtenDocumento21 páginasVan GenuchtenrshaghayanAinda não há avaliações

- TM11-5855-213-23&P - AN-PVS4 - UNIT AND DIRECT SUPPORT MAINTENANCE MANUAL - 1 - June - 1993Documento110 páginasTM11-5855-213-23&P - AN-PVS4 - UNIT AND DIRECT SUPPORT MAINTENANCE MANUAL - 1 - June - 1993hodhodhodsribd100% (1)

- For Immediate ReleaseDocumento3 páginasFor Immediate ReleaseLiberty Building Forensics GroupAinda não há avaliações

- Practical Troubleshooting of Electrical Equipment and Control CircuitsNo EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsNota: 4 de 5 estrelas4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsAinda não há avaliações

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ENo EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ENota: 3 de 5 estrelas3/5 (6)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionAinda não há avaliações

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNo EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNota: 4.5 de 5 estrelas4.5/5 (5)

- Laws of UX: Using Psychology to Design Better Products & ServicesNo EverandLaws of UX: Using Psychology to Design Better Products & ServicesNota: 5 de 5 estrelas5/5 (9)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNo EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNota: 5 de 5 estrelas5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemAinda não há avaliações

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessAinda não há avaliações

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- Fire Protection Engineering in Building DesignNo EverandFire Protection Engineering in Building DesignNota: 4.5 de 5 estrelas4.5/5 (5)

- Culture, Health and Illness: An Introduction for Health ProfessionalsNo EverandCulture, Health and Illness: An Introduction for Health ProfessionalsAinda não há avaliações

- Workbook to Accompany Maintenance & Reliability Best PracticesNo EverandWorkbook to Accompany Maintenance & Reliability Best PracticesNota: 3.5 de 5 estrelas3.5/5 (3)

- Incidents That Define Process SafetyNo EverandIncidents That Define Process SafetyAinda não há avaliações

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesAinda não há avaliações

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsNo EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsNota: 4 de 5 estrelas4/5 (11)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesAinda não há avaliações

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableNo EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableAinda não há avaliações