Escolar Documentos

Profissional Documentos

Cultura Documentos

Comparison of Diesel With Butane Gas in Firing Crucible Furnace For Melting Aluminium

Enviado por

Peeka Prabhakara RaoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Comparison of Diesel With Butane Gas in Firing Crucible Furnace For Melting Aluminium

Enviado por

Peeka Prabhakara RaoDireitos autorais:

Formatos disponíveis

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol.

1 Issue 4, June - 2012

Comparison of Diesel with Butane Gas in Firing Crucible Furnace for Melting Aluminium

Musa Nicholas Akhaze Mechanical Engineering Department Auchi Polytechnic, Auchi Edo State, Nigeria. Madonick1@yahoo.com

Abstract The high cost of fuel is one of the reasons why alternatives are sought. Furnaces used for melting aluminium are being fired with diesel or butane gas on industrial scale, because of epileptic power supply in most developing countries like Nigeria. The cost of the fuel and the earliest time the aluminium can melt and reach its pouring temperature, using diesel and butane gas individually, to fire the furnace have not been the parameters used for selection. So this paper examined the aforementioned parameters and discovered that butane gas in comparison with diesel, when used to fire the furnace, melt and bring aluminium to its pouring temperature faster, with a minimal cost. Key words: Aluminium, Butane gas, Diesel, Melting furnace. Pouring temperature. gas or propane gas are used to fire Aluminium melting furnace, on both laboratory and industrial scale. The choice of either butane gas or diesel for firing furnace has been adduced to little or no reason, and not to the cost of the fuel and the earliest possible time of melting and bringing the metal to its pouring temperature. These are evident in the opinions and works of notable researchers which are highlighted as follows: The use of butane gas for firing furnace is one of the measures of reducing gas flaring problem, which results in colossal waste of both natural resources and energy in developing countries like Nigeria[2]. A nonferrous melting furnace fired with butane gas was modelled [3]. The reason for considering butane gas instead of other types of fuel such as diesel, was not stated by the researcher. The design of furnace, fired with diesel was embarked upon by [4]. There reason was to eliminate the use of heating element that required electric power which is poorly supplied in Nigeria. A furnace fired with diesel was considered by [5], in their experimental investigations and CFD study of temperature distribution during oscillating combustion in a crucible furnace. The reason for their consideration was not however stated. It was stated by [6] that in the foundry laboratories, a furnace fired with diesel had been used for studies of sand casting in the mechanical field. The view expressed by [7] was that the furnace fired with diesel is more synonymous with the duty of non ferrous melting. In the work of [8], he considered the axis metrical furnace for his calculation of flow properties with a view to finding out, the extent to which the local flow properties and wall heat flux in an axis metrical reversed flow furnace, can be controlled by furnace geometry, and consequent effect on local temperature and combustion efficiency. The furnace was fired with jet of butane. The researcher did not state why consideration was given to butane instead of diesel for firing. Neuro-fuzzy technique was used by [9] to model a rotary furnace

1. Introduction Aluminium has a huge number of uses. Its good electrical conductivity is an important property and is widely used for overhead cables[1]. The high resistance to corrosion and its nontoxicity make it a useful metal for cooking utensils. It is extensively used in aircraft and automobile components where saving of weight is an advantage. Aluminium may be blanked, formed, drawn, turned, cast and die cast into the desired product. Prior to the casting of the aluminium, into the desired product, the scraps or blanks are melted in crucible furnaces. These furnaces are fired with either electricity or fossil fuels or Biofuels. On industrial scale, biofuel fired furnaces have been found not to be suitable because of the long periods they take in melting non-ferrous metals such as Aluminium . More often than not, Diesel or butane

1

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 4, June - 2012

parameters to predict the melting rate of molten metal required to produce homogenous castings, they considered light diesel oil fired furnace. They did not state the reason for their consideration. So the aim of this research is to find out between diesel and butane gas fired furnace, the one that is more suitable in terms of minimal cost of fuel and earliest possible time of melting and bringing aluminium to its pouring temperature. 2. Materials And Methods The diesel fired furnace and butane gas fired furnace in the foundry shop of Auchi Polytechnic, Auchi, Edo State, Nigeria, were used to carry out the tests. The two furnaces were individually charged with 12kg of aluminium blanks having the following compositions 99.59% (Al), 0.03% (Cu), 0.04% (fe) and 0.34% (Si). They were respectively fired with 20 litres of diesel and 12.5kg of butane gas. The combustion temperatures, melting temperatures of aluminium and flue gas temperatures were measured with type K thermocouple in an interval of 5 minutes, until the pouring temperatures of aluminium were obtained. Figure 1 shows the opened diesel fired furnace after melting aluminium and bringing it to its pouring temperature. Figure 2 shows the opened butane gas fired furnace after melting aluminium and bringing it to its pouring temperature.

Figure 2: An opened butane gas fired furnace after melting Aluminium and bringing it to its pouring temperature

The variations of the combustion, melting and the flue gas temperatures with time for the respective diesel and butane gas fired furnaces are shown in figures 3 and 4. The quantity of fuel used, the cost as well as the burn rates in each case were determined, and depicted in Tables 1 and 2 respectively. 3. Results and Discussions

1400 1200 1000 Tc oC TA oC Tg oC

Temperature(oC)

Figure 1: An opened diesel fired furnace after melting Aluminium and bringing it to its pouring temperature

800 600 400 200 0

0 5 10 15 20 25 30 35 40 45 50 Time(mins) Figure 3: Variation of combustion, Aluminium melting and flue gas temperature with time using Diesel

From Figure 3, as the combustion temperatures (Tc) increased, the melting temperatures and flue gas temperature (TA and Tg) also increased, that is between 0 and 50 minutes. Drops in temperatures were not experienced. This is because, there was no refueling of the furnace. The furnace was able to melt aluminium and bring it to its pouring temperature of 7310C in 50 minutes.

2

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 4, June - 2012

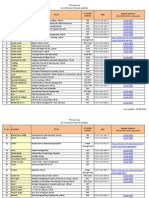

Table 1: Quantity and cost of diesel for firing the melting furnace to melt Aluminium

Volum e of diesel fed into the tank (m3) 0.02 0.02 0.02 0.02 Volum e of diesel left in the tank (m3) 0.0108 0.0105 0.0105 0.0106 Volum e of diesel used (m3) Cost of diesel used (Nair a) Duratio n (mins)

Table 2 Weights and Cost of Butane gas used for firing the melting furnace

Initial weigh t of the gas (kg) 12.5 12.5 12.5 12.5 Final weigh t of the gas (kg) 11.16 11.14 11.21 11.17 Gas use d (kg) Cost of gas (Naira ) Duratio n (Mins)

1st 2nd 3rd Averag e

0.0092 0.0095 0.0095 0.0094

1380 1425 1425 1410

50 50 50 50

1st 2nd 3rd Averag e

1.34 1.36 1.29 1.33

375.2 380.8 361.2 372.4

45 45 45 45

From Table 2, it can be seen that the average weight of butane gas used to fire the furnace that melted aluminium was 1.33kg at the cost of Three Hundred and Seventy-Two Naira, Forty Kobo( N372.40) which is about 2.4 US dollar. 4. Conclusion

From Table 1, it can be seen that an average of 9.4 litres of diesel was consumed by the burner of the furnace to melt 12kg of aluminium at the cost of One Thousand, Four Hundred and Ten Naira (N1410) which is about 8.9 US dollar.

1200 1000 Temperature(oC) 800 600 400 200 0 TA oC Tg oC Tc oC

On the basis of the overall result and in line with the aim of this research work, the following conclusions can be made. Butane gas has been found to be viable for use in firing furnace for melting aluminium. This is as a result of the low cost of the gas and the earliest possible time of bringing aluminium to its pouring temperature compare to diesel. It is therefore recommended that on industrial scale, the use of butane gas should be explored in melting aluminium.

5. References Figure 4: Variation of 5 10 15 Time(mins) 20 25 30 35 40 45 combustion, Aluminium melting and flue gas temperature with time using Butane gas [1] Khurmi R.S and Gupta J. K. A Textbook of Workshop Technology.(Manufacturing Process) Reprint, Rajendra Roindra Printers (PVT) Ltd Rum Nagar New Delhi India, 2006. [2] Bello S. (2004) Design and Construction of a Gas Fired Crucible Furnace. M.Eng Thesis submitted to the Department of Mechanical Engineering, Ambrose Ali University, Ekpoma, Nigeria. [3]. Ighodalo O.A (2010) Modelling a non-ferrous melting furnace.Research Journal of Applied Sciences, Engineering and Technology. 2 (8), pp 798-804. [4]. Alaneme, K.K. and Olanrewaju S.O. (2010) Design of a Diesel Fired heat treatment furnace. Journal of Minerals and Materials

Figure 4, revealed that as the combustion temperatures (Tc) increased, the melting and flue gas temperatures (TA and Tg) increased. There were no drops in temperatures. This is as result of uniform combustion of the gaseous fuel. The furnace using butane gas for firing, was able to melt aluminium in 35 minutes and raised it to its pouring temperature of 7430C in 45 minutes.

3

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 4, June - 2012

characteristics and 7, pp.581-591.

Engineering. Vol. 9, No.

[5] Govardhan J., Rao G.V.S and Narasaiah J.(2011) Experimental Investigations and CFD study of temperature distribution during oscillating combustion in a crucible furnace. International Journal of Energy and Environment. Vol. 2, Issue 5, pp. 783-796. [6]. Amirul S.B.H.O (2010) Design and Manufacture the top head of a diesel furnace. Diploma in Mechanical Engineering report, submitted to Faculty of Mechanical Engineering University. Malaysia Pahang. .

[7]. Tuan M.S.A (2010) Design and Manufacture of the Outer Shell of Diesel Furnace. Diploma in Mechanical Engineering Universiti MalaysiaPahang. pp. 1-24. [8]. Khalil E.E. (1979) Assessment of Numerical Computation of Flow properties in an axisymmetric reversed flow furnace.Applied Mathematical modelling. Vol. 3, Issue pp. 2531. [9]. Ranjit S. Rajat S. and Gurumukh D. (2008) Neuro-fuzzy Modelling of Rotary Furnace Parameters for the Agile Production of Quality Casting. XXXII Natural Systems Conference. NSC. pp. 364-368.

4

www.ijert.org

Você também pode gostar

- Cupola FurnacesDocumento8 páginasCupola Furnacesmiroslav2paunovAinda não há avaliações

- 10 5923 J Ijmee 20160501 03Documento6 páginas10 5923 J Ijmee 20160501 03Yarga PuritzaAinda não há avaliações

- Analysis of combustion characteristics in a aluminium melting furnaceDocumento5 páginasAnalysis of combustion characteristics in a aluminium melting furnaceDanilo AmorimAinda não há avaliações

- Design and Manufacturing of Portable Metal Melting FurnaceDocumento3 páginasDesign and Manufacturing of Portable Metal Melting Furnaceendale asebeAinda não há avaliações

- JMMCE 2014111809383149omoleDocumento9 páginasJMMCE 2014111809383149omoleHassan ShirivandAinda não há avaliações

- 2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Documento2 páginas2-2-A-2-Pulverized Coal Injection For Blast Furnace (PCI)Tonny FebryanAinda não há avaliações

- Design and Construction of A 50kg CapaciDocumento7 páginasDesign and Construction of A 50kg Capaciمصطفى الذاريAinda não há avaliações

- Mill ScaleDocumento6 páginasMill ScaleJhovanny RendónAinda não há avaliações

- High Efficiency Pulverized Coal-Fired Power Generation Technology (Ultra Super Critical Steam Condition)Documento2 páginasHigh Efficiency Pulverized Coal-Fired Power Generation Technology (Ultra Super Critical Steam Condition)Hns Kvn Chavez100% (2)

- Lec 5Documento25 páginasLec 5Anonymous LSPoghJ5nAinda não há avaliações

- 1981 Catalytic Combustion Hydrogen1 MaterialsSelection PDFDocumento8 páginas1981 Catalytic Combustion Hydrogen1 MaterialsSelection PDFAlex CoțAinda não há avaliações

- Project ProposalDocumento4 páginasProject ProposalRidwan BamideleAinda não há avaliações

- Electric Arc Furnace With Oxygen ReactionpdfDocumento9 páginasElectric Arc Furnace With Oxygen ReactionpdfMarisa RobertsAinda não há avaliações

- Design and Development of Tilting Rotary Furnace: IOP Conference Series: Materials Science and EngineeringDocumento8 páginasDesign and Development of Tilting Rotary Furnace: IOP Conference Series: Materials Science and EngineeringaliAinda não há avaliações

- Energy: Ivan Najdenov, Karlo T. Rai C, Gordana KokezaDocumento9 páginasEnergy: Ivan Najdenov, Karlo T. Rai C, Gordana Kokeza......Ainda não há avaliações

- Combustion, Boilers, and Steam Raising: Technologies for Energy GenerationDocumento1 páginaCombustion, Boilers, and Steam Raising: Technologies for Energy GenerationNorman IskandarAinda não há avaliações

- Study of Carbon and Silicon Loss Through Oxidation in Cast Iron Base Metal Using Rotary Furnace For MeltingDocumento6 páginasStudy of Carbon and Silicon Loss Through Oxidation in Cast Iron Base Metal Using Rotary Furnace For Meltingagbajelola idrisAinda não há avaliações

- EAF Energy OptimizationDocumento7 páginasEAF Energy OptimizationAron LopezAinda não há avaliações

- Metal Scrap Preheating Using Flue Gas Waste HeatDocumento8 páginasMetal Scrap Preheating Using Flue Gas Waste HeatDiptoAinda não há avaliações

- Renewable Carbon Trial in Liquid SteelmakingDocumento13 páginasRenewable Carbon Trial in Liquid SteelmakingRidwand KartikaAinda não há avaliações

- Journal Pre-Proofs: Applied Thermal EngineeringDocumento45 páginasJournal Pre-Proofs: Applied Thermal EngineeringRuggero ColaAinda não há avaliações

- CB08S - Effects of Fire Cycle Time on Heat Transfer Characteristics and E..Documento4 páginasCB08S - Effects of Fire Cycle Time on Heat Transfer Characteristics and E..Pedro Milton ChibulachoAinda não há avaliações

- Study of C and Si Loss Through Oxidation in Cast Iron Base Metal Using Rotary Furnace For MeltingDocumento7 páginasStudy of C and Si Loss Through Oxidation in Cast Iron Base Metal Using Rotary Furnace For Meltingagbajelola idrisAinda não há avaliações

- Coal Blending With Fly Ash-An ApproachDocumento28 páginasCoal Blending With Fly Ash-An ApproachcaptainrajneeshAinda não há avaliações

- 3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Documento2 páginas3A3. Direct Iron Ore Smelting Reduction Process (DIOS)Imran Hanif LubisAinda não há avaliações

- IJEDR1703010Documento8 páginasIJEDR1703010Belay AyalewAinda não há avaliações

- State-of-the-art oxyfuel solutions for reheating and annealing in steel industryDocumento7 páginasState-of-the-art oxyfuel solutions for reheating and annealing in steel industryCatanescu Alexandru-LaurentiuAinda não há avaliações

- 1 s2.0 S2214157X21002100 MainDocumento11 páginas1 s2.0 S2214157X21002100 MainChayapon SaiboutongAinda não há avaliações

- Itmk3 Process: Shoichi Kikuchi, Shuzo Ito, Dr. Isao Kobayashi, Osamu Tsuge, Koji TokudaDocumento8 páginasItmk3 Process: Shoichi Kikuchi, Shuzo Ito, Dr. Isao Kobayashi, Osamu Tsuge, Koji TokudabalaasenthilAinda não há avaliações

- Cupola Regression AnalysisDocumento6 páginasCupola Regression AnalysisMayank SharmaAinda não há avaliações

- ALTERNATIVE FUELS AND SULPHUR RELEASEDocumento6 páginasALTERNATIVE FUELS AND SULPHUR RELEASEElwathig BakhietAinda não há avaliações

- Journal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerDocumento7 páginasJournal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerElif ArancıAinda não há avaliações

- Energy Survey of The Coal Based Sponge Iron IndustDocumento15 páginasEnergy Survey of The Coal Based Sponge Iron IndusttapashnagAinda não há avaliações

- Efficiency and Boiler Parameters Effects in Sub-Critical Boiler With Different Types of Sub-Bituminous CoalDocumento11 páginasEfficiency and Boiler Parameters Effects in Sub-Critical Boiler With Different Types of Sub-Bituminous CoalSantosh kumar SahuAinda não há avaliações

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDocumento8 páginasIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklAinda não há avaliações

- The Design and Development of A Dual Fuel BurnerDocumento6 páginasThe Design and Development of A Dual Fuel BurnerGidAinda não há avaliações

- The Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereDocumento7 páginasThe Influences of Alloy Elements On The Carburized Layer in Steels Using Vacuum Carburization in An Acetylene AtmosphereSumit KumarAinda não há avaliações

- Performance Evaluation of Alcohol in An Insulated Di Diesel Engine With Various Piston InsertsDocumento9 páginasPerformance Evaluation of Alcohol in An Insulated Di Diesel Engine With Various Piston InsertsInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Effects of Different Types of Sub-bituminous Coal on Boiler Efficiency and ParametersDocumento11 páginasEffects of Different Types of Sub-bituminous Coal on Boiler Efficiency and ParametersnarayananaliveAinda não há avaliações

- Effect of Quench Media on Steel PropertiesDocumento4 páginasEffect of Quench Media on Steel PropertiesskluxAinda não há avaliações

- Jurnal Sarmidi Revisi Final 52 58Documento7 páginasJurnal Sarmidi Revisi Final 52 58bernadinus irvinAinda não há avaliações

- Combustion Engineering FundamentalsDocumento51 páginasCombustion Engineering FundamentalsRiki MandolAinda não há avaliações

- Coal Selection CriteriaDocumento31 páginasCoal Selection CriteriaHardik Kumar MendparaAinda não há avaliações

- Reed Briquettes Provide Clean Domestic HeatingDocumento4 páginasReed Briquettes Provide Clean Domestic HeatingDan ErvinAinda não há avaliações

- Bake Hardening ST 14 SteelDocumento8 páginasBake Hardening ST 14 SteelDavid JendraAinda não há avaliações

- Design and Fabrication of Aluminium Melting PDFDocumento9 páginasDesign and Fabrication of Aluminium Melting PDFO Onoriode OsticksAinda não há avaliações

- SC Khattoi G.G.Roy IIT KGP ARIM-10 53 2020 PDFDocumento13 páginasSC Khattoi G.G.Roy IIT KGP ARIM-10 53 2020 PDFIlhem Blel100% (1)

- AL Fueled GT ModelsDocumento5 páginasAL Fueled GT ModelsMehulkumar PatelAinda não há avaliações

- Ijet V4i3p38 PDFDocumento10 páginasIjet V4i3p38 PDFInternational Journal of Engineering and TechniquesAinda não há avaliações

- Design and CFD Analysis of Combustion Chamber in IDocumento10 páginasDesign and CFD Analysis of Combustion Chamber in IRuvimboAinda não há avaliações

- Combined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessDocumento8 páginasCombined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessKeysler PonceAinda não há avaliações

- An Energy Analysis of A Slab Preheating Chamber For A Reheating FurnaceDocumento12 páginasAn Energy Analysis of A Slab Preheating Chamber For A Reheating FurnaceZulfa Ilham BasyarahilAinda não há avaliações

- 5A1. Hydrogen Production by Reaction Integrated Novel Gasification Process (Hypr-Ring)Documento2 páginas5A1. Hydrogen Production by Reaction Integrated Novel Gasification Process (Hypr-Ring)TrifosaAjengRiswantiWulandariAinda não há avaliações

- Induction Heating Tecnology - VerDocumento8 páginasInduction Heating Tecnology - Verdenivaldo2009Ainda não há avaliações

- Swedish Steel Industry Energy Efficiency & Fuel Conversion OptionsDocumento8 páginasSwedish Steel Industry Energy Efficiency & Fuel Conversion OptionsyaaamaaanAinda não há avaliações

- Al FurnaceDocumento8 páginasAl Furnacekomatsu2562Ainda não há avaliações

- 16 F 1amit KohliDocumento11 páginas16 F 1amit KohliragvshahAinda não há avaliações

- Heat BalanceDocumento11 páginasHeat BalanceB V S Kumar100% (1)

- 2 China PDFDocumento4 páginas2 China PDFSiddharth ModiAinda não há avaliações

- Al-based Energetic Nano Materials: Design, Manufacturing, Properties and ApplicationsNo EverandAl-based Energetic Nano Materials: Design, Manufacturing, Properties and ApplicationsAinda não há avaliações

- Industry 4.0 On Lean Production SysytemsDocumento7 páginasIndustry 4.0 On Lean Production SysytemsSachin SriramAinda não há avaliações

- Impact of Industry On Business Govt and PeopleDocumento3 páginasImpact of Industry On Business Govt and PeoplePeeka Prabhakara RaoAinda não há avaliações

- Understanding 3D Printing BasicsDocumento62 páginasUnderstanding 3D Printing Basicsnihco gallo100% (4)

- Department of Electrical & Electronics Engineering: WEEK-4, Assignment-4Documento2 páginasDepartment of Electrical & Electronics Engineering: WEEK-4, Assignment-4Peeka Prabhakara RaoAinda não há avaliações

- Conventionalrepresentation 1Documento12 páginasConventionalrepresentation 1Peeka Prabhakara RaoAinda não há avaliações

- Department of Electrical & Electronics Engineering: WEEK-4, Assignment-4Documento2 páginasDepartment of Electrical & Electronics Engineering: WEEK-4, Assignment-4Peeka Prabhakara RaoAinda não há avaliações

- QemDocumento27 páginasQemArun MozhiAinda não há avaliações

- Chapter 20Documento41 páginasChapter 20Peeka Prabhakara RaoAinda não há avaliações

- 8.6 Measurement of Screw Threads: Engineering Metrology and MeasurementsDocumento8 páginas8.6 Measurement of Screw Threads: Engineering Metrology and MeasurementsAliaa NasserAinda não há avaliações

- Constr Materials B PDFDocumento72 páginasConstr Materials B PDFAgniva DuttaAinda não há avaliações

- Department of Electrical & Electronics Engineering: WEEK-4, Assignment-4Documento2 páginasDepartment of Electrical & Electronics Engineering: WEEK-4, Assignment-4Peeka Prabhakara RaoAinda não há avaliações

- Assignment WEEK 5 SolutionsDocumento5 páginasAssignment WEEK 5 SolutionsPeeka Prabhakara RaoAinda não há avaliações

- A-4 SolutionsDocumento5 páginasA-4 SolutionsPeeka Prabhakara RaoAinda não há avaliações

- Department of Electrical & Electronics Engineering: WEEK-4, Assignment-4Documento2 páginasDepartment of Electrical & Electronics Engineering: WEEK-4, Assignment-4Peeka Prabhakara RaoAinda não há avaliações

- A-2 Solutions PDFDocumento4 páginasA-2 Solutions PDFPeeka Prabhakara RaoAinda não há avaliações

- A-2 Solutions PDFDocumento4 páginasA-2 Solutions PDFPeeka Prabhakara RaoAinda não há avaliações

- A-2 Solutions PDFDocumento4 páginasA-2 Solutions PDFPeeka Prabhakara RaoAinda não há avaliações

- Department of Electrical & Electronics Engineering: WEEK-4, Assignment-4Documento2 páginasDepartment of Electrical & Electronics Engineering: WEEK-4, Assignment-4Peeka Prabhakara RaoAinda não há avaliações

- List of Solution Manuals Available from PHI LearningDocumento8 páginasList of Solution Manuals Available from PHI LearningRavish Yadav0% (1)

- List of Solution Manuals Available from PHI LearningDocumento8 páginasList of Solution Manuals Available from PHI LearningRavish Yadav0% (1)

- 113AQ032017 MSM PDFDocumento2 páginas113AQ032017 MSM PDFPeeka Prabhakara RaoAinda não há avaliações

- List of Solution Manuals Available from PHI LearningDocumento8 páginasList of Solution Manuals Available from PHI LearningRavish Yadav0% (1)

- Autocad PPRDocumento44 páginasAutocad PPRPeeka Prabhakara RaoAinda não há avaliações

- 113AQ112017 MSM PDFDocumento2 páginas113AQ112017 MSM PDFPeeka Prabhakara RaoAinda não há avaliações

- WWW - Manaresults.Co - In: (Common To Me, MCT, Ame)Documento2 páginasWWW - Manaresults.Co - In: (Common To Me, MCT, Ame)Peeka Prabhakara RaoAinda não há avaliações

- Engg Graphics 2Documento97 páginasEngg Graphics 2Shubhankar ChakrabortyAinda não há avaliações

- 113AQ112017 MSM PDFDocumento2 páginas113AQ112017 MSM PDFPeeka Prabhakara RaoAinda não há avaliações

- Engineering Drawing Notes PDFDocumento47 páginasEngineering Drawing Notes PDFUjjawal kumarAinda não há avaliações

- Lesson 1 Intro To DrawingDocumento67 páginasLesson 1 Intro To DrawingGiang Hoai Vu100% (1)

- Mech 211 - Lecture 1Documento90 páginasMech 211 - Lecture 1Nancy PierreAinda não há avaliações

- Gas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 ADocumento33 páginasGas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 APélagie DAH SERETENONAinda não há avaliações

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Documento6 páginasAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Matriculation Chemistry Introduction To Organic Compound Part 1 PDFDocumento24 páginasMatriculation Chemistry Introduction To Organic Compound Part 1 PDFiki292Ainda não há avaliações

- Chapter 3 Step Wise An Approach To Planning Software Projects 976242065Documento31 páginasChapter 3 Step Wise An Approach To Planning Software Projects 976242065RiajiminAinda não há avaliações

- Biology Notes HSCDocumento107 páginasBiology Notes HSCGouri DasAinda não há avaliações

- Math Tutoring Announcement for 4th Year Literary StudentsDocumento5 páginasMath Tutoring Announcement for 4th Year Literary Studentsabed azzamAinda não há avaliações

- Chemistry Sectionwise Analysis of PYQs (2024) - Ec3e53a7 c902 4e85 A5dd 12c4bf1f4ae7 1Documento5 páginasChemistry Sectionwise Analysis of PYQs (2024) - Ec3e53a7 c902 4e85 A5dd 12c4bf1f4ae7 1lakhbhat2020Ainda não há avaliações

- Knight Boiler ManualDocumento80 páginasKnight Boiler ManualAnonymous 7xHNgoKE6eAinda não há avaliações

- A RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionDocumento23 páginasA RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionLeonardo Duarte MilfontAinda não há avaliações

- Catalogo Carbones Helwig GDE-006Documento17 páginasCatalogo Carbones Helwig GDE-006Sergio HernandezAinda não há avaliações

- Ansoff Matrix Template User GuideDocumento6 páginasAnsoff Matrix Template User Guidebernardo95Ainda não há avaliações

- Hopper Volume CalculationDocumento1 páginaHopper Volume CalculationWael AboudAinda não há avaliações

- Cylindrical Plug Gage DesignsDocumento3 páginasCylindrical Plug Gage DesignskkphadnisAinda não há avaliações

- Cost Estimation TechniquesDocumento41 páginasCost Estimation TechniquessubashAinda não há avaliações

- 2021 Book AppliedAdvancedAnalyticsDocumento236 páginas2021 Book AppliedAdvancedAnalyticsKitykatmely LoveAinda não há avaliações

- Sensitive Albuminuria Analysis Using Dye-Binding Based Test StripsDocumento24 páginasSensitive Albuminuria Analysis Using Dye-Binding Based Test StripsВалерия БедоеваAinda não há avaliações

- Impact of GIC On Power TransformersDocumento141 páginasImpact of GIC On Power TransformersAkash Verma100% (1)

- Forrester Roi StudyDocumento30 páginasForrester Roi StudymcgettsAinda não há avaliações

- Heat Combustion Laboratory ReportDocumento8 páginasHeat Combustion Laboratory ReportSteven Lee100% (1)

- Service Manual (V1.22)Documento529 páginasService Manual (V1.22)JensAinda não há avaliações

- AC axial compact fan technical specificationsDocumento5 páginasAC axial compact fan technical specificationsdhanasekhar27Ainda não há avaliações

- Failure Mode For Gas CHromatographDocumento2 páginasFailure Mode For Gas CHromatographardi-Ainda não há avaliações

- Welcome: Bahasa Inggris Teknik I Ahmad Nusi, S. PD., M. PDDocumento11 páginasWelcome: Bahasa Inggris Teknik I Ahmad Nusi, S. PD., M. PDAsril SalongAinda não há avaliações

- SteganographyDocumento13 páginasSteganographyIgloo JainAinda não há avaliações

- Antenna Specifications Electrical PropertiesDocumento2 páginasAntenna Specifications Electrical PropertiesLuis Adolfo Mazini RodriguesAinda não há avaliações

- NTSE 2015 Stage I Official Result Karnataka PDFDocumento10 páginasNTSE 2015 Stage I Official Result Karnataka PDFAnnu NaikAinda não há avaliações

- Differential Analysis of Fluid FlowDocumento42 páginasDifferential Analysis of Fluid FlowAmr Faisal RaghebAinda não há avaliações

- Java 8 Interview QuestionsDocumento31 páginasJava 8 Interview QuestionsAmit Sharma100% (2)

- JasminDocumento125 páginasJasminudoraboxAinda não há avaliações

- Weld CheckDocumento6 páginasWeld CheckArnold c ElverAinda não há avaliações