Escolar Documentos

Profissional Documentos

Cultura Documentos

Flange Leakage Check

Enviado por

Phornlert WanaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Flange Leakage Check

Enviado por

Phornlert WanaDireitos autorais:

Formatos disponíveis

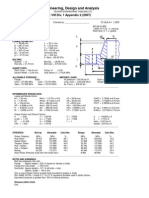

PIPEMILL - Piping Engineering, Design and Analysis

Version: 3.01d Full Run

TECHNIP ENGINEERING THAILAND LTD.

FLANGE DESIGN TO ASME VIII Div. 1 Appendix 2 (2007)

____________________________________________________________________________________________________________

Calculation by: ____________________

Checked by: ______________________

Project / Description

Calculation Details

,.. 1,2555

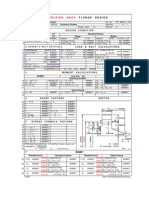

API 6A Tp.6BX

15000 # 3-1/16 in. nominal

Weld neck, R. T. J. gasket

File name:

Load Case: Pressure Only

FLANGE GEOMETRY:

t = 56.64 mm.

A = 287.27 mm.

B = 78.49 mm.

C = 230.12 mm.

g0 = 21.84 mm.

g1 = 37.72 mm.

L = 23.11 mm.

h = 63.50 mm.

rf = 7.620 mm.

FD = 153.92 mm.

Corrosion allw:

ca = .000 mm.

E. Mod.= 199.95 GPa

BOLTING:

Number = 8

Hole dia. = 31.75 mm.

g1

Bolt Dia. = 28.58 mm.

Bolt area = 470.00 mm2.

GASKET DATA:

Pitch Circle = 104.44 mm.

Section Width = 12.40 mm.

g0

t

rf

FD

C

A

Factor 'm'

= 6.50

Seat Stress 'y' = 179.26 MPa

ALLOWABLE STRESSES:

IMPOSED LOADS:

Flange:

Bolts:

Int.pressure = 100.00 bar G

Equiv. pres. = 53873.53 bar G

Cold = 137.895 MPa

Cold = 172.370 MPa

Long. mom. = 1200.000 kN.m

Design pres. = 100.00 bar G

Oper.= 137.895 MPa

Oper.= 172.370 MPa

Ax. Force = 200.00 kN

_______________________________________________________________________________________________

INTERMEDIATE DESIGN DATA:

Loads and Moment Arms:

b0 = 1.55 mm.

Wm1= 1.51761 e+5 N

b = 1.55 mm.

Wm2= 9.11303 e+4 N

G = 104.44 mm.

Am1 = 880.48 mm2.

HP = 6.6088 e+4 N

Am2 = 528.72 mm2.

H = 8.56727 e+4 N

Am = 880.48 mm2.

W = 3.9992 e+5 N

Ab = 3760.00 mm2.

hD = 56.96 mm.

hG = 62.84 mm.

hT = 69.33 mm.

HD = 4.83786 e+4 N

HG = 6.6088 e+4 N

HT = 3.72941 e+4 N

hDHD = 2.75562 e+6 N.mm.

hGHG = 4.15294 e+6 N.mm.

hTHT = 2.58558 e+6 N.mm.

M. Op.= 9.49414 e+6 N.mm.

M.Atm.= 2.51308 e+7 N.mm.

Shape Factors and Stress Factors:

K

= 3.66

T = 1.06749

F = .73538

d

= 1.94320 e+5

g1/g0 = 1.727

U = 1.71424

V = .17429

e

= 1.776 e-2

h0

= 41.406

Y = 1.55996

f = 1.

beta = 2.3413 e+0

h/h0 = 1.534

Z = 1.16133

lamda= 2.8143 e+0

_______________________________________________________________________________________________

STRESSES:

Bolt-up

Allowable

Calc/Allw.

Design

Allowable

Calc/Allw.

Stress Category:

MPa

MPa

%

MPa

MPa

%

Hub Stress

79.972

206.843

38.7

30.213

206.843

14.6

Radial Stress

83.031

137.895

60.2

31.368

137.895

22.7

Tangent. Stress

59.268

137.895

43.0

22.391

137.895

16.2

Hub + Radial

81.502

137.895

59.1

30.790

137.895

22.3

Hub + Tangent.

69.620

137.895

50.5

26.302

137.895

19.1

Bolting

24.238

172.370

14.1

40.364

172.370

23.4

Axial Stress (Pressure at g0 end: Not Code req't.)

8.983

68.948

13.0

_______________________________________________________________________________________________

NOTES AND WARNINGS:

Bolt area adaquate, Ab>=Am

Flange : Approx weight = 305. N (based on density of steel)

Flange thru' hub length = 150.9 mm.

Stud-bolts: Approx weight = 131. N (all bolts + nuts).

Approx. length = 194.2 mm.

One or more Shape Factors exceed limits provided by graphs in Code.

Ref. ASME VIII Div. 1,charts 2-7.1 to 2-7.6, equations provided used to obtain factors.

Equivalent pressure is greater than 50% of internal pressure.

Stresses within limits

End

Page 1 of 1

Você também pode gostar

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocumento16 páginasASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Trunnion load calcsDocumento4 páginasTrunnion load calcsChirag Shah50% (2)

- Pipe Stress Manual CalcDocumento62 páginasPipe Stress Manual CalcEsapermana Riyan100% (2)

- Sif B31.3Documento10 páginasSif B31.3Rob Gillespie100% (1)

- Piping Stress Handbook - by Victor Helguero - Part 2 PDFDocumento121 páginasPiping Stress Handbook - by Victor Helguero - Part 2 PDFCESAR100% (2)

- Nozzle CalculationsDocumento2 páginasNozzle CalculationsBaher Elsheikh100% (3)

- Flange CalculationsDocumento3 páginasFlange CalculationssanjaysyAinda não há avaliações

- Norsok M001 MaterialsDocumento31 páginasNorsok M001 MaterialsbreeeeezzzzzeAinda não há avaliações

- Line Stop Welded To Shoe CalculationDocumento16 páginasLine Stop Welded To Shoe CalculationmohdnazirAinda não há avaliações

- Questions For Stress AnalysisDocumento3 páginasQuestions For Stress AnalysisSunday PaulAinda não há avaliações

- Pipe Pressure RatingDocumento1 páginaPipe Pressure RatingbakellyAinda não há avaliações

- CAESAR II TrainingDocumento61 páginasCAESAR II TrainingReaderRRGHT86% (7)

- Reinforcement CalculationDocumento2 páginasReinforcement CalculationVekaymech100% (9)

- Nozzle Movement Calculation GuideDocumento23 páginasNozzle Movement Calculation GuidePriyanathan Thayalan100% (4)

- Flange CalculationsDocumento5 páginasFlange CalculationsswapnavattemAinda não há avaliações

- Piping Stress Critical Lines - Basis For Piping Critical Line ListDocumento4 páginasPiping Stress Critical Lines - Basis For Piping Critical Line Listashish.mathur1Ainda não há avaliações

- Pipe Line Flexibility Manual CalculationDocumento20 páginasPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Caesar GuidelineDocumento152 páginasCaesar Guidelineraghib_afzal0% (1)

- Branch Reinforcement Pad Requirement CalculationDocumento2 páginasBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pipeline Stress Analysis with Caesar IIDocumento16 páginasPipeline Stress Analysis with Caesar IIPugel YeremiasAinda não há avaliações

- Design of Flanges - Loose Hub Type 2010Documento58 páginasDesign of Flanges - Loose Hub Type 2010bakellyAinda não há avaliações

- Flange Dimensions and Pressure Ratings ChartDocumento24 páginasFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocumento8 páginasDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Stress Analysis of GRP GRE FRP Piping System Using Caesar IIDocumento5 páginasStress Analysis of GRP GRE FRP Piping System Using Caesar IIiaftAinda não há avaliações

- Surge Analysis Alabama FacilityDocumento73 páginasSurge Analysis Alabama FacilityCONNOR MENSAH100% (1)

- Calculation For Reinforced PadDocumento4 páginasCalculation For Reinforced Padjsridhar_34750% (2)

- Body Flange Bolt TorqueDocumento1 páginaBody Flange Bolt TorqueLcm Tnl100% (1)

- PIPE STRESS ANALYSIS USING CAESAR IIDocumento90 páginasPIPE STRESS ANALYSIS USING CAESAR IImsdohar100% (1)

- 2006-4200-1J-0004 Rev 0 STN-S Pipe Stress Analysis Report Flare Piping System - ApprovedDocumento98 páginas2006-4200-1J-0004 Rev 0 STN-S Pipe Stress Analysis Report Flare Piping System - ApprovednanoAinda não há avaliações

- Gasket ParametersDocumento9 páginasGasket Parametersttr_1947Ainda não há avaliações

- Flange Leakage Check SheetDocumento1 páginaFlange Leakage Check SheetEhtisham AndrAbiAinda não há avaliações

- Load Check For Shoe Welded SupportDocumento313 páginasLoad Check For Shoe Welded Supportscrbdgharavi100% (2)

- Stress Sample Calculation On Base EllDocumento1 páginaStress Sample Calculation On Base EllLionel TorradoAinda não há avaliações

- Reinforcement Pad CalculationDocumento4 páginasReinforcement Pad CalculationMohammad AbdullahAinda não há avaliações

- Pressure Design Straight Pipe (Run Pipe)Documento6 páginasPressure Design Straight Pipe (Run Pipe)gembirasekaliAinda não há avaliações

- Calculating Stresses PDFDocumento55 páginasCalculating Stresses PDFpilotte7Ainda não há avaliações

- Operating Case Trunnion Calculation Sheet: Input DataDocumento1 páginaOperating Case Trunnion Calculation Sheet: Input DataJagadish JasAinda não há avaliações

- Pipe Stress Training Course - SSUTADocumento10 páginasPipe Stress Training Course - SSUTAalizadeh2222Ainda não há avaliações

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocumento3 páginasASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyAinda não há avaliações

- Wall Thickness Calculation Verification under StressDocumento1 páginaWall Thickness Calculation Verification under StresshhgjdfAinda não há avaliações

- Expansion Loop DesignDocumento11 páginasExpansion Loop DesignsabahiraqAinda não há avaliações

- Pveng: Pressure Vessel Engineering LTDDocumento11 páginasPveng: Pressure Vessel Engineering LTDSivateja NallamothuAinda não há avaliações

- Selection Criteria For Lines Subject To Comprehensive Stress AnalysisDocumento10 páginasSelection Criteria For Lines Subject To Comprehensive Stress AnalysisNithin Zs100% (1)

- Expansion Loop CalculationDocumento2 páginasExpansion Loop Calculationsk130986100% (1)

- Fid1 A, (18072018hdov/hdo 2018-07-18 13-23-10/M021.D)Documento2 páginasFid1 A, (18072018hdov/hdo 2018-07-18 13-23-10/M021.D)Brandon AdameAinda não há avaliações

- Ex6 1Documento3 páginasEx6 1abdallh bakerAinda não há avaliações

- Leafspring AnalysisDocumento7 páginasLeafspring AnalysisdailywaziAinda não há avaliações

- Gradation Hydrometer PI (BH AB1 AS1)Documento10 páginasGradation Hydrometer PI (BH AB1 AS1)Kiran Chandra PrakashAinda não há avaliações

- Sampel TehDocumento2 páginasSampel TehasuwatanaAinda não há avaliações

- FEA Code in Matlab For A Truss StructureADocumento33 páginasFEA Code in Matlab For A Truss StructureAiScribdRAinda não há avaliações

- API 510 PC 30apr05 YNB Case Study 2 Thickness CalculationsDocumento3 páginasAPI 510 PC 30apr05 YNB Case Study 2 Thickness CalculationsMohamed Karim MohamedAinda não há avaliações

- Division Worksheet Practice Problems Under 40 CharactersDocumento6 páginasDivision Worksheet Practice Problems Under 40 Charactersmenaha kaliananAinda não há avaliações

- IEC Technical Committee 82 Standards for Solar Photovoltaic SystemsDocumento23 páginasIEC Technical Committee 82 Standards for Solar Photovoltaic Systemskolombo1776Ainda não há avaliações

- Mechanical Calculation - Inspection Port NeckDocumento18 páginasMechanical Calculation - Inspection Port Neckfaizal rizkiAinda não há avaliações

- Mass Oscillation with Surge ShaftDocumento16 páginasMass Oscillation with Surge ShaftSuresh CAinda não há avaliações

- Biochemistry Pre Laboratory Activities Nos 1 5Documento10 páginasBiochemistry Pre Laboratory Activities Nos 1 5Yeachien MalbaciasAinda não há avaliações

- Pt. Ossiana Sakti Ekamaju: Schedule A: Pricing Schedule Schedule A Part I: Schedule of RateDocumento8 páginasPt. Ossiana Sakti Ekamaju: Schedule A: Pricing Schedule Schedule A Part I: Schedule of RateRendi Ahmadhusein PohanAinda não há avaliações

- Engineering Design Project Dynamics AnalysisDocumento8 páginasEngineering Design Project Dynamics AnalysisNavnoor kaurAinda não há avaliações

- Dimensional Analysis 1-ClasspracticeDocumento2 páginasDimensional Analysis 1-Classpracticeapi-261484540Ainda não há avaliações

- 508x10 CHSDocumento8 páginas508x10 CHSMuhammad BilalAinda não há avaliações

- Bai Bao Nuoc Ngoai Truoc TS 04Documento5 páginasBai Bao Nuoc Ngoai Truoc TS 04EL NeidAinda não há avaliações

- Shooting Black and WhiteDocumento22 páginasShooting Black and Whitemanoj kumar0% (1)

- Comparison of Fatigue Assessment Techniques for HRSGsDocumento12 páginasComparison of Fatigue Assessment Techniques for HRSGsMiguel A. GarciaAinda não há avaliações

- Welding Log BookDocumento5 páginasWelding Log BookPhornlert WanaAinda não há avaliações

- Foot ValveDocumento2 páginasFoot ValvePhornlert WanaAinda não há avaliações

- Vibration TechnologyDocumento18 páginasVibration TechnologySakthimgsAinda não há avaliações

- 2012 LTRDocumento23 páginas2012 LTRAnkit AgrawalAinda não há avaliações

- PSL CatalogueDocumento10 páginasPSL CataloguePhornlert WanaAinda não há avaliações

- Beta New API Standard 618Documento11 páginasBeta New API Standard 618Dae Ick Kim100% (1)

- 2012 LTRDocumento23 páginas2012 LTRAnkit AgrawalAinda não há avaliações

- Flange Leakage CheckDocumento1 páginaFlange Leakage CheckPhornlert WanaAinda não há avaliações

- MS 02 340Documento20 páginasMS 02 340Phornlert WanaAinda não há avaliações

- 2 Kinds of Pulsation StudiesDocumento1 página2 Kinds of Pulsation StudiesmondelAinda não há avaliações

- MS 02 340Documento20 páginasMS 02 340Phornlert WanaAinda não há avaliações

- Interpretations To Asme b31 3Documento17 páginasInterpretations To Asme b31 3Phornlert WanaAinda não há avaliações

- PIPEMILL - Piping Engineering Design and Analysis Pipe Support Shoe Heat TransferDocumento1 páginaPIPEMILL - Piping Engineering Design and Analysis Pipe Support Shoe Heat TransferPhornlert Wana100% (1)

- WWW - Coleparmer.com Techinfo ChemcompresultsDocumento2 páginasWWW - Coleparmer.com Techinfo ChemcompresultsPhornlert WanaAinda não há avaliações

- Swagelok Ball ValveDocumento4 páginasSwagelok Ball ValvePhornlert WanaAinda não há avaliações

- Matlab FemDocumento45 páginasMatlab Femsohailrao100% (3)

- Starline Firesafe Ball ValveDocumento6 páginasStarline Firesafe Ball ValvePhornlert WanaAinda não há avaliações

- Starline Firesafe Ball ValveDocumento6 páginasStarline Firesafe Ball ValvePhornlert WanaAinda não há avaliações

- Fisher Globe ValveDocumento16 páginasFisher Globe ValvePhornlert WanaAinda não há avaliações

- APPENDIX D - CORROSION RATE and REMAINING LIFE CALCULATIONDocumento6 páginasAPPENDIX D - CORROSION RATE and REMAINING LIFE CALCULATIONPhornlert Wana100% (2)

- Pipe MillDocumento1 páginaPipe MillPhornlert WanaAinda não há avaliações

- Marine Seawater ValvesDocumento8 páginasMarine Seawater ValvesPhornlert WanaAinda não há avaliações

- DBB Ansi Din R002 SDocumento2 páginasDBB Ansi Din R002 SPhornlert WanaAinda não há avaliações

- Pipe MillDocumento1 páginaPipe MillPhornlert WanaAinda não há avaliações

- Nikon F3 ManualDocumento46 páginasNikon F3 ManualDefineHumanAinda não há avaliações

- Project ManagementDocumento57 páginasProject ManagementPhornlert WanaAinda não há avaliações