Escolar Documentos

Profissional Documentos

Cultura Documentos

Alkalized Cocoa Powders Article PDF

Enviado por

hozhabrTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alkalized Cocoa Powders Article PDF

Enviado por

hozhabrDireitos autorais:

Formatos disponíveis

Discussion Period (Q&A)

Alkalized Cocoa Powders

Bill Dyer

Blommer Chocolate Company

ocoa powder has gained a signicant amount of attention in the industry, not only because of its volatile price, but also because of the increase in the consumption of cocoa powder in non-confectionery applications (i.e., dairy and bakery segments). Because of this growth in use, it is important to understand the uses and applications of various powders. This paper gives an overview of cocoa powder as it applies to its process and application; identies the types of cocoa based on the alkalization process; determines its flexibility and limitations in a given application; and shows how to select a cocoa powder for a specic application. WHAT IS COCOA POWDER? The FDA defines cocoa powder as the food prepared by pulverizing the material remaining after part of the cocoa fat has been removed from ground cocoa nibs. It is the product obtained by grinding the solids remaining after cocoa butter has been pressed out of chocolate liquor. This separation of cocoa solids and cocoa butter is achieved typically through hydraulic pressing. Chocolate liquor contains about 54 percent cocoa butter; after pressing, cocoa solids will have about 10 12 percent cocoa butter. Cocoa powder evolved in the chocolate industry as a by-product. The original purpose of pressing chocolate liquor was to obtain cocoa butter, which is utilized in the manufacture of chocolate coatings. How-

ever, a variety of new applications, particularly in the dairy and bakery industries, and increased consumption in developing countries have increased demand for cocoa powder. There have been several other factors in the last two years that have contributed to a shortage of supply and increase in cost of cocoa powder. For instance, the use of cocoa butter equivalents and pgpr (a viscosity-reducing emulsier) has reduced the demand for cocoa butter, thus reducing the cocoa butter/cocoa powder production, and outsourcing by large manufacturers that were once large producers of cocoa butter and cocoa cake has taken some manufacturing capacity off line. An increase in demand for cocoa powder coupled with static demand for cocoa butter has created a global shortage of quality cocoa powders and soaring prices. This cocoa supply issue will remain until the demand for cocoa powder is rationalized in line with the relative demand for cocoa butter. Like any other ingredient, cocoa powders have a specic role in food applications. They are expected to deliver avor and color while not imparting any negative attributes. Not all cocoa powders are the same and no one cocoa powder meets the requirements for all applications.This means one needs to have a very clear understanding of whether a cocoa can or cannot perform its functions in a given application. COCOA POWDER PRODUCTION In order to learn about and understand dif-

Dyer is the director of technical sales and service at Blommer Chocolate Company. He joined the company in 1996. Dyer previously worked at Loders Croklaan, Durkee Industrial Foods, and Gill and Duffus Products.

Bill Dyer

128

57th PMCA Production Conference, 2003

Alkalized Cocoa Powders

ferent types of cocoas and how they can be used in various applications, we need to start with a brief overview of the cocoa process, from selection of beans through alkalization. With this in mind, three subjects will be discussed briey: cocoa beans, roasting process and types of roasters. More time will be spent on alkalization processes and cocoa applications. The following terminologies will be used frequently in the rest of this paper: Nib Shell-free cocoa bean pieces. Chocolate liquor Paste resulting from grinding nibs. Press cake Cocoa solids remaining in the press pot after part of the cocoa butter has been removed by hydraulic press (the fat content is generally 10 percent to 12 percent). Kibbled press cake Pieces of crushed press cake after they are removed from the press. Alkalization A process where nibs, chocolate liquor or crushed press cake (coarse cocoa powder) is treated with a suitable alkali solution and, subsequent to alkali treatment, the moisture is removed during drying and/or the roasting process. Cocoa powders derived from these processing options are referred to as nib-alkalized cocoa, liquoralkalized cocoa or cake-alkalized cocoa. Cake-alkalized cocoa is also referred to as powder-alkalized cocoa. Cake alkalization/powder alkalization refers to the alkalization process where crushed cocoa press cake is treated with a suitable alkali solution. Beans The making of cocoa powder is a manystep process that begins with the bean. Each step at each stage of cocoa powder production can have a large impact on the nal powder product application. In The Application of Cocoa Powders in Chocolate Confectionery, Hans Kattenberg very clearly shows the correlation between beans from various origins and their characteristic avor notes (Figure 1). This knowledge is a very helpful tool to predict a flavor profile in powders based on a type of bean or a blend of several beans. Problems can arise due to variable climate conditions during a given year, changing the profile for a given origin. Political instability can affect the availabilities of specific types of beans in specific quantities at times. These unpredictable variables have prompted the industry to put more emphasis on processing, specifically roasting and alkalization, which are the two key processing steps that can assure quality and maintain quality consistently. Roasting In general, there are three ways to roast cocoa beans or cocoa nibs. Fluid bed roasters are designed for bean roasting. In these roasters cocoa beans are in constant motion from hot air on an oscillating conveyor. These roasters are commonly used for large-volume operations where the objective is to roast one or two types of beans. The second category of roaster is the static bed roaster where a bed of beans or nibs is conveyed horizontally or vertically through various heating and cooling zones. There are two types of static bed roasters. In the rst type, a bed of nibs or wet nibs (after alkalization) travels horizontally through several zones where the wet nibs are first dried, then roasted and finally cooled. This type is more practical in the nib alkalization process because this roaster can be used not only for roasting, but drying as well. Flavor Notes of Cocoa Beans

Origin Indonesia Malaysia & New Guinea West Africa Ecuador Figure 1 Typical Flavor Prole Bitter to acrid Acid to astringent Rich cocoa avor Floral/perfumy

An increase in demand for cocoa powder coupled with static demand for cocoa butter has created soaring prices and a global shortage of quality cocoa powders.

57th PMCA Production Conference, 2003

129

Alkalized Cocoa Powders

By controlling the degree of alkalization, the types of alkali applied, the cocoa bean types and at which stage of the cocoa process the alkalization takes place, a whole spectrum of alkalized cocoa powders can be produced.

The second type of static bed roaster is more suited to cocoa beans and not nibs. The beans travel vertically through several heat zones. Roasting is achieved by forcing heated air through the bed of beans as it travels through each zone. With this roaster, there are options to sterilize the beans with a pressure cooker-type system prior to roasting. This approach allows one to obtain liquors and powders free of spore-forming bacteria. The third roasting method utilizes the rotary drum. Rotary drum roasters are used in nib roasting and are the most widely used form of roasters. They are also used in the nib alkalization process. After the alkalization treatment, wet nibs are dried and roasted in drum roasters. Hot air is blown into a rotary drum, causing maximum exposure of nibs to heat. Utilizing this method, process parameters can be customized to achieve a range of flavors and colors for natural cocoa powders (nonalkalized cocoa powders). Powders Cocoa powders are categorized based on two factors. First, cocoa powders are categorized by the percent of cocoa butter in the powder. Powders with 10 to 12 percent cocoa butter are referred to as low fat cocoas. Fat contents of 16 to 18 percent are called medium fat cocoa. Fat contents of 22 to 24 percent are called breakfast cocoa or high fat cocoa. Secondly, cocoa powders are further differentiated based on whether or not powders were processed with alkali at the nib, liquor or cake stages. Powders not processed with alkali are referred to as cocoa or natural cocoa, and alkalized cocoas are referred to as simply cocoa processed with alkali or dutch process cocoa. Today, 95 percent of the powders used in the food industry are low fat. Natural cocoa powder varieties are few because they are limited to the types of cocoa beans available for blending and to the type of cocoa bean roasters. Conversely, there are many types of alkalized cocoa powders. By controlling the degree of alkalization, the types of alkali applied, the cocoa bean types and at which stage of the cocoa process the alkalization takes place, a whole spectrum of alkalized cocoa powders can be produced. ALKALIZATION The alkalization process has been well documented by Mike Kostic. In Cocoa Alkalization he covers in detail the types of alkali and the types of alkalizing methods. The purpose of alkalization is threefold: To neutralize the acidity of the cocoa beans and remove astringent cocoa avor. To promote reaction between cocoa pigment and alkali in the presence of oxygen and heat to develop colors ranging from light brown to red, and in some cases very dark colors. To promote avor development by promoting reaction between protein and reducible sugars present in the cocoa beans. Alkalized cocoa powders can be obtained by using any one of these approaches: liquor alkalization, powder alkalization or nib alkalization. Each process results in certain advantages and disadvantages. Liquor Alkalization Liquor alkalization is ideal to get mild-avored alkalized cocoa powders. However, the process is limited to the amount of moisture that can be added during alkali treatment. The ideal amount of water required to promote optimum reaction during alkali treatment is not possible with liquor because water and cocoa butter are not miscible and there is a potential for degradation of the cocoa butter, also leading to viscosity issues in the finishing of the process. Limited amounts of water added to liquor to promote alkali treatment will yield a narrow

130

57th PMCA Production Conference, 2003

Alkalized Cocoa Powders

range of color and avor proles. Similar to nib-alkalized cocoa, there is added cost with this method of production since the cocoa butter obtained from this process requires deodorization. Powder Alkalization or Cake Alkalization Powder alkalization is a less sophisticated process requiring a basic reacting vessel with heat and vacuum capabilities. In this process press cake is crushed to a coarse powder prior to treatment with a suitable alkali solution. It is a cost-effective option because, unlike nib or liquor alkalization, the cocoa butter is not factored into the cost of cake-alkalized cocoa. However, the color and avor attributes of cake-alkalized powders are limited. Powder alkalization is useful in making very dark cocoa powders where avor is not a criterion. Cocoa powders consist of 19 to 20 percent protein and 10 to 15 percent starch. The increased surface area in the powder to be alkalized exposes these proteins and starches to heat and moisture. As a result, during the drying process protein is denatured, giving unfavorable textural effects in dairy and in some confectionery applications. Starches go through irreversible chemical modications due to heat and hydration and as a result are jellied. Chemical and physical changes of proteins and starches during powder alkalization also have an impact on grinding capabilities of batches after the alkalization process. It is difficult to grind alkalized cocoa cake to achieve a neness of 99.5 percent through 200 US mesh, which is the industry standard. Grinding throughput rates drop significantly in order to achieve a good fineness. The impact on grinding also relates to the degree of alkalization; the higher the degree of alkalization in the cocoa, the greater the decrease in grinding throughput rates. Nib Alkalization Nib alkalization provides the best option. There is less detrimental impact on the composition of nibs during alkalization because the components of the nibs are still in their natural state. By contrast, in chocolate liquor alkalization, all of the cocoa butter is released and nonfat components are in emulsion phase, making the alkalization less effective. A stronger alkali treatment to liquor can lead to detrimental effects on cocoa butter. The powder is even more sensitive to alkalization. In powders, the nonfat components, specifically proteins and starch, are concentrated because the fat is removed and they are subjected to a maximum exposure as a result of particle size reduction from grinding into powder. Given the physical and chemical state of starting material for alkalization, it should not be surprising to us that nib alkalization offers the best results for color and avor attributes in cocoa. Another benet of nib alkalization is that during this process spore-forming thermophylic and mesophylic bacteria are greatly reduced. The reduction of these bacteria is especially benecial to the dairy industry as the presence of spore formers in dairy products, such as cocoa-avored milk beverages, can shorten the shelf life drastically. The disadvantage of nib alkalization is that powders derived from this process are expensive. Every pound of nib-alkalized cocoa results in one pound of cocoa butter, and cocoa butter pressed from nib-alkalized liquor must be deodorized, which is an added manufacturing cost. Cocoa butter has the highest commodity value in the butter/powder equation, therefore the cost of the powder is dictated by the cost of cocoa butter involved in nib alkalization (Figure 2). Also, nib alkalization is more capital intensive, adding to manufacturing complexity and cost.

There is less detrimental impact on the composition of nibs during alkalization because the components of the nibs are still in their natural state.

57th PMCA Production Conference, 2003

131

Alkalized Cocoa Powders

Another benet of nib alkalization is that during this process sporeforming thermophylic and mesophylic bacteria are greatly reduced.

MATRIX OF PH VERSUS COLOR IN COCOA POWDERSXXXXXXXXXXXX As we discussed, the objective of alkalization is to neutralize the acidity and promote the color development in cocoa powders. There is a close correlation between color and pH of cocoa powders. Powders with light brown colors have a pH of 6.5 to 7.0 and the pH of darker and red powders ranges from 7.0 to 8.0. Very dark powders such as black can have a pH of up to 8.2. This is seen in Figure 3 where the color of cocoa paste (25 percent cocoa powder, 75 percent water) is measured by a HunterLab colorimeter. APPLICATIONS Cocoa powders are used in a wide range of applications in the food industry. It is the only ingredient that remains as a by-product in a chocolate plant where chocolate liquor is pressed and yet it is an ingredient that is in great demand in the bakery, dairy and beverage industries. Color of Cocoa Powders in Applications Before we discuss the applications, we need to address the unique property of colors seen in cocoa powders. The colors of cocoa powders in a given application can be defined similar to food colors, i.e., lakes (which are dyes plated on a carrier), or dyes (which are water-soluble pigments). The visual perception of powder colors and applications of powders in oil-based or anhydrous products are analogous to lakes except cocoa powders visual appearance is more complex. The powder color can vary depending on the cocoa butter as well as the orientation of the cocoa butter crystals in the powder. During shelf life, due to fluctuations of temperature, the cocoa butter crystals will melt and recrystallize, but never in the original orientation, and the crystals may even shift to the surface of the cocoa particle. This constant shift in fat crystals changes the appearance of powders, resulting in different color perception of the same powder, and is often mistaken for color degradation or for a deviation in color control from the specication. The higher the fat content in powder, the greater the changes in visual perception. While the visual appearance of the powder may be alarming, due to cocoa butter bloom, it will not affect the product application. In a water-based application, the pig-

Cocoa Butter/Powder Prices

3.00 2.75 $4,500 $4,250 $4,000

Butter & Cake Ratios

2.50 2.25 2.00 1.75 1.50 1.25 1.00 0.75 0.50 0.25 0.00

$3,750 $3,500 $3,250 $3,000 $2,750 $2,500 $2,250 $2,000 $1,750 $1,500 $1,250 $1,000 $750 72 74 76 78 80 82 84 86 88 90 92 94 96 98 00 02 $500

73

75

77

79

81

83

85

87

89

91

93

95

97

99

01

Butter Ratio

Figure 2

Cake Ratio

Futures Price

Cocoa Powders pH versus Color

BLACK DARK DUTCH RED DUTCH DUTCH B A L PH

NATURAL 0 5 10 15 20 25

The L value is indicative of darkness, the A value is indicative of red color and the B value is indicative of brown color in cocoa powders

Figure 3

Futures Price

132

57th PMCA Production Conference, 2003

Alkalized Cocoa Powders

ments are dissolved like dyes and the perception of color is different. Two powders may look similar in their raw form before being placed in an application, but appear differently in a water-based application. Conversely, two powders may appear different in their raw form and yet result as similar colors in application. In Figure 4 the three powders appear to be different in color, and the color measured by HunterLab agrees with visual perception. These three cocoa powders are the same but they were exposed to different temperatures over time, resulting in a change in the visual color. Typical cocoa powder avors and their applications can be seen in Figure 5. In bakery, dairy, beverage and other water-containing product applications there is enough water for colors to leach out of cocoa particles to deliver the appealing colors in the nished product. In confectionery applications such as confectionery coatings, meltaways, oil- or fat-based llings and in some truffles, water-soluble colors do not play a role because they cannot deliver colors in oil phase. But what is perceived is the color of the cocoa itself. There are no oil-soluble pigments in the cocoa bean and if they are present in trace amounts, they are removed along with cocoa butter during pressing. Compound Coatings In compound coatings, the benets of nibalkalized cocoa powders are very easily assessed. Due to the higher avor and color intensity of alkalized cocoa powders, a reduction in the amount of powder can be achieved in compound formulas (Figure 6). The graph in Figure 7 shows the sensory assessment of the two products referred to in Figure 6. The compound coating with alkalized cocoa at a lower application level functions similar to natural cocoa without compromising color and avor attributes.

Figure 4

Particle Size Relationship to Application The industry standard for fineness of cocoa powders is a minimum of 99.5 percent through a US 200 mesh, which means 99.5 percent of the particles must be under 74 microns. The fineness is less critical in baked goods and compound coatings. Fineness is less detectible in baked goods; in compound coatings a further particle size reduction is done during the refining process. The most critical role of cocoa particles is in water-based applications such as icings, toppings, syrups, puddings, fillings, nougats, aerated creams and truffles. In these applications, cocoa particles will swell due to hydration leading to a perception of coarse texture. The degree of swelling of particles depends Powder Color at Various Temperatures

Due to the higher avor and color intensity of alkalized cocoa powders, a reduction in the amount of powder can be achieved in compound formulas.

Cocoa Powders Typical Flavors and Applications

Type of Cocoa Typical Flavor Naturalnonalkalized Milk, cocoay notes Common Applications Compounds, syrups, bakery toppings, confectionery Alkalizedlight dutch Mild, cocoay notes with mild Dairy, beverage, creams, alkali undertones syrups, toppings, confectionery Alkalizedred Moderate to strong alkali Bakery, dairy, beverage, notes creams, confectionery Alkalizeddark Milk to moderate alkali notes Bakery, confectionery Alkalizedblack Intensely unique alkali avors Cookies, coloring agent Figure 5

57th PMCA Production Conference, 2003

133

Alkalized Cocoa Powders

The most critical role of cocoa particles is in water-based applications. In these applications, cocoa particles will swell due to hydration leading to a perception of coarse texture.

on several factors in various cocoa powder applications: Type of alkalized cocoa powder The amount of water in the formula Processing heat Time line from process to consumption (aging process and shelf life) Powder-alkalized cocoa powders respond to heat and hydration differently compared to nib-alkalized cocoa powders. This difference could be due to the state of proteins and starches in the cocoa powder. Denatured proteins and jellied starches may behave differently compared to the same components found in nib-alkalized cocoa powders. In an attempt to demonstrate this behavior two test models were selected. In the first model (Figure 8) samples of cocoa powder and water suspension (1 part cocoa and 10 parts water) were stored at 65C for 24 hours to simulate an accelerated shelf-life condition. Samples were collected from the top, middle and bottom of each suspension. Compared to the particle size of dry powders We see an increase in the population of large particles. In the second model, a lling was made with the same cocoa powders as before but using the formula in Figure 9. Corn syrup, condensed milk and cocoa powder blends were stored at 65C for 24 hours to simulate an accelerated shelf life condition. Sensory (Figure 10) and particle size analysis of the llings show that cake- or powderalkalized cocoa powders result in a grittiness as a result of swelling of the particle. PH of Cocoa Powders in Applications Although the neutralizing of acids in cocoa powders does have avor benets, a higher degree of alkalization can result in performance problems. Following are some of the critical factors related to applications and pH of cocoa powders: In baked goods, especially in products where leavening agents are used, higher pH cocoa powders will interfere with leavening agents, causing larger air bubbles in cake and overspreading of cookies. In puddings and pie fillings, excess free alkali in cocoa powders interfere with jelling mechanisms of starch molecules and, as a result, end products either take a long time or fail to thicken. In chocolate syrups and toppings, pH of the finished product is targeted to be in

Compound Coatings Natural Versus Alkalized

Compound Coating with Natural Cocoa Powder Sugar Fractionated palm kernel oil Natural cocoa Skim milk Lecithin Salt Vanillin Articial avor Compound Coating with Alkalized Cocoa Powder Sugar 33.8% Lactose 4.0% Fractionated palm kernel oil 31.0% Cake-alkalized cocoa 2.0% Nib-alkalized cocoa 2.0% Skim milk 23.8% Lecithin 0.3% Salt 0.08% Vanillin 0.02% Articial avor 0.02%

33.8% 31.0% 8.0% 23.8% 0.3% 0.08% 0.02% 0.02%

Figure 6

Flavor Prole of Compound Coatings Natural versus Alkalized Cocoa

Cocoa

Alkalized

Sweet

Caramel Natural Figure 7 Alkalized

Particle Size Analysis of Nib- and Cake-Alkalized Cocoa

Dry Particle Size Nib < 74 microns < 44 microns Figure 8 Cake 20 grams of cocoa in 200 ml of water at 160F incubated for 24 hours Nib Cake Top Mid Bottom Top Mid Bottom 99.79 99.50 99.25 98.53 96.62 96.44 98.02 97.32 96.81 96.19 91.60 91.46

100 100 99.92 100

134

57th PMCA Production Conference, 2003

Alkalized Cocoa Powders

the range of 4.0 to 4.5 because at this range preservatives such as potassium sorbate are more effective. Therefore a blend of natural and lightly alkalized cocoa powders is ideal in such applications. The improper selection of cocoa powders can often result in a change of viscosity due to particle swelling. SUMMARY We are certain that there is a difference between nib-alkalized cocoa powders and powder-alkalized cocoa powders in milling powders, in flavor and color, and also in water-based applications. We are also certain that the cocoa bean contains high amounts of protein and starch, and that protein and starch are sensitive to heat and hydration. However, there is no research evidence to confirm the relationship between the application responses of alkalized cocoa powders and the state of proteins and starches. We are not certain whether modification of proteins and starches in powder-alkalized cocoa powders leads to difficulties in milling cocoa powders and swelling of particles in response to heat and hydration in applications. Given the information on how cocoa was processed, one can make a prudent assessment on how best to use this powder in a specic application. Application Suggestions: Identify the application objectives and determine if the application is water-based or fat-based. In fat-based applications powders should be selected based on color assessment using a protocol that is consistent. A quick method to assess the color in cocoa is to place 1020 g of samples to be tested along with a color standard in a 95F hot cabinet for 30 minutes and visually evaluate colors or measure color by using a colorimeter. Flavor Prole of Confectionery Fillings Cake-Alkalized versus NibAlkalized Cocoa

Alkalized

For water-based applications, cocoa powders may be evaluated in milk. A simple and quick method is to suspend 2 g of cocoa and 2 g of sugar in 100 ml of warm low fat milk (100110F). Milk provides a white hue, which aids in seeing subtle differences in color, and its slight sweetness will aid in identifying differences in avors or unacceptable avors. Talk to your cocoa supplier to learn more about cocoa processing. REFERENCES

Chocolate and Cocoa Edited by Ian Knight. Blackwell Science Ltd., 1999. Kattenberg, Hans R. Manufacturing Confectioner, 1995. Kostic, Michael J. Manufacturing Confectioner, 1997. Meursing, E.H. Manufacturing Confectioner, 1980. Trout, Richard. Manufacturing Confectioner, 2000.

Although the neutralizing of acids in cocoa powders does have avor benets, a higher degree of alkalization can result in performance problems.

Confectionery Filling

Corn syrup Condensed milk Fondant Coconut oil Cocoa Lecithin Salt Vanillin Articial avor Figure 9 8.0% 35.26% 34.78% 14% 7.5% 0.1% 0.11% 0.11% 0.14%

Graininess

Cocoa

"Fudgy" Cake Alk. Figure 10

Sweet Nib Alk.

57th PMCA Production Conference, 2003

135

Você também pode gostar

- Emulsifiers in Chocolate V7Documento26 páginasEmulsifiers in Chocolate V7Prasanna GopalrathinamAinda não há avaliações

- Kostic 1997Documento3 páginasKostic 1997Dimas RahadianAinda não há avaliações

- Effects of Different Emulsifiers On Rheological and Physical Properties of ChocolateDocumento6 páginasEffects of Different Emulsifiers On Rheological and Physical Properties of ChocolateAnisah CuzAinda não há avaliações

- AWT Pectin As Gelling AgentDocumento4 páginasAWT Pectin As Gelling AgentDayana AriasAinda não há avaliações

- Wills1998 - Water Activity and Its Importance in Making CandyDocumento4 páginasWills1998 - Water Activity and Its Importance in Making CandyKSX100% (1)

- Confectionery Science and Technology - ChocolateDocumento62 páginasConfectionery Science and Technology - ChocolateTran Duy ThaAinda não há avaliações

- Agenda: - Moulding StarchDocumento60 páginasAgenda: - Moulding StarchISRAEL ATONAL SALAZAR100% (2)

- Asian Noodles: Science, Technology, and ProcessingNo EverandAsian Noodles: Science, Technology, and ProcessingGary G. HouAinda não há avaliações

- Whey Powder ProcessingDocumento13 páginasWhey Powder Processinghozhabr100% (1)

- CHEF Quiz Multiple Choice QuestionsDocumento9 páginasCHEF Quiz Multiple Choice QuestionsMylene Elvina100% (3)

- Radisson Blu UdaipurDocumento13 páginasRadisson Blu UdaipurRaakesh KanodiaAinda não há avaliações

- AW ApplicationNote ChocolateDocumento4 páginasAW ApplicationNote Chocolateulva mohtarAinda não há avaliações

- Chocolate Functional FoodDocumento0 páginaChocolate Functional FoodrendaoAinda não há avaliações

- Fat Bloom in Chocolate and Compound CoatingDocumento34 páginasFat Bloom in Chocolate and Compound CoatingSartika Mutiarasani100% (1)

- The Journey From Cacao Pod To ChocolateDocumento9 páginasThe Journey From Cacao Pod To Chocolateronalit malintadAinda não há avaliações

- Experiments in Tempering ChocolateDocumento7 páginasExperiments in Tempering Chocolateklruppe3950Ainda não há avaliações

- Invert Sugars and Blends Offer Solutions To A Range ofDocumento4 páginasInvert Sugars and Blends Offer Solutions To A Range ofcinnamaldehidAinda não há avaliações

- Adam Lechter: Resident Course in Confectionery TechnologyDocumento73 páginasAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenAinda não há avaliações

- Palsgaard® PGPR 4125Documento3 páginasPalsgaard® PGPR 4125Erik ChoqueAinda não há avaliações

- The Solubility of The SugarsDocumento2 páginasThe Solubility of The Sugarsadevirgie100% (1)

- Lactose Crystalization TM 2537-1eDocumento4 páginasLactose Crystalization TM 2537-1eJuan Jose Escobar P.Ainda não há avaliações

- HUMECTANTDocumento12 páginasHUMECTANTSakhtar_ft100% (2)

- How To Substitute Chocolate, Chocolate SubstitutionsDocumento4 páginasHow To Substitute Chocolate, Chocolate SubstitutionsuraiAinda não há avaliações

- Aerated Food GelsDocumento12 páginasAerated Food GelsOana SilviaAinda não há avaliações

- Chocolate Making NotesDocumento6 páginasChocolate Making Notesapi-240759474Ainda não há avaliações

- 010-Particle Size Analysis of Cocoa PowdersDocumento3 páginas010-Particle Size Analysis of Cocoa PowdersAlvian Maulana SAinda não há avaliações

- AAK CBE BrochureDocumento16 páginasAAK CBE BrochureSami AlzahraniAinda não há avaliações

- Sugar Syrups From MaizeDocumento8 páginasSugar Syrups From Maizesyenikeyev3220Ainda não há avaliações

- Emulsifier in ChocolateDocumento2 páginasEmulsifier in ChocolateyongqeeAinda não há avaliações

- Extruded Marshmallow NCA Candy School Pilot Plant Exercise: Ingredients Weight For 1500 GMDocumento10 páginasExtruded Marshmallow NCA Candy School Pilot Plant Exercise: Ingredients Weight For 1500 GMJulio KinenAinda não há avaliações

- Chocolate ProcessDocumento49 páginasChocolate Processsarpal1234Ainda não há avaliações

- AWT Pectin Amid CS 005Documento8 páginasAWT Pectin Amid CS 005Dayana AriasAinda não há avaliações

- Cocoa ProductionDocumento57 páginasCocoa ProductionumeshAinda não há avaliações

- Nutela WikiDocumento3 páginasNutela WikinecitacAinda não há avaliações

- Caramel - Raw Materials and Formulations: Back To Basics - CaramelDocumento7 páginasCaramel - Raw Materials and Formulations: Back To Basics - CaramelJulio KinenAinda não há avaliações

- Milk PowderDocumento28 páginasMilk PowderJinggazoomAinda não há avaliações

- Viscosity GLC SyrupsDocumento18 páginasViscosity GLC SyrupsJán PeterAinda não há avaliações

- Soft Caramel ReportDocumento14 páginasSoft Caramel ReportHans Demas Kosasih100% (1)

- 1-DAIRY PRODUCTS (Lecture 6)Documento31 páginas1-DAIRY PRODUCTS (Lecture 6)inshirahizhamAinda não há avaliações

- AWT Pectin Classic As 511Documento3 páginasAWT Pectin Classic As 511Dayana AriasAinda não há avaliações

- Cocoa Butter CrystallisationDocumento8 páginasCocoa Butter Crystallisationmarica56100% (1)

- Filling Cream Pada Biskut, WaferDocumento4 páginasFilling Cream Pada Biskut, WaferFadhilla SetyaAinda não há avaliações

- Latest Technology in Cereals ProductionDocumento5 páginasLatest Technology in Cereals ProductionNadherah MohamadAinda não há avaliações

- Fulltext 12088 PDFDocumento83 páginasFulltext 12088 PDFkharajurgAinda não há avaliações

- Cocoa Chemistry and Processing PDFDocumento70 páginasCocoa Chemistry and Processing PDFdindaAinda não há avaliações

- Yogurt ProductionDocumento2 páginasYogurt ProductionFifi Lifia0% (1)

- Stabilisers Used in Ice CreamDocumento5 páginasStabilisers Used in Ice CreamAshima SharmaAinda não há avaliações

- ParleDocumento56 páginasParlenamrocks0% (2)

- Soybean Protein Concentrates-FAODocumento6 páginasSoybean Protein Concentrates-FAOyanxunAinda não há avaliações

- Wafers: Basic Wafer TypesDocumento7 páginasWafers: Basic Wafer TypesSebastianHornaAinda não há avaliações

- Processing of Cereal GrainsDocumento43 páginasProcessing of Cereal GrainsSagar ShahAinda não há avaliações

- Chocolate (Pralines) : NeededDocumento5 páginasChocolate (Pralines) : NeededCristian VasilescuAinda não há avaliações

- Nougat, Fruit Chews & Taffy: Barb KlubertanzDocumento45 páginasNougat, Fruit Chews & Taffy: Barb KlubertanzJulio Kinen100% (1)

- Mechanisms of Crystallization in Ice CreamDocumento10 páginasMechanisms of Crystallization in Ice CreamgombossandorAinda não há avaliações

- Cake Quality and Evaluation BAKERpaperDocumento9 páginasCake Quality and Evaluation BAKERpaperGaganpreet KaurAinda não há avaliações

- 5 Production of Ice Cream PDFDocumento5 páginas5 Production of Ice Cream PDFIJEAB JournalAinda não há avaliações

- B) Chocolate (Same) C) Non - Chocolate Confectionary ProductDocumento33 páginasB) Chocolate (Same) C) Non - Chocolate Confectionary ProductMickey Singh100% (1)

- GS Recipe Library: Bakery Filling CreamsDocumento3 páginasGS Recipe Library: Bakery Filling CreamsfernandoferozAinda não há avaliações

- Influence of Alkaline Formulation On Oriental Noodle Color and TextureDocumento7 páginasInfluence of Alkaline Formulation On Oriental Noodle Color and Textureelisa1027Ainda não há avaliações

- Confectionery and Chocolate Engineering: Principles and ApplicationsNo EverandConfectionery and Chocolate Engineering: Principles and ApplicationsAinda não há avaliações

- Cocoa ProcessingDocumento20 páginasCocoa ProcessingystdfmAinda não há avaliações

- Lessons From Chocolate ProcessingDocumento3 páginasLessons From Chocolate ProcessingIndra bayuAinda não há avaliações

- Chocolate and FatsDocumento2 páginasChocolate and FatsMaría Pía Mogues100% (3)

- GEA Standomat Automatic Standardization Unit Tcm25 67307Documento16 páginasGEA Standomat Automatic Standardization Unit Tcm25 67307hozhabrAinda não há avaliações

- 03 Maggie Becher String Cheese CITDocumento35 páginas03 Maggie Becher String Cheese CIThozhabrAinda não há avaliações

- Pipeline 2009 Vol21 01Documento12 páginasPipeline 2009 Vol21 01hozhabrAinda não há avaliações

- Aseptic Terminology PDFDocumento14 páginasAseptic Terminology PDFhozhabrAinda não há avaliações

- Agitator Shaft DeflectionDocumento9 páginasAgitator Shaft DeflectionTan Chee MingAinda não há avaliações

- Dairy 100 TABLE PDFDocumento9 páginasDairy 100 TABLE PDFhozhabrAinda não há avaliações

- Air Filtration Training Manual - 23 Oct 2008Documento43 páginasAir Filtration Training Manual - 23 Oct 2008Alper İstotanAinda não há avaliações

- 4 51 MM 63 MM 76 MM: Capacity M /HDocumento1 página4 51 MM 63 MM 76 MM: Capacity M /HhozhabrAinda não há avaliações

- Cooled CreamDocumento1 páginaCooled CreamhozhabrAinda não há avaliações

- Tle 9 - Cookery 2ND Quarter ExaminationDocumento5 páginasTle 9 - Cookery 2ND Quarter ExaminationJessa G. CalooyAinda não há avaliações

- Menu GrabDocumento1 páginaMenu GrabSyazwanAinda não há avaliações

- SoulmateDocumento4 páginasSoulmateFarley ElliottAinda não há avaliações

- Unit 11 Pickles, Chutneys, Sauces and Tomato Products: StructureDocumento24 páginasUnit 11 Pickles, Chutneys, Sauces and Tomato Products: StructureS NanzAinda não há avaliações

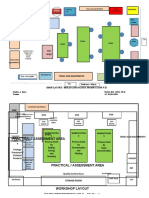

- SHOP LAYOUT BPP Food ProcDocumento3 páginasSHOP LAYOUT BPP Food ProcMylina Fabi67% (3)

- At The Grocer's, Greengrocer's, Baker's, Butcher's Quantities and ContainersDocumento1 páginaAt The Grocer's, Greengrocer's, Baker's, Butcher's Quantities and Containersdavidmore84Ainda não há avaliações

- Some-Any-Much-Many-A Few-A Little PDFDocumento1 páginaSome-Any-Much-Many-A Few-A Little PDFKevin Santiago Baron LeonAinda não há avaliações

- The Botanical Bar Menu - South Yarra MelbourneDocumento1 páginaThe Botanical Bar Menu - South Yarra MelbourneThe BotanicalAinda não há avaliações

- Recipe: Fresh Spring Roll Appetizer Yield: 8 PcsDocumento4 páginasRecipe: Fresh Spring Roll Appetizer Yield: 8 PcsMich PringAinda não há avaliações

- HB UoE Unit 5Documento19 páginasHB UoE Unit 5Guillermo JaureguiAinda não há avaliações

- Jackie Arceo - Co-Founder of Local Edition Coffee and TeaDocumento3 páginasJackie Arceo - Co-Founder of Local Edition Coffee and TeaMykel Alburo100% (1)

- Horlicks Draft All in OneDocumento8 páginasHorlicks Draft All in OneDanielNathAinda não há avaliações

- Track Changes Oreo BallDocumento5 páginasTrack Changes Oreo Ballapi-520060335Ainda não há avaliações

- Лексика методичкаDocumento66 páginasЛексика методичкаNatalie PupkovaAinda não há avaliações

- 25 Amazing Facts About FoodDocumento32 páginas25 Amazing Facts About Foodtrebornaggy100% (3)

- German CuisineDocumento52 páginasGerman CuisineSriramSachinGudimellaAinda não há avaliações

- Pathfit 1 - Food LogDocumento7 páginasPathfit 1 - Food LogErwin Mark ManaliliAinda não há avaliações

- Inventory Control Spreadsheet: OTC & Medicine Inventory Control Spreadsheet: OTC & MedicineDocumento221 páginasInventory Control Spreadsheet: OTC & Medicine Inventory Control Spreadsheet: OTC & MedicineAzmi FauziAinda não há avaliações

- Slang Names For AlcoholDocumento4 páginasSlang Names For AlcoholFAIZA MALIKAinda não há avaliações

- Culinary Courses AND Recipes: By: David VillartaDocumento16 páginasCulinary Courses AND Recipes: By: David VillartaDavid VillartaAinda não há avaliações

- Global Healing Complete Body Cleanse Program InstructionsDocumento84 páginasGlobal Healing Complete Body Cleanse Program InstructionsdyneaAinda não há avaliações

- Mangoes Round The Year Class 5 Notes CBSE EVS Chapter 4 (PDF)Documento4 páginasMangoes Round The Year Class 5 Notes CBSE EVS Chapter 4 (PDF)krishna GAinda não há avaliações

- Jam RecipesDocumento23 páginasJam RecipesiMiklaeAinda não há avaliações

- TLE HE ReviewDocumento7 páginasTLE HE ReviewMarites RegaladoAinda não há avaliações

- AdlaiDocumento10 páginasAdlaiMerlyn LabrillaAinda não há avaliações

- McDonalds USA Ingredients Listing For Popular Menu ItemsDocumento19 páginasMcDonalds USA Ingredients Listing For Popular Menu ItemsMatt NooxAinda não há avaliações

- Shelf Life Testing of Fresh MeatDocumento4 páginasShelf Life Testing of Fresh Meatlinpok100% (1)

- Steamed Bream With Ginger and Spring OnionsDocumento1 páginaSteamed Bream With Ginger and Spring Onionsapi-55495178Ainda não há avaliações