Escolar Documentos

Profissional Documentos

Cultura Documentos

Alloys

Enviado por

Helinar KryxeraDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alloys

Enviado por

Helinar KryxeraDireitos autorais:

Formatos disponíveis

Alloys Much of human civilization revolves around metals.

Since pre-historic times, people have used metals to meet their needs. But metals have their limits. Metals like iron oxidize (rust) quickly, while those that do not rust (such as aluminium) are not as strong. To overcome these problems, people started mixing metals to produce new materials. These mixtures of metals are called alloys, and they can have properties quite different from the pure metals that make up the alloy. For example, people added tin (12%) to copper (88%) to make bronze. Bronze is harder than both tin and copper, and also easier to work with. Unlike pure metals, alloys do not have fixed melting and boiling points. Instead, they melt and boil over a range of temperatures. Some alloys are quite similar to the metals mixed to make them, while others have properties quite different from those of their ingredients. Steel is very There is a Turkish legend that in 1623 an alchemist discovered the amazing sound produced when he accidentally dropped a bronze ingot on the ground. Thus, cymbals were born. similar to iron, and white gold - a nickel-gold alloy - looks very similar to nickel. However, when nickel is mixed with copper and zinc to make an alloy called German silver, the alloy (unlike nickel) is no longer magnetic. Similarly, mixing copper (brown) with gold produces a pink alloy that looks quite different from both copper and gold. Bronze The first alloy to be made and used in large quantities by man was bronze. It is thought to have got its name from the Italian word "bronzo", or the Persian word "berenj". Almost all known ancient civilizations and cultures used bronze. Early uses of bronze go back to 4000BC, but it gained wide usage closer to 3000BC. At first, bronze was made by alloying copper with arsenic. After some time, the arsenic was replaced by tin which is non-toxic. Bronze made of copper and tin is also harder and easier to cast into different shapes. In addition to weapons and armor, bronze was also used to make everyday articles such as jugs, vases, pots and pans from bronze. Ancient civilizations also made statues out of bronze. Today, bronze is used mainly to make decorative items. Unlike steel, bronze does not generate sparks when struck against a hard surface. So it is used to make hammers, mallets, wrenches and other tools for use in situations where sparks would be dangerous. In India, a lot of bronze is still used to make statues of god and goddesses. Bronze is also used to

make a variety of instruments such as bells, saxophones and cymbals. Nearly all professional cymbals are made of bronze. Steel Alloys can contain materials other than just metals. For example, carbon, a non-metal, mixes with iron to make steel. Ancient people added some carbon to ingots of iron, and melted them together. When the mixture cooled, they found they had steel - stronger than iron, and more resistant to corrosion. If too much carbon is added, the steel becomes harder but brittle. About 500 years ago, people realised that adding a little bit of manganese to steel makes it less brittle. Since then, people have added other elements to steel to give it special properties. Adding molybdenum makes steel stronger, while chromium gives it shine and makes it stainless. Adding tungsten makes steel more durable. Steel is a very useful alloy that contains over 95% iron, up to 2% carbon, and trace quantities of other metals like manganese, molybdenum and tungsten. The earliest steel has been found in East Africa, dating back to 1400BC. The ancient Chinese used steel from the 4th century BC onwards. An early use of steel was to make weapons and armor. Steel weapons were stronger and more durable than those of bronze or iron, and the superiority of steel changed the course of many a battle. Several types of steel were developed. Wootz steel was a durable type of steel used by people in India and Sri Lanka 2500 years ago. Damascus steel, named after the place where it was developed, originated from Wootz steel. When Europe was attacked by Middle-Eastern warriors carrying sharp swords made of Damascus steel, Europeans too learnt to forge swords of similar steel. In the 16th and 17th centuries, blister steel was made in Britain from wrought iron bars. In the 18th century, Europeans made crucible steel by melting steel at high temperatures in special furnaces. Since the late 1880s, modern technology, using electricity, enabled us to make steel on a much larger scale than ever before. After the Industrial Revolution, new inventions such as cars and planes have increased the demand for steel. Steel has many uses, starting from small objects such as spoons, forks and knives to large structures such as the skeletons of stadiums and skyscrapers. To meet the huge and growing need for steel, today's industrial furnaces can change 350 tons of pig iron (iron with a lot of carbon) into steel in about 40 minutes. The temperatures in some of these furnaces can range from 200C at the top to 2000C at the bottom, near the liquid metal. Steelmaking has two steps: refining the iron, and then adding other materials to make steel. Iron ore is smelted into pig iron, which contains a lot of carbon. To make steel, all impurities except for a little carbon are removed from the pig iron in a blast furnace. A hot blast

of air is blown upwards from the bottom of the furnace. As it passes through the molten metal, it oxidizes the sulphur, phosphorus, and other impurities into gases that leave the furnace. Then, other metals such as manganese, tungsten and molybdenum are added to give the steel the special properties desired. Different types of steel have different uses. Molybdenum hardened steel is used to make armor and weapons for the military, while stainless steel is used to make cutlery, utensils and tools. Steel used to make rails (for trains to run on) mixes iron with small quantities of manganese, silicon, chromium, aluminium, vanadium and calcium. Over time, our ancestors replaced their bronze articles with steel items. Bronze is harder, less brittle and stronger than iron, but iron as a metal is far more abundant than the copper and tin needed to make bronze. Steel also melts at a higher temperature than bronze, and is slightly lighter. Using cheaper ingredients (iron and carbon) than bronze (copper and tin), steel is cheaper to produce. This economic advantage helped steel displace bronze as the most widely used alloy. Brass Another important alloy known to man since prehistoric times is brass. This alloy of copper and zinc has a bright gold-like shine, and has been made and used since the bronze age. Brass is more malleable than both copper and zinc, so it can be shaped more easily. With its low melting temperature between 900C and 940C, brass was relatively easy for ancient people to melt and work with. Brass can crack when exposed to ammonia, but the problem is reduced by cooling the molten alloy slowly (annealing). Brass is used to make many musical instruments such as the trombone, the tuba, the trumpet and the French horn. Because it looks like gold, brass is also used to make decorative objects. It is espcially useful in products that require low friction, such as locks, hinges, bearings and zippers. Being ductile, brass is easily drawn into pipes and electrical wires. The copper in brass kills germs, so brass doorknobs can disinfect themselves in about eight hours. This is why they were used in hospitals. In ancient times, brass was also used to make pots and pans for cooking. Throughout history, brass has been used to make coins. A special kind of brass, with 1% manganese added in, is used to make the Golden Dollar coins in the United State. Alloys have been used by humans since pre-historic times. Man learned to make alloys soon after he learned to work with metals. Since then, we have created many alloys suitable for particular objects. Some alloys like White Gold (gold mixed with nickel or palladium) are used in small quantities. Other alloys like bronze, steel, and brass have changed our history and our modern world. Back to Smiths' Corner

http://library.thinkquest.org/08aug/01930/commonmetals/alloys.html

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Snow Goose, Figurative LanguageDocumento10 páginasSnow Goose, Figurative LanguageHelinar KryxeraAinda não há avaliações

- GKN Materials and Processes EN PDFDocumento40 páginasGKN Materials and Processes EN PDFarnella_h100% (1)

- Fabrication Guide PDFDocumento96 páginasFabrication Guide PDFbookpp100% (2)

- Mil STD 2197aDocumento19 páginasMil STD 2197aLe Thanh HaiAinda não há avaliações

- CSWIP (Welding Inspector Exam) Perparatory Question (Set 1 To 7)Documento19 páginasCSWIP (Welding Inspector Exam) Perparatory Question (Set 1 To 7)Box EmptyAinda não há avaliações

- Amsteel CatalogueDocumento45 páginasAmsteel CatalogueSyafiq KamaluddinAinda não há avaliações

- Total Physical Response (TPR)Documento12 páginasTotal Physical Response (TPR)Helinar Kryxera100% (1)

- Total Physical Response (TPR)Documento12 páginasTotal Physical Response (TPR)Helinar Kryxera100% (1)

- Standard Comparison SKK 490 To Q345DDocumento1 páginaStandard Comparison SKK 490 To Q345DFred HanAinda não há avaliações

- Comic StripDocumento11 páginasComic StripHelinar Kryxera100% (1)

- Marking Scheme Upsr Paper 2Documento7 páginasMarking Scheme Upsr Paper 2Mike MauludAinda não há avaliações

- Analytic RubricDocumento3 páginasAnalytic RubricHelinar Kryxera100% (2)

- 3 To 5 Level Rubric FrameDocumento2 páginas3 To 5 Level Rubric FrameHelinar KryxeraAinda não há avaliações

- Task 1: English Lesson PlanDocumento1 páginaTask 1: English Lesson PlanHelinar KryxeraAinda não há avaliações

- Uses of Aromatic HydrocarbonsDocumento2 páginasUses of Aromatic HydrocarbonsHelinar Kryxera80% (5)

- English For Undergraduates: Afrah Izzati Fatin Munira Muhammad Zaki Muhammad AizzuddinDocumento8 páginasEnglish For Undergraduates: Afrah Izzati Fatin Munira Muhammad Zaki Muhammad AizzuddinHelinar KryxeraAinda não há avaliações

- 04 MeasuresDocumento71 páginas04 MeasuresHelinar KryxeraAinda não há avaliações

- Forest Resources and Ecosystem Conservation in MalaysiaDocumento6 páginasForest Resources and Ecosystem Conservation in MalaysiaHelinar KryxeraAinda não há avaliações

- SAU Tools Itally - PR-215-1Documento28 páginasSAU Tools Itally - PR-215-1*mile*Ainda não há avaliações

- BLACK CAT - Grader Blade Product Sheets - v6Documento6 páginasBLACK CAT - Grader Blade Product Sheets - v6Anonymous xxFArUCSAinda não há avaliações

- Heavier Elements (Metallurgy)Documento34 páginasHeavier Elements (Metallurgy)Natish JaglanAinda não há avaliações

- Reinforcing Steel Bars Price List: Structural (Astm Grade 33)Documento1 páginaReinforcing Steel Bars Price List: Structural (Astm Grade 33)Emileandro Perito QuindiaganAinda não há avaliações

- Making Tongs For Blacksmithing: Register For Our ClassDocumento14 páginasMaking Tongs For Blacksmithing: Register For Our ClassTemesgen HenokAinda não há avaliações

- Wollo University Kiot: Designinig of Bushed Pin CouplingDocumento16 páginasWollo University Kiot: Designinig of Bushed Pin CouplingBirhanu AsfawAinda não há avaliações

- Corrosion Inhibitors - IntechOpenDocumento20 páginasCorrosion Inhibitors - IntechOpenPritha DasAinda não há avaliações

- BS en 10154-2002Documento20 páginasBS en 10154-2002Bravo RdAinda não há avaliações

- 6061 Vs 6063Documento9 páginas6061 Vs 6063SrRonAinda não há avaliações

- Mech-Ultrasonic MachiningDocumento20 páginasMech-Ultrasonic MachiningSymbol Of LoveAinda não há avaliações

- BS 7191 Weldabel Structural Steel For OffshoreDocumento48 páginasBS 7191 Weldabel Structural Steel For Offshoreyasser awadallhAinda não há avaliações

- Metal Extraction Through Chlorine MetallurgyDocumento28 páginasMetal Extraction Through Chlorine MetallurgyMaria Paula Villanueva JaraAinda não há avaliações

- Allowable Stress MPa ASME Section II ParDocumento1 páginaAllowable Stress MPa ASME Section II ParNg kok ThongAinda não há avaliações

- Iso - Iso Standards - Ics 25.220Documento8 páginasIso - Iso Standards - Ics 25.220Harish Kumar Kannepalli0% (1)

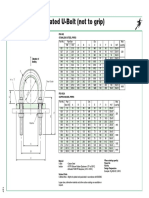

- C&P WITCHLINER Insulated U-Bolt (Not To Grip)Documento1 páginaC&P WITCHLINER Insulated U-Bolt (Not To Grip)Achraf BoudayaAinda não há avaliações

- Astm - A760 A760m 10 PDFDocumento15 páginasAstm - A760 A760m 10 PDFLuis Wilmer Nuñez EchaccayaAinda não há avaliações

- Improved Technology of Scandium Recovery...Documento7 páginasImproved Technology of Scandium Recovery...Balakrushna PadhiAinda não há avaliações

- Borax Method of Gold Extraction PDFDocumento6 páginasBorax Method of Gold Extraction PDFAcosta FaustoAinda não há avaliações

- AM Industry - Steel PrequalificationDocumento63 páginasAM Industry - Steel PrequalificationAbdul RaqeebAinda não há avaliações

- Basic Oxygen FurnaceDocumento30 páginasBasic Oxygen FurnacePatel Ki BahuAinda não há avaliações

- Custom Manufacturing For Aerospace and Defense: Greg PaulsenDocumento25 páginasCustom Manufacturing For Aerospace and Defense: Greg Paulsenitsme5616Ainda não há avaliações

- Corrosion: Standard Grade ChemistryDocumento4 páginasCorrosion: Standard Grade ChemistryStashy LoteAinda não há avaliações

- Report On Explosion WeldingDocumento15 páginasReport On Explosion Weldingpulkit1412Ainda não há avaliações

- Appendix PDFDocumento29 páginasAppendix PDFtomviolence100% (1)