Escolar Documentos

Profissional Documentos

Cultura Documentos

H-3 Power Point (Air Heater)

Enviado por

wisokresnoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

H-3 Power Point (Air Heater)

Enviado por

wisokresnoDireitos autorais:

Formatos disponíveis

SAUDI ARABIA SHUQAIQ-2 IWPP PROJECT

COURSE- H-3 ITEM Boiler & auxiliaries CONTENTS

Heater

25 October 2009

MITSUBISHI HEAVY INDUSTRIES, LTD.

NAGASAKI SHIPYARD & MACHINARY WORKS

Basic of Boiler

PAGE 2

Part.1

General for Ljungstrom Air Heater

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 3

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 4

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 5

Company Introduction Company History of ALSTOM K.K.

1907 1979 1988 1999 2000 2007 Founded as Gadelius Trading Co. Merged into Flakt AB Sweden Merged into ABB Group Jointed with ALSTOM- formed ABB ALSTOM Power Transferred to ALSTOM Group 100th Anniversary

Long Presence in Japan

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 6

Company Introduction

ALSTOM Ljungstrom Group

APER APER GmbH GmbH Div. Div. Air Air Preheater Preheater Europe Europe Alstom Alstom KK KK EER EER Asia Asia Air Air Preheater Preheater Company Company North North America America

Bammental, Germany Shanghai, China Osaka, Japan (NK) (CNEER) Kobe, Japan Concordia, KS Shanghai, China (CNASAEER) Wellsville, NY (Headquarters)

Vinhedo, Brazil Engineering Facilities Manufacturing Facilities

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 7

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 8

General Explanation of Ljungstrom Air Heater Function of Ljungstrom Air Heater

DeDe-SOx System Boiler

AH

EP STACK

SAH

FDF

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 9

General Explanation of Ljungstrom Air Heater

Air and Gas Flows Air Gas

Hot Side Hot Side

Cold Side

Cold Side

Air

Gas

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 10

General Explanation of Ljungstrom Air Heater Construction of Ljungstrom Air Heater

Heating Element Rotor Diaphragm Stay Plate Corner Duct Guide Bearing Center Section Bypass Seal Radial Seal Soot Blower

Rotor Drive Unit Housing Panel Pin Rack Axial Seal

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 11

General Explanation of Ljungstrom Air Heater Explanation of Ljungstrom Air Heater type

Ex.

26 -VI- 1325

Element Total Height (mm) Flow Type: V, VI=Vertical shaft, H=Horizontal shaft

AH Nominal Size: Related to Rotor Diameter

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 12

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 13

Heating Element

Explanation of where the HE are installed

NF DUNTM

Stay Plate Heating Element Diaphragm

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 14

Heating Element

Heating Element Spec. of AH for Shuqaiq-2

Layer Depth (mm) Type Thickness (mm) Material

Hot

1025

DUN

0.6

Mild steel

Cold

300

NF

1.2

CRLS*

* CRLS : Corrosion Resistant Low-alloy Steel

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 15

Heating Element

Element performance characteristic tendency

Pressure drop

DUNTM DU

NF

Thermal efficiency

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 16

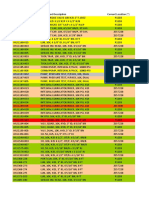

Reference List - DUNTM Heating element (excerpted)

Company name

Griffin Energy Pty Ltd. (Australia) Cuba Cairo Electricity Production Corp. (Egypt) Chugoku Electric Power Co., Ltd. (Japan) Genex Co., Ltd. (Japan) Idemitsu Kosan (Japan) Mitsubishi Chemical Co. (Japan) Sumitomo Chemiccal Co. (Japan) Tokyo Electric Power Co., Ltd. (Japan) SKS Power RDN.BHD. (Malaysia) SKS Power RDN.BHD. (Malaysia) Comision Federal De Electricida (Mexico) State Power Development Corp. (Philippines) Power Seraya Ltd. (Singapore) Chinese Petrochemical co. (Taiwan) Vietnam

Plant name

Blue Waters Unit 1&2 Carlos Manuel De Cespedes Unit No. 4 Cairo West Unit 7&8 Shin Onoda Unit1&2 Mizue Unit1 IPP Aichi Unit3 Mizushima Unit3 Chiba Plant CBL B15 Hitachi-naka Unit1 Tanjung Bin, Johor Jimah Tula Power Plant Unit5 Mindanao Seraya P.S. Unit1~3 Lin-Yuang EVN O MON

Capacity

226MW 158 MW 350MW 500MW 185MW --450T/H 250t/h 1000MW 700MWx3 700MWx2 300MW 210MW 250MWx3 --300MW

Fuel

Coal Oil N.Gas&Oil Coal VR&Gas VR Oil Oil & Gas Coal Coal Coal Oil Coal Oil Oil Crude Oil

AH type

30.5-VI-1625 (RT) 24-VIRX-2200 28.5-VIX-2225 30.5-VI-2525(RT) 26.5-VI-1800 28-VIX-1025 23.5-VIR-1350 23-HRX-1250 33.5-VI-2450(RT) 32.5-VI-1900 (RT) 32.5-VI-1900 (RT) 27.5-VIX-1800 27.5-VI-1700(RT) 26-VIX-1950 27-VIX-2150 28-VIX-2400

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 17

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 18

Sealing System

Explanation of Leakage

GAS

- Direct leakage W=CA(2g P) SEAL C : Flow coefficient A : Total areas of seal gap (m2) AXIAL 2) g : Gravitational acceleration (m/sSEAL : Specific weight of gas (kg/m3) P: Pressure difference between two flows - Entrained leakage

W= VRPH V : Volume of rotor plenum (m3) RPH: Rotor revolutions per hour

BY-PASS

HOT SECTOR SIDE PLATE Radial Leakage

ENTRAINED LEAKAGE

Axia l seal Axial Leakage plat e RADIAL SEAL SECTOR PLATE

AIR

COLD SIDE

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 19

Sealing System

Rotor Seals (Typical)

POST SEAL (HOT)

SECTOR PLATE (HOT)

RADIAL SEAL (HOT) HOLDING STRIP ROTOR DIAPHRAGM ROTOR POST

BY-PASS SEAL ANGLE BY-PASS SEAL (HOT) T BAR AXIAL SEAL T BAR BY-PASS SEAL (COLD) HOUSING

POST SEAL (COLD)

RADIAL HOLDING SEAL STRIP (COLD)

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 20

Agenda

1st topic 2nd topic Company Introduction General Explanation of Ljungstrom Regenerative Air Heater Heating element Page 5

Page 8

3rd topic

Page 13

4th topic

Sealing System

Page 18

5th topic

Auxiliary Equipment for SHUQAIQ

Page 21

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 21

Auxiliary Equipment of AH for SHUQAIQ

Rotor Drive Unit Bearing Lubricant Oil Circulation Unit Sootblower Fire Detecting Device Water Washing Device Fire Extinguishing Device (for Hot side)

Lubricant Oil Circulation Unit Guide Bearing

Soot Blower

Fire Detecting Device Water Washing Device

Rotor Drive Unit

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 22

Auxiliary Equipment for SHUQAIQ

Rotor Drive Unit

Rotor Drive Unit (RDU) consists of speed reducer, main electric motor and auxiliary air motor. A pinion gear is mounted to the output shaft which engages a pin rack. The rotor assembly, containing the heating elements, is rotated by this RDU through the air and gas streams at approximately 1.8 RPM. The air motor, coupled to the main electric motor, is used as auxiliary motor for emergency and maintenance operation.

Air motor Electric motor Speed reducer Pinion gear cover

(Utility) Electric power : 7.5kw Compressed air : 4.1barg 4.0m3/min.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 23

Auxiliary Equipment for SHUQAIQ

Rotor Bearing

Guide Bearing : #23052

The guide bearing is responsible for supporting the redial loads at the top of the air heater

Support Bearing : #29456

The air heater rotor is supported by the support bearing at the bottom of the air heater

Bearing

(Self-aligning roller bearing)

Bearing

(Thrust self-aligning roller bearing)

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 24

Auxiliary Equipment for SHUQAIQ

Lubricant Oil Circulation Unit (for Guide Bearing)

The purpose of this unit is to circulate the lubricant oil for cooling when the temperature of the oil in the guide bearing housing reaches 50 degree Celsius. (Utility) Electric power : 0.75kw Cooling water : 2.9barg, 3.6ton/hr

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 25

Auxiliary Equipment for SHUQAIQ

Sootblower (for Cold side)

Cleaning Heating element surface by superheated steam

Heating element

Steam

Type : Half Retractable Type Steam condition (Cold side) Blowing Press. 11.8barg Consumption 1.7ton/hr Electric power : 0.1kw

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 26

Auxiliary Equipment for SHUQAIQ Fire Detecting System (FDS)

The purpose of the system is to monitor the gas temperature leaving the air heater and detect the fire at early stage. If hot spot become present in the rotor, the gas temperature will increase unexpectedly.

Detecting sensor : Thermocouple Installation position of Thermocouple : Gas outlet duct : 4 pcs.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 27

Auxiliary Equipment for SHUQAIQ Water Washing Device

Type : Stationary Multi Nozzle Type (at gas inlet & gas outlet duct) Water Condition Blowing Press. : 4.9barg Consumption : 96ton/hr/each side

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 28

Auxiliary Equipment for SHUQAIQ

Fire Extinguishing Device (for Hot side)

Fire extinguishing device Socket Nozzle Washing Tube

The fire extinguishing device consist of 1 stationary multi nozzle pipe located in the gas inlet duct. The device is used in conjunction with the water washing device. The device is design to emit large amount of water onto a concentrated area of the heating element surface. Type : Stationary Multi Nozzle Type (at gas inlet) Water Condition Blowing Press. : 4.9barg Consumption : 192ton/hr

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 29

Part.2

Operation and Maintenance for Ljungstrom Air Heater

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 30

Agenda

1st Operation 1-1. Pre start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 31

Agenda

2nd Maintenance 2-1. Daily inspections 2-2. Periodical Inspections 2-3. Water washing 3rd Safety precautions

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 32

Agenda

1st Operation 1-1. Pre start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 33

1-1.Pre start-up checks

Instructions

To determine whether or not the Air Hater is ready for service, a complete inspection of the Air Heater and its auxiliary equipment is required. The operator should be concerned with all components being installed correctly, clean, and correctly lubricated. Prior to start-up, the operator must pay particular attention to the following areas to ensure safe and efficient operation of the Air Heater.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 34

1-1.Pre start-up checks

Instructions

FINAL CHECK-OUT LUBRICATION ROTOR INSPECTION ROTOR SEALS GUARDS AND COVERS PLANT UTILITIES ELECTRICAL CONNECTIONS AND CONTROL SYSTEM ROTOR ROTATION SOOT BLOWER STEAM PIPING

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 35

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 36

1-2.Cold running test

Instructions

Confirm unobstructed operation by air motor drive Finish

- Start the auxiliary air motor by opening the hand valve. - Observe the rotor for unobstructed operation.

Continuous running test Finish

- Energize the main drive motor and run the rotor - Check the motor temp., abnormal sound,vibration...etc.

Back-up test Finish

- Test the automatic operation of the air motor solenoid valve upon power loss to the main drive motor.

Hot-run adjustment

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 37

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 38

1-3.Hot-run adjustment

Instructions

b. Soot blower blowing pressure adjustment

(1) Blowing pressure: 11.8 barg (Cold Side)

NOTE: This adjustment should be done at 100%-load during hot-run test

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 39

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 40

1-4.Start-up

Instructions

The following operation sequence should be used to place the air heater into service. Start the air heater's main drive motor before the forced and induced daft fans are started. The rotor must be rotating before emitting hot flue gas through the air heater. B. When firing the boiler on oil, start cold end soot blowing to the air heater continuously during start-up using an auxiliary blowing medium until stable boiler conditions are achieved and the normal soot blowing medium is available. C. Energize the guide bearings oil circulation units. The pump motors will start upon oil temperature rise. D. Start the air heater's auxiliary equipment control system. E. After normal soot blowing medium is available, activate the air heater soot blower A.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 41

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 42

1-5.Shutting down

Instructions

The following sequence should be used to remove the air heater from service. A. B. C. D. E. Activate the soot blower to remove any deposits which may have accumulated on the heating element surface. Keep the FD & ID fans running during the cleaning operation so that the air heater temperature will decrease more rapidly. Deactivate the air heater soot blowers. De-energize the air heater's auxiliary equipment control system. Keep the rotor turning and the fans operating until the gas inlet temperature at the heater inlet drops below 150C. This will evenly distribute the effects of thermal distortion, over the entire rotor structure. Shut down the FD & ID fans. De-energize the rotor drive unit of the air heater. Close the manual valve to stop compressed air to the auxiliary air drive motor. Deactivate the guide bearing oil circulation units.

F. G. H. I.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 43

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 44

1-6.Rotor stoppage due to motor failure

Back-up start

Air Motor (Aux. Drive)

Over running clutch(ORC) Elec. Motor (Main Drive)

Trip!!

Instructions ! CAUTION

If operation mode is selected to manual mode, aux. air motor does not start automatically. Operation mode of aux. electric motor should select to AUTO at normal condition.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 45

NOTE: The air heater structure will not experience permanent damage as long as the temperature of the gas entering the air heater does not exceed 480. However, if the rotor cannot be restarted immediately (within approx.15 min), damage to some of the seals and/or sealing plates is likely to occur due to non-uniform thermal expansion of the rotor.

Non-uniform thermal expansion of the rotor

Gas side

Air side

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 46

Agenda

1st Operation 1-1. Pre Start-up checks 1-2. Cold-run inspection 1-3. Hot-run adjustment 1-4. Start-up instructions 1-5. Shutting down instructions 1-6. Rotor stoppage due to motor failure 1-7. Operation procedure of soot blower

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 47

1-7.Operation procedure of Soot Blower

Frequency and occasion for soot blowing

(Standard operation frequency) : once every 8 hours for the cold side, in principle

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 48

1-7.Operation procedure of Soot Blower

Operation procedure of soot blower Discharge the drain in the steam piping line for soot blowing

Open the stop valve of steam for soot blowing

Close the drain valve after having discharged the drain of steam

Make soot blowing of the air heater

Close the main valve and open the drain valve

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 49

1-7.Operation procedure of Soot Blower

Instructions !CAUTION

BLOWING WITH PRESSURES HIGHER THAN SPECIFIED WILL REDUCE THE LIFE OF THE HEATING ELEMENT AND MAY RESULT IN MATERIAL FRACTURE OR BREAK-UP.

* Design value of soot blowing steam pressure : 1.18MPag Note ; The blowing pressure should be adjusted by using orifice plate in the steam piping.

ENSURE THAT MOISTURE IS NOT ALLOWED TO ENTER THE AIR HEATER THROUGH THE SOOTBLOWING STEAM. WET STEAM USED FOR SOOT BLOWING CAN CAUSE DAMAGE TO THE ROTOR SEALS AND HEATING ELEMENTS.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 50

Agenda

2nd Maintenance 2-1. Daily inspections 2-2. Periodical Inspections 2-3. Water washing 3rd Safety precautions

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 51

2-1.Daily Inspections

Draft loss and temperature Check and record the draft loss both side and temperature Lubricant oil circulation unit Check the oil pressure and cooling water. Rotor guide&support bearing Check the rotating sound, oil level, gas leak.

Soot blower Check the blowing pressure and leak. Rotor Visual Check the elements and seals condition from observation port. Rotor drive unit Check the temp., vibration, current, oil level.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 52

Agenda

2nd Maintenance 2-1. Daily inspections 2-2. Periodical Inspections 2-3. Water washing 3rd Safety precautions

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 53

2-2.Periodical inspections (Summary)

Components parts Rotor proper - Rotor post,Rotor,Pin rack T-bar Bearings - Support,Guide, Air seal cover Rotor trunnion - Trunnion bolts,Locking bar Lubrication oil circulation unit - Oil pump,filter,cooler, Safety valve AH proper - Cold side partition plate, Cold side housing panel, ...etc Heating element Contents of inspection 1.Visual check 2.Measuring the thickness 3.Liquid penetrate testing 1.Visual check 2.Hand check 3.Oil sampling 1.Hammering 2.Visual check 1.Overhaul 2.Visual check 3.Leak test 4.Functional test 1.Thickness measurement 2.Visual check Measures at abnormal - Repair. - Replacement.

- Repair. - Replacement - Repair. - Replacement.

- Repair. - Replacement

- Repair - Replacement - Repair. - Replacement

1.Visual check 2.Measuring the Weight, thickness

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 54

Components parts Rotor drive unit - Speed reducer,Elec. motor Aux motor,Pinion gear Rotor seal - Post seal, Radial seal, Bypass seal, Axial seal, Static seal,Sector plate Soot blower - Speed reducer, Carriage, Feed tube, Lance tube, Wall box, Flanges Stationary water washing Fire extinguishing device - Nozzle,Tube Others - Manholes, doors Observation port

Contents of inspection 1.Overhaul 2.Visual check 3.Measuring 1.Hammering 2.Measuring the thickness 3.Measuring the seal clearance 4.Measuring the degree of parallelism 1.Visual check 2.Overhaul 3.Measuring

Measures at abnormal - Repair. - Replacement

- Repair. - Replacement - Readjustment

- Repair. - Replacement

1.Visual check 2.Measuring the thickness

- Repair. - Replacement

1.Visual check

- Repair. - Replacement

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 55

Agenda

2nd Maintenance 2-1. Daily inspections 2-2. Periodical Inspections 2-3. Water washing 3rd Safety precautions

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 56

Water washing

Water washing

2-3.Water washing

Initial value

Operation

Out of service Operation

Out of service

Instructions

When pressure drop across the Air heater keeps increasing despite continued use of the soot blower properly, it is a sign that the deposits have coagulated and stick fast to the heating element surface. In general, we recommend that when the pressure drop exceeds the initial value x 1.5times, water washing shall be carried with the Air heater during out of service.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 57

Operation procedure of water washing

Instructions Preparation

1) Make sure that the temperature of gas inlet is below 150. It may cause damages on AH if it is higher than 150. 2) Line up the water line. 3) Check the drain lines to be able to drain adequately. 4) Shut off steam valves for soot blower 5) Observe the condition of deposit on heating element.

Finish

Start water washing

The auxiliary air motor drive should be used to reduce the speed to approximately to RPM.

8-12hr

- Measuring the pH value of drain water. - Check the supply water pressure. - Check the piping for drain out. - Check the conditions of washing.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 58

Instructions Determine the completion

a) Completion may be determined from the difference of pH value between washing water and drain water. When the difference is less than 1, it may be completed in principle.

Finish

pH value pH

Washing water Drain water -> pH value decreases due to sulfuric acid

b) Observe the heating elements over entire area to check deposit being removed. If deposits still remain, continue washing. 1) Close water valves 2) Open dampers in the inlet and outlet ducts 3) Remove the illumination light 4) Close drain lines 5) Dry up heating elements(It is desirable to dry by operating the fans) 6) Stop rotor rotation

Complete

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 59

DANGER: WASHING OF THE AIR HEATER HEATING ELEMENT SHOULD ONLY BE CARRIED OUT WHEN THE AIR HEATER IS OUT OF SERVICE AND THE GAS SIDE TEMPERATURE IS COOL ENOUGH TO ALLOW MAINTENANCE PERSONNEL ENTRY TO THE AIR HEATER AND ADJACENT DUCTS. HOWEVER, IN NO CASE SHOULD WATER BE EMITTED ONTO THE ROTOR UNTIL THE METAL TEMPERATURE OF THE GAS INLET HEATING ELEMENT IS BELOW 150C. CAUTION: BEFORE AND DURING WATER-WASHING, INSPECT HOPPER DRAINS TO INSURE THAT THE DRAINS ARE NOT PLUGGED. TREMENDOUS QUANTITIES OF WATER MUST EXIT THE DRAINS OR THE CONNECTING DUCTS CAN BECOME FLOODED CAUTION: INSUFFICIENT WATER WASHING HAS ADVERSE EFFECTS TO THE HEATING ELEMENT AND INCOMPLETE DRYING WILL CAUSE RAPID PROGRESSION OF CORROSION AND ACCUMULATION OF DEPOSITS ON THE HEATIMNG ELEMENTS WHEN RETURNING TO SERVICE.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 60

Agenda

2nd Maintenance 2-1. Daily inspections 2-2. Periodical Inspections 2-3. Water washing 3rd Safety precautions

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 61

! IMPORTANT

For detail operation and maintenance instructions, please refer to:

Operation & Maintenance Manual

DANGER: NEVER ATTEMPT TO ENTER THE AIR HEATER UNTIL

THE FOLLOWING CONDITIONS ARE MET. ALL ELECTRIC POWER TO THE ROTOR DRIVE UNIT AND THE SOOTBLOWER UNIT HAS BEEN ISOLATED. THE LOCAL COMPRESSED AIR HAND VALVE AT THE AIR MOTOR SHOULD BE SECURED IN THE OFF POSITION. THE SURFACE TEMPERATURE OF THE AIR HEATER IS BELOW 100F (38C). O2 AND CO2 CONCENTRATION ARE SATISFIED TO ENTER.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 62

CAUTION: WHENEVER WELDING IS DONE ON THE ROTOR POST OR ROTOR ASSEMBLY, THE ROTOR POST (MAIN SHAFT) MUST BE CONNECTED TO AN EARTH GROUND.FAILURE TO PROVIDE A PROPER GROUND MAY RESULT IN DAMAGE TO THE AIR HEATER BEARINGS.

DANGER: NEVER APPROACH OR TOUCH ANY ROTATING PARTS (SHAFTS, COUPLINGS, ETC.) DURING OPERATION. LOOSE CLOTHING CAUGHT IN THESE ROTATING PARTS MAY RESULT IN SEVERE INJURY AND/OR DEATH.

CAUTION: OPERATING THE AIR HEATER WITH GAS INLET TEMPERATURES IN EXCESS TO THE MAXIMUM DESIGN TEMPERATURES CAUSE THE ROTOR SEALS TO CONTACT THE AIR HEATER STRUCTURE AND RESULT IN PREMATURE WEAR OR POSSIBLE PERMANENT DAMAGE TO THE SEALING SYSTEM.

MHI BUSINESS CONFIDENTIAL

Basic of Boiler

PAGE 63

www.alstom.com

MHI BUSINESS CONFIDENTIAL

Você também pode gostar

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocumento224 páginasBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadAinda não há avaliações

- Air Cooled Condenser and Non PerformanceDocumento67 páginasAir Cooled Condenser and Non Performanceparthi20065768100% (2)

- Bi-Drum Vs Single Drum - Research Paper 2Documento6 páginasBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Ennore Thermal Power StationDocumento14 páginasEnnore Thermal Power StationRajesh Kumar100% (2)

- Epri Cooling Tower Water Rfi PDFDocumento4 páginasEpri Cooling Tower Water Rfi PDFdrjonesg19585102Ainda não há avaliações

- Chapter I General Information of Pump UnitDocumento42 páginasChapter I General Information of Pump UnitRahmat Budi HartantoAinda não há avaliações

- CW Pumps Tripping On Over Load, 210 MW Unit, 02-03Documento5 páginasCW Pumps Tripping On Over Load, 210 MW Unit, 02-03Charu ChhabraAinda não há avaliações

- A Report On Industrial VisitDocumento15 páginasA Report On Industrial VisitChandni Bhagchandani100% (1)

- Pulverizer and Fuel Delivery GuidelinesDocumento152 páginasPulverizer and Fuel Delivery GuidelinesnaseemAinda não há avaliações

- Lub Oil SystemDocumento20 páginasLub Oil SystemAshwani DograAinda não há avaliações

- Turbines - New Module Hay PDFDocumento191 páginasTurbines - New Module Hay PDFThái Mai Đình100% (1)

- Wingwall SH Distortion in CFBC Boilers by K.K.parthiban Jan 2018Documento3 páginasWingwall SH Distortion in CFBC Boilers by K.K.parthiban Jan 2018parthi20065768Ainda não há avaliações

- Supercritical Benson BoilerDocumento18 páginasSupercritical Benson BoilerJerry Mateo100% (2)

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocumento9 páginasDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596Ainda não há avaliações

- Mechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inDocumento24 páginasMechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inbtdoss72100% (1)

- Clyde Bergemann PDFDocumento6 páginasClyde Bergemann PDFenjineringAinda não há avaliações

- Overiew of Comb Cycle Rev 6.0 - Part 1Documento73 páginasOveriew of Comb Cycle Rev 6.0 - Part 1SamAinda não há avaliações

- NTPC BoilerDocumento57 páginasNTPC BoilerSami ZamaAinda não há avaliações

- 4 - Silica in BoilerDocumento3 páginas4 - Silica in BoilerKrishnan ManiAinda não há avaliações

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocumento15 páginas3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGAinda não há avaliações

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocumento24 páginasTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranAinda não há avaliações

- Operation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODocumento5 páginasOperation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODaniel DubeAinda não há avaliações

- JIS Standard For Boiler Water - 1 PDFDocumento80 páginasJIS Standard For Boiler Water - 1 PDFCornelius Toni Kuswandi100% (1)

- Catalog Steam Turbines 2013 Engl PDFDocumento36 páginasCatalog Steam Turbines 2013 Engl PDFvamsiklAinda não há avaliações

- Feed Water Deaeration in Thermal Power PlantDocumento46 páginasFeed Water Deaeration in Thermal Power PlantAshwani Dogra100% (2)

- Design and Thermal Analysis of A Supercritical CFB BoilerDocumento89 páginasDesign and Thermal Analysis of A Supercritical CFB Boilerbharathkumar0310Ainda não há avaliações

- Extraction Condensing Steam Turbine PDFDocumento2 páginasExtraction Condensing Steam Turbine PDFAaronAinda não há avaliações

- WH Vacuum in Steam TurbineDocumento2 páginasWH Vacuum in Steam Turbinemiths_0087Ainda não há avaliações

- Extraction Condensing Steam TurbineDocumento3 páginasExtraction Condensing Steam TurbineNaeemSiddiquiAinda não há avaliações

- Ash Handling 0Documento6 páginasAsh Handling 0蓉蓉Ainda não há avaliações

- # AhpDocumento21 páginas# AhprahulAinda não há avaliações

- Boiler Types and ClassificationsDocumento26 páginasBoiler Types and ClassificationshardikAinda não há avaliações

- Boiler Feed Water PumpsDocumento71 páginasBoiler Feed Water Pumpsbakhtyar21Ainda não há avaliações

- Chloride Contamination of The Water Steam Power Plant PDFDocumento15 páginasChloride Contamination of The Water Steam Power Plant PDFDiniAinda não há avaliações

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocumento10 páginasEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaAinda não há avaliações

- Poor Vacuum During Initial CommissioningDocumento4 páginasPoor Vacuum During Initial CommissioningCharu ChhabraAinda não há avaliações

- Steam Turbine BasicsDocumento77 páginasSteam Turbine Basicsas5236Ainda não há avaliações

- Air Cooled CondenserDocumento7 páginasAir Cooled Condensermoreds1983Ainda não há avaliações

- Condensate Extraction Pump: GeneralDocumento5 páginasCondensate Extraction Pump: GeneralAnonymous DKv8vpAinda não há avaliações

- High Silica After Overhaul of Fouled TurbineDocumento3 páginasHigh Silica After Overhaul of Fouled Turbineak_thimiriAinda não há avaliações

- Types and Functions, Constructional Details,: Air Pre HeatersDocumento77 páginasTypes and Functions, Constructional Details,: Air Pre HeatersBala VigneshAinda não há avaliações

- Cathotic ProtectionDocumento5 páginasCathotic Protectionkrishna_swaroop99Ainda não há avaliações

- ME6701-Power Plant EngineeringDocumento16 páginasME6701-Power Plant EngineeringNizam MAAinda não há avaliações

- Boiler Water High PresureDocumento43 páginasBoiler Water High PresureVinod SindhavAinda não há avaliações

- Steam TurbineDocumento46 páginasSteam TurbineIbrahim Mostafa50% (2)

- Components of Coal-Fired Steam Power PlantDocumento5 páginasComponents of Coal-Fired Steam Power PlantDanBenedictAcuzarAinda não há avaliações

- Hydrazine DosingDocumento2 páginasHydrazine DosingAnonymous 3HTgMDO100% (1)

- Boiler Feed PumpDocumento46 páginasBoiler Feed Pumppratapsingh12100% (1)

- HRSG Supplier's Chemistry IonDocumento11 páginasHRSG Supplier's Chemistry IonJoe Schroeder100% (1)

- A Case Study On-Shutdown Audit of AFBC BoilerDocumento12 páginasA Case Study On-Shutdown Audit of AFBC BoilerSelvakumar Palaniandavar100% (1)

- Steam Attemperation Valve and Desuperheater Driven Problems On HRSG'sDocumento25 páginasSteam Attemperation Valve and Desuperheater Driven Problems On HRSG'stetracm100% (1)

- Condenser in Power PlantDocumento20 páginasCondenser in Power PlantPrabir Kumar PatiAinda não há avaliações

- Boiler NotesDocumento34 páginasBoiler NotesRakesh Singh BhadoriyaAinda não há avaliações

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocumento41 páginasReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonAinda não há avaliações

- Blackout RestorationDocumento26 páginasBlackout RestorationSiddhant SatpathyAinda não há avaliações

- Siemens HedrichDocumento51 páginasSiemens HedrichpabloalienadoAinda não há avaliações

- Hangzhou Fuchuan Electric Equipment Co.,Ltd - PPTDocumento23 páginasHangzhou Fuchuan Electric Equipment Co.,Ltd - PPTRahmat Nur IlhamAinda não há avaliações

- Electrical Lecture 1 - Basic of Power PlantDocumento92 páginasElectrical Lecture 1 - Basic of Power PlantNoli OtebaAinda não há avaliações

- Shaangu For Metalurgical Industry 2013Documento49 páginasShaangu For Metalurgical Industry 2013zzgiadinhzzAinda não há avaliações

- Diploma 2013 256217 AbstractDocumento1 páginaDiploma 2013 256217 AbstractwisokresnoAinda não há avaliações

- Jurnal Ryan Nur Harjanto (C2A606098)Documento35 páginasJurnal Ryan Nur Harjanto (C2A606098)wisokresnoAinda não há avaliações

- 1 - Bottled Uht Milk and Dairy Drinks - UsDocumento6 páginas1 - Bottled Uht Milk and Dairy Drinks - UswisokresnoAinda não há avaliações

- APSN Language Resources KAMUS LSMDocumento74 páginasAPSN Language Resources KAMUS LSMwisokresnoAinda não há avaliações

- GAMELAN: A Knowledge Management Approach For Digital Audio Production WorkflowsDocumento6 páginasGAMELAN: A Knowledge Management Approach For Digital Audio Production WorkflowswisokresnoAinda não há avaliações

- Cuu Long Delta Rice Research Institute (CLRRI) Can Tho University (CTU)Documento7 páginasCuu Long Delta Rice Research Institute (CLRRI) Can Tho University (CTU)wisokresnoAinda não há avaliações

- Report GCGDocumento7 páginasReport GCGwisokresnoAinda não há avaliações

- Corium 4060Documento2 páginasCorium 4060wisokresnoAinda não há avaliações

- Catalogue of Cleaning & Maintenance ChemicalsDocumento24 páginasCatalogue of Cleaning & Maintenance ChemicalswisokresnoAinda não há avaliações

- Penawaran Mesin Utk ZeoliteDocumento3 páginasPenawaran Mesin Utk ZeolitewisokresnoAinda não há avaliações

- Brinedril VisDocumento1 páginaBrinedril ViswisokresnoAinda não há avaliações

- BIBLIOGDocumento1 páginaBIBLIOGwisokresnoAinda não há avaliações

- Activated Carbon SpecDocumento1 páginaActivated Carbon SpecwisokresnoAinda não há avaliações

- Train P - PTC Markup PDFDocumento43 páginasTrain P - PTC Markup PDFJovan BorakAinda não há avaliações

- BOSS Commissioning Valve BrochureDocumento14 páginasBOSS Commissioning Valve Brochuretrabant424Ainda não há avaliações

- Heat Transfer To Fluids Without Phase ChangeDocumento56 páginasHeat Transfer To Fluids Without Phase ChangeJanice Omadto100% (2)

- IPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ADocumento3 páginasIPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ANikhil KarkeraAinda não há avaliações

- VLE ReportDocumento4 páginasVLE ReportAmeerul AhwazAinda não há avaliações

- The Science of Spray PaintDocumento1 páginaThe Science of Spray PaintChristine SabioAinda não há avaliações

- Odalog 7000 Mkii Multi Gas Monitor: Key FeaturesDocumento2 páginasOdalog 7000 Mkii Multi Gas Monitor: Key FeaturesLabLing DLH BontangAinda não há avaliações

- Discharge CoefficientDocumento11 páginasDischarge Coefficientsisai12u2420% (2)

- Gas AbsorptionDocumento19 páginasGas AbsorptionAnonymous NyvKBW100% (3)

- Pseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaDocumento3 páginasPseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaChristian PradaAinda não há avaliações

- NacelleDocumento7 páginasNacellecarlitos232067% (3)

- HansenDocumento4 páginasHansenBruna MacedoAinda não há avaliações

- Qualified Welder List Valid Until - 03-12-2019Documento2 páginasQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Ig-55 (ADocumento6 páginasIg-55 (Aundertaker55Ainda não há avaliações

- Principles of Flight - 081 POFDocumento476 páginasPrinciples of Flight - 081 POFobrajiorAinda não há avaliações

- 312D Hyd PDFDocumento2 páginas312D Hyd PDFMbahdiro Kolenx100% (3)

- DS D5611aDocumento1 páginaDS D5611arajindo1Ainda não há avaliações

- Deaeration Technique DT199505 - A01Documento3 páginasDeaeration Technique DT199505 - A01smallik3Ainda não há avaliações

- PC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemDocumento144 páginasPC450 (LC, HD) - 8 UEN02233-00 Hydraulic SystemdatphuongAinda não há avaliações

- UntitledDocumento6 páginasUntitledmankour wahidAinda não há avaliações

- Erosional VelocityDocumento7 páginasErosional VelocityCHANADASAinda não há avaliações

- Designing Spiral Heat ExchangerDocumento10 páginasDesigning Spiral Heat Exchangerak100% (5)

- 49 CFR Part 180 Subpart C (Up To Date As of 8-04-2022)Documento25 páginas49 CFR Part 180 Subpart C (Up To Date As of 8-04-2022)Cristhian342Ainda não há avaliações

- KICK ToleranceDocumento16 páginasKICK ToleranceIshtiaq Khalid100% (1)

- 20 Practical Tips For Safe Gas Welding and Cutting Operations On ShipsDocumento24 páginas20 Practical Tips For Safe Gas Welding and Cutting Operations On ShipsmivanoAinda não há avaliações

- 2020 1 T7 B FluidsDocumento2 páginas2020 1 T7 B FluidsI Made Medika SuryaAinda não há avaliações

- Instruction Anweisung Instructions Instructie Instruções IstruzioniDocumento16 páginasInstruction Anweisung Instructions Instructie Instruções IstruzioniAdel MercadejasAinda não há avaliações

- Hibon PD BlowerDocumento3 páginasHibon PD BlowerAbhinav SaiAinda não há avaliações

- Process OperatorDocumento2 páginasProcess Operatorapi-78201706Ainda não há avaliações

- Model 4Wg 100 - 800 HP Boilers: Table A3-8. 4Wg Low Nox Dimensions - Hot WaterDocumento4 páginasModel 4Wg 100 - 800 HP Boilers: Table A3-8. 4Wg Low Nox Dimensions - Hot WatersebaversaAinda não há avaliações