Escolar Documentos

Profissional Documentos

Cultura Documentos

Aculvert

Enviado por

Jaydie CadungogDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Aculvert

Enviado por

Jaydie CadungogDireitos autorais:

Formatos disponíveis

A culvert is a drain or pipe that allows water to flow under a road, railroad, trail, or similar obstruction.

Culverts differ from bridges mainly in size and construction. Culverts are generally smaller than bridges, ranging from 0.3-metre (1 ft) pipes to larger reinforced concrete structures. Culverts are typically surrounded by soil. For legal purposes in the United States, structures with total spans under 20 feet (6.1 m) are considered culverts, and longer structures are bridges. When boxes or pipes are placed side-by-side to create a width of greater than twenty feet, the culvert is defined as a bridge in the United States. This is a requirement of the federal bridge inspection standards and ensures that the culvert is inspected on a [1] regular basis.

Contents

[hide]

1 Types 2 Accidents due to culvert failures 3 Environmental impacts 4 Minimum energy loss culverts 5 Forestry 6 See also 7 References 8 External links

Types[edit]

Precast concrete culvert segments

Transportation routes cross over waterways using either a bridge or a culvert. Culverts come in many sizes and shapes. Shapes may include round, elliptical, flat-bottomed, pear-shaped, and box. Culverts [2] may be made of concrete, galvanized steel, aluminum, or plastic, typically high density polyethylene. Two or more materials may be combined to form composite structures. For example, open-bottom corrugated steel structures are often built on concrete footings, or corrugated.

Plastic culvert liners are also inserted into failing concrete or steel structures in order to repair the structure without excavating and closing the road.

Accidents due to culvert failures[edit]

Culverts fail due to corrosion of the materials they are made from, or erosion of the soil around or under them. If the failure is sudden and catastrophic, it can result in injury or loss of life. Sudden road collapses are often at poorly designed culvert crossing sites. Water passing through undersized culverts will scour away the surrounding soil over time. This can cause a sudden failure during medium sized rain events. There are more than 5,000,000 culverts currently in use in the United States alone. Continued inspection, maintenance, and replacement of these structures is crucial for infrastructure and safety. Accidents due to culverts can also occur if a flood overwhelms it, such as with the Jacobs Creek Flood of 2003, or disrupts the road or railway above it, such as with the Bethungra accident of 1885, which killed seven people. Soil and sand carried through a culvert can wear away the galvanizing of a steel culvert, allowing it to corrode and eventually collapse, disrupting the road or railway above it. This happened at a culvert [3] near Gosford, New South Wales in 2007, killing five.

Environmental impacts[edit]

This culvert has a natural surface bottom connecting wildlife habitat. Vermont

Safe and stable stream crossings can accommodate wildlife and protect stream health while reducing expensive erosion and structural damage. Undersized and poorly placed culverts can cause problems for water quality and aquatic organisms. Poorly designed culverts can degrade water quality via scour and erosion and also restrict aquatic organisms from being able to move freely between upstream and downstream habitat. Fish are a common victim in the loss of habitat due to poorly designed crossing structures. Culverts that offer adequate aquatic organism passage reduce impediments to movement of fish, wildlife and other aquatic life that require instream passage. These structures are less likely to fail in medium to large scale [citation needed] rain/snow melt events.

This culvert cannot accommodate wildlife passage

Poorly designed culverts are also more apt to become jammed with sediment and debris during medium to large scale rain events. If the culvert cannot pass the water volume in the stream, the water may overflow over the road embankment. This may cause significant erosion, washing out the culvert. The embankment material that is washed away can clog other structures downstream, causing them to fail as well. It can also damage crops and property. A properly sized structure and hard bank armoring can help to alleviate this pressure.

Aquatic organism passage compatible culvert replacement in Franklin, Vermont, just upstream from Lake Carmi

Minimum energy loss culverts[edit]

Culvert size relative to a person

In the coastal plains of Queensland (north-east Australia), torrential rains during the wet season place a heavy demand on culverts. The natural slope of the flood plains is often very small and little fall (or head

loss) is permissible in the culverts. Professors Gordon R. McKay and Colin J. Apelt developed and patented the design procedure of minimum energy loss culverts waterways which yield small afflux. Colin J. Apelt, (emeritus) professor of civil engineering at the University of Queensland, presented an [4] [5] authoritative review of the topic (1983) and a well-documented documentary (1994). A minimum energy loss culvert or waterway is a structure designed with the concept of minimum head loss. The flow in the approach channel is contracted through a streamlined inlet into the barrel where the channel width is minimum, and then it is expanded in a streamlined outlet before being finally released into the downstream natural channel. Both the inlet and outlet must be streamlined to avoid significant form losses. The barrel invert is often lowered to increase the discharge capacity. The concept of minimum energy loss culverts was developed by Norman Cottman, shire engineer in Victoria (Australia) and by Professor Gordon McKay, University of Queensland (Brisbane, Australia) [6] during the late 1960s. While a number of small-size structures were designed and built in Victoria, some major structures were designed, tested and built in South-East Queensland.

Você também pode gostar

- Ferrous and Non-Ferrous MetalDocumento8 páginasFerrous and Non-Ferrous MetalJayChristian QuimsonAinda não há avaliações

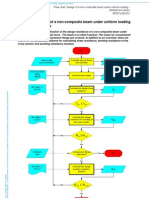

- EC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed ProcedureDocumento5 páginasEC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed Procedurejskolmen100% (1)

- Scour Failure of BridgesDocumento14 páginasScour Failure of BridgessujupsAinda não há avaliações

- Sentry Wellhead Catalog PDFDocumento129 páginasSentry Wellhead Catalog PDFMuhammad TahirAinda não há avaliações

- Canal FallsDocumento10 páginasCanal Fallsnizamaniza80% (5)

- DrainageDocumento30 páginasDrainageReniel Cordero Maghopoy100% (1)

- Engineer's Report On Collapse of South Alabama Football FacilityDocumento22 páginasEngineer's Report On Collapse of South Alabama Football Facilitycreg1973100% (1)

- River DiversionDocumento57 páginasRiver DiversionAzaz Ahmed100% (4)

- Caimbang 4thqtrFINALDocumento131 páginasCaimbang 4thqtrFINALChesella Kaye Lungay100% (1)

- Types of Hydraulic StructuresDocumento3 páginasTypes of Hydraulic StructuresShah Nawaz79% (14)

- Culverts: Submitted To-Mr - Vikas Srivastava SIRDocumento25 páginasCulverts: Submitted To-Mr - Vikas Srivastava SIRsarthak mishraAinda não há avaliações

- AtkinsDocumento37 páginasAtkinsganeshakceAinda não há avaliações

- Design of Structural Connections To Eurocode 3Documento135 páginasDesign of Structural Connections To Eurocode 3Habtamu Gebreselassie100% (2)

- WeirDocumento12 páginasWeirBabylyn Austria100% (1)

- Pier Head Type P1, 3.0mX2.5m Column, Seismic Restrainer Type 2Documento20 páginasPier Head Type P1, 3.0mX2.5m Column, Seismic Restrainer Type 2John Paul LlauderAinda não há avaliações

- Assignment 9.3 - DamsDocumento6 páginasAssignment 9.3 - DamsJurel GonzalesAinda não há avaliações

- Conduits Through Embankment DamsDocumento12 páginasConduits Through Embankment Damsdjajadjaja100% (1)

- ASME B36.19M-2004 (R2010) - UnlockDocumento14 páginasASME B36.19M-2004 (R2010) - UnlockadprimAinda não há avaliações

- Conceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Documento16 páginasConceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dawit SolomonAinda não há avaliações

- St7016 Prefabricated StructuresDocumento128 páginasSt7016 Prefabricated StructuresSelva Raj77% (13)

- Tailift FBT18-20 Displ Zapi GrandeDocumento203 páginasTailift FBT18-20 Displ Zapi Granderodrigo aguilarAinda não há avaliações

- Method Statement For Installation of Road Culverts in Water CoursesDocumento5 páginasMethod Statement For Installation of Road Culverts in Water Coursesabsalom mkhatshwaAinda não há avaliações

- Melbourne's Water Catchments: Perspectives on a World-Class Water SupplyNo EverandMelbourne's Water Catchments: Perspectives on a World-Class Water SupplyAinda não há avaliações

- Materials: Pipe Reinforced Concrete United Kingdom Watercourse DitchesDocumento4 páginasMaterials: Pipe Reinforced Concrete United Kingdom Watercourse DitchesChristine Marquez RamosAinda não há avaliações

- Environmental Impacts: ScourDocumento2 páginasEnvironmental Impacts: ScourShah KhanAinda não há avaliações

- 5th SEM RECORD Pappers On Working Progress PDFDocumento81 páginas5th SEM RECORD Pappers On Working Progress PDFTechnical Media BossAinda não há avaliações

- CulvertDocumento13 páginasCulvertKhushboo Khanna100% (1)

- Chapter 1Documento3 páginasChapter 1shaik saifulla lAinda não há avaliações

- My Project Work RepDocumento55 páginasMy Project Work Repshaik saifulla lAinda não há avaliações

- Causes of Failure of Earth Dams Criteria For Safe Design of Earth Dams Slope Stability of Earth DamsDocumento11 páginasCauses of Failure of Earth Dams Criteria For Safe Design of Earth Dams Slope Stability of Earth DamsAhmed AmediAinda não há avaliações

- Flood and Erosion Control StructuresDocumento5 páginasFlood and Erosion Control StructuresAurelio Flores Jr.Ainda não há avaliações

- Types of SeawallDocumento9 páginasTypes of SeawallBernadette MausisaAinda não há avaliações

- Grade Control StructuresDocumento7 páginasGrade Control StructuresRod PasionAinda não há avaliações

- Earth Dam (Only Types of Dams) PDFDocumento4 páginasEarth Dam (Only Types of Dams) PDFveeraiahAinda não há avaliações

- Suraj Barale WRE Roll NO 11Documento14 páginasSuraj Barale WRE Roll NO 11Parth KshirsagarAinda não há avaliações

- Planning and Design Criteria For Protection Dams Against Debris FlowsDocumento8 páginasPlanning and Design Criteria For Protection Dams Against Debris FlowsMarcelo ProtzAinda não há avaliações

- Chapter One Introduction 1-1 IntroductionDocumento28 páginasChapter One Introduction 1-1 Introductionmohammed boraAinda não há avaliações

- Final Report (Dam 2)Documento27 páginasFinal Report (Dam 2)Ahmed AmediAinda não há avaliações

- Eng 01 00013 With CoverDocumento24 páginasEng 01 00013 With CoverJose SantosAinda não há avaliações

- Guidelines For Culverts FactDocumento4 páginasGuidelines For Culverts FactrajeevAinda não há avaliações

- Types of Dam: Arch DamsDocumento8 páginasTypes of Dam: Arch DamsAlnielen EcobenAinda não há avaliações

- Archimedes' Law of Buoyancy and The Backfilling of Drainage StructuresDocumento0 páginaArchimedes' Law of Buoyancy and The Backfilling of Drainage StructuresFerdinand YeoAinda não há avaliações

- ch2 PDFDocumento6 páginasch2 PDFEdwin David Gonzáles MurilloAinda não há avaliações

- Chapter 6 Physical MethodsDocumento18 páginasChapter 6 Physical MethodsFaisal JunaidAinda não há avaliações

- Irrigation Engineering CE-431: Engr. Asim Qayyum ButtDocumento30 páginasIrrigation Engineering CE-431: Engr. Asim Qayyum ButtAshhad ShafiqueAinda não há avaliações

- Indian Railways Bridge Manual (Edition 1998)Documento24 páginasIndian Railways Bridge Manual (Edition 1998)p.k.guptaAinda não há avaliações

- Box CulvertDocumento29 páginasBox Culvertmohammed boraAinda não há avaliações

- HYDRO Asiignment 22222Documento7 páginasHYDRO Asiignment 22222Arif HassenAinda não há avaliações

- Final CausesDocumento9 páginasFinal CausesShahnawaz ZardariAinda não há avaliações

- Assignment " ON: Types & Construction of DamsDocumento7 páginasAssignment " ON: Types & Construction of DamsSaurabh VermaAinda não há avaliações

- Canal FallsDocumento10 páginasCanal FallsSubin GajurelAinda não há avaliações

- Types of Dams by StructureDocumento7 páginasTypes of Dams by StructureSiva SankarAinda não há avaliações

- Trabajo FluidosDocumento7 páginasTrabajo FluidosJaneth Lopez ContrerasAinda não há avaliações

- Ma. Jessa I. Corpuz Bsce 5ADocumento4 páginasMa. Jessa I. Corpuz Bsce 5AMJ JessaAinda não há avaliações

- Civil Work ResearchDocumento15 páginasCivil Work ResearchKarissa LimosAinda não há avaliações

- Chapter 1-IntroductionDocumento15 páginasChapter 1-IntroductionMohamed Al-OdatAinda não há avaliações

- HYDRAULICSDocumento29 páginasHYDRAULICSAbdullahi AwwalAinda não há avaliações

- Faizan MPDocumento32 páginasFaizan MPAnkitAinda não há avaliações

- Critical Review of Stilling Basin Models For Pipe Outlet WorksDocumento4 páginasCritical Review of Stilling Basin Models For Pipe Outlet WorksInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- MaKur M.Documento8 páginasMaKur M.marekmanyielAinda não há avaliações

- DamsDocumento20 páginasDamsYandi TVAinda não há avaliações

- What Is Dam: Classification of Dams According To The Material Used For Dam ConstructionDocumento4 páginasWhat Is Dam: Classification of Dams According To The Material Used For Dam ConstructionMir Masood ShahAinda não há avaliações

- Concrete Launches: Ramps, Stairs, and MatsDocumento25 páginasConcrete Launches: Ramps, Stairs, and Matsqatarstructz30Ainda não há avaliações

- A Dam Is A Barrier Built Across A Water Course To Hold Back or Control The Water Flo1Documento3 páginasA Dam Is A Barrier Built Across A Water Course To Hold Back or Control The Water Flo1natnael23Ainda não há avaliações

- Rock-Fill Dams: Impounds Water Floodgates Levees Dikes Hydropower Pumped-Storage HydroelectricityDocumento1 páginaRock-Fill Dams: Impounds Water Floodgates Levees Dikes Hydropower Pumped-Storage HydroelectricityShah KhanAinda não há avaliações

- Submarine PipelineDocumento10 páginasSubmarine Pipelinepiping stressAinda não há avaliações

- A Little History of DamsDocumento10 páginasA Little History of DamsJohn Rulen CariñoAinda não há avaliações

- Scientific American Supplement, No. 497, July 11, 1885No EverandScientific American Supplement, No. 497, July 11, 1885Ainda não há avaliações

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionAinda não há avaliações

- Soil Sample SizesDocumento7 páginasSoil Sample SizesJaydie CadungogAinda não há avaliações

- Rectangular ChannelDocumento2 páginasRectangular ChannelJaydie CadungogAinda não há avaliações

- Phillip Jack BrooksDocumento1 páginaPhillip Jack BrooksJaydie CadungogAinda não há avaliações

- (Z) (A) (P) (E-) (N) : Atomic Number Name Symbol Atomic Mass Protons Electrons NeutronsDocumento3 páginas(Z) (A) (P) (E-) (N) : Atomic Number Name Symbol Atomic Mass Protons Electrons NeutronsJaydie CadungogAinda não há avaliações

- Dynamic Study of Step Back and Set Back Building: ResearchDocumento7 páginasDynamic Study of Step Back and Set Back Building: ResearchSristi GuptaAinda não há avaliações

- Financials For... Box CulvertDocumento5 páginasFinancials For... Box CulvertAnonymous CPEha1db7UAinda não há avaliações

- Tilt and TurnDocumento9 páginasTilt and TurnMohsin KhanAinda não há avaliações

- James M Apple K R Govindan S.C.Sharma-R.B.Choudary & G.R.N.Tagore - D.R.SuleDocumento73 páginasJames M Apple K R Govindan S.C.Sharma-R.B.Choudary & G.R.N.Tagore - D.R.SuleWeecky HunterAinda não há avaliações

- Construction Quiz1MTDocumento1 páginaConstruction Quiz1MTMelvin EsguerraAinda não há avaliações

- Chapter 6 - Beam-Columns PDFDocumento15 páginasChapter 6 - Beam-Columns PDFNj Concepcion RobeniolAinda não há avaliações

- Grs 552Documento34 páginasGrs 552newid idAinda não há avaliações

- Concrete Mix Design As Per Indian Standard CodeDocumento4 páginasConcrete Mix Design As Per Indian Standard CodesemakambaAinda não há avaliações

- Se Sovent Design Manual 101o New011007Documento24 páginasSe Sovent Design Manual 101o New011007jomy_pj8106Ainda não há avaliações

- Cables Catalogue 2Documento6 páginasCables Catalogue 2fikih padliAinda não há avaliações

- Translate - T300+Documento36 páginasTranslate - T300+VănHồ NguyễnAinda não há avaliações

- Walrus hq800 Water Pressure PumpDocumento2 páginasWalrus hq800 Water Pressure PumpDenata Machmud SugandhiAinda não há avaliações

- Window and Facade Magazine Global (September-October 2023)Documento60 páginasWindow and Facade Magazine Global (September-October 2023)Abdul NabiAinda não há avaliações

- Fire Damper InfoDocumento14 páginasFire Damper InfoXAVIER RUBIOAinda não há avaliações

- Report Water Resources - Spillways, Crest Gates, and Outlet WorksDocumento13 páginasReport Water Resources - Spillways, Crest Gates, and Outlet WorksChristian BaldoAinda não há avaliações

- Design of Concrete Structures - I Question PaperDocumento3 páginasDesign of Concrete Structures - I Question PaperSourav Sil50% (2)

- B V DoshiDocumento30 páginasB V DoshiJeeva Z FedricoAinda não há avaliações

- Proy. C - Completo - 2018Documento12 páginasProy. C - Completo - 2018Gosbony SKAinda não há avaliações