Escolar Documentos

Profissional Documentos

Cultura Documentos

Karim Ahmed Fahmy 200330237 Lab 6 Investigation of The Variation in Refrigerator Coefficient of Performance For Various Evaporating Temperatures

Enviado por

Kristin OlsonTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Karim Ahmed Fahmy 200330237 Lab 6 Investigation of The Variation in Refrigerator Coefficient of Performance For Various Evaporating Temperatures

Enviado por

Kristin OlsonDireitos autorais:

Formatos disponíveis

Karim Ahmed Fahmy 200330237 Lab 6 Investigation of the variation in refrigerator coefficient of performance for various evaporating temperatures

Summary The objective of this lab is to examine the operation of a standard vapour compression refrigeration cycle and to determine the production of the cycle diagram under various conditions, the production of an energy balance for the refrigerator and the coefficient of performance of the cycle

Procedure: 1- Turn on main water supply, then start the system with a refrigeration load of approximately 200 W. Set the cooling water flow to give a condenser pressure of approximately 800-1000 KN/m2 . Record all temperatures, pressures, flow, and power readings after 5 to 10 minutes for stabilization. 2- The unit should be run for few minutes at a moderation load of approximately 400-800 W and then set to the desired conditions for the test. The evaporator temperature,t4,is set by adjusting the evaporator heat input. The condensing temperature is set by adjustment of condenser cooling water flow unit the condenser pressure is the saturation pressure at the desired condensing temperature. 3- Take 4 set of data with constant condensing pressure and another 4 sets of data with constant evaporating pressure. Aspects of refrigeration

CONDENSER

Compressor Expansion Valve

EVAPORATOR

The procedure that the refrigerant goes through begins with it entering the compressor as a vapor and is then compressed to the condenser pressure. It leaves the compressor at high pressure and cools down and condenses as it passes the coil of the condenser by ejecting heat. The second law of thermodynamic includes the statement, it is impossible to transfer heat from a region at a lower temperature to another higher temperature without the aid of an external agency. Refrigerators and heat pumps are examples of machines that transfer heat from a low to high temperature region and the external agency employed may either work or high grade heat.

Results and Discussion

Data Series test No: Condenser Pressure (Pc) Evaporator Pressure (Pe) Compressor Suction (t1) Compressor Delivery (t2) Liquid leaving condensor (t3) Evaporator inlet (t4) Water inlet (t5) Water outlet (t6) Water flowrate (Mw) R134a Flow Rate (Mr) Evaporator load (Qe) Motor input (Qme) Spring Balance F(N) Compressor speed (nc) Motor speed (nm) =nc*1.98 Constant condenser pressure 1 2 3 4 850 850 850 850 30 50 70 90 -21 -13.2 -9.1 -4 50.8 56.3 60.4 62 30.9 -21.4 20 37 7 2 188 380 7 855 1692. 9 34 -17.6 20.6 35.5 9 2.5 273 398 7.1 832 1647.3 6 34.3 -15.1 20.3 34.1 12 2.8 332 409 7.5 816 1615.6 8 33.9 -12.1 18.7 33.2 13 3.2 425 427 8 796 1576.0 8 Constant evaporator pressure 1 2 3 4 850 900 1000 1110 90 90 90 90 -4 -9.7 -6 -4.2 62 62.9 64 66.4 33.9 -12.1 18.7 33.2 13 3.2 425 427 8 796 1576.0 8 34.4 -12 18.2 36 10 3 400 425 7.9 795 1574. 1 36.3 -12.3 19 40.5 8.1 2.8 356 430 8 790 1564. 2 39.1 -12.3 19.3 44.8 6 2.6 324 433 8.2 783 1550.3 4

Pe abs (kpa) T sat (0C) COP

130 -20.55 0.4947

150 -17.185 0.6859

170 -14.165 0.8117

190 -11.41 0.9953

950 37.48 0.9953

1000 39.37 0.9412

1100 42.83 0.8279

1210 46.6 0.7483

Equipment: Unit R713, P.A Hilton ltd.

References Lab 4,5 and 6 handouts

http://www.eng.su.ac.th/me/elearning/ThermodynamicsII/3RefrigerationCycle.pdf

Recommendations: 1) Make sure that there is no leak in the whole system 2) Wait till values become stable before recording them 3) Make sure to follow the correct order when performing the experiment

Você também pode gostar

- Mechanical Heat Pump-2 PDFDocumento9 páginasMechanical Heat Pump-2 PDFRushikesh PatilAinda não há avaliações

- Refrigerator Test R1Documento9 páginasRefrigerator Test R1GHyukendo Shaddiq AkhbarAinda não há avaliações

- Refrigerantion Complete 2Documento27 páginasRefrigerantion Complete 2Ricardo Wan Aguero50% (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersAinda não há avaliações

- Refrigeration LabDocumento16 páginasRefrigeration LabFaizal IbrahimAinda não há avaliações

- Experiment T4 For CN2108Documento8 páginasExperiment T4 For CN2108Kiang Teng LimAinda não há avaliações

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsAinda não há avaliações

- 803 Rac (Me-803) Exp. ManualDocumento47 páginas803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToAinda não há avaliações

- Experiment 6 (Refrigerator) ) 1Documento10 páginasExperiment 6 (Refrigerator) ) 1Meor Fitri SE100% (1)

- Refrigeration and Air ConditioningDocumento21 páginasRefrigeration and Air ConditioningShiva Kumar H MAinda não há avaliações

- Understanding Process Equipment for Operators and EngineersNo EverandUnderstanding Process Equipment for Operators and EngineersNota: 4.5 de 5 estrelas4.5/5 (3)

- BK16110252 - Experiment V1 - KM31401-1718-II - REPORTDocumento6 páginasBK16110252 - Experiment V1 - KM31401-1718-II - REPORThasmikaAinda não há avaliações

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationAinda não há avaliações

- Lab Sheet: Title: Refrigeration SystemDocumento6 páginasLab Sheet: Title: Refrigeration SystemShan aliAinda não há avaliações

- Refrigerant Unit Lab ReportDocumento19 páginasRefrigerant Unit Lab Reportakmal100% (2)

- Air Water Heat PumpDocumento14 páginasAir Water Heat PumpKeshav GopaulAinda não há avaliações

- Me20b092 E14Documento5 páginasMe20b092 E14momo momosAinda não há avaliações

- University of Zakho College of Engineering Mechanical DepartmentDocumento9 páginasUniversity of Zakho College of Engineering Mechanical DepartmentDler SabryAinda não há avaliações

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentAinda não há avaliações

- T4 Air Conditioning StudyDocumento10 páginasT4 Air Conditioning StudySzeQiLungAinda não há avaliações

- Refrigeration Report WebDocumento20 páginasRefrigeration Report WebTyler HenryAinda não há avaliações

- University of Zakho College of Engineering Mechanical DepartmentDocumento14 páginasUniversity of Zakho College of Engineering Mechanical DepartmentDilshad S FaisalAinda não há avaliações

- Performance Analysis of A Domestic Refrigerator Using Various Alternative ReffrigerantDocumento12 páginasPerformance Analysis of A Domestic Refrigerator Using Various Alternative ReffrigerantGulshan SahuAinda não há avaliações

- Lab Refrigeration N Cooling TowerDocumento21 páginasLab Refrigeration N Cooling TowerShahran IezzatAinda não há avaliações

- Heat Transfer in Laminar FlowDocumento6 páginasHeat Transfer in Laminar Flowanil chejaraAinda não há avaliações

- Lab Report On Cooling Tower: Performed byDocumento9 páginasLab Report On Cooling Tower: Performed byramesh pokhrelAinda não há avaliações

- Forced Convection: Indian Institute of Technology PatnaDocumento8 páginasForced Convection: Indian Institute of Technology PatnaPranav BajajAinda não há avaliações

- T2. Air Conditioning StudyDocumento8 páginasT2. Air Conditioning StudyHaha WoNgAinda não há avaliações

- AWP LabDocumento11 páginasAWP LabAmirul HusniAinda não há avaliações

- Refrigeration Test Ring.Documento12 páginasRefrigeration Test Ring.பிரேம் ஆனந்த்Ainda não há avaliações

- Suyat Experiment-7Documento8 páginasSuyat Experiment-7Lpt Ashley OlbinarAinda não há avaliações

- Steam Plant Alalysis ReportDocumento17 páginasSteam Plant Alalysis Reportميسرة100% (11)

- kkkkkk مدمجDocumento4 páginaskkkkkk مدمجMr assassin hunterAinda não há avaliações

- H2LAB grp8Documento7 páginasH2LAB grp8jjain26904Ainda não há avaliações

- Rac 7th Sem ManualDocumento26 páginasRac 7th Sem Manualmanishsingla88Ainda não há avaliações

- Rac Solution Set BDocumento12 páginasRac Solution Set BxofigoAinda não há avaliações

- Screenshot 2023-01-11 at 8.11.58 PMDocumento15 páginasScreenshot 2023-01-11 at 8.11.58 PMAbdla DoskiAinda não há avaliações

- Rac Lab ManualDocumento30 páginasRac Lab ManualPrakharGupta100% (1)

- AE May 2013 07 Mec A1Documento6 páginasAE May 2013 07 Mec A1Hariz BayuAinda não há avaliações

- Experiment 1: Refrigeration and Mechanical Heat Pump ExperimentDocumento12 páginasExperiment 1: Refrigeration and Mechanical Heat Pump ExperimentMohamad FaizAinda não há avaliações

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Documento8 páginasDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainAinda não há avaliações

- Cooling Tower ReportDocumento27 páginasCooling Tower ReportWengLiLeongAinda não há avaliações

- Filmdropwise LabDocumento47 páginasFilmdropwise Labaizaqsyazwan50% (2)

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDocumento30 páginasEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiAinda não há avaliações

- Vapour Compression RefrigerationDocumento4 páginasVapour Compression RefrigerationAhmadAinda não há avaliações

- Experiment 4 (2023) - 2Documento6 páginasExperiment 4 (2023) - 2Hussein SaeedAinda não há avaliações

- Refrigeration and Air Conditioning ReportDocumento20 páginasRefrigeration and Air Conditioning ReportToke BekeleAinda não há avaliações

- Generator Hydrogen CoolingDocumento4 páginasGenerator Hydrogen CoolingBanamali MohantaAinda não há avaliações

- Cooling TowerDocumento10 páginasCooling TowerMohammed IslamAinda não há avaliações

- Regr I RationDocumento2 páginasRegr I RationFrancisco ServignaAinda não há avaliações

- 32.passive CoolingDocumento13 páginas32.passive CoolingmariyaAinda não há avaliações

- There Are Several Types of FogDocumento2 páginasThere Are Several Types of FogTim RolandAinda não há avaliações

- Pages From HVAC Design Handbook (301 450)Documento150 páginasPages From HVAC Design Handbook (301 450)zaffar731Ainda não há avaliações

- Thermal Load SummaryDocumento1 páginaThermal Load SummaryMohammad Altaf HussainAinda não há avaliações

- Passive Solar Building Design: B.ARCH (6 Semester) Bar 608 - Theory of Sustainable ArchitectureDocumento67 páginasPassive Solar Building Design: B.ARCH (6 Semester) Bar 608 - Theory of Sustainable ArchitectureMohit VermaAinda não há avaliações

- Chapter 2 Pressure Distribution in A FluidDocumento4 páginasChapter 2 Pressure Distribution in A FluidAlvaro CujiAinda não há avaliações

- Humidity Sensor: Key Kai WongDocumento15 páginasHumidity Sensor: Key Kai WongDeepak sutarAinda não há avaliações

- Psychrometric Chart, 5400 FT.: Temperature, FDocumento3 páginasPsychrometric Chart, 5400 FT.: Temperature, FROMEE REY CALDERONAinda não há avaliações

- of Refrigeration Basic Prinicple and ProblemsDocumento39 páginasof Refrigeration Basic Prinicple and ProblemsUday Kiran BokkaAinda não há avaliações

- Calculation Exhaust FanDocumento14 páginasCalculation Exhaust Fanm khaeronAinda não há avaliações

- Mini P PRO-MP50Documento12 páginasMini P PRO-MP50ctmtectrolAinda não há avaliações

- How Thermometers Work 1Documento5 páginasHow Thermometers Work 1Wira Putri WinataAinda não há avaliações

- Contoh Soal Ukp MeteorologiDocumento18 páginasContoh Soal Ukp Meteorologiade fadliAinda não há avaliações

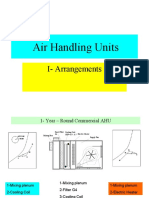

- Air Handling Units: I-ArrangementsDocumento29 páginasAir Handling Units: I-ArrangementsAbdulrahman EL-GammalAinda não há avaliações

- ASHRAE UFADdesignguide PDFDocumento255 páginasASHRAE UFADdesignguide PDFCarlos EduardoAinda não há avaliações

- Useful Evaporative Cooling FormulasDocumento1 páginaUseful Evaporative Cooling FormulaszhobeysAinda não há avaliações

- 1 E-Clim Clima Fadu UbaDocumento16 páginas1 E-Clim Clima Fadu UbaNatalyRochaAinda não há avaliações

- BIT 25 - LAE Controller Manual PDFDocumento6 páginasBIT 25 - LAE Controller Manual PDFrafik1995100% (1)

- 7th Lecture - Humidifiers and Its TypesDocumento21 páginas7th Lecture - Humidifiers and Its TypesHaseeb RazaAinda não há avaliações

- Dry Saturated Steam Tables-Technical InformationDocumento2 páginasDry Saturated Steam Tables-Technical InformationanwarhAinda não há avaliações

- Atmospheric PressureDocumento7 páginasAtmospheric PressureJames FranklinAinda não há avaliações

- Seminar On AC System PDFDocumento33 páginasSeminar On AC System PDFJagadish SahuAinda não há avaliações

- AirconDocumento24 páginasAirconMelvin Mhds100% (1)

- Atmospheric Pressure - Wikipedia, The Free EncyclopediaDocumento9 páginasAtmospheric Pressure - Wikipedia, The Free Encyclopediaelvi anggiovennyAinda não há avaliações

- Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDFDocumento56 páginasDaikin VRV III (Selection Installation Proceedure) Technical Data Book PDFHarveen Singh100% (1)

- Chapter Eight Class 9th PDFDocumento15 páginasChapter Eight Class 9th PDFMuneer KaleriAinda não há avaliações

- Ashrae 2009 - Climatic Design InformationDocumento17 páginasAshrae 2009 - Climatic Design InformationJack SparrowAinda não há avaliações

- Guias Tecnicos Aplicacoes Avac en 0Documento25 páginasGuias Tecnicos Aplicacoes Avac en 0cachiletAinda não há avaliações

- Open and Closed Air Refrigeration CyclesDocumento4 páginasOpen and Closed Air Refrigeration CyclesrajsharmarajAinda não há avaliações