Escolar Documentos

Profissional Documentos

Cultura Documentos

ADC3 en REVA 2009 Lift Magnet Supply

Enviado por

a2345Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ADC3 en REVA 2009 Lift Magnet Supply

Enviado por

a2345Direitos autorais:

Formatos disponíveis

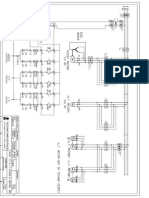

DCS800 Lift Magnet Supply

ADC3 EN REVA 2009

supply Multiple magnet supply Emergency backup configurations

AC input 3-ph

Application notes

I>>

K01

electronics-, fan- supply

DCS800

+ -

Many cranes lift ferrous material by using a magnet instead of a hook. Nowadays new cranes, like small tower cranes or overhead bridge cranes (EOT), are equipped with AC drives and a thyristor-based DC supply for the lift magnet. Lift magnets are used for a wide range of applications. They are also used in metals plants for lifting rods and coils. Iron Scrap cranes and iron rod and bar handling cranes use magnetic force for the iron goods. When replacing the magnet supply, the new magnet supply must have an application program that adapts to all different control concepts and handles the original relay logic.

service switch K02.0

K03D

K04B

K02.1

K02.2

Many different load and operation types are required

Simple scrap magnets Complex metal sheet stacks Demagnetization control One magnet

AC input 3-ph

Typical lift magnet system with load from several switched magnet and back-up battery

Demagnetization

The physical remnants of the magnets create a residual force even if the input current of the magnet is zero. The release of light weight loads is done by demagnetization. Decreasing alternating (positive and negative) magnet current will erase the residual force. A four-quadrant converter which can supply current in either direction is required for this operation.

I>>

K01

electronics-, fan- supply

DCS800

+ -

Flux forcing for higher dynamic

The electrical circuit characteristic of this type of magnet consists of a high amount of inductance in series with a resistance. This ends up in a very long time constant when switching the magnet's input current ON and OFF. This will lengthen the cycle times of the operation and decrease the total crane efficiency. The time constant can be decreased by increasing the input voltage during current changes. For example, a 200 V DC magnet

Minimum lift magnet supply with one magnet

ADC3 EN REVA 2009

is powered by a 440 V DC supply system. During continuous operation, the converter provides 200 V DC to the magnet. When energizing and de-energizing the magnet, the converter is able to provide maximum or minimum output voltage which, in this case, is positive 440 V DC or negative 440 V DC. This decreases the current ramp time by 80%.

Voltage

Current Time

Typically, magnet installations have more than one magnet connected in parallel. The number of magnets used depends on the load and will be switched ON and OFF with contactors controlled by the operator. This saves energy for the whole installation. The converter controls the output voltage and not the output current. The output voltage is independent from the number of connected magnets. Newer cranes usually do not use contactors. They use independent converters for each magnet. This redundancy provides higher safety for the user. Be aware that normal contactors are not able to switch the magnet current. Only the switch ON can be handled by the contactors. The installation must be equipped with an overvoltage protection to clamp the maximum output voltage of the converter when switching the contactors.

Customer benefits

Easy to handle - less training Full current range Fits on classic lift magnet installations Meet all requirements for modern and

new installations All common serial communication interfaces Upgrade of old systems by adaptation via IEC 61131 programming Voltage and current control mode Synergy with DCS800 crane drives Synergy with ACS800 drives

ABB Automation Products Wallstadter Strae 59 68526 Ladenburg GERMANY Phone +49(0)6203-71-0 Fax +49(0)6203-71-7609 www.abb.com/motors&drives dc-drives@de.abb.com

Copyright 2009 ABB. All rights reserved. Specifications subject to change without notice.

Application notes

Step by step release

If the load is a stack of sheet metal, the operator can unload the crane sheet by sheet by slowly reducing the magnetic force. The converter can simply reduce the output voltage and thus the output current. This is a big advantage compared to traditional diode magnet supplies.

Current controlled switch ON magnet Add magnets by contactor Reduce magnet force by reducing Voltage / current Switch OFF magnet by reversing current for demagnetization

Emergency battery backup operation

Falling material can always be dangerous and can also waste a lot of money. Therefore, some crane systems are equipped with an emergency back-up battery. This battery can supply the DC current to the magnets for a short while. The batteries are connected via a contactor in case of mains loss.

Emergency backup battery charge

In some configurations the magnet supply converter is also used to charge the emergency backup battery during crane standby. The different configurations will be switched by contactors.

Switched parallel operation of several magnets depending on load

The DCS800 converter can handle the lift magnet application and meet customer's requirements. Additional functions are controlled by the CoDeSys IEC 61131 program, especially magnetic specific functions. It can customize the application to the customer's requirements and IO functions. New small tower cranes or new bridge cranes (EOT) are equipped with AC drives nowadays. ACS800 drives for the hoist and the trolley together with a DCS800 lift magnet supply provide convenient synergies to the customer. The control interfaces, serial communication, the monitor and maintenance equipment is the same. That means less training and easy support. Older crane installations are equipped with DC drives for hoist and trolley. The DCS800 meets the requirements of large cranes like a container crane or a garb ship unloader. A DCS800 crane drive application module provides all required functions like shared motion for hoists and gantry as well as brake control, power optimization and stand alone joystick interface.

Você também pode gostar

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Nota: 2.5 de 5 estrelas2.5/5 (3)

- EditedDocumento55 páginasEditedMeshack LeeAinda não há avaliações

- Serie R eDocumento36 páginasSerie R ev5bw57b7tzAinda não há avaliações

- Welding Power SupplyDocumento3 páginasWelding Power SupplyDeepak Kumar Kant KesriAinda não há avaliações

- VSC Product Introduction-EnDocumento36 páginasVSC Product Introduction-EnAldeni Prima AnugrahAinda não há avaliações

- NCL ReportDocumento20 páginasNCL ReportSwati Tripathi33% (3)

- EO6ADocumento35 páginasEO6Amspd2003Ainda não há avaliações

- v42 63Documento5 páginasv42 63Bala KumarAinda não há avaliações

- Switchyard & Its Equipment AND HVDC Transmission: Deepak Kumar SahuDocumento36 páginasSwitchyard & Its Equipment AND HVDC Transmission: Deepak Kumar SahuDeepak Kumar SahuAinda não há avaliações

- Presentation On Substation 220 KVDocumento37 páginasPresentation On Substation 220 KVPiyush Bansal75% (12)

- (VT Ranganathan) Course Notes On Electric DrivesDocumento119 páginas(VT Ranganathan) Course Notes On Electric DrivesPowerranger2.0Ainda não há avaliações

- CA Vcontact VSC (En) I 1vcp000165 1002Documento42 páginasCA Vcontact VSC (En) I 1vcp000165 1002ayalmalikiAinda não há avaliações

- Assignment#2: Applications of Thyristors in HVDCDocumento5 páginasAssignment#2: Applications of Thyristors in HVDCRashid AltafAinda não há avaliações

- Iot Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaDocumento17 páginasIot Based Control and Monitoring of Smart Grid and Power Theft Detection by Locating AreaakashlogicAinda não há avaliações

- DC Motor Speed ControlDocumento54 páginasDC Motor Speed ControlAbhishek Gupta100% (3)

- Power InverterDocumento11 páginasPower Inverterriz2010Ainda não há avaliações

- Electrical Engineering Interview Questions: Verilog Task Verilog FunctionDocumento6 páginasElectrical Engineering Interview Questions: Verilog Task Verilog FunctionProject TeamAinda não há avaliações

- Presentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarDocumento70 páginasPresentation On: By-Er Rajinder Kumar Lecturer Electrical Engg. Govt Polytechnic College AmritsarAnonymous ExWAN2xjFJ100% (1)

- Project - On Power Sub StationDocumento22 páginasProject - On Power Sub StationRavi KumarAinda não há avaliações

- Photovoltaic Ac Module Based On A Cuk Converter With A Switched-Inductor StructureDocumento4 páginasPhotovoltaic Ac Module Based On A Cuk Converter With A Switched-Inductor StructureBrightworld ProjectsAinda não há avaliações

- Induction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion PerformanceDocumento9 páginasInduction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion Performancemlkz_01Ainda não há avaliações

- DC Motor Fyp EdittdDocumento20 páginasDC Motor Fyp EdittdRabia BilalAinda não há avaliações

- Contact orDocumento5 páginasContact orZol MaksebAinda não há avaliações

- Sine Wave Inverter With PICDocumento50 páginasSine Wave Inverter With PICmtrapkAinda não há avaliações

- Automatic Power Factor Controlling PanelDocumento15 páginasAutomatic Power Factor Controlling PanelheruvalaAinda não há avaliações

- Applications of MatixDocumento2 páginasApplications of MatixSugu SukuAinda não há avaliações

- SVC ProductsDocumento15 páginasSVC Productsjoydeep_d3232Ainda não há avaliações

- DC Traction Energy Recovery InvertersDocumento4 páginasDC Traction Energy Recovery Invertersrvim0002Ainda não há avaliações

- 5 HVDCDocumento40 páginas5 HVDCghulamqadir.pmpAinda não há avaliações

- Barau MaidammaDocumento4 páginasBarau MaidammaAbdulrahaman AbdulraheemAinda não há avaliações

- Variable Shunt ReactorsDocumento8 páginasVariable Shunt ReactorsAdeniji OlusegunAinda não há avaliações

- Abb Circuit Breaker-LiteratureDocumento44 páginasAbb Circuit Breaker-LiteraturecetpcapgencoAinda não há avaliações

- Final Year Electrical Gss ReportDocumento35 páginasFinal Year Electrical Gss ReportRavi Rajpurohit0% (1)

- SmpsDocumento5 páginasSmpscalvarez_5Ainda não há avaliações

- Overview of Industrial Motor Control SystemsDocumento8 páginasOverview of Industrial Motor Control Systemsiwuo4797Ainda não há avaliações

- An Application of Matlab/Simulink For Speed Control of DC Series Motor Using Buck ConverterDocumento5 páginasAn Application of Matlab/Simulink For Speed Control of DC Series Motor Using Buck ConverterArghya MukherjeeAinda não há avaliações

- Chapter 2 PPT - Lecture 1&L2Documento29 páginasChapter 2 PPT - Lecture 1&L2Biniyam DameneAinda não há avaliações

- Voltage Source Inverter Drive: Ece 504 - Experiment 2Documento17 páginasVoltage Source Inverter Drive: Ece 504 - Experiment 2Olimpiu StoicutaAinda não há avaliações

- Dual ConverterDocumento11 páginasDual ConverterRoshan GokheAinda não há avaliações

- PPTDocumento23 páginasPPTyashAinda não há avaliações

- Interview QuestionDocumento49 páginasInterview Questionshubha christopherAinda não há avaliações

- Ee 328 Lecture 1Documento40 páginasEe 328 Lecture 1Hasan Hatice IlcalıAinda não há avaliações

- Power Quality: Mechanism of Harmonic Generation-Harmonic Indices (THD, TIF, DIN, C - Message WeightsDocumento61 páginasPower Quality: Mechanism of Harmonic Generation-Harmonic Indices (THD, TIF, DIN, C - Message WeightsabhilashkrishnantkAinda não há avaliações

- TransformerDocumento20 páginasTransformernabeel hassan ali100% (1)

- Power Supply Description:: The Power Supply Circuit Comprises of Four Basic PartsDocumento19 páginasPower Supply Description:: The Power Supply Circuit Comprises of Four Basic PartsEr. Piush Jindal100% (1)

- Engineering QuestionsDocumento31 páginasEngineering QuestionsRizwan ShahidAinda não há avaliações

- SUBstation Equipmens TLDocumento12 páginasSUBstation Equipmens TLJecer Casipong NuruddinAinda não há avaliações

- Module-I 3 Con TopoDocumento4 páginasModule-I 3 Con TopoLalbahadur MajhiAinda não há avaliações

- 53 - 36765 - ME593 - 2014 - 1 - 1 - 1 - DC Motors PDFDocumento56 páginas53 - 36765 - ME593 - 2014 - 1 - 1 - 1 - DC Motors PDFDora TengAinda não há avaliações

- Brochure Inverter SG825865BEN A02-05.13Documento4 páginasBrochure Inverter SG825865BEN A02-05.13zarun1Ainda não há avaliações

- Siemens - Medium Voltage Equipment Range For SubstationsDocumento16 páginasSiemens - Medium Voltage Equipment Range For SubstationsUrsula JohnsonAinda não há avaliações

- UHVDC Article AbbDocumento5 páginasUHVDC Article AbbAbhideep DasguptaAinda não há avaliações

- EEE Interview Question and AnswersDocumento20 páginasEEE Interview Question and AnswersAlexander JagannathanAinda não há avaliações

- 4 Crucial Switching Functions of A MV Circuit Breaker (Facts You MUST Know)Documento14 páginas4 Crucial Switching Functions of A MV Circuit Breaker (Facts You MUST Know)mostafaAinda não há avaliações

- Workhorses of Industry: Industrial Transformers in A DC EnvironmentDocumento7 páginasWorkhorses of Industry: Industrial Transformers in A DC Environmentreza515heiAinda não há avaliações

- TMdrive-MVG - TMEIC's Medium Voltage AC DriveDocumento16 páginasTMdrive-MVG - TMEIC's Medium Voltage AC Drivepavithra27Ainda não há avaliações

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsNo EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsNota: 3.5 de 5 estrelas3.5/5 (6)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlNo EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlNota: 5 de 5 estrelas5/5 (1)

- VFD ApplicationDocumento54 páginasVFD ApplicationAna-Maria GligorAinda não há avaliações

- Apc Smartups 1500 Smt1500 ManualDocumento21 páginasApc Smartups 1500 Smt1500 ManualskibcobsaivigneshAinda não há avaliações

- Ch09 AC DrivesDocumento28 páginasCh09 AC Drivesa2345Ainda não há avaliações

- Long Products Bulletin 2011Documento60 páginasLong Products Bulletin 2011a2345Ainda não há avaliações

- JSPL 220tp20 - 5 Set Post DrawingDocumento21 páginasJSPL 220tp20 - 5 Set Post Drawinga2345Ainda não há avaliações

- JSPL 220tp20 - 5 Set Post DrawingDocumento21 páginasJSPL 220tp20 - 5 Set Post Drawinga2345Ainda não há avaliações

- Presentation 2Documento1 páginaPresentation 2a2345Ainda não há avaliações

- SG Eot Elect DRG CraneDocumento1 páginaSG Eot Elect DRG Cranea2345Ainda não há avaliações

- Three-Phase Asynchronous MotorsDocumento46 páginasThree-Phase Asynchronous Motorswartsil100% (4)

- SG Eot Elect DRG CraneDocumento1 páginaSG Eot Elect DRG Cranea2345Ainda não há avaliações

- EarthingDocumento10 páginasEarthingSatyavan L RoundhalAinda não há avaliações

- Work FlowDocumento20 páginasWork Flowa2345Ainda não há avaliações

- Upto 145kV 40ka 3150A Operating ManualDocumento64 páginasUpto 145kV 40ka 3150A Operating Manuala234588% (17)

- Upto 145kV 40ka 3150A Operating ManualDocumento64 páginasUpto 145kV 40ka 3150A Operating Manuala234588% (17)

- Harmonic Mitigation of 12 Pulse DriveDocumento1 páginaHarmonic Mitigation of 12 Pulse Drivea2345Ainda não há avaliações

- Multiple Imputation MethodDocumento72 páginasMultiple Imputation MethodSrea NovAinda não há avaliações

- Adapting Musical Activities For Persons With DisabilitiesDocumento5 páginasAdapting Musical Activities For Persons With DisabilitiesMinas TheodorakisAinda não há avaliações

- 3BUA000279R0002 en Bridge Controller and Process Bus Adapter (BRC-400 and BRC-300 PBA-200) PDFDocumento123 páginas3BUA000279R0002 en Bridge Controller and Process Bus Adapter (BRC-400 and BRC-300 PBA-200) PDFJavier Enrique Contreras SierraAinda não há avaliações

- Commonly Used Methods of Component ClassDocumento4 páginasCommonly Used Methods of Component ClassSudha MadhuriAinda não há avaliações

- UntitledDocumento928 páginasUntitledRafael Leal MartinsAinda não há avaliações

- Method 2: Automatically Start A VNC Session Via A Systemd Service ScriptDocumento2 páginasMethod 2: Automatically Start A VNC Session Via A Systemd Service ScriptjoAinda não há avaliações

- Image Compression: JPEG: Summary: SourcesDocumento21 páginasImage Compression: JPEG: Summary: SourcesNgô Hiếu TrườngAinda não há avaliações

- Vlfeat - An Open and Portable Library of Computer Vision AlgorithmsDocumento4 páginasVlfeat - An Open and Portable Library of Computer Vision AlgorithmsdesyagustinnAinda não há avaliações

- Smartphone Market in IndiaDocumento3 páginasSmartphone Market in IndiaAnshika YadavAinda não há avaliações

- KFC Case StudyDocumento3 páginasKFC Case StudyAnkita shaw100% (2)

- CPT 168 HW#13 Answer KeyDocumento6 páginasCPT 168 HW#13 Answer KeyJordan0% (1)

- Assignment Summary: Creating A Multimedia PresentationDocumento2 páginasAssignment Summary: Creating A Multimedia PresentationAria LeAinda não há avaliações

- CSE313 - Final Exam Question - PC-A - TH - Fall20Documento2 páginasCSE313 - Final Exam Question - PC-A - TH - Fall20Md Zahidul IslamAinda não há avaliações

- SLOOP: A European Project Focused On The Realization of A Shared Repository of Free Learning ObjectsDocumento7 páginasSLOOP: A European Project Focused On The Realization of A Shared Repository of Free Learning ObjectsPierfranco Ravotto100% (1)

- EH Slips PDFDocumento13 páginasEH Slips PDFvickram shettyAinda não há avaliações

- Chapter Six 6. Fundamentals of Printers and Scanners 6.1Documento22 páginasChapter Six 6. Fundamentals of Printers and Scanners 6.1belete tilahunAinda não há avaliações

- Case Study of Netflix (Mis-20102052)Documento16 páginasCase Study of Netflix (Mis-20102052)Himanshu PanwarAinda não há avaliações

- Gradle VM Options Android StudioDocumento3 páginasGradle VM Options Android StudioJoseAinda não há avaliações

- Advanced Algorithms TUTORIAL 6 Dynamic ProgrammingDocumento47 páginasAdvanced Algorithms TUTORIAL 6 Dynamic ProgrammingDone KitaAinda não há avaliações

- Learning Check AnswersDocumento5 páginasLearning Check AnswersTebogo McDonaldAinda não há avaliações

- Ramana ADF MSBI powerBIDocumento5 páginasRamana ADF MSBI powerBIraamanAinda não há avaliações

- 10 Best Computer Science Projects To Hone Your SkillsDocumento21 páginas10 Best Computer Science Projects To Hone Your SkillsHassani MahamuduAinda não há avaliações

- README Withered Arm V 1.33.7Documento2 páginasREADME Withered Arm V 1.33.7august1929Ainda não há avaliações

- Autonomous CarDocumento28 páginasAutonomous CarNagabhushana0% (1)

- სხეულის ენაDocumento322 páginasსხეულის ენაtikooAinda não há avaliações

- IT 160 Final Lab Project - Chad Brown (VM37)Documento16 páginasIT 160 Final Lab Project - Chad Brown (VM37)Chad BrownAinda não há avaliações

- How Effective Is ICDL Training For Omani TeachersDocumento104 páginasHow Effective Is ICDL Training For Omani TeachersGeorge VeletsianosAinda não há avaliações

- Siemense Operate 27sp1 Pcu50Documento3 páginasSiemense Operate 27sp1 Pcu50Dörky LefieuwAinda não há avaliações

- Method Statement For Testing & Commissioning of Disabled Toilet Alarm DTA SystemDocumento3 páginasMethod Statement For Testing & Commissioning of Disabled Toilet Alarm DTA Systemvin ssAinda não há avaliações

- G7028 G7052 CR 8-4 PDFDocumento418 páginasG7028 G7052 CR 8-4 PDFcarlos bronsonAinda não há avaliações