Escolar Documentos

Profissional Documentos

Cultura Documentos

Details of CC Pavement Design

Enviado por

Rajesh BabuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Details of CC Pavement Design

Enviado por

Rajesh BabuDireitos autorais:

Formatos disponíveis

5.

0

5.1

PAVEMENT DESIGN

PAVEMENT TYPES & DESIGN

All road pavements shall be designed in consideration of design traffic loadings and evaluation of subgrade materials, environmental factors and available materials. Typical pavements types are as follows: Unbound granular flexible pavement which may contain one or more modified layers Bound granular flexible pavement Segmental block pavements Rigid pavements (concrete)

A pavement design for all new roadworks shall be prepared for approval, subject to a geotechnical engineers report. The report shall utilise 4 day soaked Californian Bearing Ratio (CBR) testing undertaken on the relevant subgrade in accordance with AS 1289 and shall recommend a design CBR and a pavement design, determined using the methods outlined in Austroads Pavement Design, and Austroads Pavement Design for Light Traffic APT36/06, and the ARRB Special Report No. 41, or their equivalent revision or replacement within the nominated authorities/bodies based on Councils minimum standard Equivalent Standards Axle (ESA) requirements. The full goetechnical report shall be submitted with the engineering plans. The engineering plans shall show the details (including the nominated ESA and design CBR parameters) of an approved pavement design based on that report. In deep cuttings, fills or other instances where testing of subgrade is not possible until completion of bulk earthworks, pavement design or re-evaluation of a design, may be required upon examination at subgrade level. Records of actual pavement construction, together with any subgrade replacement or modification, shall be collated as a final report to accompany the WAE plans.

Page 41

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

5.2

DESIGN TRAFFIC LOADINGS

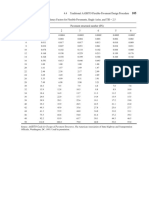

The design traffic loadings of Equivalent Standard Axels (ESA) are given in the following table. The nominated values may be subject to increment, subject to an assessment of any special circumstances for subdivision or development, where an adopted value is based on ultimate traffic generation for the catchment area, originating from: strategic planning for future rezoning of land ultimate development of current zoned land staging of works and the resultant development and construction traffic Design Traffic Loadings

Road type Access Place Local - Minor Local - Secondary Local - Primary Collector Distributor - Secondary Distributor - Primary Arterial or Sub-Arterial Rural Residential Rural - Minor Industrial - Minor Industrial Max No. Lots 10 20 50 100 200 400 800 > 800 per above 50 10 > 10 ESAs 1x10 5 1x10 2x10 5 5x10 1x10 6 2x10 5x10 6 1x10 min per above 5 1x10 5x10 6 1x10 min.

7 7 6 5 5

Notes: Where it is deemed that traffic type and volume demands are or may be significantly different, ESA values may be increased, at Councils discretion. Cross reference should be made to the table at section 4.2.1 for relevant explanatory notes. For purposes of determining an adequate pavement design, attention is drawn to Section 7.12 for construction requirements to satisfy characteristic deflection. 5.3 SUBGRADE EVALUATION

Investigation and testing of existing subgrade materials shall be performed by a practicing geotechnical engineer through a NATA registered laboratory. A pavement design report, including subgrade investigation and 4 day soaked CBR test results establishing a design CBR, shall accompany the Construction Certificate (and engineering design), and be submitted to Council or the Accredited Certifier for approval.

Page 42 Manual Of Engineering Standards ~ 2008 Chapter 5 Pavement Design

Assessment of the supporting subgrade strength shall be in accordance with APRG Report No. 21 or Austroads Pavement Design. For minor works within a public road (such as short lengths of shoulder, kerb & gutter in-fill, or access works) full testing described above may not be necessary, subject to an engineers assessment. Minimum requirements may be as follows: 30mm AC10 over a 10mm primer seal or a 2 coat bitumen seal 300mm compacted thickness of a granular base course material (200mm may be considered for very minor traffic loadings) a compacted and stable subgrade

Alternatively, the developer may submit a geotechnical design report for alternative pavement treatments. All pavement investigations and design by the Geotechnical Engineer shall provide comment in respect to APRG Report No. 21 with reference to extent of testing, site investigation and assessment and pavement design. 5.4 SUBSURFACE DRAINAGE

Subsurface drainage must be provided to protect the subgrade and pavement in locations that necessitate its use such as boxed construction, cuttings or areas with high water tables or in areas where subsurface moisture requires treatment. Subsoil drainage pipes shall be provided on both sides of road pavements and where required by design, at new-to-existing pavement joints (see section 5.5.8 & SD032) 5.5 PAVEMENT PROFILE TYPES

Public road pavements shall comprise of at least one subbase layer and one basecourse layer with a sealed wearing surface. Pavement layers may be combined into a single layer of base course material subject to section 5.5.1 5.5.1 FLEXIBLE PAVEMENT

Pavement thickness designs shall be based upon assessed subgrade strength and the following tables, being consistent with Figure 8.4 in Austroads Pavement Design Guide, and for minor rural roads, (other than designated state and regional roads) table 13.8.2(B) of A Guide

Page 43

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

to the Design of New Pavements for Light Traffic (APRG report 21 or fig.8.5 of AP-T36/06), or their equivalent revision or replacement within the nominated authorities/bodies.

DESIGN CHART FOR GRANULAR PAVEMENTS WITH THIN BITUMINOUS SURFACING FROM AUSTROADS PAVEMENT DESIGN GUIDE

The minimum pavement thickness for flexible pavements will be derived as follows: Basecourse shall be determined from the Pavement Thickness Design Chart, where the minimum thickness is 100mm. Subbase thickness shall be determined from the Pavement Thickness Design Chart, using the relevant CBR curve by subtracting the basecourse layer thickness from the required total pavement thickness. Irrespective of the foregoing, the minimum subbase thickness shall not be less than 170mm. Asphaltic concrete thickness shall be a minimum of 30mm and may be included as pavement "depth" in determining the pavement thickness. Two coat flush bitumen seals shall not be considered part of the pavement thickness. The pavement designer should be satisfied that the design will meet the requirements of this manual in respect to permissible deflection and pavement life. Where a combined subbase/base single-layer (with for example bound materials) pavement is proposed, a geotechnical engineer shall report on the proposal, nominating the materials (source) and relevant compaction and testing methods.

Page 44 Manual Of Engineering Standards ~ 2008 Chapter 5 Pavement Design

5 x 10 5

DESIGN CHART FOR GRANULAR PAVEMENTS WITH THIN BITUMINOUS SURFACING, BASED ON A 90 PERCENT CONFIDENCE LEVEL (for minor rural roads)

5.5.2

RIGID PAVEMENT

Rigid pavements on public roads shall be jointed reinforced concrete paving in accordance with the following documents: Concrete Pavement Design for Residential Streets - Cement and Concrete Assoc. of Aust. Pavement Design - Austroads RTA Form No. 76 (supplement to the Austroads Guide) and relevant RTA Directory notes. RTA Concrete Pavement Manual. Sub-base concrete thickness- 150mm minimum Base concrete thickness - 170mm minimum

Details prepared by an engineer, are required of (but not limited to): a. a proposed sub-base concrete mix adopting 5MPa minimum characteristic strength b. a proposed base concrete mix adopting 32MPa minimum characteristic strength c. a nominated maximum slump and testing procedure (see section 7.12.2) d. proposed thickness of sub-base and base courses e. steel reinforcement

Page 45 Manual Of Engineering Standards ~ 2008 Chapter 5 Pavement Design

f. joint types and locations g. interface treatments between layers h. placement, compaction, surface texture and curing methods i. subgrade preparation for a design CBR 5.5.3 SEGMENTAL BLOCK PAVEMENT

Segmental block pavements, where permitted, shall be constructed of concrete or clay pavers. Such pavements shall be designed in accordance with the following: Clay segmental block pavements:Up to 106 ESAs Clay Segmental Pavements Design manual, Clay Brick and Paver Association. Between 106 ESAs and 107 ESAs The design will involve the above document and Austroads Pavement Design Manual with the method producing the thicker design to be adopted. Over 107 ESAs Austroads Pavement Design Manual. Concrete segmental block pavements:Up to 106 ESAs Cement and Concrete Association Technical Note 35. Over 106 ESAs Austroads Pavement Design Manual. Concrete pavers shall be 80mm thick Shape A with clay pavers being 65mm thick Class 4 being laid in a herring bone pattern. All areas of block paving are to have a suitable concrete edge restraint. Large paved areas shall be laid/bedded in accordance with the suppliers guidelines. Allowance must be made for an adequate number of expansion joints and restraining beams. Shape C concrete pavers may be permitted in small infill areas such as residential street thresholds. (see section 5.5.7) 5.5.4 ACCESSWAY PAVEMENTS

Accessways to special areas or facilities such as public utility plant, parks, pollution control devices etc, that provide access for heavy vehicles, shall be constructed in concrete in accordance with the publication by the Cement and Concrete Association of Australia Concrete Pavement Design for Residential Streets.

Page 46

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

Generally the following parameters shall be maintained: 150mm thick 32 MPa 28 day strength Two layers of SL72 mesh fabric Sub-base, 100mm compacted thickness of road-base material

Pavements that provide eductor truck/backhoe access to Gross Pollutant Traps shall be a minimum of 3.0 metres wide. 5.5.5 ROUNDABOUTS

All roundabout pavements shall be constructed in fibre-reinforced concrete, designed with reference to rigid pavement RTA standard design and construction requirements. The minimum concrete design mix specification shall provide 32MPa characteristic strength, 4.25 Flex, with 50kg/m3 of steel fibre (Reo Pave 25 or equivalent). Consideration may be given to alternative pavements, such as deep-strength asphalt or similar, in special circumstances, where justifiable. (See also 4.2.8) 5.5.6 CYCLEWAYS

Cycleways shall be constructed of reinforced concrete in accordance with Council's standard drawing SD012 5.5.7 INTERSECTION THRESHOLDS

Where intersection thresholds are approved they shall be provided as per the following options: a) in accordance with standard drawing SD025 sheet 1, as a heavy duty plain concrete pavement as shown on SD012, with reference to SD026 where a dished drain is necessary, or b) with interlocking pavers (see section 5.5.3) on an approved concrete sub-base including integral edge restraints. Coloured concrete is not considered a satisfactory long-term treatment, but where approved, colour additive must include hardener (75-90MPa), be applied as two coats and be sealed with a polymer solvent based sealer. Texture may be applied to a maximum depth of 5mm.

Page 47

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

5.5.8

PAVEMENT JOINS

All vertical pavement joins (new-to-existing), whether longitudinal or transverse joins, shall be benched a minimum of 300mm. Unless the adjoining pavements consist of the same material, and satisfactory compaction bonding of those materials can be achieved, subsoil drainage shall be installed in accordance with RTA QA Spec R37 Intra-pavement Drains at the direction of Council or the geotechnical engineer. (see SD032) Where new works abut an existing natural gravel pavement, the new pavement materials shall be an approved natural gravel in accordance with the specifications of this Manual. 5.6 WEARING COURSE

For bituminous surfacing, refer to Chapter 11. For alternative decorative finishes, Councils approval is required to use such finishes in public roads. Smooth and/or irregular surfaces for roads and footway crossings, such as deepstamped or exposed river gravel paving is not permitted. Supporting documentation shall be submitted with any request to decorative finished products and shall include: Full specifications of the product. Durability and colour fastness Skid/abrasion resistance.

Refer also to section 5.5.7. Final approval rests with Council. 5.7 EXISTING PAVEMENT RECONSTRUCTION

Where required by Council, existing road pavements shall be reconstructed, subject to an approved design, and where new works abut an existing natural gravel pavement, the new pavement materials shall be an approved natural gravel in accordance with the specifications of this Manual. Circumstances where reconstruction may be necessary are: Where either the existing pavement or surface quality are assessed by Council as incapable of sustaining the additional traffic loads from the development

Page 48 Manual Of Engineering Standards ~ 2008 Chapter 5 Pavement Design

Where vehicle turning movements occur, such that an asphalt wearing surface is appropriate to control premature deterioration of the existing wearing surface Where a longitudinal surface profile is significantly irregular Where surface shape (eg. crossfall) does not conform to standard design parameters Where small local patching type pavement failures are required by Council. Where works coincide with Councils Management Plan.

The limits of such works shall be determined by Council, but will normally be applied to development that: creates new intersections onto an existing road requires shoulder or parking lane works warrants new or replacement kerb and gutter has frontage to, or requires vehicle access along an existing road that exhibits stress and/or has significant surface deterioration, and (subject to geotechnical testing) exhibits a failure to meet design requirements in this Manual. Best design practice shall be employed such that a holistic approach is achieved, eliminating partial (patchwork), or single or part-lane pavement sections.

Page 49

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

Page 50

Manual Of Engineering Standards ~ 2008

Chapter 5 Pavement Design

Você também pode gostar

- Input Parameters for Rigid Pavement DesignDocumento6 páginasInput Parameters for Rigid Pavement DesignSrujhana RaoAinda não há avaliações

- Pavement Design University of Western Australia CIVL 4121Documento46 páginasPavement Design University of Western Australia CIVL 4121April IngramAinda não há avaliações

- Design Notes-Retaining Wall-PCC Wall 2m HeightDocumento114 páginasDesign Notes-Retaining Wall-PCC Wall 2m Heightnikhilnagpal2121994Ainda não há avaliações

- Topi C:-: Pavement DesignDocumento59 páginasTopi C:-: Pavement Designabhishek sinhaAinda não há avaliações

- HIPAVE User ManualDocumento102 páginasHIPAVE User Manualholasa666Ainda não há avaliações

- Rigid Pavement Design by Aashto MethodDocumento1 páginaRigid Pavement Design by Aashto MethodmdalgamouniAinda não há avaliações

- Crack Width CalculationsDocumento1 páginaCrack Width CalculationsdfdgggAinda não há avaliações

- CC Pavement DesignDocumento7 páginasCC Pavement DesignDurga Rama Swamy KalvakolanuAinda não há avaliações

- Rigid Pavement DesignDocumento33 páginasRigid Pavement DesignDebasis PalAinda não há avaliações

- Method B18 - The Determination of The Average Least Dimension of Aggregates.Documento3 páginasMethod B18 - The Determination of The Average Least Dimension of Aggregates.GUO LEIAinda não há avaliações

- Flexible Pavement DesignDocumento39 páginasFlexible Pavement DesignSaurabh KumarAinda não há avaliações

- Rigid Pavement DesignDocumento10 páginasRigid Pavement DesignBilal A BarbhuiyaAinda não há avaliações

- Slab DesignDocumento5 páginasSlab DesignSitche ZisoAinda não há avaliações

- Pavement Design Report - MU06 PDFDocumento182 páginasPavement Design Report - MU06 PDFartiAinda não há avaliações

- 2018-Retaining Walls, Indian Highways IRCDocumento8 páginas2018-Retaining Walls, Indian Highways IRCRajendra ChalisgaonkarAinda não há avaliações

- CVPDDocumento4 páginasCVPDmiestyAinda não há avaliações

- "Brgplt9" - Beam Bearing Plate DesignDocumento3 páginas"Brgplt9" - Beam Bearing Plate DesignPhanikrishnab100% (2)

- Optimal Deign of Pile FoundationDocumento13 páginasOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Bearing Capacity - Sand Overlying ClayDocumento1 páginaBearing Capacity - Sand Overlying ClayMehdi.Most100% (1)

- CIRCLY 7.0 Workshop - Brisbane - 24 October 2019 - 1 Page Per Slide PDFDocumento310 páginasCIRCLY 7.0 Workshop - Brisbane - 24 October 2019 - 1 Page Per Slide PDFLewis HamiltonAinda não há avaliações

- Pile Cap DesignDocumento13 páginasPile Cap DesignWahid wrbelAinda não há avaliações

- IMPROVEMENT OF ALIPINGAL-KHAIRA ROADDocumento15 páginasIMPROVEMENT OF ALIPINGAL-KHAIRA ROADPradeepta PatraAinda não há avaliações

- Design of Flexible Design - AASHTODocumento9 páginasDesign of Flexible Design - AASHTOdineshAinda não há avaliações

- Revised Design of 90kn MicropilesDocumento2 páginasRevised Design of 90kn MicropilesChin ChloeAinda não há avaliações

- Locked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019Documento5 páginasLocked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019ajay_430Ainda não há avaliações

- RCC DESIGN OF CANTILEVER CHAJJADocumento32 páginasRCC DESIGN OF CANTILEVER CHAJJAjaffnaAinda não há avaliações

- Soil Embankment Settlement 3d AnalysisDocumento15 páginasSoil Embankment Settlement 3d AnalysisSajid IqbalAinda não há avaliações

- Gabion DesignDocumento6 páginasGabion DesignyasirjurabaAinda não há avaliações

- Flow Chart of Pavemeent DesignDocumento2 páginasFlow Chart of Pavemeent DesignSamiul IslamAinda não há avaliações

- Analysis of Bearing Capacity Driven PileDocumento22 páginasAnalysis of Bearing Capacity Driven PileGEOMAHESHAinda não há avaliações

- Anchored Piled Retaining Wall 24-06-2016Documento9 páginasAnchored Piled Retaining Wall 24-06-2016rowatersAinda não há avaliações

- Retaining Wall Design Parameters and LoadsDocumento12 páginasRetaining Wall Design Parameters and LoadsJahara GarciaAinda não há avaliações

- Pavement Design and Analysis for Road Upgrading Project in Nueva VizcayaDocumento12 páginasPavement Design and Analysis for Road Upgrading Project in Nueva VizcayaPriodeep ChowdhuryAinda não há avaliações

- Foundation Bearing Capacity (SPT BasedDocumento8 páginasFoundation Bearing Capacity (SPT BasedAziz ul HakeemAinda não há avaliações

- Eu 022Documento10 páginasEu 022Khurshed Alam IndiaAinda não há avaliações

- Rigid Pavement Design ParametersDocumento9 páginasRigid Pavement Design ParametersgeoprabhatAinda não há avaliações

- Culvert Design - Google SearchDocumento3 páginasCulvert Design - Google SearchMuhafeez GoolabAinda não há avaliações

- Flexible Pavement Design ToolDocumento13 páginasFlexible Pavement Design ToolSaurabh Kumar SharmaAinda não há avaliações

- 5.0 Cost Estimate R (2) For Package - II Dated 14-05-2021Documento51 páginas5.0 Cost Estimate R (2) For Package - II Dated 14-05-2021Mohanraj SAinda não há avaliações

- Name of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshDocumento4 páginasName of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshUpadhyayula Subba RaoAinda não há avaliações

- 1 - Depth of Fixity of Piles in Clay Under Dynamic Lateral PDFDocumento15 páginas1 - Depth of Fixity of Piles in Clay Under Dynamic Lateral PDFSwapan PaulAinda não há avaliações

- Design of Vertical CurvesDocumento4 páginasDesign of Vertical CurvesniranjanchouAinda não há avaliações

- Pile Calculation-SiloDocumento3 páginasPile Calculation-Silovishnumani3011100% (1)

- IS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFDocumento22 páginasIS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFRajan VAAinda não há avaliações

- RAILWAY Geogrid DesignDocumento11 páginasRAILWAY Geogrid DesignPetrucio José Dos Santos JuniorAinda não há avaliações

- Geosynthetics Product Brochure 2Documento32 páginasGeosynthetics Product Brochure 2Mulsa KTGAinda não há avaliações

- Week 2 - Interpretation of SI Borelog and Lab Parameters Foundation EngineeringDocumento18 páginasWeek 2 - Interpretation of SI Borelog and Lab Parameters Foundation EngineeringMUSLIHAH AQILAH MUSAFFENDYAinda não há avaliações

- Design of 15m Span Superstructure Re - 2Documento1 páginaDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Rigid Pavement Design Software Automates AASHTO GuideDocumento8 páginasRigid Pavement Design Software Automates AASHTO GuideOlaolu OlalekanAinda não há avaliações

- 012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Documento40 páginas012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Jimmy Villca Sainz100% (1)

- GrillageDocumento6 páginasGrillagevasanthk81Ainda não há avaliações

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Documento13 páginasBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshAinda não há avaliações

- Dowel Bars at Joints / Jacketing Requirement R4Documento1 páginaDowel Bars at Joints / Jacketing Requirement R4Kumy engineeringAinda não há avaliações

- Auditorium Line EstimateDocumento163 páginasAuditorium Line EstimatePARASASRINIVASAinda não há avaliações

- Flexible - Pavement - Design - Tool AASHTO 1993Documento12 páginasFlexible - Pavement - Design - Tool AASHTO 1993Awang DarmawangsaAinda não há avaliações

- Pile Capacity Hanumante RevisedDocumento4 páginasPile Capacity Hanumante RevisedAmit VarmaAinda não há avaliações

- Bca Eurocodes Traffic Loading and Design AssumptionsDocumento2 páginasBca Eurocodes Traffic Loading and Design AssumptionsFreddie KooAinda não há avaliações

- Atterberg Limit TestDocumento1 páginaAtterberg Limit TestAkram MuzakkiAinda não há avaliações

- Flexible Pavement DesignDocumento15 páginasFlexible Pavement Designপ্রিয়দীপ প্রিয়ম100% (1)

- ANDHRA PRADESH FINANCIAL CODEDocumento296 páginasANDHRA PRADESH FINANCIAL CODERajesh BabuAinda não há avaliações

- GraniteDocumento21 páginasGraniteRajesh Babu100% (1)

- GraniteDocumento21 páginasGraniteRajesh Babu100% (1)

- R2 2Documento1 páginaR2 2Rajesh BabuAinda não há avaliações

- STD Data 2017-18 DT 3.11.2017 PDFDocumento374 páginasSTD Data 2017-18 DT 3.11.2017 PDFPratap Kumar ChennuruAinda não há avaliações

- 14072015maud RT497Documento2 páginas14072015maud RT497Rajesh BabuAinda não há avaliações

- Writers HandbookDocumento592 páginasWriters Handbookknocks911Ainda não há avaliações

- Data Book For Engineers PDFDocumento118 páginasData Book For Engineers PDFRajesh BabuAinda não há avaliações

- Weight Chart of Cast Iron FittingsDocumento5 páginasWeight Chart of Cast Iron FittingsRajesh BabuAinda não há avaliações

- Meesevaapplication EmployeesDocumento4 páginasMeesevaapplication Employeesapi-218060126Ainda não há avaliações

- PlantDocumento1 páginaPlantRajesh BabuAinda não há avaliações

- Install NotesDocumento1 páginaInstall NotesRajesh BabuAinda não há avaliações

- Engineering and Design - Standard Practice For Concrete For Civil Works StructuresDocumento124 páginasEngineering and Design - Standard Practice For Concrete For Civil Works Structuresmanasbabu_mondalAinda não há avaliações

- Endt No 123Documento2 páginasEndt No 123Rajesh Babu100% (4)

- Simulation of Water Distribution Networks The Use of EPANETDocumento31 páginasSimulation of Water Distribution Networks The Use of EPANETMohammad Risky Na100% (2)

- AP Standard Data - AllDocumento963 páginasAP Standard Data - AllRajesh Babu93% (15)

- Regular Employee Details FormDocumento4 páginasRegular Employee Details FormRajesh BabuAinda não há avaliações

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDocumento4 páginasExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusRajesh Babu100% (1)

- Work Charge FormDocumento2 páginasWork Charge FormRajesh BabuAinda não há avaliações

- Basic Data of Works For Inspection of (V&e)Documento4 páginasBasic Data of Works For Inspection of (V&e)Rajesh BabuAinda não há avaliações

- Basic Data of Works For Inspection of (Vigilance & Enforcement)Documento2 páginasBasic Data of Works For Inspection of (Vigilance & Enforcement)Rajesh BabuAinda não há avaliações

- Regular Employee Details FormDocumento4 páginasRegular Employee Details FormRajesh BabuAinda não há avaliações

- 1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsDocumento2 páginas1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsTKASHIQUE100% (1)

- 2013fin MS119Documento2 páginas2013fin MS119Naga NelluriAinda não há avaliações

- Friction FactorDocumento6 páginasFriction Factorrajeshsapkota123Ainda não há avaliações

- 2498Documento22 páginas2498Rajesh BabuAinda não há avaliações

- 1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsDocumento2 páginas1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsTKASHIQUE100% (1)

- Barbed Wire FencesDocumento4 páginasBarbed Wire FencesRajesh BabuAinda não há avaliações

- GO - Ms.No.13 Dt.15.Documento5 páginasGO - Ms.No.13 Dt.15.Rajesh Babu50% (2)

- 2013fin MS119Documento2 páginas2013fin MS119Naga NelluriAinda não há avaliações

- CE6503 Highway Materials Lec2Documento16 páginasCE6503 Highway Materials Lec2AhmedAinda não há avaliações

- Road Note 29 & 31Documento12 páginasRoad Note 29 & 31Yasruddin Mt71% (7)

- 1.) Bitmix, Core PresentationDocumento41 páginas1.) Bitmix, Core PresentationBrian PaulAinda não há avaliações

- Road MaterialDocumento11 páginasRoad MaterialGrachelle Andrea CapiralAinda não há avaliações

- 7528 RAP Report FINAL 20160617 SM PDFDocumento32 páginas7528 RAP Report FINAL 20160617 SM PDFMohd EruwanAinda não há avaliações

- Recommendations About Overlays On Cement Concrete Pavements: Indian Roads Congress Special Pubucation 17Documento33 páginasRecommendations About Overlays On Cement Concrete Pavements: Indian Roads Congress Special Pubucation 17kruttika_apAinda não há avaliações

- Kandhal Asphalt Literature For India Rev. 3 January 2019Documento27 páginasKandhal Asphalt Literature For India Rev. 3 January 2019Prof. Prithvi Singh Kandhal100% (1)

- TOPIC 5-MAINTENANCE & REHABILITATION 1 Dec 2019Documento68 páginasTOPIC 5-MAINTENANCE & REHABILITATION 1 Dec 2019Alma AinaAinda não há avaliações

- STONE MASTIC ASPHALT PERFORMANCEDocumento30 páginasSTONE MASTIC ASPHALT PERFORMANCESandip Jagdale100% (1)

- Summary BOQ New Line Drain ProjectDocumento14 páginasSummary BOQ New Line Drain ProjectMasaya Salad PremiumAinda não há avaliações

- Pengaruh Air Hujan Pada Proses Pemadatan Di Lapangan Terhadap CampuranDocumento11 páginasPengaruh Air Hujan Pada Proses Pemadatan Di Lapangan Terhadap CampurandeliaAinda não há avaliações

- Rubberized BitumenDocumento5 páginasRubberized BitumensvivekAinda não há avaliações

- Kinerja Campuran Split Mastic Aspal (SMA) Yang Menggunakan Serat Selulosa Alami Dedak PadiDocumento15 páginasKinerja Campuran Split Mastic Aspal (SMA) Yang Menggunakan Serat Selulosa Alami Dedak PadiRandigilaucul uculAinda não há avaliações

- Complete Item CodesDocumento43 páginasComplete Item CodesGenevieve GayosoAinda não há avaliações

- Table 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5Documento6 páginasTable 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5fadi eidAinda não há avaliações

- Time Variance Report 17.12.2020Documento6 páginasTime Variance Report 17.12.2020Cliff Jude ZehnderAinda não há avaliações

- Improving Silay-Lantawan RoadDocumento10 páginasImproving Silay-Lantawan RoadRandy Cerna100% (1)

- Beton Yol Yapımı (Power Point İngilizce Sunu)Documento46 páginasBeton Yol Yapımı (Power Point İngilizce Sunu)Doğan ÖzdemirAinda não há avaliações

- Public Works Department: Government of Tamilnadu Approved List of Crushed Stone Sand Manufacturing Units AS ON 16.09.2020Documento32 páginasPublic Works Department: Government of Tamilnadu Approved List of Crushed Stone Sand Manufacturing Units AS ON 16.09.2020Jeeva NanthamAinda não há avaliações

- Paver (Vehicle)Documento3 páginasPaver (Vehicle)RasoolKhadibiAinda não há avaliações

- Introduction to Bituminous Mixes and Volumetric AnalysisDocumento19 páginasIntroduction to Bituminous Mixes and Volumetric AnalysisShre BAinda não há avaliações

- 3.15 Roads and Pavings (Class Q) PDFDocumento3 páginas3.15 Roads and Pavings (Class Q) PDFMuhammad FaqrullahAinda não há avaliações

- MOS For Road ConstructionDocumento7 páginasMOS For Road ConstructionHussam WaleedAinda não há avaliações

- Voegele Einbaufibel EN PDFDocumento119 páginasVoegele Einbaufibel EN PDFIvica ŠućurAinda não há avaliações

- Thesis LetterDocumento3 páginasThesis LetterRichard Cairo SantosAinda não há avaliações

- Daftar Pustaka - 4Documento24 páginasDaftar Pustaka - 4Surya Mandala PutraAinda não há avaliações

- QCPDocumento8 páginasQCPrrpenolioAinda não há avaliações

- CALIFORNIA BEARING RATIO TESTDocumento6 páginasCALIFORNIA BEARING RATIO TESTKovan AzizAinda não há avaliações

- PWD NH Zone Raipur Schedule of Rates Errata AmendmentDocumento10 páginasPWD NH Zone Raipur Schedule of Rates Errata Amendmentnitin guptaAinda não há avaliações

- A Mini Project On Bituminous Road LayersDocumento20 páginasA Mini Project On Bituminous Road Layersapi-1988935887% (39)