Escolar Documentos

Profissional Documentos

Cultura Documentos

Ball Mill Sizing

Enviado por

vvananthDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ball Mill Sizing

Enviado por

vvananthDireitos autorais:

Formatos disponíveis

Cement ball mill sizing method explanation 1 Introduction: - The Bond method is used to size a cement ball mill.

- Efficiency correction factors are applied with the Bond equation. - The method is valid both for clinker grinding and for raw materials grinding. - This method only gives a rough and initial idea for sizing a cement ball mill. To go ahead, a deeper study is necessary with ball mills suppliers or a specialized engineering office. - Two calculators have been developed for sizing mono chamber mills and two compartments mills. 2 Bond equation and correction factors: - The well-known Bond formula used is the following:

With: E = specific energy in kWh/t Wi = work index in kWh/t C = correction factor P80 = sieve wich has 80% of passing in the product F80 = sieve wich has 80% of passing in the feed - Efficiency correction factors are giving by yhe following equation:

With: C1 is a correction for dry grinding, C2 is a correction for open circuit C3 is a correction for mill diameter, C4 is a correction for feed size, C5 is a correction for product fineness. C6 is a correction for high-efficiency separators. - C1 definition:

- C2 definition: The graph here below is the basis to get C2:

- C3 definition:

- C4 definition:

- C5 definition:

- C6 definition:

Define fresh feed characteristics: - Composition: Percentage of each component, Specific gravity (kg/dm3), Work indes (kWh/t) and F80. - F80 must be a representative average of various sampling campaigns of each component.

Define target fineness: - Blaine fineness (cm2/gr) and/or a residue on a certain sieve - Specify the P80 of the product. It must be a representative average of various particle size analysis of the product.

Define production target: - Production of the mill in t/h

Define efficiency factors: - Determine if it is a wet or dry process. In the cement industry, the dry process is always used except some old

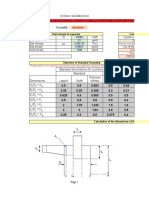

installations where the raw mills are working in wet process. - Determine if it is a closed or open circuit. New installations are 99% in closed circuit. - To define C3 which is the correction factor for mill diameter, it is indispensable to choose a temporary diameter (which is in fact an unknown) in meters. An experienced Process Engineer has already a good idea about the future diameter of the mill. Later, he will have to modify this diameter in function of the result given by the calculation. It is an iteration. - C4 and C5 factors are automatically calculated with the data of point 4. - Determine if it is a High Efficiency separator or not. 7 Define the estimated mill specific energy: - This calculation is carried out with the main Bond formula. 8 Define the absorbed power required: - Multiply the estimated energy required E by the target production. The found value is the absorbed power at the mill shaft, in other words before the transmission. - Determine the type of transmission to add the inefficiency factor. - Recalculate the specific energy with the absorbed power required at terminals. 9 Sizing of the ball mill: - Define the right Length/Diameter ratio in function of the circuit. Usual values can be seen below:

- Multiply this L/D ratio by the diameter to find the usefull mill length. - Define the mill speed respecting usual values as shown below:

- Specify the specific energy required in chamber 1 depending of the following table:

- Multiplying the value found here above by the production target will give the required absorbed power for chamber 1. - Specify a working filling degree (volume load) in % for first chamber:

- With the power formula, we can now calculate the length of chamber 1. - If a DIN (*) configuration is selected, define a new length closed to the calculated value and verify if the new specific power is OK. (*) distance of 250mm between bolts on the length - A new chamber 1 absorbed power is calculated with the DIN length. - Verify again if the chamber 1 specific power is correct. - Calculate the second chamber length. - If a DIN configuration is selected, define a new length closed to the calculated value. - Specify a working filling degree (volume load) in % for second chamber with the table above.

- Calculate the absorbed power of chamber 2. - Calculate the total absorbed power. - Iteration starts here comparing the absorbed power calculated just before with the one found in point 8. - A difference of maximum 2% is allowed between both powers. If the difference is higher, modify the mill diameter, the L/D ratio, the mill speed and the filling degrees in order to decrease the difference but keeping in mind that all usual values are respected. Maybe changing one or two parameters is enough to get the result. Warning: the method is the same for a monochamber mill. It is even easier because there isn't 1st chamber. 11 Other power correction factors: - If there is 50% or more slag in the fresh feed, - If the clinker is for the production of Alumina cement (ciment fondu in french), - If there are retention rings (similar as Danula rings) in the second chamber, - If there are cylpebs in the second chamber, - If there is a lifting-classifying lining in case of monochamber mill and - If the fresh feed is coal in case of monochamber mill, - Various corrections factors are applied for first chamber and/or second chamber and for monochamber mill absorbed power. 11 Ball mill final dimensions: - Specify the width internals: feed end liners, intermediate diaphragm and outlet diaphragm to know the full length length of the mill. - Calculate the tonnage of balls in function of the volume loads defined before. 12 If necessary, drying chamber (for raw mill): - Specify the maximum moisture of the fresh feed components. - The required drying chamber volume is automatically calculated. - Define the diameter which usually is the same than the grinding part of the mill but can also be a bit lower. - The required length is automatically calculated by dividing the volume by the area. - If a DIN configuration is selected, define a new length closed to the calculated value.

- The drying chamber absorbed power is calculated. - The total mill absorbed power is calculated. 13 Required installed power: - We take into consideration a factor of 1,1 to calculate the installed power of the mill but the mill's supplier has to recommend for that (possibility of filling degree increase).

9.1. The drying chamber: This chamber helps the drying of the material with the help of lifters. The material is lifted and after falls in the hot gas stream. Which length must have a drying chamber? According to industrial experiences, it is possible to dry a maximum of 220-230 l/m3.h of water to be efficient. This figure is generally accepted to size the drying chamber. Example: - Mill diameter: 4.6 m - Mill output: 230 t/h - Limestone moisture: 4% => quantity of water: 230 * 1000 * 4% = 9200 l/h => volume requested: 9200 / 225 = 40.89 m3 => length of the drying chamber: 40.35 / (p * 4.62 / 4) = 2.46 m (with the transfer diaphragm) We will take a length of 2.50 m as it is DIN.

Você também pode gostar

- Annex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasDocumento2 páginasAnnex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasIrfan AhmedAinda não há avaliações

- Neraca Massa dan Energi Ball Mill dan SeparatorDocumento10 páginasNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanAinda não há avaliações

- Mill Calculation: Plant: Date: Mill: VisaDocumento2 páginasMill Calculation: Plant: Date: Mill: VisaThaigroup CementAinda não há avaliações

- 8 Crusher Rod MillDocumento4 páginas8 Crusher Rod MillvvananthAinda não há avaliações

- CPB Brochure Diaphragms en 2Documento12 páginasCPB Brochure Diaphragms en 2ebrahimAinda não há avaliações

- Vertical Roller Mill State of The Art Raw GrindingDocumento4 páginasVertical Roller Mill State of The Art Raw GrindingzementheadAinda não há avaliações

- RABH-sugest by SatputeDocumento1 páginaRABH-sugest by Satputegvrr1954Ainda não há avaliações

- Design Guide For Air Slide ConveyorDocumento4 páginasDesign Guide For Air Slide Conveyordoh16810% (1)

- Modern Cement Grinding Systems ComparedDocumento14 páginasModern Cement Grinding Systems ComparedCao Ngoc AnhAinda não há avaliações

- Presep Air Separator VTP enDocumento6 páginasPresep Air Separator VTP enBrunoAinda não há avaliações

- Bucket ElevatorsDocumento11 páginasBucket ElevatorsMehmet CAinda não há avaliações

- Hydraulic Cylinder Maintenance ChecklistDocumento10 páginasHydraulic Cylinder Maintenance Checklisthaziq100% (1)

- Jaypee Cement Project ReportDocumento29 páginasJaypee Cement Project ReportPurnendu MishraAinda não há avaliações

- Bucket Elevator Vs AirliftDocumento10 páginasBucket Elevator Vs AirliftSunil D Pujari100% (1)

- Filter media selection for cement production processesDocumento4 páginasFilter media selection for cement production processesm_verma21Ainda não há avaliações

- Importance of Dedusting Pipe LayoutDocumento4 páginasImportance of Dedusting Pipe LayoutManoj ThakurAinda não há avaliações

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDocumento4 páginasFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayAinda não há avaliações

- Cyclone Design Calculation Tool SimplifiedDocumento6 páginasCyclone Design Calculation Tool SimplifiedKevin WilliamAinda não há avaliações

- Fluid Coupling in Belt Conveyor DrivesDocumento12 páginasFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- Designing of Screw ConveyorDocumento6 páginasDesigning of Screw ConveyorErickk RoqueeAinda não há avaliações

- Bucket Elevators: Installation and Operation ManualDocumento20 páginasBucket Elevators: Installation and Operation Manualboyka yuriAinda não há avaliações

- 15 X 21 Batch Ball MillDocumento12 páginas15 X 21 Batch Ball MillAnil Kumar KnAinda não há avaliações

- FLSPfister IB05000 I GBTRWSD0216 MailDocumento26 páginasFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaAinda não há avaliações

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDocumento1 páginaRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanAinda não há avaliações

- Vedanta Green Anode Plant Liquid Pitch Stirring ManualDocumento47 páginasVedanta Green Anode Plant Liquid Pitch Stirring ManualSubhransu MohapatraAinda não há avaliações

- Pneumatic Conveying: Technology You Can TrustDocumento16 páginasPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinAinda não há avaliações

- Conveyor Design Stockpile Volume FormulasDocumento1 páginaConveyor Design Stockpile Volume FormulasmetkarchetanAinda não há avaliações

- Gear and equipment specification summaryDocumento4 páginasGear and equipment specification summaryprashant mishraAinda não há avaliações

- Multistage Flowsheets Sabc1Documento204 páginasMultistage Flowsheets Sabc1alonsogonzalesAinda não há avaliações

- Horizontal Vacuum Belt Filter Studies On Heavy MineralsDocumento11 páginasHorizontal Vacuum Belt Filter Studies On Heavy MineralsGyan PrameswaraAinda não há avaliações

- Trojosky2019 PDFDocumento21 páginasTrojosky2019 PDFHector CabezasAinda não há avaliações

- Coal Mill Wear Measurement 29.09.2014Documento1 páginaCoal Mill Wear Measurement 29.09.2014Durga PrasadAinda não há avaliações

- Bosh Rotary ScreenDocumento2 páginasBosh Rotary Screencumpio425428Ainda não há avaliações

- 15th NCB Technical PaperDocumento10 páginas15th NCB Technical PaperSalah RomdaniAinda não há avaliações

- 4 NewThickener PDFDocumento3 páginas4 NewThickener PDFRogerio CannoniAinda não há avaliações

- Ball Mill Sizing CalculatorDocumento6 páginasBall Mill Sizing CalculatorHoàng HùngAinda não há avaliações

- Anempirical Approach Tothe Design Oftrommel Screens Forfine Screening Ofdomestic RefuseDocumento13 páginasAnempirical Approach Tothe Design Oftrommel Screens Forfine Screening Ofdomestic RefuseNcls BMAinda não há avaliações

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocumento8 páginasSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- Muller Mixer Machine - Specifications and Description - SuryaDocumento2 páginasMuller Mixer Machine - Specifications and Description - Suryakeshab_machineries100% (1)

- The Rhodax® Process For Dry Mix Preparation in Anodes PlantsDocumento37 páginasThe Rhodax® Process For Dry Mix Preparation in Anodes PlantsGupta AnacoolzAinda não há avaliações

- Comminution 2Documento159 páginasComminution 2Kumar RajeshAinda não há avaliações

- CycloSim SingleDocumento12 páginasCycloSim Singlejvchique100% (1)

- The Cement Grinding Office: Home About Us Services Mining AreaDocumento3 páginasThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarAinda não há avaliações

- Particle TechnologyDocumento40 páginasParticle Technologyasharab70Ainda não há avaliações

- Rotary Airlock FeedersDocumento28 páginasRotary Airlock Feederslhphong021191Ainda não há avaliações

- Slurry. Pumps. Power Law, Bingham. Heterogeneous FlowDocumento113 páginasSlurry. Pumps. Power Law, Bingham. Heterogeneous FlowAnonymous K3FaYFlAinda não há avaliações

- Air Classifier ArticleDocumento16 páginasAir Classifier ArticlePeyman KhAinda não há avaliações

- Auditoría Molino 5Documento22 páginasAuditoría Molino 5ElZeroMJAinda não há avaliações

- Motor Load List - VRMDocumento21 páginasMotor Load List - VRMmanohar1005Ainda não há avaliações

- Hammer DesaignDocumento21 páginasHammer DesaignZahlul AmriAinda não há avaliações

- Ball Mill OptimizationDocumento7 páginasBall Mill OptimizationWael Fanous100% (1)

- Grindability TestsDocumento6 páginasGrindability TestskidcatAinda não há avaliações

- Chap 10CDocumento10 páginasChap 10CToat SumohandoyoAinda não há avaliações

- Micro Gas TurbineDocumento8 páginasMicro Gas TurbineRamachandran VenkateshAinda não há avaliações

- Mod 3-Process Engineering ObjectivesDocumento141 páginasMod 3-Process Engineering ObjectiveslovjnxAinda não há avaliações

- Fire Pump Sizing and Selectio1Documento14 páginasFire Pump Sizing and Selectio1Rahul Deva100% (2)

- Cement Kiln Installed Capacity Calculation MethodsDocumento2 páginasCement Kiln Installed Capacity Calculation Methodsemad sabriAinda não há avaliações

- Production Process of Spinning Flow Chart:: 1-Basic Operations in The Blow RoomDocumento9 páginasProduction Process of Spinning Flow Chart:: 1-Basic Operations in The Blow RoomAazzy AzizAinda não há avaliações

- 2 DKSinghalDocumento48 páginas2 DKSinghalMostafizur Rahman100% (1)

- Ball Mill SizingDocumento10 páginasBall Mill SizingvvananthAinda não há avaliações

- Ball Mill Vs VRMDocumento15 páginasBall Mill Vs VRMvvananth0% (2)

- 2Documento6 páginas2vvananthAinda não há avaliações

- 3Documento9 páginas3vvananthAinda não há avaliações

- EJsDocumento1 páginaEJsvvananthAinda não há avaliações

- Ball Mill Vs VRMDocumento15 páginasBall Mill Vs VRMvvananth0% (2)

- Coal Cost & Blend CalculatorDocumento4 páginasCoal Cost & Blend Calculatorvvananth100% (3)

- 2Documento6 páginas2vvananthAinda não há avaliações

- 1Documento91 páginas1vvananthAinda não há avaliações

- Bin & SilosDocumento30 páginasBin & SilosvvananthAinda não há avaliações

- Ball Mill Vs VRMDocumento15 páginasBall Mill Vs VRMvvananth0% (2)

- CrushersDocumento11 páginasCrushersRenzo Chavez100% (1)

- Impact CrushersDocumento2 páginasImpact CrushersshivmsAinda não há avaliações

- CementDocumento48 páginasCementMostafa MohamedAinda não há avaliações

- 10 CRUSHER Stages of The CrushingDocumento6 páginas10 CRUSHER Stages of The CrushingvvananthAinda não há avaliações

- CrushersDocumento11 páginasCrushersRenzo Chavez100% (1)

- CrushersDocumento11 páginasCrushersRenzo Chavez100% (1)

- Nasdaq Aaon 2002Documento26 páginasNasdaq Aaon 2002gaja babaAinda não há avaliações

- Electronics MCQsDocumento17 páginasElectronics MCQslovelyosmile253Ainda não há avaliações

- Solar Water HeaterDocumento27 páginasSolar Water HeaterSantosh ThapaAinda não há avaliações

- Carter Auto Water Pump Components 072420Documento2 páginasCarter Auto Water Pump Components 072420geniusAinda não há avaliações

- Flowserve Oil and Gas Upstream and Pipeline PDFDocumento20 páginasFlowserve Oil and Gas Upstream and Pipeline PDFmesplamaxAinda não há avaliações

- Notification 1 2017 For CGST Rate ScheduleDocumento74 páginasNotification 1 2017 For CGST Rate ScheduleIti CglAinda não há avaliações

- HYpact Compact HybridDocumento24 páginasHYpact Compact HybridMateo Alvez100% (1)

- BIOCNGDocumento23 páginasBIOCNGDhruva DAinda não há avaliações

- PPE Question Bank Covers Thermal, Hydro, Nuclear PowerDocumento7 páginasPPE Question Bank Covers Thermal, Hydro, Nuclear PowerKanagaraj Chelladurai100% (1)

- Asco Avtron 2000 Series With Sigma LT User Manual PDFDocumento43 páginasAsco Avtron 2000 Series With Sigma LT User Manual PDFfernandoAinda não há avaliações

- 0401544-Hydraulic StructuresDocumento38 páginas0401544-Hydraulic StructuresEfremWakjiraHodeAinda não há avaliações

- He165 (A4)Documento4 páginasHe165 (A4)KennethWilfredoVegaOviedoAinda não há avaliações

- Final Et NotesDocumento123 páginasFinal Et NotesyounusmohamadAinda não há avaliações

- Gates em Ingles 2010Documento76 páginasGates em Ingles 2010felipeintegraAinda não há avaliações

- Simulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel CellsDocumento18 páginasSimulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel Cellswww.beatricechongAinda não há avaliações

- Reaction kinetics and reactor design conceptsDocumento43 páginasReaction kinetics and reactor design conceptsnoelAinda não há avaliações

- Brazil Chapter 12: Agriculture, Minerals, Industries & TradeDocumento8 páginasBrazil Chapter 12: Agriculture, Minerals, Industries & TradeHaseebullahAinda não há avaliações

- Chemical ThermodynamicsDocumento46 páginasChemical ThermodynamicsHardik0% (1)

- Particulate Photocatalysts CRDocumento67 páginasParticulate Photocatalysts CRYiou WangAinda não há avaliações

- Microprocessor Engine/Generator Controller: Model MEC 20Documento4 páginasMicroprocessor Engine/Generator Controller: Model MEC 20Gerardo OrtizAinda não há avaliações

- RI Library Construction UpdateDocumento1 páginaRI Library Construction UpdaterooseveltislanderAinda não há avaliações

- State of Art Research in AlgaeDocumento20 páginasState of Art Research in AlgaeSambhavAinda não há avaliações

- Learn Discrete ComponentsDocumento2 páginasLearn Discrete ComponentsamitcrathodAinda não há avaliações

- Magnetism and Heat Transfer Test Answers RevealedDocumento6 páginasMagnetism and Heat Transfer Test Answers RevealedMaryHazelClaveBeniga100% (1)

- TM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceDocumento221 páginasTM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceAdvocateAinda não há avaliações

- Plantilla WPS (GMAW-MIG) Junta VDocumento1 páginaPlantilla WPS (GMAW-MIG) Junta Vjhojan garciaAinda não há avaliações

- Calculate Specific Heat of MetalDocumento2 páginasCalculate Specific Heat of MetalIsabelAinda não há avaliações

- TOBUL OandMsheet052909v2Documento5 páginasTOBUL OandMsheet052909v2Walter JosephAinda não há avaliações

- Centrifugal compressor wet seal gas recoveryDocumento13 páginasCentrifugal compressor wet seal gas recoveryAhmad Riaz KhanAinda não há avaliações

- Starting - Rav4 Sxa1Documento19 páginasStarting - Rav4 Sxa1Christian Linares AbreuAinda não há avaliações

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsNo EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsNota: 4.5 de 5 estrelas4.5/5 (6)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (241)

- Nuclear Energy in the 21st Century: World Nuclear University PressNo EverandNuclear Energy in the 21st Century: World Nuclear University PressNota: 4.5 de 5 estrelas4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNo EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNota: 5 de 5 estrelas5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- An Architect's Guide to Construction: Tales from the Trenches Book 1No EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Ainda não há avaliações

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- Building Construction Technology: A Useful Guide - Part 1No EverandBuilding Construction Technology: A Useful Guide - Part 1Nota: 4 de 5 estrelas4/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationNo EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationNota: 4 de 5 estrelas4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNo EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNota: 5 de 5 estrelas5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionNo EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionNota: 4.5 de 5 estrelas4.5/5 (2)

- Chemical Process Safety: Learning from Case HistoriesNo EverandChemical Process Safety: Learning from Case HistoriesNota: 4 de 5 estrelas4/5 (14)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsAinda não há avaliações

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNo EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNota: 5 de 5 estrelas5/5 (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentAinda não há avaliações

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNo EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNota: 3.5 de 5 estrelas3.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationAinda não há avaliações

- Building Construction Technology: A Useful Guide - Part 2No EverandBuilding Construction Technology: A Useful Guide - Part 2Nota: 5 de 5 estrelas5/5 (1)

- Civil Engineer's Handbook of Professional PracticeNo EverandCivil Engineer's Handbook of Professional PracticeNota: 4.5 de 5 estrelas4.5/5 (2)

- Field Guide for Construction Management: Management by Walking AroundNo EverandField Guide for Construction Management: Management by Walking AroundNota: 4.5 de 5 estrelas4.5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedNo EverandMarkup & Profit: A Contractor's Guide, RevisitedNota: 5 de 5 estrelas5/5 (11)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItNo EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItNota: 4 de 5 estrelas4/5 (16)

- Guidelines for Siting and Layout of FacilitiesNo EverandGuidelines for Siting and Layout of FacilitiesAinda não há avaliações