Escolar Documentos

Profissional Documentos

Cultura Documentos

MS For Chemical Engg Syllabus

Enviado por

Sirish Chand PutlaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MS For Chemical Engg Syllabus

Enviado por

Sirish Chand PutlaDireitos autorais:

Formatos disponíveis

PCCH 3102 MATERIALS SCIENCE FOR CHEMICAL ENGINEERS UNIT-I (17 Hours) Introduction: Material Science and Engineering,

Classification of Engineering materials, Levels of Structure, Structure-Property relationships in materials Crystal Geometry And Structure Determination: Space lattice and limit cell. Bravais lattices, crystal systems with examples. Lattice coordinates, Miller indices, Bravais indices for directions and places: crystalline and non-crystalline solids; ionic, covalent and metallic solids; packing efficiency, ligancy and coordination number; structure determination by Brags X-ray diffraction and powder methods. Structure of Solids: The crystalline and non -crystalline states inorganic solids: Covalent solids, metals and alloys, Ionic solids, UNIT-II (17 Hours) Crystal Imperfection: Point defects, line defects-edge and screw dislocation, Burgers circuit and Burgers, vectors, dislocation reaction, dislocation motion, and multiplication of dislocations during deformation, role of dislocation on crystal properties; surface defects, dislocations on crystal properties; surface defects; dislocation density and stress required to move dislocations. Phase diagrams: The Phase rule, single component systems, binary phase diagrams, microstructural changes during cooling, the lever rule, some typical phase diagrams, other applications of phase diagrams. Elastic, Anelastic and Visco elastic behavior: Elastic Behavior: Atomic model of elastic behavior, the modulous as a parameter in design, rubber like elasticity Anelastic behavior: Relaxation processes Viscoelastic behavior: Spring-dashpot models UNIT-III (16 Hours) Plastic deformation: the tensile stress-strain curve, Plastic deformation by slip, the shear strength of perfect and real crystals, the stress to move a dislocation, the effect of temperature on the stress to move a dislocation, multiplication of dislocations during deformation, work hardening and dynamic recovery, the effect of grain size on dislocation motion, the effect of solute atoms on dislocation motion, the effect of precipitate particles on dislocation motion. Creep: Mechanisms of Creep, creep resistant materials Precipitation hardening: Age hardening, Overaging, combined hardening, heat Treatments of steels: Annealing processes, Quenching and Tempering process, Hardenability of Steels: Hardenability curves, use of hardenability curves, Tempered hardeness. Text Book: 1. Material Science and Engineering; V. Raghavan; 4th Edition, Prentice Hall of India Pvt. Ltd., 2. Elements of Material Science and Engineering, Lawrence H. Van Vlack, 6th Edition, Addison-Wesley Publishing Company Reference Books: 1. Science of Engineering Materials Vol. 1 &2; Manaschand; Mcmillan Company of India Ltd. 2. Principles of Materials science and engineering; William F.Smith, MGH Publishing Company 3. Materials science for engineering; William.DCallistersJr; Wiley & Sons.

Você também pode gostar

- Western Dragon V3 Updated PDFDocumento19 páginasWestern Dragon V3 Updated PDFMark Moldez94% (17)

- PHD Entrance Test Syllabus For PEC ChandigarhDocumento1 páginaPHD Entrance Test Syllabus For PEC ChandigarhjasvindersinghsagguAinda não há avaliações

- An Introduction to Metallic Glasses and Amorphous MetalsNo EverandAn Introduction to Metallic Glasses and Amorphous MetalsNota: 5 de 5 estrelas5/5 (1)

- KDW1.1 100 300 W1 220 Mainspindle Drive Indramat ManualDocumento146 páginasKDW1.1 100 300 W1 220 Mainspindle Drive Indramat ManualSven TackAinda não há avaliações

- BS en 00480-2-2006Documento14 páginasBS en 00480-2-2006Shan Sandaruwan Abeywardene100% (1)

- Andrew KC Chan (2003) - Observations From Excavations - A ReflectionDocumento19 páginasAndrew KC Chan (2003) - Observations From Excavations - A ReflectionMan Ho LamAinda não há avaliações

- 671 - BP Well Control Tool Kit 2002Documento20 páginas671 - BP Well Control Tool Kit 2002Uok Ritchie100% (1)

- 113107048Documento4 páginas113107048Hiren MistryAinda não há avaliações

- B. TECH. (4 Semester) Mechanical Engineering Material Science (Me - 204 E)Documento2 páginasB. TECH. (4 Semester) Mechanical Engineering Material Science (Me - 204 E)Jai SheokandAinda não há avaliações

- AM Material ScienceDocumento4 páginasAM Material ScienceTushar Mani AgarwalAinda não há avaliações

- Physical Metallurgy: Page 18 of 74Documento2 páginasPhysical Metallurgy: Page 18 of 74Narasimha Murthy InampudiAinda não há avaliações

- Comprehensive SyllabusDocumento2 páginasComprehensive SyllabusAnantharam GSAinda não há avaliações

- Code: MTT218 Mechanical Behavior & Testing of Materials Credit: 04 L-T-P: (3-1-0) Course ContentDocumento1 páginaCode: MTT218 Mechanical Behavior & Testing of Materials Credit: 04 L-T-P: (3-1-0) Course Contentrishikesh vaishnavAinda não há avaliações

- B Tech Aeronautical Syllabus PDFDocumento45 páginasB Tech Aeronautical Syllabus PDFNizam muddinAinda não há avaliações

- Mmse Apj KtuDocumento5 páginasMmse Apj KtuSherwinAinda não há avaliações

- MaterialDocumento2 páginasMaterialShashi Bhushan SinghAinda não há avaliações

- ME 210 Metallurgy and Materials EngineeringDocumento5 páginasME 210 Metallurgy and Materials Engineeringnandan144Ainda não há avaliações

- Metallurgy and Material Science - Module 1Documento36 páginasMetallurgy and Material Science - Module 1Devasivan Csr100% (1)

- HGHFFDocumento2 páginasHGHFFJob ShortsAinda não há avaliações

- Part Ii Materials Science Course C12: Plasticity and Deformation ProcessingDocumento120 páginasPart Ii Materials Science Course C12: Plasticity and Deformation Processingmma666Ainda não há avaliações

- Syllabus For Materials Science (Xe: Section C) : StructureDocumento2 páginasSyllabus For Materials Science (Xe: Section C) : StructureKRUNAL ParmarAinda não há avaliações

- Xec PDFDocumento2 páginasXec PDFKRUNAL ParmarAinda não há avaliações

- Me6501 Mechanical Behaviour of MaterialsDocumento54 páginasMe6501 Mechanical Behaviour of MaterialsSiddarthanSrtAinda não há avaliações

- MM1101 - Material ScienceDocumento3 páginasMM1101 - Material Sciencedevashishkumar693Ainda não há avaliações

- Material Science and EngineeringDocumento1 páginaMaterial Science and EngineeringRap itttt88% (8)

- ME 210 Metallurgy and Materials EngineeringDocumento5 páginasME 210 Metallurgy and Materials EngineeringkannanAinda não há avaliações

- ME309 Metallurgy and Material Science PDFDocumento4 páginasME309 Metallurgy and Material Science PDFPremnath G100% (1)

- Xec Syllabus GATE 2013Documento2 páginasXec Syllabus GATE 2013Anonymous 8pCXXsAinda não há avaliações

- PI Syllabus 201516Documento60 páginasPI Syllabus 201516garvit1509Ainda não há avaliações

- Me209 Mechanical Properties of Structural Materials PDFDocumento4 páginasMe209 Mechanical Properties of Structural Materials PDFjishnuAinda não há avaliações

- Topic Suggested Number of Lectures Introduction: Structure-Property Correlation in Wide Range of Structure (11L)Documento2 páginasTopic Suggested Number of Lectures Introduction: Structure-Property Correlation in Wide Range of Structure (11L)AshutoshKumarAinda não há avaliações

- HardnessDocumento22 páginasHardnessmina_karaliAinda não há avaliações

- B.tech Automobile (III VIII Sem) W.e.f2012 13Documento48 páginasB.tech Automobile (III VIII Sem) W.e.f2012 13Kuldeep BhattacharjeeAinda não há avaliações

- Cohesive Fracture and Scaling: CE-430 & MS-441Documento3 páginasCohesive Fracture and Scaling: CE-430 & MS-441MsmMostafaAinda não há avaliações

- AMIE Section A Diploma Stream SyllabusDocumento7 páginasAMIE Section A Diploma Stream SyllabusJames WolfeAinda não há avaliações

- Ms&e FD&MDocumento2 páginasMs&e FD&Mnetwing2009Ainda não há avaliações

- M. Tech WLF SyllabusDocumento22 páginasM. Tech WLF SyllabusAkhil AroraAinda não há avaliações

- IISC Bangalore - Materials Engineering Courses-2013-14Documento8 páginasIISC Bangalore - Materials Engineering Courses-2013-14Sri PuduAinda não há avaliações

- Syllabus - Phy Met - 2022-23Documento2 páginasSyllabus - Phy Met - 2022-23Athlur Sai KiranAinda não há avaliações

- Chen 2018Documento18 páginasChen 2018jonathan arayaAinda não há avaliações

- Material Science: Prof. Satish V. KailasDocumento34 páginasMaterial Science: Prof. Satish V. KailasAbir RoyAinda não há avaliações

- Material Science - Unit I-R-12.12.22Documento122 páginasMaterial Science - Unit I-R-12.12.22SOMESH DWIVEDIAinda não há avaliações

- MSE 101 - Lecture 12 - Plastic DeformationDocumento33 páginasMSE 101 - Lecture 12 - Plastic DeformationKate Lynn PabelicoAinda não há avaliações

- 1 s2.0 S0924013607009405 MainDocumento12 páginas1 s2.0 S0924013607009405 MainCaio CruzAinda não há avaliações

- 1 THDocumento2 páginas1 THAditya TAinda não há avaliações

- Bmee209l Materials-science-And-Engineering TH 1.0 67 Bmee209lDocumento3 páginasBmee209l Materials-science-And-Engineering TH 1.0 67 Bmee209lKrijayAinda não há avaliações

- 113106032Documento2 páginas113106032sreeAinda não há avaliações

- Mechanical Engg SyllabusDocumento33 páginasMechanical Engg SyllabusKRISHNA KANT GUPTAAinda não há avaliações

- Journal of The Mechanics and Physics of SolidsDocumento23 páginasJournal of The Mechanics and Physics of SolidsjotagacsAinda não há avaliações

- Materials Science - Examination QuestionsDocumento2 páginasMaterials Science - Examination QuestionsNoura Nour ElshamsAinda não há avaliações

- EdDocumento1 páginaEdpandirajaAinda não há avaliações

- The Benefits and Drawbacks of eDocumento5 páginasThe Benefits and Drawbacks of esaikumarAinda não há avaliações

- Polycrystalline Materials - Theoretical and Practical AspectsDocumento176 páginasPolycrystalline Materials - Theoretical and Practical AspectsJosé RamírezAinda não há avaliações

- Synopis 2Documento4 páginasSynopis 2chima melfordAinda não há avaliações

- C12HDocumento129 páginasC12Hkhudhayer1970Ainda não há avaliações

- Mangalore Institute of Technology and Engineering: Material Science and MetallurgyDocumento203 páginasMangalore Institute of Technology and Engineering: Material Science and MetallurgyNISHAANTH S 1861462Ainda não há avaliações

- Introduction To CeramicsDocumento3 páginasIntroduction To CeramicsHarini MunasingheAinda não há avaliações

- Web Site: - : Centurion University of Technology & Management ODISHA-761211, INDIADocumento29 páginasWeb Site: - : Centurion University of Technology & Management ODISHA-761211, INDIAJames OrtegaAinda não há avaliações

- Xiong 2019Documento13 páginasXiong 2019Sam JacorAinda não há avaliações

- Material ScienceDocumento368 páginasMaterial Sciencechethan_n75% (4)

- Advances in Fracture Resistance and Structural IntegrityNo EverandAdvances in Fracture Resistance and Structural IntegrityV.V. PanasyukNota: 1 de 5 estrelas1/5 (1)

- Metal Forming and Impact Mechanics: William Johnson Commemorative VolumeNo EverandMetal Forming and Impact Mechanics: William Johnson Commemorative VolumeS. R. ReidNota: 5 de 5 estrelas5/5 (1)

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaNo EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinAinda não há avaliações

- CTE - 1,2,3,4,5 (2019-2020) Assignment Final ASGDocumento8 páginasCTE - 1,2,3,4,5 (2019-2020) Assignment Final ASGSirish Chand PutlaAinda não há avaliações

- Titus: Chapter 1Documento2 páginasTitus: Chapter 1Sirish Chand PutlaAinda não há avaliações

- Locus of A PointDocumento1 páginaLocus of A PointSirish Chand PutlaAinda não há avaliações

- Definite Integral Calculator - SymbolabDocumento3 páginasDefinite Integral Calculator - SymbolabSirish Chand PutlaAinda não há avaliações

- Total Internal ReflectionDocumento2 páginasTotal Internal ReflectionSirish Chand PutlaAinda não há avaliações

- 7CIVILDocumento9 páginas7CIVILSirish Chand PutlaAinda não há avaliações

- Solution: Midpoint Sum (Also Midpoint Approximation) Midpoints of SubintervalDocumento1 páginaSolution: Midpoint Sum (Also Midpoint Approximation) Midpoints of SubintervalSirish Chand PutlaAinda não há avaliações

- Genesis 31 Benson CommentaryDocumento16 páginasGenesis 31 Benson CommentarySirish Chand PutlaAinda não há avaliações

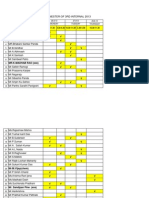

- 3rd EEE-A Attendance Upto 17-11-12Documento4 páginas3rd EEE-A Attendance Upto 17-11-12Sirish Chand PutlaAinda não há avaliações

- SolutionsDocumento3 páginasSolutionsSirish Chand PutlaAinda não há avaliações

- GRE DemoDocumento3 páginasGRE DemoSirish Chand PutlaAinda não há avaliações

- ES Question Paper 1Documento1 páginaES Question Paper 1Sirish Chand PutlaAinda não há avaliações

- Imrovement Exam Duty Chart 2014 14.6.14Documento3 páginasImrovement Exam Duty Chart 2014 14.6.14Sirish Chand PutlaAinda não há avaliações

- 1st Sem Roll - BTech - 2013Documento10 páginas1st Sem Roll - BTech - 2013Sirish Chand PutlaAinda não há avaliações

- Mercury in Glass Thermometer PDFDocumento6 páginasMercury in Glass Thermometer PDFSirish Chand PutlaAinda não há avaliações

- 3rd Sem Chemical Attendace Upto 17-11-12Documento5 páginas3rd Sem Chemical Attendace Upto 17-11-12Sirish Chand PutlaAinda não há avaliações

- 68 - Rvised House Rent & Electric Charges Circular PDFDocumento3 páginas68 - Rvised House Rent & Electric Charges Circular PDFSirish Chand PutlaAinda não há avaliações

- Assignment 2 SolutionDocumento31 páginasAssignment 2 SolutionSirish Chand Putla0% (1)

- MANUALDocumento3 páginasMANUALSirish Chand PutlaAinda não há avaliações

- BiblograohyDocumento2 páginasBiblograohySirish Chand PutlaAinda não há avaliações

- U1l 9Documento40 páginasU1l 9JOSEPH HERBERT MABELAinda não há avaliações

- 3rd Sem Chemical Attendace Upto 17-11-12Documento5 páginas3rd Sem Chemical Attendace Upto 17-11-12Sirish Chand PutlaAinda não há avaliações

- 183 PDFDocumento0 página183 PDFSirish Chand PutlaAinda não há avaliações

- FM Assignment 1Documento2 páginasFM Assignment 1Sirish Chand PutlaAinda não há avaliações

- Duty Chart For 1St Semester of 3Rd Internal 2013: Time MR - Manoj Ku - Kar (Cse)Documento3 páginasDuty Chart For 1St Semester of 3Rd Internal 2013: Time MR - Manoj Ku - Kar (Cse)Sirish Chand PutlaAinda não há avaliações

- 1st Sem Roll - BTech - 2013Documento10 páginas1st Sem Roll - BTech - 2013Sirish Chand PutlaAinda não há avaliações

- Axial VelocityDocumento1 páginaAxial VelocitySirish Chand PutlaAinda não há avaliações

- Developmental Charge Details PDFDocumento4 páginasDevelopmental Charge Details PDFSirish Chand PutlaAinda não há avaliações

- Grade 3 & 4 - Activated SludgeDocumento55 páginasGrade 3 & 4 - Activated SludgeSirish Chand PutlaAinda não há avaliações

- Centurion University of Technology & Management School of Engineering & Technology, Paralakhemundi Department of Mechanical Engineering Roll List For 3 Semester Sec-ADocumento2 páginasCenturion University of Technology & Management School of Engineering & Technology, Paralakhemundi Department of Mechanical Engineering Roll List For 3 Semester Sec-ASirish Chand PutlaAinda não há avaliações

- TUC5+ Modbus ID Details PDFDocumento10 páginasTUC5+ Modbus ID Details PDFvijikeshAinda não há avaliações

- L011375 - MT4434TE Spec SheetDocumento2 páginasL011375 - MT4434TE Spec SheetJunior BautistaAinda não há avaliações

- Palette For Colorfastness PilotDocumento25 páginasPalette For Colorfastness Pilotjenal aripinAinda não há avaliações

- DRK109A&B Touch-Screen Bursting Strength TesterDocumento2 páginasDRK109A&B Touch-Screen Bursting Strength Testermohamadreza1368Ainda não há avaliações

- 2021 SEM 4 CC 9 OrganicDocumento3 páginas2021 SEM 4 CC 9 OrganicGaurav KumarAinda não há avaliações

- Alex H.: Penguin ProjectDocumento13 páginasAlex H.: Penguin Projectapi-504550016Ainda não há avaliações

- Math 138 Functional Analysis Notes PDFDocumento159 páginasMath 138 Functional Analysis Notes PDFAidan HolwerdaAinda não há avaliações

- Ap T240 13Documento92 páginasAp T240 13mehdiAinda não há avaliações

- Question Bank-JavaDocumento3 páginasQuestion Bank-Javarachana saiAinda não há avaliações

- Craig Pirrong-Commodity Price Dynamics - A Structural Approach-Cambridge University Press (2011) PDFDocumento239 páginasCraig Pirrong-Commodity Price Dynamics - A Structural Approach-Cambridge University Press (2011) PDFchengadAinda não há avaliações

- Conectar A BD en SeleniumDocumento4 páginasConectar A BD en SeleniumCristhian Andrés GonzálezAinda não há avaliações

- Jet Powered BoatDocumento22 páginasJet Powered BoatMagesh OfficialAinda não há avaliações

- Opposite Corners CourseworkDocumento8 páginasOpposite Corners Courseworkpqltufajd100% (2)

- St. Xavier'S School, Burdwan: o o o oDocumento2 páginasSt. Xavier'S School, Burdwan: o o o obidyut naskarAinda não há avaliações

- Enatel FlexiMAX24a500Kw PDFDocumento2 páginasEnatel FlexiMAX24a500Kw PDFJosé Angel PinedaAinda não há avaliações

- Structural Design 2Documento43 páginasStructural Design 2Meymuna AliAinda não há avaliações

- Random Numbers in PythonDocumento3 páginasRandom Numbers in PythonShubham RawatAinda não há avaliações

- 1piece Exam - Week 11 Solution (Geas)Documento14 páginas1piece Exam - Week 11 Solution (Geas)Elguapito DelisciusoAinda não há avaliações

- What Is Asterisk?: What Do We Have? ConfigurationsDocumento2 páginasWhat Is Asterisk?: What Do We Have? ConfigurationsClicku NetAinda não há avaliações

- MDM Heiana Nadia Hamzah: Prepared byDocumento50 páginasMDM Heiana Nadia Hamzah: Prepared bySyarfa FurzanneAinda não há avaliações

- Design and Simulation of A QCA 2 To 1 MultiplexerDocumento5 páginasDesign and Simulation of A QCA 2 To 1 MultiplexerzubifayazAinda não há avaliações

- QuesTeksFerriumC61C64andC6 PDFDocumento23 páginasQuesTeksFerriumC61C64andC6 PDFEmily MillerAinda não há avaliações

- Data Sheet - enDocumento2 páginasData Sheet - enrodriggoguedesAinda não há avaliações

- Maths4u SylDocumento87 páginasMaths4u SylDJAinda não há avaliações

- Chameleon ChipDocumento2 páginasChameleon ChipChetan KumarAinda não há avaliações