Escolar Documentos

Profissional Documentos

Cultura Documentos

Biaxial Analysis of General Shaped Base Plates

Enviado por

baska14Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Biaxial Analysis of General Shaped Base Plates

Enviado por

baska14Direitos autorais:

Formatos disponíveis

Biaxial Analysis of General Shaped Base Plates

R. GONZALO ORELLANA 1 Summary: A linear model is used for the contact stresses calculation between a steel base plate and a concrete foundation. It is also considered that the anchor rods tensions vary linearly. Furthermore, strain compatibility is proposed. The non-linear system has as variables: the neutral axis angle, the maximum anchor rods tension, the bearing length and optionally the maximum stress in the concrete. The Newton-Raphsons method is used to solve the system. Key words: Base plate; Biaxial; Compressive; Newton-Raphson

INTRODUCTION Base plate design is an essential part of any structural project. All available bibliography related to the analysis and subsequent design of base plates considers uniaxial behavior. However, since many structural models are tridimensional, the reactions obtained from the structure have moments about both axes, as shown in Figure 1. In this article uniaxial methods are extended to handle biaxial problems.

plate is considered as fully rigid and the strains in compression and tension zones have a lineal relationship. METHOD DEVELOPMENT To develop the methodology we will take as an example an octagonal base plate with an inscribed circle radius of 10 in (8.28 in per side approx.). An opening is made, also octagonal, with an inscribed radius of 4 in (3.31 in per side approx.). 8 anchor rods of 5/8 are included symmetrically in a circular placement with an 8.5 in circle radius. An important step is the borders definition. The external borders are defined counterclockwise and the openings clockwise as shown in Figure 2. Then, each line segment is taken in the same way for all defined borders.

Figure 1. Biaxially loaded base plate To solve biaxial problems a non-linear equations system is needed, because concrete can only handle compression forces and anchor rods can only handle tension. In general, the system variables are: the maximum compressive concrete stress, maximum anchor rods tension, neutral axis angle and bearing length. A common practice is to fix maximum compressive concrete stress by the adopted design code. In this case; we have a three equations and three variables system. In addition, a new equation could be included: strain compatibility; that is to say, the base

1

Figure 2. Borders definition Linear models are proposed for concrete compressive stresses and anchor rods tension forces, see Figure 3. The next step for numerical solution is to transform the base plate border and anchorage geometry to a local coordinate system, see Figure 3.

Civil engineer, personal e-mail: gonchio@hotmail.com, work e-mail: gonzalo.orellana@bentley.com

1/5

similar to and concentric with the loaded area. To solve the non-linear system, the equations must also be three: the vertical forces equilibrium, Equation (2), the moment equilibrium about X axis, Equation (3) and the moment equilibrium about Y axis, Equation (4). It is mandatory to calculate the equations in the same coordinate system. In addition, optionally, a fourth variable could be included with its respective equation. (2)

(3)

(4) Figure 3. Linear model and local coordinate system where, T = maximum tension force on anchor rods. = maximum compressive stress. = neutral axis (NA) angle. Y = bearing length. f = maximum anchor rod distance from NA. The three variables of the biaxial problem are: bearing length, maximum anchor rod tension and the neutral axis angle. A simplification is to consider that the maximum concrete stress reaches the maximum concrete bearing strength by the adopted design code. The Equation (1), that has a limit for the term , shows the maximum design bearing strength adopted by the American Concrete Institute (ACI). where, P Mxx Myy Pi Mixx Miyy n = = = = = = = = = = applied axial force. applied moment about X global axis. applied moment about Y global axis. axial force for segment i. moment about X global axis for segment i. moment about Y global axis for segment i. total segment number. force tension in anchor rod i. global coordinates of anchor rod i. total anchor rods number.

Instead of considering the maximum concrete compressive stress constant by the design code, we could take it as a fourth variable and add the strain compatibility, Equation (5), to the equation system to reach equilibrium. (5) where, T = maximum tension force on anchor rods. a = maximum tension anchor rod area. = maximum compressive stress. Y = bearing length. f = maximum anchor rod distance from NA. n = elasticity ratio. (6) = modulus of elasticity of steel. = modulus of elasticity of concrete. 2/5

(1) where, = maximum design bearing strength, Section 10.14, ACI 318-08. = compression resistance factor 0.65 by Section 9.3, ACI 318-08. = specified compressive strength of concrete. = base plate area.

A1

A2 = maximum area of the portion of the supporting surface that is geometrically

To calculate the tension, in the anchor rod i, we use a linear interpolation employing its local coordinate y, as shown in Equation (7). (7) where, T f = tension in anchor rod i. = maximum tension force on anchor rods. = maximum anchor rod distance from NA. = local coordinate y of anchor rod i.

= compressive stress for node i+1. = local coordinates for node i. = local coordinates for node i+1. NEWTON-RAPHSON METHOD This article explains briefly a method for a nonlinear equations system based on Newton-Raphson, applied to a biaxial base plate problem case. The problem is to obtain variable values, such that the functions proposed are balanced. (12) We denote by X the entire variables vector, then each function could be expanded by Taylor series.

The compressive concrete stress for node i of a border segment is calculated by linear interpolation as shown in Equation (8). (8) where, = compressive stress at node i. = maximum compressive stress. = bearing length. = local coordinate y of node i.

(13)

The equivalent force, moment about local x axis and moment about local y axis for a line segment between node i and node i+1 can be determined by the Equations (9), (10) and (11) respectively.

Terms and higher are neglected. Then, we obtain a set of four lineal equations to determine the correction vector , which moves the functions closer to zero simultaneously on each iteration. Since the system converges, the term in the Equation (13) , then we get,

(14)

(9)

The Equation (14) could be written in matrix notation as,

(10)

(15)

(11)

These matrices must be calculated by a lineal equations solver like the Gauss Method. Thus, we get the values to modify the variables in the next iteration, (16) The iterative process stops when values are less than the tolerance and the variables values do not change. To determine the partial derivates a numerical procedure is used as shown in Equation (17), 3/5

where, Pi Mixx Miyy

= axial force for segment i. = moment about local x axis for segment i. = moment about local y axis for segment i. = compressive stress for node i.

(17) donde, = differential of variable j. PRACTICAL APPLICATION To continue with the numerical example, we applied an external axial compression load of 90 kip, a moment about global X axis of 300 kipin and another moment about global Y axis of 440 kipin to the base plate. The steel of the base plate has a modulus of elasticity equal to 29000 ksi and the modulus of elasticity of the supporting concrete is 3122.02 ksi.

The next step is to determine the equivalent forces and moments in the local coordinate system for the concrete compression and anchor rods tension.

Considering the strain compatibility for current example we will use four equations with four variables. An important step to solve a non-linear equation system using the Newton-Raphson method, is to use an adequate set of initial values for the variables. We suggest the following initial values for the problem.

Next, forces an moments must be transfomed to the global coordinate system to obtain the equilibrium differences.

We used an initial neutral axis angle as a function of applied loads.

As initial bearing length we take the distance between the origin and the maximum compressed fiber of the base plate border.

The maximum tension in the anchor rod depends on another set of initial values and could be solved from Equation (5).

This procedure must be repeated until the equations converge to zero using a numerical method for a non-linear equations system. In the current example the Newton-Raphson method was employed. After six iterations the system converges and the results below are calculated: 4/5

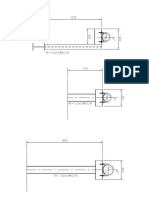

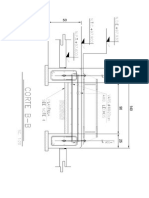

In Figure 4, the base plate to concrete contact stresses are shown. The steel anchor rods tension forces are displayed in Figure 5.

REFERENCES 1. Blodgett, Omer W., Design of Welded Structures, 1982. 2. Dake, Richard M. and Elkin, Sharon J., BeamColumn Base Plate Design LRFD Method, 1999. 3. Rodrguez, J. A. and Aristizabal, J. Dario, Contact Pressure Caused by a Rigid Footing of Any Shape Subjected to Eccentric Axial Load, 2004 4. American Institute of Steel Construction (AISC) Manual, 13th Edition, 2005 5. Base Plate and Anchor Rod Design, Steel Design Guide 1, 2nd Edition, 2006

Figure 4. Concrete stresses

Figure 5. Anchor rods tension forces

CONCLUSIONS Since the developed procedure is an extension of uniaxial methods, widely accepted for the analysis of base plates, it also gives accurate results for moments about one axis. Another advantage, of the presented biaxial procedure calculation, is to be an alternative to the finite element method (FEM) for the analysis of special projects with arbitrary base plate shapes with openings. This method could be easily abstracted into a computational algorithm.

5/5

Você também pode gostar

- Numerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFDocumento6 páginasNumerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFAnonymous BuFjdLAinda não há avaliações

- Impact Load FactorsDocumento13 páginasImpact Load FactorsMuralidharan ShanmugamAinda não há avaliações

- Torsional StressesDocumento48 páginasTorsional StressesKory EstesAinda não há avaliações

- Exact Solution To Free Vibration of Beams Partially Supported by An Elastic FoundationDocumento11 páginasExact Solution To Free Vibration of Beams Partially Supported by An Elastic FoundationSurej Jayan CherilAinda não há avaliações

- Theory of StructuresDocumento35 páginasTheory of StructurespjAinda não há avaliações

- Forex Traders Cheat Sheet PDFDocumento37 páginasForex Traders Cheat Sheet PDFivantrax11650% (2)

- CE 437/537 Retaining Wall Design ExampleDocumento8 páginasCE 437/537 Retaining Wall Design ExampleJefferson Nobleza67% (3)

- Symmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNo EverandSymmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNota: 4 de 5 estrelas4/5 (2)

- Structural Theory 2 - Structural Analysis of A Two Storey HouseDocumento194 páginasStructural Theory 2 - Structural Analysis of A Two Storey HouseEmmanuel Lazo80% (30)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionNo EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionNota: 2.5 de 5 estrelas2.5/5 (4)

- Beams and Framed Structures: Structures and Solid Body MechanicsNo EverandBeams and Framed Structures: Structures and Solid Body MechanicsNota: 3 de 5 estrelas3/5 (2)

- Ada 405009Documento253 páginasAda 405009ivantrax116Ainda não há avaliações

- The Stress TensorDocumento18 páginasThe Stress Tensorhiimruju50% (2)

- pvp2000 Vol399Documento4 páginaspvp2000 Vol399Bogdan GabrielAinda não há avaliações

- Fea-Finite Element Analysis: Chapter-1 Stress TensorDocumento106 páginasFea-Finite Element Analysis: Chapter-1 Stress Tensorkamsubh66Ainda não há avaliações

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsAinda não há avaliações

- Biaxial Analysis of General Shaped Base PlatesDocumento5 páginasBiaxial Analysis of General Shaped Base Platesivantrax116Ainda não há avaliações

- Biaxial Analysis of General Shaped Base PlatesDocumento5 páginasBiaxial Analysis of General Shaped Base PlatesSuheil BagasrawalaAinda não há avaliações

- Implementation of The Modified Compression Field TheoryDocumento33 páginasImplementation of The Modified Compression Field TheoryDang Bao TranAinda não há avaliações

- C C D I D S: Ontrolling Onductor Eviation With Nclined Riving HOEDocumento6 páginasC C D I D S: Ontrolling Onductor Eviation With Nclined Riving HOEAnre Thanh HungAinda não há avaliações

- Elastic Analysis & Application Tables of Rectangular Plates (Artigo-Papanikolaou)Documento20 páginasElastic Analysis & Application Tables of Rectangular Plates (Artigo-Papanikolaou)MelekeenAinda não há avaliações

- Elastic and Inelastic Analysis of Non-Prismatic Members Using Finite Difference.Documento16 páginasElastic and Inelastic Analysis of Non-Prismatic Members Using Finite Difference.joshuaAinda não há avaliações

- Galambos 2001 Q2Documento13 páginasGalambos 2001 Q2bobmarley20161934Ainda não há avaliações

- Calculation of The Collapse Load of An ADocumento13 páginasCalculation of The Collapse Load of An ALuminita GeorgetaAinda não há avaliações

- Wilson 1990Documento13 páginasWilson 1990Sebastiao SilvaAinda não há avaliações

- Eindhoven University of Technology - Hybrid Formulation For Torsion and WarpingDocumento11 páginasEindhoven University of Technology - Hybrid Formulation For Torsion and WarpingFrancisco ContrerasAinda não há avaliações

- Discrete Crack Modeling in Concrete StructuresDocumento16 páginasDiscrete Crack Modeling in Concrete StructuresjahidAinda não há avaliações

- An Approach To Finite Element Analysis of Boiler Tube-SheetDocumento4 páginasAn Approach To Finite Element Analysis of Boiler Tube-SheetAJER JOURNALAinda não há avaliações

- Contact stresses in pin-loaded platesDocumento11 páginasContact stresses in pin-loaded plateskhudhayer1970Ainda não há avaliações

- Materi 4Documento18 páginasMateri 4Adiel WusqaAinda não há avaliações

- Neuber FEADocumento12 páginasNeuber FEAPrashantha RajuAinda não há avaliações

- General Solution for Eccentric Loads on Welded JointsDocumento10 páginasGeneral Solution for Eccentric Loads on Welded JointsMark OglesbyAinda não há avaliações

- Stress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorDocumento7 páginasStress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorYasser BahaaAinda não há avaliações

- Capitulo 4Documento0 páginaCapitulo 4saded05Ainda não há avaliações

- Finite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreDocumento8 páginasFinite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreGhouse ShaikAinda não há avaliações

- Structures Determinacy TheoryDocumento35 páginasStructures Determinacy TheoryPatricia Nicole ElediaAinda não há avaliações

- Analytical Solutions and Numerical Procedures For Minimum-Weight Michell StructuresDocumento23 páginasAnalytical Solutions and Numerical Procedures For Minimum-Weight Michell StructuresWolelaw EndalewAinda não há avaliações

- Welcome To International Journal of Engineering Research and Development (IJERD)Documento9 páginasWelcome To International Journal of Engineering Research and Development (IJERD)IJERDAinda não há avaliações

- Analyses of The Lateral Load Tests at The Route 351 BridgeDocumento32 páginasAnalyses of The Lateral Load Tests at The Route 351 BridgeBerkeley XiaoAinda não há avaliações

- Lehigh University Civil and Environmental Engineering Fritz Laboratory Reports Column ResearchDocumento49 páginasLehigh University Civil and Environmental Engineering Fritz Laboratory Reports Column ResearchAKAinda não há avaliações

- Finite Element Modelling SoftwareDocumento27 páginasFinite Element Modelling SoftwarerkAinda não há avaliações

- A General Solution For Eccentric Loads On Weld GroupsDocumento10 páginasA General Solution For Eccentric Loads On Weld GroupsMaryam KhorsandAinda não há avaliações

- Some Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element MethodDocumento21 páginasSome Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element Methodp71089Ainda não há avaliações

- Lab 5Documento10 páginasLab 5Tayyab ZafarAinda não há avaliações

- Non Linear Analysis of Piled Raft Foundation HG PoulosDocumento9 páginasNon Linear Analysis of Piled Raft Foundation HG Poulospperic13Ainda não há avaliações

- Study of Envelopes for Seismic Response VectorsDocumento13 páginasStudy of Envelopes for Seismic Response VectorsBodhi RudraAinda não há avaliações

- Analysis of Framed StructuresDocumento12 páginasAnalysis of Framed StructuresTonymeriAinda não há avaliações

- Cie 525Documento12 páginasCie 525Richard PadillaAinda não há avaliações

- Outline of Lecture 9: Structural DynamicsDocumento68 páginasOutline of Lecture 9: Structural DynamicslotushAinda não há avaliações

- CH 05Documento72 páginasCH 05LeonardoMadeira110% (1)

- Inelastic Buckling of Beams PDFDocumento18 páginasInelastic Buckling of Beams PDFlyeshiunAinda não há avaliações

- Bi Axial ExtensionDocumento8 páginasBi Axial ExtensionPHAM Duong HungAinda não há avaliações

- Etabs Column DesignDocumento15 páginasEtabs Column Designmagdyamdb100% (1)

- MechVib Assign4 FreeVdofDocumento1 páginaMechVib Assign4 FreeVdofSamuelAndresAinda não há avaliações

- Mechanics of Material Lab6Documento36 páginasMechanics of Material Lab6NiroexAinda não há avaliações

- Chapter - 8 Master Dynamic Stability Formula For Structural Members Subjected To Periodic LoadsDocumento14 páginasChapter - 8 Master Dynamic Stability Formula For Structural Members Subjected To Periodic LoadsSumanth BhavanasiAinda não há avaliações

- Analysis of StructuresDocumento24 páginasAnalysis of Structuresa_j_sanyal259Ainda não há avaliações

- Finite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreDocumento8 páginasFinite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreseventhhemanthAinda não há avaliações

- Coupled Computation of Meshing and Bearings StiffnDocumento7 páginasCoupled Computation of Meshing and Bearings Stiffnranim najibAinda não há avaliações

- 2004 Behaviour ICJDocumento8 páginas2004 Behaviour ICJshilp88Ainda não há avaliações

- Investigation of A Cross-Section With A Constant TDocumento12 páginasInvestigation of A Cross-Section With A Constant Traziul.aliAinda não há avaliações

- 591 Edward Summers 2009 PWRDocumento75 páginas591 Edward Summers 2009 PWRNono_geotecAinda não há avaliações

- Plata Form ADocumento1 páginaPlata Form Aivantrax116Ainda não há avaliações

- Anchor Detail PDFDocumento1 páginaAnchor Detail PDFivantrax116Ainda não há avaliações

- Software stresses reportDocumento1 páginaSoftware stresses reportivantrax116Ainda não há avaliações

- Lifting Lug DetailsDocumento1 páginaLifting Lug Detailsivantrax116Ainda não há avaliações

- Detail 121Documento1 páginaDetail 121ivantrax116Ainda não há avaliações

- Anchor DetailDocumento1 páginaAnchor Detailivantrax116Ainda não há avaliações

- Detail 113Documento1 páginaDetail 113ivantrax116Ainda não há avaliações

- Connections DetailsDocumento1 páginaConnections Detailsivantrax116Ainda não há avaliações

- Detail 112Documento1 páginaDetail 112ivantrax116Ainda não há avaliações

- Detail 111Documento1 páginaDetail 111ivantrax116Ainda não há avaliações

- Detail 113Documento1 páginaDetail 113ivantrax116Ainda não há avaliações

- Detail 112Documento1 páginaDetail 112ivantrax116Ainda não há avaliações

- Details 6Documento1 páginaDetails 6ivantrax116Ainda não há avaliações

- Detail 115Documento1 páginaDetail 115ivantrax116Ainda não há avaliações

- Detail 107Documento1 páginaDetail 107ivantrax116Ainda não há avaliações

- Detail 109Documento1 páginaDetail 109ivantrax116Ainda não há avaliações

- Detail 110Documento1 páginaDetail 110ivantrax116Ainda não há avaliações

- Details 7Documento1 páginaDetails 7ivantrax116Ainda não há avaliações

- Details 5Documento1 páginaDetails 5ivantrax116Ainda não há avaliações

- DETAIL 108 Pedestal ConcreteDocumento1 páginaDETAIL 108 Pedestal Concreteivantrax116Ainda não há avaliações

- Trabe Mena 2Documento1 páginaTrabe Mena 2ivantrax116Ainda não há avaliações

- Details 8Documento1 páginaDetails 8ivantrax116Ainda não há avaliações

- Details 11Documento1 páginaDetails 11ivantrax116Ainda não há avaliações

- Details 4Documento1 páginaDetails 4ivantrax116Ainda não há avaliações

- Details 2Documento1 páginaDetails 2ivantrax116Ainda não há avaliações

- Details 3Documento1 páginaDetails 3ivantrax116Ainda não há avaliações