Escolar Documentos

Profissional Documentos

Cultura Documentos

CFD Simulation of Round and Flat Tube Fin Heat Exchanger For Laminar and Turbulent Flow Models

Enviado por

whyreadTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CFD Simulation of Round and Flat Tube Fin Heat Exchanger For Laminar and Turbulent Flow Models

Enviado por

whyreadDireitos autorais:

Formatos disponíveis

1

Proceedings of the 37

th

International & 4

th

National Conference on Fluid Mechanics and Fluid Power

FMFP2010

December 16-18, 2010, IIT Madras, Chennai, India

FMFP2010

CFD SIMULATION OF ROUND AND FLAT TUBE FIN HEAT EXCHANGER

FOR LAMINAR AND TURBULENT FLOW MODELS

Gurjeet Singh Gulshan Sachdeva

National Institute of Technology,

Kurukshetra-136119, Haryana, India

gurjit_414@yahoo.com

National Institute of Technology,

Kurukshetra-136119, Haryana, India

gulshan4you@gmail.com

ABSTRACT

ThermalHydraulic CFD study of round and flat

tube-fin heat exchanger having staggered

arrangement has been carried out to simulate the

fluid flow and heat transfer characteristics for

laminar and turbulent flow models. The problem

has been simulated for different mass flow rates in

the Reynolds number range 330-7200 in order to

determine the Pressure drop and Nusselt number so

as to calculate the main parameters of interest like

Friction Factor and Colburn Factor respectively.

These are further compared with experimental

results available from the literature. The

comparison has been presented in terms of charts

and images. The methodology includes 2-D

computational model of fluid flow region between

two parallel fins through the tube, developed and

meshed with quadrilateral scheme in gambit. The

water at 333K flowing through the copper tubes

while the air is flowing at 278K through the heat

exchanger in the velocity range of 0.3 to 6.2 m/s.

Periodic flow conditions are applied at inlet and

outlet. Laminar and Turbulent (k-epsilon) models

have been chosen to study variation of flow

parameters. In the post processing fluid Flow and

Thermal fields are examined and some conclusion

have been drawn which will be discussed in

subsequent sections.

Keywords: CFD, Flat and round tube-fin heat

exchanger, Reynolds number, Turbulent flow,

Friction factor, Laminar flow

INTRODUCTION

So far many researchers have carried out extensive

work pertaining to plate and tube-fin heat

exchanger. Wang et al., 1996 concluded that fin

spacing has negligible effect on heat transfer

coefficient and both Friction and Colburn Factor

were found to be independent of fin thickness. Jang

et al., 1996 reported that heat transfer practically

remain independent of number of tube rows for

N>4. The Colburn and Friction factor for staggered

tube arrangement are 15 to 27 % and 20 to 30 %

respectively higher that those of inline arrangement.

Jang et al., 1998 made numerical and experimental

measurements of plain fin-and-tube heat exchangers

having round and flat tube-fin configuration. They

found that for same perimeter of the tubes, the heat

transfer coefficient for the flat tube was 35-50%

higher than that for round tube configuration

whereas the pressure drop of the former is 25-30%

of that of latter. Others [1, 2, 3, 5, and 8] also have

performed extensive study pertaining to round and

flat tube-fin heat exchangers.

STATEMENT OF THE PROBLEM

In the present problem the experimental results of

Colburn and Friction Factors from the Wang et

al.[1996] for round tube have been validated against

the simulated results. Moreover comparative studies

of the above factors have been carried out for the

round and flat tube-fin configuration for Laminar

and Turbulent Flow Model. The Flow and Thermal

Fields have been analyzed. The comparisons have

173

Proceedings of the 37th National & 4th International Conference on Fluid Mechanics and Fluid Power

December 16-18, 2010, IIT Madras, Chennai, India.

FMFP10 - HT - 20

2

been plotted on graphs to see the relative variation

of the flow and thermal parameters.

GOVERNING EQUATIONS AND

NUMERICAL SCHEME

The basic governing equations for fluid flow and

heat transfer have been taken from [6] which are

discretised and solved by the finite volume method

using Fluent 6.1. It is solved on a staggered grid

using solvers for laminar and turbulent flow

models. To ensure coupling between velocity and

pressure, the SIMPLE or SIMPLEC algorithm is

used.

Governing equations for Turbulence Modeling

The Turbulent viscosity

t

P is expressed as:

t t

u l P U = (4.1)

Where

( )

2 2 2

2 1

' ' '

3 3

t

u k u v w = = + +

(4.2)

The dissipation of the turbulent kinetic energy is

expressed as:

2/3

k

l

H = or as related to viscosity

'

'

j

t i

k k

u

u

x x

P

H

U

c

c

=

c c

(4.3)

Reynoldss stresses

2

' '

3

j

i

ij i j t ij

j i

U

U

u u k

x x

W U P U G

| | c

c

= = +

|

|

c c

\ .

(4.4)

Turbulent scalar transport is proportional to mean

scalar value gradients and can be expressed as

' '

i t

i

u

x

M

U M

c

= I

c

where

t

I refers to turbulent

(eddy) diffusivity.

The Turbulent Kinetic Energy Equation, as

shown below

( )

' '

' '

' ' ' '

2 ' '

i j

i i i

i i i j

i i j j j

uu

U u u k

Uk u p uu

t x x x x x

U

U U U P

( | | c c c c c c

+ = +

( |

c c c c c c

\ .

(4.5)

The term first on LHS is Transient term, the second

term on LHS is convective transport term while the

first term on RHS is Diffusive Transport Term, the

second term is production term, and the third term

is viscous

Transport ETXDWLRQIRU

( )

1 2

' '

t i

i i j

i i i j

U

U C u u C

t x x x k x k

H

P UH H H H

U H U U H

V

| |

( c c c c c

+ = + |

(

|

c c c c c

\ .

(4.6)

The first term on LHS indicate accumulation of ,

the second term shows destruction of , whereas

first term on RHS indicate diffusive transport of ,

The second term shows production of , the third

term shows transport of by convection.

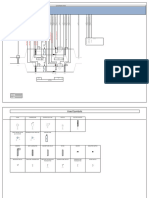

COMPUTATIONAL DOMAIN

Computational model for round and flat tube-fin

configuration is shown in fig: 1. gambit 2.1 is used

to create and mesh the computational model. The

flow region is densely meshed around the tubes

with uniform boundary layer meshing and

quadrilateral meshing is used in rest of the flow

region. The entire computational domain is made

up of approximately 64000 cells round tube and

70000 for flat tube-fin heat exchanger model. The

cell number is chosen on the basis of grid

independence testing.

Geometrical Details

The geometrical details of flat and round tube-fin

configurations have been shown in the table 3.1

shown below.

Table 1. Geometrical Dimensions of round and

flat tube-fin heat exchanger model.

3

Fig. 1, 2. Computational Domain for round and

flat tube-fin heat exchanger model

Boundary conditions

The computational domain has contains boundary

conditions for Tube surfaces, Dirichlet BC as T =

T

w

, and Fins, Dirichlet BC as T = T

fw

with no slip

condition for both. Inlet, Dirichlet BC as Uniform

velocity u = u

in

, v = w = 0 and

T = 5 C. Outlet, Neuman BC as Zero gradients, u,

v, w, pressure, and temperature. (One-way), Free

stream planes: (top and bottom planes of the

extended surface areas) as slip conditions: (cu/c:)

=0, (cv/c:) 0, w 0, (cT/c:) 0. Side planes:

symmetry planes

(cu/cy)0, v 0, (cw/cy) 0, (cT/cy) 0

Computational Details

CFD code Fluent 6.1 is used for the numerical

solution of NavierStrokes and Energy Equations.

Fluent uses a control volume based technique to

convert the governing equations to algebraic

equations that can be solved numerically. This

involves subdividing the region in which the flow is

to be solved into finite number of control volumes

so that equation can be integrated numerically or a

cell by cell basis to produce discrete algebraic

(finite volume) equations [24, 25]. The

SIMPLE/SIMPLEC Algorithm is used to couple

pressure and velocity. A Power Law up winding

Scheme is used for space discretisation of

momentum, turbulence and energy equation in

simulation. The periodic conditions are imposed at

inlet and outlet of flow domain. At the inlet flow

velocity and temperature are defined by user.

PERFORMANCE PARAMETERS

1) Fanning friction factor (f) 2) Colburn factor (j)

The Fanning friction factor is the ratio of wall shear

stress to the flow kinetic energy. It is related to

pressure drop in tube-and-fin heat exchangers. The

Colburn j-factor is the ratio of convection heat

transfer (per unit duct surface area) to the amount

virtually transferable (per unit of cross-sectional

flow area.

2

2 1 2

1 1

(1 ) 1

2

m

in c in c

p G A

f

p g p A

Q Q Q

V

Q Q

( | | A

= + +

( |

\ .

(6.1)

1/ 3

c

D

Nu

j

Re Pr

=

(6.2)

VALIDATION OF RESULTS FOR FRICTION

AND COLBURN FACTOR WITH

LITRATURE

0

0.02

0.04

0.06

0.08

0.1

0.12

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

F

R

I

C

T

I

O

N

F

A

C

T

O

R

FRICTION FACTOR (f) FOR

LAMINAR FLOWMODEL

FRICTION FACTOR (f) FOR

TURBULENT FLOWMODEL

FRICTION FACTOR (f)

FROM LITRATURE

Fig.3. Variation of friction factor with Reynolds

number

Here we find in case of laminar flow model for

round tube simulations the laminar flow region

extends up to Re = 1300, but in order to clearly

demarcate the different flow regimes, the turbulent

flow model is used, which indicate that the

transition zone exist between Re = 1300 to 2900,

further this is also noticeable that turbulence region

exist beyond Re = 2900.

4

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

C

O

L

B

U

R

N

F

A

C

T

O

R

COLBURN FACTOR(j) FOR

LAMINAR FLOWMODEL

COLBURN FACTOR(j) FOR

TURBULENT FLOWMODEL

COLBURN FACTOR(j) FROM

LITRATURE

Fig. 4. Variation of Colburn factor with

Reynolds number

The results for laminar region are better simulated

by LFM while results for turbulent and transition

region better simulated by TFM. The variation of

Colburn Factor for each of model follows the same

trend as that of experimental however TFM gives a

better picture of heat transfer in turbulent regime

whereas the LFM gives better results of heat

transfer for laminar flow regime in each of the tube-

fin configuration.

COMPARISON OF FRICTION FACTOR FOR

ROUND TUBE AND FLAT TUBE FOR LFM

AND TFM

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

F

R

I

C

T

I

O

N

F

A

C

T

O

R

FRICTION FACTOR ( f )

FOR LAMINAR FLOW

MODEL FOR FLAT TUBE.

FRICTION FACTOR (f) FOR

LAMINAR FLOWMODEL

FOR ROUND TUBE

Fig.5. Comparative plot of friction factor for

laminar flow model for round and flat tube-fin

configurations

The results of friction factor for round tube

configuration is always higher throughout the range

of Reynolds number in comparison with flat tube

configuration which clearly indicate that the

frictional losses are comparatively higher in round

tube. This is also observable that flow direction

continuously changes across the heat exchanger.

0

0.02

0.04

0.06

0.08

0.1

0.12

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

F

R

I

C

T

I

O

N

F

A

C

T

O

R

FRICTION FACTOR (F) FOR

TURBULENT FLOWMODEL

FOR FLAT TUBE

FRICTION FACTOR (f) FOR

TURBULENT FLOWMODEL

FOR ROUND TUBE

Fig.6. Comparative plot of friction factor for

Turbulent flow model for round and flat tube-fin

configurations

The obstruction to the smooth flow of air is higher

in round tube than that of flat tube fin configuration.

Moreover the continuous convergent divergent

movement of the air flow between the parallel

plates across the tubes is also held responsible for

pressure loss contributions. The fin spacing for the

present case is very low which shows the higher

pressure drop for each of tube-fin configurations.

COMPARISON OF COLBURN FACTOR FOR

ROUND TUBE AND FLAT TUBE FOR LFM

AND TFM

0

0.005

0.01

0.015

0.02

0.025

0.03

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

C

O

L

B

U

R

N

F

A

C

T

O

R

COLBURN FACTOR.(J) FOR

LAMINAR FLOWMODEL FOR

FLAT TUBE

COLBURN FACTOR(j) FOR

LAMINAR FLOWMODEL FOR

ROUNDTUBE

Fig.7.Comparative plot of variation of colburn

factor between round and flat tube-fin

configurations

The Colburn factor for laminar flow model for flat

tube is 25% to 35% higher in laminar flow regime

whereas for rest of flow regimes it nearly exhibits

same results as that of experimental for entire range

of Reynolds number though the variation is limited

between the 6% to 10.

5

0

0.005

0.01

0.015

0.02

0.025

0.03

0 1000 2000 3000 4000 5000 6000 7000 8000

REYNOLDS NUMBER

C

O

L

B

U

R

N

F

A

C

T

O

R

COLBURN FACTOR(J) FOR

TURBULENT FLOWMODEL FOR

FLAT TUBE

COLBURN FACTOR(j) FOR

TURBULENT FLOWMODEL FOR

ROUND TUBE

Fig.8. Comparative Plot of variation of colburn

factor between round and flat tube-fin

configurations

The variation of Colburn factor for TFM for flat

tube lies in the range between 25% to 31% for

laminar flow regime whereas for turbulent and

transition flow regimes this variation is limited

between 13% to 23% which corresponds to

literature values.

FLOW CHARACTERISTICS

The flow characteristics for laminar and turbulent

flow models for round and flat tube-fin

configurations have been shown in following

figures (9,10,11,12,13,14).

Fig.9. v = 0.3m/s (LFM)

Flow enters the heat exchanger region almost at the

velocity equal to that of inlet. The flow bifurcates in

magnitude while passing over the tube rows and

gradually gains the velocity when it passes through

the area between the two tubes.

Fig.10. v = 0.3 m/s (TFM)

Fig.11. v = 6.2 m/s (TFM)

At low velocity when the flow passes over the tube

rows the flow separation takes place. Thus the flow

in downstream region after the each tube gets

converted into the wake and recirculation zone

whereas on the upstream side of the tube rows the

horse shoe vortex generation takes place [20]. Then

flow makes smooth transition through the minimum

flow area at higher velocity. The comparison of

flow for two velocities shows that no flow

stagnation regions are observed in front of first and

second tube whereas in case of flow at high velocity

the stagnation region is observed only in front of

the second tube. In relative comparison of velocities

for the flat tube-fin configuration it is clearly visible

that for laminar flow model flow stagnation zones

are being observed in front of each tube row at low

velocity whereas these zones are entirely missing at

high velocity.

6

Fig.12. v = 0.3m/s (LFM)

Fig.13. v = 0.3 m/s (TFM)

Fig.14. v = 6.2 m/s (TFM)

The rear of each tube row experiences a wake zone

which is having very poor strength thus due to

above reasons the frictional losses are little on

higher side for low velocity whereas comparatively

negligible at high velocity. Flow transition through

the flow region is entirely smooth since flat tube

does not offer much resistance to flow though the

flow velocity is little increased in the region

between the two tubes.

FLOWTEMPERATURE DISTRIBUTION

The flow temperatures for round and flat tube-fin

configurations for laminar and turbulent flow model

have been shown in following figures (15, 16, 17,

18, 19, and 20).

Fig.15. v = 0.3m/s (LFM)

Fig.16. v = 0.3 m/s (TFM)

In case of laminar flow model the hydrodynamic

study states that heat transfer is higher at leading

edge of the fin due to thin boundary layer and also

in front of the tube region where horse vortex

region is present. The portion in front of the tube

participates more into heat transfer than that of back

[20]. The horse-shoe vortices produced in the

staggered arrangement appears directly in front of

the tubes [16].

7

Fig.17. v = 6.2 m/s (TFM)

In the wake region the heat transfer is better than

that of other areas since the flow recirculation are

present there for longer duration of the time. Hence

the heat transfer is observed to be better at low

velocity.

Fig.18. v = 0.3m/s (LFM)

A high temperature zone exists after each tube row

which clearly simulates that heat transfer is far

better in laminar flow regime. It can also be

concluded that the heat transfer in flat tube is more

than that of round tube as the flow remains more in

contact with flat tube surface.

Fig.19. v = 0.3 m/s (TFM)

Fig.20. v = 6.2 m/s (TFM)

As it is being seen in figure 18, 19, 20 that flow

temperature around the first and second row tubes

are higher at low velocity compared to higher

velocity for turbulent flow model.

9.1 Flow velocity and Temperature Plots for

Laminar (LMF) and Turbulent flow model

(TFM)

The comparative plots of flow velocity and

temperature distribution for round and flat tube-fin

configurations have been shown in following

figures (21,22,23,24,25and 26).

8

Fig.21. v = 0.3m/s (LFM)

Fig.22. v = 0.3m/s (TFM)

Fig.23. v = 6.2 m/s (TFM)

The variation for round and flat tube is shown by

red and black line respectively. These variation are

observed along the length of heat exchanger at a

section Y= 0.00836m. Cyclic variation is observed

in flow velocity in each of flow model for round

tube whereas the variation comparatively steady for

flat tube. However the turbulent model gives better

picture of variation of flow velocity for each of the

configuration.

Fig.24. v = 0.3m/s (LFM)

Fig.25. v = 0.3m/s (TFM)

Fig.26. v = 6.2 m/s (TFM)

Temperature variation for low velocity

laminar flow model is cyclic for round tube but this

variation is comparatively steady rise for flat tube.

At high velocity the temperature variation is

constant over first tube row then it suddenly raises

thereafter it adopts a steady constant profile.

9

10. CONCLUSION

- From the experimental values given in the

literature, the laminar flow region for this

particular geometry of heat exchanger

switched to transitional at around Reynolds

number 1300, and continues up to Re =

2900 for each of the configurations.

- For turbulent flow model the friction factor

for flat tube is 13% to 17% higher than that

of round tube between Re = 330-1300

whereas between Re = 2900-7200 the

friction factor for round tube is 40% to 45%

higher than that of flat tube.

- Colburn factor for laminar flow model for

flat tube is 25% to 35% higher between

- Re = 330-1300 whereas between Re = 2900-

7200 it nearly exhibits same results though

the variation is limited between the 6% to

10%

- The variation of Colburn factor for turbulent

flow model for flat tube is 25% to 31%

higher between Re = 330-1300 whereas

between Re = 1300-7200, this variation is

limited between 13% to 23% which

corresponds to literature values.

- In case of laminar flow model between Re =

330-1300 a small back flow region as well

as recirculation zone is observed after each

row of tubes whereas in case of Re>2900

these region gets narrowed down though

intensity of these regions may increase.

- The variation of friction and Colburn factor

for the round tube fin configurations during

the laminar flow regime is better simulated

by laminar flow model and for the transition

and turbulent flow regime; the variation is

better depicted by turbulent flow model.

- The frictional losses due to formation of

recirculation zones and wake formations

after each of the tube rows in round tube is

observed to be higher in intensity than that

of flat tubes.

- The heat transfer in leading part of the round

tube is higher due to developing boundary

layer phenomena and also the heat transfer

is higher in forward part of tube due to

formation of horse shoe vortex system [20].

- Since the flow becomes turbulent for Re >

3000 therefore the laminar model stands

invalid for Re> 3000. Hence laminar model

suits to simulations for laminar flow regime.

To carry out simulations for turbulent and

transition regime the turbulent flow model

perfectly suits to present problem.

10

REFERENCE

1. Jang et al., 1998 Experimental and 3D

Numerical Analysis of ThermalHydraulic

Characteristics of Elliptical Finned Tube

Heat Exchangers, Heat Transfer

Engineering 19, 55-67

2. Jang et al., 1996. Numerical and

experimental Studies of three-dimensional

plate-fin and tube heat exchangers,

International Journal of Heat and Mass

Transfer, 39(14), 3057-3066

3. Wang et al., 1997. "Heat Transfer and

Friction Characteristics of Typical Wavy

Fin-and-tube Heat Exchangers,"

Experimental Thermal and Fluid Science,

14(2), 174-186

4. Wang et al., 1998. "Experimental Study of

Heat Transfer and Friction Characteristics

of Typical Louver Fin-and-Tube Heat

Exchangers," International Journal of Heat

and Mass Transfer, 41(4-5), 817-822

5. Wang et al., 1997. Heat Transfer and

Friction Characteristics of typical Wavy

Fin-and-Tube Heat Exchangers,"

Experimental Thermal and Fluid Science,

14(2), 174-186

6. Wang et al., 1996. "Sensible Heat and

Friction Characteristics of Plate Fin-and-

Tube Heat Exchangers Having Plane Fins,"

International Journal of Refrigeration, 4,

223-230

7. Rathod et al., 2006 Performance

Evaluation of Flat finned tube-fin heat

exchanger with different fin surfaces,

Applied Thermal Engineering, 27, 2131-

2137

8. Versteeg H.K., Malalasekera W., 1998.

An Introduction to Computational Fluid

Dynamics The Finite Volume Method ,

Second edition, Pearson Education Limited,

Essex, England (2007)

11

Você também pode gostar

- XAT 2015 Question PaperDocumento43 páginasXAT 2015 Question PaperParnil SinghAinda não há avaliações

- Qa Ho 1001820Documento2 páginasQa Ho 1001820whyreadAinda não há avaliações

- Ptolemy's Theorem Relation for Cyclic QuadrilateralsDocumento2 páginasPtolemy's Theorem Relation for Cyclic Quadrilateralsরেজাউল হকAinda não há avaliações

- TEACHING PROGRESSIONDocumento16 páginasTEACHING PROGRESSIONwhyreadAinda não há avaliações

- CBSE Class 12th Physics 2013Documento11 páginasCBSE Class 12th Physics 2013Anonymous ooVjeOqlAinda não há avaliações

- Science & Technology 1Documento16 páginasScience & Technology 1hussainamini100% (1)

- XAT 2015 Question PaperDocumento43 páginasXAT 2015 Question PaperParnil SinghAinda não há avaliações

- XAT 2015 Question PaperDocumento43 páginasXAT 2015 Question PaperParnil SinghAinda não há avaliações

- Division: Preferred Location: IIT Aipmt: Application Form For Faculty / Trainees / Center ManagerDocumento2 páginasDivision: Preferred Location: IIT Aipmt: Application Form For Faculty / Trainees / Center ManagerwhyreadAinda não há avaliações

- Atoms and NucleiDocumento30 páginasAtoms and NucleiwhyreadAinda não há avaliações

- GATE Mathematics Questions All Branch by S K MondalDocumento192 páginasGATE Mathematics Questions All Branch by S K Mondalmyidprince96% (23)

- DeterminationDocumento20 páginasDeterminationwhyreadAinda não há avaliações

- Stock and Share: Total Investment Total Income Total Facevalue Investment in Share Income From Share Face of ShareDocumento2 páginasStock and Share: Total Investment Total Income Total Facevalue Investment in Share Income From Share Face of SharewhyreadAinda não há avaliações

- 100 - Vectors - 9Documento6 páginas100 - Vectors - 9whyreadAinda não há avaliações

- Lecture Plan of Be-105 (ED) 2014Documento5 páginasLecture Plan of Be-105 (ED) 2014whyreadAinda não há avaliações

- v71 55Documento7 páginasv71 55whyreadAinda não há avaliações

- Atoms & Nuclear Physics Paper 2 Cbse BoardDocumento2 páginasAtoms & Nuclear Physics Paper 2 Cbse BoardwhyreadAinda não há avaliações

- Shree Gaurang Glory: Coaching For 9, 10, 11, 12, Aieee & Iitjee Ap + GP + HPDocumento89 páginasShree Gaurang Glory: Coaching For 9, 10, 11, 12, Aieee & Iitjee Ap + GP + HPwhyreadAinda não há avaliações

- ObservationsDocumento10 páginasObservationswhyreadAinda não há avaliações

- DeterminationDocumento20 páginasDeterminationwhyreadAinda não há avaliações

- Wilson Hartnell GovernorDocumento5 páginasWilson Hartnell GovernorwhyreadAinda não há avaliações

- Ec 1st Sem - EDDocumento2 páginasEc 1st Sem - EDwhyreadAinda não há avaliações

- Time ManagemenyDocumento2 páginasTime ManagemenywhyreadAinda não há avaliações

- CtheDocumento10 páginasCthewhyreadAinda não há avaliações

- Teachings of Queen KuntiDocumento130 páginasTeachings of Queen KuntiSarthak JoshiAinda não há avaliações

- Optics Paper 1 Cbse BoardDocumento1 páginaOptics Paper 1 Cbse BoardwhyreadAinda não há avaliações

- Test Complex NumberDocumento3 páginasTest Complex NumberwhyreadAinda não há avaliações

- Page No. - Lecture No - UNIT - TOPICDocumento1 páginaPage No. - Lecture No - UNIT - TOPICwhyreadAinda não há avaliações

- Ex 51 New Solution of Transient AnalysisDocumento9 páginasEx 51 New Solution of Transient AnalysiswhyreadAinda não há avaliações

- Determinant Theory For CBSE, ICSE, IITDocumento58 páginasDeterminant Theory For CBSE, ICSE, IITwhyreadAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Cooling of Transformer: Unit 3 Electrical Machine DesignDocumento13 páginasCooling of Transformer: Unit 3 Electrical Machine DesignYazid AbouchihabeddineAinda não há avaliações

- Macroinvertebrates LessonDocumento2 páginasMacroinvertebrates Lessonapi-497946823Ainda não há avaliações

- Genetic Drift ReportDocumento3 páginasGenetic Drift ReportLiza Mae NeisAinda não há avaliações

- AZ024 Lecture 7 Steel ConnectionDocumento14 páginasAZ024 Lecture 7 Steel ConnectionTong Kin Lun100% (15)

- The Noble Gases: © Boardworks LTD 2003Documento15 páginasThe Noble Gases: © Boardworks LTD 2003azimkhanAinda não há avaliações

- Resync Deck PDFDocumento11 páginasResync Deck PDFNikita SalkarAinda não há avaliações

- EOT Crane Load CalculationsDocumento8 páginasEOT Crane Load Calculationstimothy ogbechieAinda não há avaliações

- 學測部分試題小測Documento3 páginas學測部分試題小測蘇文采Ainda não há avaliações

- Flower Imagery in McGuckian and H.DDocumento27 páginasFlower Imagery in McGuckian and H.DlidiaglassAinda não há avaliações

- Sony HCD-GNX60Documento76 páginasSony HCD-GNX60kalentoneschatAinda não há avaliações

- Catalogue Wastewater Treatment SolutionsDocumento49 páginasCatalogue Wastewater Treatment SolutionsmentolAinda não há avaliações

- Camp Buddy Choice GuideDocumento28 páginasCamp Buddy Choice GuideM. Isra al miradAinda não há avaliações

- MIP737ICS: Main Instrument Panel Integrate Circuit SystemDocumento12 páginasMIP737ICS: Main Instrument Panel Integrate Circuit SystemcrickdcricketAinda não há avaliações

- Mathematics QuizDocumento18 páginasMathematics QuizIyarna YasraAinda não há avaliações

- PEMERIKSAAN THORAX AND JANTUNGDocumento59 páginasPEMERIKSAAN THORAX AND JANTUNGImada KhoironiAinda não há avaliações

- Safety and Hygienic Practices in Storing DessertsDocumento3 páginasSafety and Hygienic Practices in Storing DessertsMARY JOY VILLARUEL100% (1)

- Progress Drilling Project DBM Bumanik: Block Keuno Pit BDocumento6 páginasProgress Drilling Project DBM Bumanik: Block Keuno Pit Bnaldy07Ainda não há avaliações

- Structural Steel Detailing Standard Rev 0Documento9 páginasStructural Steel Detailing Standard Rev 0lillie0175% (4)

- Diagnostic Trouble Codes (DTC) : 14.1 About The Codes Shown in The TableDocumento6 páginasDiagnostic Trouble Codes (DTC) : 14.1 About The Codes Shown in The Tablejorgebbcaarg100% (1)

- Electrical Layout - L1Documento1 páginaElectrical Layout - L1sushant moreyAinda não há avaliações

- The ONE Invisible Code - An Uncommon Formula To Breakthrough Mediocrity and Rise To The Next Level (Sharat Sharma)Documento139 páginasThe ONE Invisible Code - An Uncommon Formula To Breakthrough Mediocrity and Rise To The Next Level (Sharat Sharma)Santhosh ReddyAinda não há avaliações

- Smooth SailingDocumento9 páginasSmooth SailingNancyAinda não há avaliações

- How To Configure A 3COM SwitchDocumento5 páginasHow To Configure A 3COM Switchama1738Ainda não há avaliações

- Bahay KuboDocumento21 páginasBahay KuboEulalio NinaAinda não há avaliações

- Grade 6 Agriculture Note QuestionsDocumento5 páginasGrade 6 Agriculture Note QuestionsmtetwabAinda não há avaliações

- Guidelines For Optimum Water Consumption in Bulk Drugs Manufacturing Industry PDFDocumento128 páginasGuidelines For Optimum Water Consumption in Bulk Drugs Manufacturing Industry PDFSivakumar SelvarajAinda não há avaliações

- Mapiful - How To Make Your Home More YouDocumento35 páginasMapiful - How To Make Your Home More YouElina100% (1)

- Gen Physics 1 Wk3Documento10 páginasGen Physics 1 Wk3Hannah Bianca RegullanoAinda não há avaliações

- Introduction To Experimental PsychologyDocumento27 páginasIntroduction To Experimental PsychologyJhonel NautanAinda não há avaliações

- AHU Cable Termination 2 1Documento2 páginasAHU Cable Termination 2 1naing linAinda não há avaliações