Escolar Documentos

Profissional Documentos

Cultura Documentos

Bit Hydraulics 1

Enviado por

scrbdgharaviTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bit Hydraulics 1

Enviado por

scrbdgharaviDireitos autorais:

Formatos disponíveis

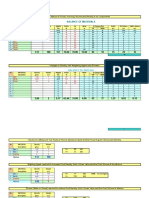

Name of Company: Well Name & Number: Date: July 21, 2013

See User notes @ cell A42 before using this application.

WELL GEOMETRY SEC 1 SEC 2 SEC 3

DRILLING APPLICATION

EVALUATE or DESIGN BIT HYDRAULICS

SEC 4

SEC 5

SEC 6

SEC 7

Length, ft? = Open Hole Size or Casing ID, in? = Drill String OD, in? = Drill String ID, in? =

CONDITIONS

1,021 28 5 4.276 3 15

2,417 17.5 5 4.276

DRILLING MUD

Number of Jets in 1st Set? = Size 1st Set of Jets, 32nds? = Number of Jets in 2nd Set? = Size 2nd Set of Jets, 32nds? = Reynolds Number PSI Drop MWD and/or Mud Motor? =

TVD CALCULATION

Mud Weight, ppg? = Plastic Viscosity, cp? = Yield Point, lb/100ft? =

DEPTHS CASING and BIT MD

9.2 5.0 29

TVD

2,000 250 1 1,021 1,021 1,021 1,021

SEC 1

For Last Casing Set, ft.? = For Bit, ft.? =

MUD PUMP - TRIPLEX

1,021 3,438

NO. 1

1,021 3,428

NO. 2

Angle of Last Survey? = MD Last Survey? = TVD Last Survey? = MD for a New or Projected TVD? = TVD Result, ft

RESULT by SECTION

Liner Size, in? = Stroke Length, in? = Pump Rate, spm? = Efficiency of Pump, % (1 - 100)? = Output, gpm

SEC 2 SEC 3 SEC 4 SEC 5

6.5 12 95

SEC 6 SEC 7

Annular Velocity, fpm Critical Velocity Annulus, fpm Critical Flow Rate Annulus, gpm Flow Type Annular Lag Times, mins Drill Pipe Bore Pressure Losses Annular Pressure Losses

351 10869

352 4039

RESULTS

Pressure Loss for Casing Annulus Lag or Bottoms-Up Time, mins ECD @ Last Casing Set, ppg ECD @ Bit Depth, ppg Nozzle Area Surface Equipment Loss Bit Pressure Drop

LAST UPDATE JANUARY 1997

9.20 9.20 0.5177

Estimated Pump Pressure Nozzle Velocity Pump Hydraulic Horsepower Bit Hydraulic Horsepower %HP @ Bit Bit HP/in Impact Force

APPLICATION CREATED IN 1994

250

THE END

USER NOTES - Make the first Well Geometry entry in SEC 1 starting at the top of the hole ending at the projected or current MD for bit. - Provision made to calculate a TVD. The result can be used for a New or Projected TVD for the Bit or Casing. - If the calculated MD for Bit in cell H17 is not correct, there is an error in one or more of the Section Length entries. - Provision made for two mud pumps in the event each pump has a different size liner. - Date is automatically posted by Excel. If the result for ECD @ Last Casing Set shows "ERROR", the comparison check made to verify casing measured depth has found a condition in which the Section Length entries are not in agreement with the measured depth used for the last casing set. Check the Section Length entries for Casing as well and the MD entry for the Casing in cell H16. This application can evaluate or design for optimum bit hydraulics. Design is by Trial and Error. It involves varying nozzle area, flow rate, mud properties and Reynolds Number to arrive at an optimum design for Bit Hydraulic Horsepower or Jet Impact Force within any defined limitations. When HHP is at Max, JIF is 94% of its max. When JIF is at max, HHP is with in 91% of its max. Max HHP Theory recommended when the best bottom hole cleaning needed at lower flow rates. The Max JIF Theory is recommended when higher flow rates are needed. Optimum HHP 65% and JIF 48% of standpipe PSI. Critical Velocity is the highest velocity that flow will remain laminar. Normally, calculations are made with turbulent flow around drill collars and laminar around drill pipe. Flow rate range for design is 30 to 50 gallons per inch of hole diameter.

Você também pode gostar

- Mud FormulasDocumento10 páginasMud FormulasWilmer PalenciaAinda não há avaliações

- Bit Hydraulic e CD CalculatorDocumento1 páginaBit Hydraulic e CD CalculatorJeffrey HoAinda não há avaliações

- Adair Supply: Drilling Application Bit Hydraulics & EcdDocumento1 páginaAdair Supply: Drilling Application Bit Hydraulics & EcdscrbdgharaviAinda não há avaliações

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Documento2 páginasWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviAinda não há avaliações

- Worksheet in Test Nozzle - DesignDocumento177 páginasWorksheet in Test Nozzle - DesignkeviletuoAinda não há avaliações

- Drilling Application: Name of Company: Well Name & Number: DateDocumento1 páginaDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviAinda não há avaliações

- Cullender-Smithbhp - Xls Description: This Spreadsheet Calculates Bottom Hole Pressure WithDocumento2 páginasCullender-Smithbhp - Xls Description: This Spreadsheet Calculates Bottom Hole Pressure WithCelvin Indra JayaAinda não há avaliações

- Well Control Data Sheet: Vertical WellsDocumento2 páginasWell Control Data Sheet: Vertical WellsscrbdgharaviAinda não há avaliações

- Well Head NodalDocumento7 páginasWell Head NodalMbarouk Shaame MbaroukAinda não há avaliações

- Mitchell Engineering Primary Cementation DesignDocumento2 páginasMitchell Engineering Primary Cementation DesignscrbdgharaviAinda não há avaliações

- Hoja de Cálculo Sin TítuloDocumento44 páginasHoja de Cálculo Sin TítuloJose GarciaAinda não há avaliações

- CEMENT PLUG METRE CALCULATORDocumento1 páginaCEMENT PLUG METRE CALCULATORDian SikumbangAinda não há avaliações

- Mud Tool KitDocumento52 páginasMud Tool KitChris RoarkAinda não há avaliações

- Rmo Wellbore FlowDocumento34 páginasRmo Wellbore FlowAnonymous 3cS5mPzkT0Ainda não há avaliações

- Bottom Hole Nodal GasDocumento6 páginasBottom Hole Nodal GasJhan GavilanAinda não há avaliações

- SPE 35713 HrorizontalwellEqDocumento12 páginasSPE 35713 HrorizontalwellEqDaniel SalaAinda não há avaliações

- A Simple Productivity Equation For Horizontal Wells Based On Drainage Area PDFDocumento11 páginasA Simple Productivity Equation For Horizontal Wells Based On Drainage Area PDFWALDO DAVID SILVA SANCHEZAinda não há avaliações

- Two Phase Flow HorizontalDocumento4 páginasTwo Phase Flow Horizontalnamphong_vnvnAinda não há avaliações

- API 11-S4 RP Well Data SheetDocumento17 páginasAPI 11-S4 RP Well Data Sheetlutfi awnAinda não há avaliações

- PNG Large Offshore Gas FieldDocumento36 páginasPNG Large Offshore Gas FieldserahsalmonminakAinda não há avaliações

- Master Calculation SheetDocumento12 páginasMaster Calculation SheetTanner BoydAinda não há avaliações

- AVIARA ENERGY CORP Well Drilling ApplicationDocumento1 páginaAVIARA ENERGY CORP Well Drilling ApplicationstevebeardsleyAinda não há avaliações

- Hagedorn Brown CorrelationDocumento14 páginasHagedorn Brown CorrelationRoyanAinda não há avaliações

- Nodal AnalysisDocumento8 páginasNodal AnalysisDaniel Marulituah SinagaAinda não há avaliações

- Amount of Cuttings Produced Per Foot of Hole DrilledDocumento2 páginasAmount of Cuttings Produced Per Foot of Hole Drilledlaxmikant1983Ainda não há avaliações

- Gas Production Rate (MSCF/D) : IPR TPRDocumento5 páginasGas Production Rate (MSCF/D) : IPR TPRShakerMahmoodAinda não há avaliações

- Comp Tally W.P#14Documento3 páginasComp Tally W.P#14nabiAinda não há avaliações

- Turnerloading - XLS: Step 1: Update Input Data in Blue Step 2: View ResultsDocumento2 páginasTurnerloading - XLS: Step 1: Update Input Data in Blue Step 2: View Resultsmath62210Ainda não há avaliações

- 01 - General FormulaeDocumento10 páginas01 - General FormulaescrbdgharaviAinda não há avaliações

- Kick Tolerance FactorDocumento1 páginaKick Tolerance FactorAhmedAinda não há avaliações

- TVD & Kill Weight CalculationsDocumento40 páginasTVD & Kill Weight Calculationsfrancisryan4519Ainda não há avaliações

- 20 in Surf - 94 PPFDocumento12 páginas20 in Surf - 94 PPFAnonymous XbmoAFtIAinda não há avaliações

- Ali Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDDocumento1 páginaAli Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDMohamed Mahmoud Rezk DimoAinda não há avaliações

- Hole Size " Casing Size " Casing Weight LB/FT HWDP Size " DP Size " DC Size "Documento2 páginasHole Size " Casing Size " Casing Weight LB/FT HWDP Size " DP Size " DC Size "PawanDeepSinghAinda não há avaliações

- Bottom Hole Nodal GasDocumento7 páginasBottom Hole Nodal Gasarjun2014Ainda não há avaliações

- 09 Spotting LCM Pill in The Annulus - QuartzDocumento1 página09 Spotting LCM Pill in The Annulus - QuartzRebarAinda não há avaliações

- Pressure Drop TheoryDocumento5 páginasPressure Drop Theorykaruna346100% (1)

- WOT DST PresentationDocumento29 páginasWOT DST PresentationAndreina AlarcónAinda não há avaliações

- WorkBook - CalculationsDocumento30 páginasWorkBook - CalculationsHunterAinda não há avaliações

- Esp PVT-PropertiesDocumento17 páginasEsp PVT-PropertiesJSN179Ainda não há avaliações

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocumento16 páginasHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranAinda não há avaliações

- Cement CalcDocumento6 páginasCement Calcmmohsinaliawan100% (1)

- Hydraulics Report for Romania WellDocumento1 páginaHydraulics Report for Romania WelltibismtxAinda não há avaliações

- PBL Hole CleaningDocumento2 páginasPBL Hole CleaningOlgaLuciaAinda não há avaliações

- Gas Viscosity CalculationDocumento2 páginasGas Viscosity CalculationgrabettyAinda não há avaliações

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocumento2 páginasBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarAinda não há avaliações

- Calculation Before A Cement JobDocumento4 páginasCalculation Before A Cement Jobreza khAinda não há avaliações

- Multiple Hydrofracs Vs TortuosityDocumento87 páginasMultiple Hydrofracs Vs TortuosityRamanamurthy PalliAinda não há avaliações

- EmpiricalDocumento4 páginasEmpiricalViral rAinda não há avaliações

- Spot Heavy MudDocumento1 páginaSpot Heavy MudstevebeardsleyAinda não há avaliações

- Reserve Estimation Unit: Ooip Recov Oil (MMSTB) (MMSTB)Documento8 páginasReserve Estimation Unit: Ooip Recov Oil (MMSTB) (MMSTB)FreddyCorredorAinda não há avaliações

- Tdi FCR Data 9 625 47ppf n80 BTC Rev 6Documento1 páginaTdi FCR Data 9 625 47ppf n80 BTC Rev 6Villalba XavichoAinda não há avaliações

- Hydraulic Calc by VassDocumento1 páginaHydraulic Calc by VassKyzak K. KeorkAinda não há avaliações

- PZ Cum User ManualDocumento6 páginasPZ Cum User ManualxielfAinda não há avaliações

- Pre Recorded Imformation: Lori Michelle1-16Documento4 páginasPre Recorded Imformation: Lori Michelle1-16scrbdgharaviAinda não há avaliações

- Formula SheetDocumento4 páginasFormula SheetAlbertoBila100% (1)

- Expandable Liner Hangers reduce pressure drop in Ecuador wellsDocumento22 páginasExpandable Liner Hangers reduce pressure drop in Ecuador wellsHosam Ali100% (1)

- Engineering Data IndexDocumento11 páginasEngineering Data IndexphaindikaAinda não há avaliações

- DPS Issue No.001Documento18 páginasDPS Issue No.001Yuri Puerso100% (1)

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocumento8 páginasAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaAinda não há avaliações

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Video Training Courses in Offshore Structures DesignDocumento102 páginasVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Ref 17Documento1 páginaRef 17scrbdgharaviAinda não há avaliações

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- E&pfor 1Documento36 páginasE&pfor 1scrbdgharaviAinda não há avaliações

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityDocumento1 páginaReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviAinda não há avaliações

- Agip KCO Aircraft Manuals IndexDocumento1 páginaAgip KCO Aircraft Manuals IndexscrbdgharaviAinda não há avaliações

- Ref 4Documento1 páginaRef 4scrbdgharaviAinda não há avaliações

- 1856r0 Procedure No 1 HSSE Policies and Mandatory RulesDocumento13 páginas1856r0 Procedure No 1 HSSE Policies and Mandatory RulesscrbdgharaviAinda não há avaliações

- HSE Management - Guidelines For Working Together in A Contract EnvironmentDocumento72 páginasHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviAinda não há avaliações

- Environmental Performance Monitoring Reporting GuidelineDocumento17 páginasEnvironmental Performance Monitoring Reporting GuidelinescrbdgharaviAinda não há avaliações

- PG 1048 eDocumento6 páginasPG 1048 escrbdgharaviAinda não há avaliações

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferDocumento8 páginasAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviAinda não há avaliações

- PG 1025 eDocumento6 páginasPG 1025 escrbdgharaviAinda não há avaliações

- PG 3052 eDocumento4 páginasPG 3052 escrbdgharaviAinda não há avaliações

- Pigging Multi-Diameter Lines and Other Specialist TechniquesDocumento6 páginasPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviAinda não há avaliações

- PG 3005 eDocumento8 páginasPG 3005 escrbdgharaviAinda não há avaliações

- 0973r04 OKIOC Marine ManualDocumento79 páginas0973r04 OKIOC Marine ManualscrbdgharaviAinda não há avaliações

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinDocumento4 páginasInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviAinda não há avaliações

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDocumento6 páginasU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviAinda não há avaliações

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonDocumento6 páginasSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviAinda não há avaliações

- PG 3025 eDocumento6 páginasPG 3025 escrbdgharaviAinda não há avaliações

- Pre On-Line Inspection Pigging: by C KershawDocumento6 páginasPre On-Line Inspection Pigging: by C KershawscrbdgharaviAinda não há avaliações

- PG 3150 eDocumento4 páginasPG 3150 escrbdgharaviAinda não há avaliações