Escolar Documentos

Profissional Documentos

Cultura Documentos

11 - Strengthening Mechanisms

Enviado por

Mohamed AshfaqDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

11 - Strengthening Mechanisms

Enviado por

Mohamed AshfaqDireitos autorais:

Formatos disponíveis

Strengthening Mechanisms

Slip in single crystals

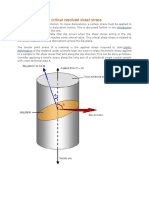

Cylindrical single crystal of area A under tensile load P.

Area of the slip plane A/cos| and load on the plane P cos.

Shear stress for slip to occur is called the critical resolved

shear stress (CRSS), t

R

.

|

|

t cos cos

cos /

cos

A

P

A

P

R = =

Effect of Grain boundaries

Grain boundaries act as obstacles to dislocations and hence,

dislocations pile up at the grain boundaries

Number of dislocations in the pile-up, n = ktt

s

L/Gb (G, shear

modulus, b, Burger vector, t

s

, avg. resolved shear stress).

A pile-up of n dislocations One big dislocation with Burger

vector nb.

Stress at the tip of the pile up = nbt

s

Grain boundary strengthening

2 / 1

+ = kD i o o o

For a dislocation source at the center of a grain diameter D,

n = ktt

s

D/4Gb

The critical shear stress to cross the grain boundary barrier,

t

c

= nt

s

= tt

s

2

D/4Gb

t

s

= t t

i

(t

i

is the lattice resistance to dislocation motion)

t

c

= t(t t

i

)

2

D/4Gb t = t

i

+ (t

c

4Gb/tD)

1/2

= t

i

+ k'D

-1/2

Expressing this in terms of normal stresses gives rise to the

Hall-Petch relationship

k is known as locking parameter, which is a measure of the

relative hardening contribution of grain boundaries and o

i

is

known as friction stress which represents overall resistance

of the lattice to dislocation motion.

Solid solution strengthening

Solute atoms introduce lattice strain as their size is different

from the host atoms.

A larger substitutional solute atom will impose a compressive

stress (Fig. a) while a smaller interstitial atom will cause tensile

stresses in the lattice (Fig. b).

Interstitial atoms are often bigger than the interstitial space

they occupy, resulting in a compressive stress field.

(a)

(b)

Solid solution hardening

Dislocations have strain field at their cores due to lattice

distortion

Solute atoms with a tensile strain field will diffuse to the

dislocation core to nullify part of the compressive strain field of

the dislocation to reduce the strain energy.

This hinders motion of the dislocation and hence, the

strength increases.

Dislocation strain field

Solid solution hardening

Precipitation hardening

Strength and hardness of some alloys can be increased by

formation of fine precipitates.

The solute should have increasing solubility with increasing

temperature (e.g. Al-Cu) for the precipitation to occur.

Heat treatment Solutionizing or heating to single phase

region. Quenching - rapid cooling to get a superstaurated solid

solution (SSS) (Normal cooling Coarse equilibrium CuAl

2

phase below T

N

). Isothermal holding at certain temperature.

Precipitation Sequence

When the supersaturated solid solution is held isothermally

(aging), fine particles of precipitates form in several steps.

The precipitation sequence Guiner-Preston (GP) zones

(cluster of Cu atoms) u'' u' u

u''and u' have different crystal structures than the parent

phase (o) and are coherent with the parent lattice, while the

equilibrium phase u, which forms on prolonged aging

(Overaging) is not coherent.

Hardening mechanism

u''and u' have different crystal structures but maintain

coherency with parent lattice resulting in lattice strain. This

impedes dislocation motion and hence, the hardness and

strength increases.

Further aging for longer time dissolves the u' phase and the

equilibrium phase u (CuAl

2

) forms. This phase is no longer

coherent with parent lattice and as a result hardness decreases,

a phenomenon called overaging.

Coherent precipitate

Incoherent precipitate

Strain Hardening

Increasing strength and hardness by plastic deformation is

called strain hardening or work hardening. Also referred as cold

working as deformation takes place at RT.

Extent of strain hardening increases with degree of cold

working (% area reduction).

Since the metal is deformed in a certain direction, grains are

elongated in the direction of working.

Initial structure

Cold-worked

Strain Hardening mechanism

Cold working generates dislocations dislocation density

increases. Higher density of dislocations impedes their motion

due to interactions of dislocation strain fields.

Hence the strength increases according to the relation

o

o

= o

i

+ oGb

1/2

. is the dislocation density, b, Burger vector,

G, shear modulus and o is a constant.

The ductility decreases after cold working.

Examples

Ex.1 Calculate the resolved shear stress for an FCC single

crystal on the (111) [01 1] slip system if a stress of 14 MPa

is applied in [001] direction.

Solution: The angle between two direction vectors [u

1

v

1

w

1

]

and [u

2

v

2

w

2

] is given as

2

2

2

2

2

2

2

1

2

1

2

1

2 1 2 1 2 1

cos

w v u w v u

w w v v u u

+ + + +

+ +

= u

Therefore, and

t

R

= 14 cos cos| = 14 x 0.707 x 0.577 = 5.7 MPa

707 . 0

2

cos = =

a

a

577 . 0

3

cos = =

a

a

|

Quiz

1. What is critical resolve shear stress? Derive the expression

for CRSS.

2. Calculate the resolved shear stress for an Ni single crystal

on the (111) [01 1] slip system if a stress of 15 MPa is applied

in [001] direction.

3. A stress of 5 MPa is applied to a single crystal FCC metal in

the [0 01] direction. Calculate the CRSS on (1 11) plane in

[1 01], [011] and [1 1 0] directions.

4. What is the mechanism of grain refinement strengthening?

5. Show that strength is proportional to D

-1/2

(D = grain dia).

6. An iron rod has a grain size of 0.01 mm and yield strength

of 230 MPa. The strength is 275 MPa at a grain size of 0.006

mm. In order achieve a yield strength of 310 MPa what should

be the grain size?

7. Why is strain hardening also called cold working?

8. What kind of microstructure develops after cold working?

Quiz

9. Why does hardness and strength increase on clod working?

What is the effect of cold working on ductility?

10. How is dislocation density related to strength?

11. What is the mechanism of strengthening by solid solution?

12. What kind of strain field interstitial atoms generally

introduce?

13. What kind of strain fields are associated with dislocations?

14. What are the different stages of precipitation hardening?

15. What kind of alloy system hardens by precipitation?

16. Will precipitation hardening occur if the alloy is cooled

slowly from the single phase region?

17. What is supersaturated solid solution?

18. How does the strength increase by precipitation?

19. What is coherent and incoherent precipitate?

20. What is the main strengthening phase in Al-Cu alloys.

References

http://www.soton.ac.uk/~engmats/xtal/deformation/control.htm

http://people.virginia.edu/~lz2n/mse209/Chapter7.pdf

http://kth.diva-portal.org/smash/get/diva2:9474/FULLTEXT01

http://imechanica.org/files/handout4.pdf

Key words. Strengthening mechanism, Hall-Petch equation,

Solid solution hardening, precipitation hardening, strain

hardening.

Você também pode gostar

- Engineering Materials 18-20 100922-150922Documento33 páginasEngineering Materials 18-20 100922-150922Sanu SouravAinda não há avaliações

- Lecture 4Documento22 páginasLecture 4Iftekhar ArefinAinda não há avaliações

- Background Knowledge Yield Strength Metals "Yield" When Dislocations Start To Move (Slip) - "Yield" Means Permanently Change ShapeDocumento25 páginasBackground Knowledge Yield Strength Metals "Yield" When Dislocations Start To Move (Slip) - "Yield" Means Permanently Change ShapePappuRamaSubramaniamAinda não há avaliações

- Ch-10 Compatibility ModeDocumento51 páginasCh-10 Compatibility Modedreamgurl9011Ainda não há avaliações

- Mse 255 Lecture 4Documento24 páginasMse 255 Lecture 4percydziksAinda não há avaliações

- Chapter 7 - Bebit, Jayvee V.Documento6 páginasChapter 7 - Bebit, Jayvee V.Ricky Bonhoc Jr.Ainda não há avaliações

- STRENGTHENING METALS THROUGH GRAIN SIZEDocumento61 páginasSTRENGTHENING METALS THROUGH GRAIN SIZENidhi SharmaAinda não há avaliações

- Publication 3 2240 1037Documento9 páginasPublication 3 2240 1037Primawati RahmaniyahAinda não há avaliações

- Materials 2: DR Philip HarrisonDocumento20 páginasMaterials 2: DR Philip Harrisonownage prank2Ainda não há avaliações

- Mechanical Properties Chapter: Strain, Stress, DeformationDocumento5 páginasMechanical Properties Chapter: Strain, Stress, DeformationAsffaq MuhdAinda não há avaliações

- Strengthening Mechanism3 PDFDocumento78 páginasStrengthening Mechanism3 PDFAmber WilliamsAinda não há avaliações

- Topic 2 - Thermal Treatment Methods To Strengthen MetalDocumento38 páginasTopic 2 - Thermal Treatment Methods To Strengthen MetalAndroi ManobAinda não há avaliações

- CH.4 Strengthening MechanismsDocumento50 páginasCH.4 Strengthening MechanismsEmad SaeedAinda não há avaliações

- MAT E 202 - Final Exam NotesDocumento16 páginasMAT E 202 - Final Exam NotesjordhonAinda não há avaliações

- Age HardeningDocumento33 páginasAge HardeningYudikaAinda não há avaliações

- Chapter 7 - Dislocation and Stringthening MechanismDocumento7 páginasChapter 7 - Dislocation and Stringthening MechanismThành Phương TấnAinda não há avaliações

- 36-Strengthening Mechanism-04-11-2023Documento22 páginas36-Strengthening Mechanism-04-11-2023NandiniAinda não há avaliações

- Strengthening MechanismsDocumento19 páginasStrengthening MechanismsAnas Anwar ArainAinda não há avaliações

- ENGINEERING METALLURGY FUNDAMENTALSDocumento87 páginasENGINEERING METALLURGY FUNDAMENTALSJay DedhiaAinda não há avaliações

- Dislocations and Strengthening Mechanisms ExplainedDocumento29 páginasDislocations and Strengthening Mechanisms ExplainedBaskar ManiAinda não há avaliações

- Work Hardening DislocationsDocumento14 páginasWork Hardening DislocationsAlhaega AnadaAinda não há avaliações

- Work Hardening DislocationsDocumento14 páginasWork Hardening DislocationsAlhaega AnadaAinda não há avaliações

- Lecture 4Documento43 páginasLecture 4Hadi PirgaziAinda não há avaliações

- Lecture 3Documento31 páginasLecture 3Hadi PirgaziAinda não há avaliações

- Material ScienceDocumento13 páginasMaterial ScienceolingxjcAinda não há avaliações

- 第6章-Physical Basis of Yield Stress-FDocumento30 páginas第6章-Physical Basis of Yield Stress-Fyasinfanus149Ainda não há avaliações

- Lecture 5 Strengthening Mechanisms LecDocumento17 páginasLecture 5 Strengthening Mechanisms LecLeencie SandeAinda não há avaliações

- Lecture 7-8 Materials StrengtheningDocumento39 páginasLecture 7-8 Materials StrengtheninghenryAinda não há avaliações

- Lecture 7-8 Ppt Slides - Materials StrengtheningDocumento47 páginasLecture 7-8 Ppt Slides - Materials StrengtheninghenryAinda não há avaliações

- ENGR 313 - Chapter 4 - DislocationsDocumento48 páginasENGR 313 - Chapter 4 - DislocationsMelissa LaraAinda não há avaliações

- Special Features of Friction Hardening of Austenitic Steel With Unstable G-PhaseDocumento3 páginasSpecial Features of Friction Hardening of Austenitic Steel With Unstable G-PhaseSinhro018Ainda não há avaliações

- High Temperature Deformation Behaviour of SteelDocumento38 páginasHigh Temperature Deformation Behaviour of SteelMallikarjunrao PanabakaAinda não há avaliações

- Strengthening Mechanism in MetalsDocumento25 páginasStrengthening Mechanism in MetalsprasadAinda não há avaliações

- Dislocation MotionDocumento40 páginasDislocation Motionart180Ainda não há avaliações

- Chapter 7 Dislocations and Strengthening MechanismsDocumento5 páginasChapter 7 Dislocations and Strengthening Mechanismsapril heramizAinda não há avaliações

- Lecture Set3 Group 3Documento107 páginasLecture Set3 Group 3Devang ThakkarAinda não há avaliações

- Deformation & StrengthDocumento35 páginasDeformation & StrengthcolorofstoneAinda não há avaliações

- Lecture 5 - Plastic Deformation PDFDocumento44 páginasLecture 5 - Plastic Deformation PDFTerry KeohAinda não há avaliações

- Strength of Materials Course June 2020Documento41 páginasStrength of Materials Course June 2020Rohit RanjanAinda não há avaliações

- Mechanical Behavior of Precipitation Hardened Aluminum Alloys WeldsDocumento26 páginasMechanical Behavior of Precipitation Hardened Aluminum Alloys WeldsKhin Aung ShweAinda não há avaliações

- Strengthening Mechanisms Notes - 2024Documento55 páginasStrengthening Mechanisms Notes - 2024achieng.omondi2Ainda não há avaliações

- Mechanical Properties and Strengthening Mechanisms QuizDocumento1 páginaMechanical Properties and Strengthening Mechanisms QuizsaeeddhclAinda não há avaliações

- Dislocations and Strengthening: Issues To Address..Documento30 páginasDislocations and Strengthening: Issues To Address..Yiğit IlgazAinda não há avaliações

- MATE1000 Lecture 12 Strengthening Mechanisms in MetalsDocumento4 páginasMATE1000 Lecture 12 Strengthening Mechanisms in MetalsclearcastingAinda não há avaliações

- Lecture 3Documento22 páginasLecture 3Iftekhar ArefinAinda não há avaliações

- Dislocations and Strengthening Mechanisms in MetalsDocumento37 páginasDislocations and Strengthening Mechanisms in MetalsColorgold BirlieAinda não há avaliações

- Lecture 35 - 2 PDFDocumento23 páginasLecture 35 - 2 PDFabhishekAinda não há avaliações

- Strengthening Techniques in Metals: Work HardeningDocumento6 páginasStrengthening Techniques in Metals: Work HardeningSiddhant SharmaAinda não há avaliações

- DislocationMotion STR Recovery Ch7Documento42 páginasDislocationMotion STR Recovery Ch7subodhcebAinda não há avaliações

- Single Crystal Slip Mechanics and Dislocation MotionDocumento15 páginasSingle Crystal Slip Mechanics and Dislocation MotionavenashaAinda não há avaliações

- Rigid PavementDocumento93 páginasRigid PavementArnold BiesAinda não há avaliações

- Mekanisme Penguatan pada Logam Melalui Strain HardeningDocumento78 páginasMekanisme Penguatan pada Logam Melalui Strain HardeningAlan SetiawanAinda não há avaliações

- Strengthening Mechanisms in MetalsDocumento33 páginasStrengthening Mechanisms in MetalsjorgeAinda não há avaliações

- Dislocations and StrenghteningDocumento19 páginasDislocations and StrenghteningAmber WilliamsAinda não há avaliações

- Processing of Aerospace Materials I (ME772) : Solid Solution Strengthening, Grain Boundary Strengthening SofteningDocumento23 páginasProcessing of Aerospace Materials I (ME772) : Solid Solution Strengthening, Grain Boundary Strengthening SofteningB RITHIKAAinda não há avaliações

- Chapter 7 - Dislocations and Strengethening MechanismsDocumento50 páginasChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringAinda não há avaliações

- Softening Effect in The Heat-Affected Zone of Laser-Welded Joints of High-Strength Low-Alloyed SteelsDocumento18 páginasSoftening Effect in The Heat-Affected Zone of Laser-Welded Joints of High-Strength Low-Alloyed SteelsengineeringAinda não há avaliações

- Detwinning Phenomenon and Its Effect On Resulting Twinning Structure of An Austenitic Hadfield SteelDocumento10 páginasDetwinning Phenomenon and Its Effect On Resulting Twinning Structure of An Austenitic Hadfield SteelinekAinda não há avaliações

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- 1 F 3 G 56 H 65 HDocumento1 página1 F 3 G 56 H 65 HRekyAinda não há avaliações

- Bab Ii Tinjauan Pustaka: Rjrk7k7Documento1 páginaBab Ii Tinjauan Pustaka: Rjrk7k7RekyAinda não há avaliações

- NN, IrhtDocumento1 páginaNN, IrhtRekyAinda não há avaliações

- U 10 Lect 5Documento16 páginasU 10 Lect 5RekyAinda não há avaliações

- LN2010 1Documento15 páginasLN2010 1RekyAinda não há avaliações

- F5 H 7 KWDocumento1 páginaF5 H 7 KWRekyAinda não há avaliações

- Pipe Components GuideDocumento172 páginasPipe Components Guideninju1Ainda não há avaliações

- Phaniraj - Dynamic Strain Ageing and Serrated Plastic Flow BehaviourDocumento13 páginasPhaniraj - Dynamic Strain Ageing and Serrated Plastic Flow BehaviourRekyAinda não há avaliações

- Best Answer Slip ND TwinDocumento1 páginaBest Answer Slip ND TwinRekyAinda não há avaliações

- Static Strain Aging of Stabilized FerritDocumento6 páginasStatic Strain Aging of Stabilized FerritRekyAinda não há avaliações

- Critical resolved shear stressDocumento2 páginasCritical resolved shear stressRekyAinda não há avaliações

- Metals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze ShapesDocumento14 páginasMetals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze Shapesrekyts31Ainda não há avaliações

- L7 Strengthening 131Documento35 páginasL7 Strengthening 131RekyAinda não há avaliações

- DislocationDocumento33 páginasDislocationmaxemon31Ainda não há avaliações