Escolar Documentos

Profissional Documentos

Cultura Documentos

34 Samss 114

Enviado por

Moustafa BayoumiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

34 Samss 114

Enviado por

Moustafa BayoumiDireitos autorais:

Formatos disponíveis

Materials System Specification

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement Custody Measurement Standards Committee Members

Fadhl, Khalid Ahmed, Chairman Britton, Richard Leo, Vice Chairman Bakhsh, Abduljalil Hamed Buerkel, David William Far, Husain Salah Morohen, Faisal Hashim Maatoug, Maatoug Abdullah Grainger, John Francis Rockwell Jr., William Allen Shaikh Jaffar, Abdullah Mohammed Roumi, Sulaiman Hamad Turairi, Mohammad Saleh Sanna'A, Zaki Abbas Hijji, Abdullah Saleh Lajami, Abdullah Ahmed Marri, Saeed Mohammad Trembley, Robert James

17 September 2007

Saudi Aramco DeskTop Standards

Table of Contents 1 2 3 4 5 6 7 8 9 10 11 12 Scope............................................................. 2 Conflicts and Deviations................................. 2 References..................................................... 2 Definitions and Abbreviations......................... 4 General Requirements................................... 5 Electrical Requirements................................. 8 Meter Design................................................. 9 Meter Tube Design....................................... 12 Identification and Tagging............................ 15 Testing and Inspection................................. 16 Shipping Requirements................................ 19 Documentation............................................. 19

Previous Issue: New Next Planned Update: 17 September 2012 Revised paragraphs are indicated in the right margin Primary contact: Roumi, Sulaiman Hamad on 966-3-8731262 CopyrightSaudi Aramco 2007. All rights reserved.

Page 1 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

Scope This specification defines the minimum mandatory requirements for multi-path ultrasonic transit-time flow meters to be used for custody metering of sales gas and ethane. This specification also defines the minimum mandatory requirements for the upstream and downstream meter tubes, and associated components if they are supplied along with the ultrasonic meter by the meter manufacturer or vendor.

Conflicts and Deviations 2.1 Any conflicts between this specification and other applicable Saudi Aramco Materials Systems Specifications (SAMSSs), Engineering Standards (SAESs), Standard Drawings, (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Process and Control Systems Department of Saudi Aramco, Dhahran. Direct all requests to deviate from this specification in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to Manager, Process and Control Systems Department of Saudi Aramco, Dhahran for Process Metering. Direct all requests for interpretation of this specification in writing to the Company or Buyer Representative who shall forward them to the Chairman, Custody Measurement Standards Committee for resolution. The Chairman, Custody Measurement Standards Committee shall be solely responsible for determining whether a proposed installation meets the requirements of this specification.

2.2

2.3

References Material or equipment supplied to this specification shall comply with the latest edition of the references listed below, unless otherwise noted. 3.1 Saudi Aramco References Saudi Aramco Engineering Procedure SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement

Page 2 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

Saudi Aramco Engineering Standards SAES-H-001 SAES-L-105 SAES-L-109 SAES-Y-100 Coating Selection & Application Requirements for Industrial Plants & Equipment Piping Material Specifications Selection of Flanges, Stud Bolts and Gaskets Regulated Vendors List for Custody Measurement Equipment

Saudi Aramco Material System Specifications 01-SAMSS-010 02-SAMSS-005 Fabricated Carbon Steel Piping Butt Welding Pipe Fittings

Saudi Aramco Standard and Library Drawing AB-036019 Thermowell Assembly and Detail

Saudi Aramco Forms and Data Sheets Form 8020-114-ENG Instrument Specification Sheet for Ultrasonic Flow Meter for Gas Custody Measurement (New) Instrument Specification Sheet for Thermowells Non Material Requirements for Instrumentation (General)

Form 8020-418-ENG Form NMR-7907 3.2 Industry Codes and Standards American Gas Association AGA Report 5 AGA Report 8 AGA Report 9 AGA Report 10

Fuel Gas Energy Metering Compressibility and Supercompressibility for Natural Gas and Other Hydrocarbon Gases Measurement of Gas by Multi-path Ultrasonic Meters Speed of Sound in natural Gas & other Gases

American Society of Mechanical Engineers ASME B16.5 ASME B31.3 Pipe Flanges and Flanged Fittings Process Piping

Page 3 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

International Electro-technical Commission IEC 61000-4-3 Electromagnetic Compatibility (EMC) - Testing and Measurement Techniques - Radiated, Radio Frequency Electromagnetic Field Immunity Test Electromagnetic Compatibility (EMC) - General Standards - Immunity for Industrial Degree of Protection provided by Enclosures

IEC 61000-6-2 IEC 60529

National Electrical Manufacturers Association NEMA 250 - 2003 NEMA ICS 6 Enclosures for Electrical Equipment (1000 Volts Maximum) Enclosures for Industrial Controls and Systems

National Fire Protection Association NFPA 70 4 Definitions and Abbreviations 4.1 Definitions Buyer: The Company (Saudi Aramco, AOC, or ASC) actually placing the order for the material. The buyer can be a third party metering customer. Buyer's Representative: The person acting on behalf of the Buyer, who may be from the Engineering, Inspection, Purchasing, or User organization. Error: The observed deviation of the meter calculated as: Error % = [(Test Meter Reading Reference Meter Reading) / (Reference Meter Reading)] x 100. Flow Computer: A dedicated off-the-shelf electronic device specifically designed for calculating and totaling metered volumes, and/or calculating meter factors during meter proving for one or more meters. Manufacturer: Company that designs, manufactures, sells and delivers multipath ultrasonic flow meters Maximum Error: The allowable error limit within specified operational range of the meter. Meter Tubes: The straight upstream pipe and fittings between the flow meter and the upstream pipe flange and the similar down-stream pipe and fittings between the flow meter and the pipe flange.

Page 4 of 20

National Electrical Code (NEC)

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

Qi: The actual measured gas flow rate passing through the ultrasonic meter under specific test conditions Qmax: The maximum gas flow rate through the meter Qmin: The minimum gas flow rate through the meter Qt: The transition gas flow rate which is 10% of the meter's maximum flow rate Repeatability: The closeness of agreement among a number of consecutive measurements of the output of the test meter for the same reference flow rate under the same operating conditions. Resolution: The smallest step by which the change of the flow velocity is indicated by the meter. Velocity Sampling Interval: The time intervals between two succeeding gas velocity measurements by the full set of transducers or acoustic paths. Vendor: The party that supplies or sells ultrasonic flow meters for gas custody transfer measurement. Zero Flow Reading: The minimum allowable flow velocity reading when the gas is at rest. 4.2 Abbreviations BTU/SCF: D: ISS: MMBTU: MMSCF: MMSCFD: MSCFH: SPU: UFM: 5 British Thermal Unit per Standard Cubic Feet Nominal Diameter of the Meter Instrument Specification Sheet Million British Thermal Unit Million Standard Cubic Feet Million Standard Cubic Feet per Day Thousand Standard Cubic Feet per Hour Signal Processing Unit Multi-Path Ultrasonic Transient-Time Flow Meter

General Requirements 5.1 Application This specification together with Instrument Specification Sheet (ISS), Form 8020-114-ENG shall be used as attachments to the Purchase Order.

Page 5 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

The Vendor shall submit a completed copy of the specification sheet along with the bid. 5.2 Approved Vendors Ultrasonic meters for gas custody metering shall be supplied by an approved vendor as specified in SAES-Y-100. 5.3 Scope of Supply The Vendor shall supply a fully assembled multi-path gas ultrasonic transit-time flow meter (UFM) that includes the following major components as a minimum: Ultrasonic Meter Body Transducers Signal Processing Unit (SPU) Connecting Cables between the transducers and the SPU

In addition, the Vendor shall provide the following spare parts and accessories: One pair of spare transducers and their seals Tools required to remove and install the transducers while the meter is under pressure Software required for the setup and diagnostics of the ultrasonic meter

The Vendor may also furnish the following items only when specified on the ISS, Form 8020-114-ENG: 5.4 Upstream meter tube Flow Conditioner Downstream meter tube

Process Conditions The ultrasonic meter and all accessories shall be suitable for measuring natural gas or ethane under the conditions specified on the ISS, Form 8020-114-ENG.

5.5

Engineering Units All dimensions shall be in the "International System of Units" (SI), and shall be followed by the equivalent value in conventional units between brackets. The following US Customary units shall be used for the measurement signals as specified on the ISS, Form 8020-114-ENG:

Page 6 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

Volume Flow Rate Static Pressure Temperature Heating Value Total Heating Value 5.6 Environmental Condition 5.6.1 Temperature

MMSCF MSCFH, MMSCFD PSIG F BTU/SCF MMBTU

Equipment and instrumentation shall operate continuously under the following ambient air temperatures without any degradation of the manufacturer's guaranteed performance:

Outdoor Sheltered (1)(2) 55C (131F) 0C (32F) Outdoor Unsheltered (2) 65C (149F) 0C (32F)

Maximum Minimum

Notes: (1) (2)

"Sheltered" refers to permanent, ventilated enclosures or buildings or permanently fixed sunshades with a top and three sides". For instruments which dissipate heat and are installed in custom engineered enclosures (e.g. enclosures not included in the original manufacturer's temperature certification), an additional 15C shall be added to the above maximum temperatures.

5.6.2

Humidity Outdoor design basis shall be 5% to 95% relative humidity (noncondensing).

5.6.3

Offshore and Near-Shore Environment Equipment and instrumentation which is not enclosed or hermetically sealed, but is situated offshore or near-shore, shall be protected against corrosion and operational failure due to wind-borne sea water spray and the accumulation of wetted salt (NaCl).

Page 7 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

Electrical Requirements 6.1 Area Classification Electrical equipment or devices which may produce arcs, sparks or high temperatures, and which are intended for operation in locations classified under NFPA 70, National Electrical Code (NEC) Article 500, shall be listed or labeled by any of the following authorities:

Country USA USA Canada UK Belgium France Germany Italy Netherlands Australia Authority Underwriters Laboratories, Inc. (UL) Factory Mutual Research Corp. (FM) Canadian Standards Assn. (CSA) BASEEFA Institut Scientifique de Service Public (ISSeP) Laboratoire Central des Industries Electriques (LCIE) Physikalisch Technische Bundesanstalt (PTB) Centro Elettrotechnico Sperimentale Italiano (CESI) KEMA Nederland B.V. (KEMA) Quality Assurance Services (QAS) Note: QAS is a subsidiary of Standards Australia Type Labeled or Listed Certified Certified Certified Certified Certified Certified Certified Certified Certified

6.2

Enclosures The Vendor shall ensure that all equipment installed outdoors is designed to withstand the environmental conditions listed in section 5.6 of this SAMSS. All enclosures shall be a minimum of weatherproof, water and dust-tight in accordance with NEMA ICS 6, and NEMA 250 Type 4X or IEC 60529, Protection Degree IP 66, and suitable for the electrical area classification as specified by Saudi Aramco Form 8020-114-ENG.

6.3

Main Power Sources Main electrical power sources for instruments may vary within the limits shown in following table, unless specified otherwise on the ISS.

Nominal 24 VDC 120 VAC, 60 2 Hz Tolerance 21 - 28.2 VDC 110 - 126 VAC

Page 8 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

6.4

Electromagnetic Compatibility Electrical and electronic equipment supplied as part of the metering systems shall carry the EC conformity mark ("CE") designating compliance with European EMC Directive 89/336/EEC. An authorized agency shall also have tested and certified the equipment as a complete assembly, i.e., meter, signal processing unit, transducers and transducer cables; is immune to electromagnetic interference, electrostatic discharge, radio frequency interference, surge and fast transients, voltage dips and interruptions at Performance Level A in accordance with IEC 61000-6-2. Tests shall have been performed to confirm the equipment is immune to radiated, radio frequency and electromagnetic emissions in accordance with IEC 61000-4-3 using Test Level 3.

Meter Design 7.1 General Requirements The meter design shall comply with the requirements of AGA Report 9 in addition to the requirements specified in this SAMSS. The meter shall have a minimum of four ultrasonic paths and shall be designed to operate in one direction. The meter shall be equipped with provisions (such as valves) and all necessary additional devices, mounted on the transducer ports in order to make it possible to remove transducers for inspection or replacement while the meter is under pressure. Provisions (bleed valve) shall be provided to release the pressure behind the transducers before the removal of transducers. The meter shall be designed to permit easy and safe handling of the meter during the transportation, installation and maintenance. The meter body shall have at least one pressure tap for measuring the static pressure in the meter. The meter shall have adequate sunshade to protect the transducers, the SPU and the wires from the ambient temperature effects. 7.2 Meter Size The meter size shall be specified in Saudi Aramco Form 8020-114-ENG. The meter shall be sized to handle the maximum flow capacity based on a gas flow velocity of 25 m/s at the normal operating pressure as specified in the ISS, Form 8020-114-ENG.

Page 9 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

The meter nominal diameter shall be restricted between 8" and 24".

Commentary Note: The lower limit is specified because meters less than 8" will have lower accuracy according to researches and may not be possible to install 8 transducers as a minimum. The upper limit is specified because of the limitations in flow calibration facilities.

7.3

Meter Design Pressure The meter shall be designed in accordance with ASME B31.3. The maximum working pressure for the meter shall be consistent with the flange rating according to ASME B16.5.

7.4

Materials of Construction The wetted parts of the meter shall be manufactured of material that provides adequate corrosion resistance for natural gas and ethane service. The internal surface of the meter is preferred to be made of stainless steel. The external parts of the meter shall be painted with a corrosion resistance coating per the manufacturer's standards for surface finishing, priming and painting. The coating and its application shall be suitable for the environmental conditions in section 5.6 of this SAMSS.

7.5

Meter Output Signals The UFM shall provide the following output signals to a flow computer as a minimum: Dual pulse (frequency) signals representing the flow rate at actual conditions Serial data interface (RS-232, RS-485, or equivalent) or Ethernet (if supported by the flow computer

Other types of meter output signals (such as 4-20 mA signal) may be provided only as backup to the above two signals. The flow rate output signal shall be scalable up to 120% of the meter's maximum flow rate. The meter's output signal shall be isolated from ground and have the necessary voltage protection to meet the electronics design testing requirements of Appendix B of AGA Report 9.

Page 10 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

7.6

Meter's Performance All ultrasonic flow meters shall meet the following minimum performance requirements prior to making any calibration factor adjustment:

Repeatability Resolution Velocity Sampling Interval Maximum Error for 12" meters and larger Maximum Error for meters smaller than 12" Zero Flow Reading 0.2% (Qt Qi Qmax) 0.4% (Qmin Qi < Qt) 0.003 ft/s (0.01m/s) 0.5 second 0.7% (Qt Qi Qmax) 1.4% (Qmin Qi < Qt) 1.0% (Qt Qi Qmax) 1.4% (Qmin Qi < Qt) < 0.020 ft/s (6 mm/s)

7.7

Transducers The transducers shall be suitable for the operating conditions (pressure and temperature ranges, and the gas composition) as specified in the ISS, Form 8020-114-ENG. It shall be possible to relocate or replace transducers without a significant impact on the meter's performance. The vendor shall specify the procedures of replacing or exchanging transducers and the associated software modification in the meter's configuration program.

7.8

Signal Processing Unit (SPU) 7.8.1 A Signal Processing Unit (SPU) shall be provided with the meter and shall be housed in an enclosure suitable for the area classification as indicated in section 6 of this SAMSS. The SPU should also be suitable for the environmental conditions specified in section 5.6 of this SAMSS. The SPU shall contain the power supply, the microcomputer, the signal processing components, the ultrasonic transducer excitation circuits and the required communication interface. The SPU may be installed on the meter body or be designed to be installed next to the meter as required for the design of the meter station. Circuit boards, interface terminals, plugs or sockets of the SPU shall be properly identified as to their function, slot, terminal, plug/socket number within the SPU chassis.

7.8.2

7.8.3

Page 11 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

7.8.4

The SPU shall have a non-volatile memory to store the computer codes responsible for the control and operation of the meter and to store all flow-calculation constants and operator entered parameters. All constants and parameters shall be protected by a password or a sealable switch. All flow-calculation constants and parameters shall be auditable while the meter is in operation without affecting the meter's performance. It shall be possible to view and print the configuration parameters used by the SPU. The SPU shall have a watch-dog-timer function to ensure automatic restart of the SPU in the event of program fault or lock-up. An alarm shall be for watch-dog operation. Also, other alarm-status output shall be provided if one or more ultrasonic path results are not usable as a minimum. The SPU shall be capable of performing diagnostic measurements as specified in AGA Report 9 and shall communicate them via serial data interface to an external computer. The SPU shall be capable of receiving the gas composition from a flow computer via the serial communication link. The speed of sound calculation shall be performed in the SPU in accordance to AGA Report 10. The SPU shall also be capable of receiving the gas temperature and pressure from a flow computer via the serial communication link to calculate the gas flow rate, volume and energy at standard conditions. The calculation shall be based on AGA Reports 5, 8 and 9. The pressure and temperature signals may be connected directly to the SPU if these signals can't be transmitted via the serial communication link.

7.8.5

7.8.6

7.8.7

7.8.8

7.8.9

7.8.10

Interface terminals, plugs or sockets shall be easily accessible when the cover of the SPU is opened or removed.

Meter Tube Design This section is applicable only when the meter's manufacturer is requested to supply the upstream and downstream meter tubes along with meter according to the ISS Form 8020-114-ENG. 8.1 General Piping Requirements

Page 12 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

8.1.1 8.1.2 8.1.3

Piping shall comply with Saudi Aramco Engineering Standard SAESL-105 and Materials Specification 01-SAMSS-010. The design pressure of the metering system piping shall match that of its interconnecting piping and as specified on the ISS 8020-114-ENG. The upstream and downstream meter tube sections shall be constructed of seamless pipe or cold drawn seamless tubing. Seamed pipe may be used for 24 inch meter tubes and larger if the internal longitudinal welds are ground flush and smooth. The tube shall be as nearly cylindrical as commercially possible with out-of-roundness deviations (difference between the maximum and minimum internal diameter measurements) not to exceed 0.5% for upstream sections and 1% for downstream. The inside pipe walls of the meter tubes shall be as smooth as commercially practicable. The wall roughness of the upstream and downstream meter tubes shall not exceed the limits specified in AGA Report 9. Pipe walls may be machined, ground, coated, honed and/or polished. Pipe fittings shall be selected according to Saudi Aramco Engineering Standard SAES-L-110. Welded flanges shall be according to Saudi Aramco Materials Specification 02-SAMSS-005. Flanges and fittings welded to meter tubes shall have internal weld joints ground to a smooth finish, flush with the internal diameter of the pipe and free of sharp edges or abrupt changes in surface level or diameter. Flanges and Gaskets shall be as per Saudi Aramco Engineering Standard SAES-L-109. Gaskets shall be purchased or trimmed to have at least a 10 mm larger inside diameter (bore) than the meter tube for 12 inch tube size and above. For 10 inch and below, gasket internal diameter shall be at least 6 mm larger inside diameter (bore) than the meter tube.

Commentary Note: This is to preclude the gasket from protruding into the tube interior through misalignment or compression.

8.1.4

8.1.5

8.1.6 8.1.7

8.1.8

8.1.9

The averages of upstream and downstream meter tube internal diameter micrometer readings shall be stamped on a stainless steel data plate which will be permanently attached to the meter tube.

Page 13 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

8.1.10 8.1.11

Flow direction shall be indicated on the meter tube close to each side of the flow meter. Protective coating shall be applied on external surfaces of all piping and equipment and shall be in accordance with Saudi Aramco Engineering Standard SAES-H-001.

8.2

Upstream Meter Tube 8.2.1 The upstream meter tube shall consist of two sections with a total minimum clear length of 20D. A flow conditioning plate shall be installed in the middle of the upstream meter tube. There shall be no pipe connections or fittings within the upstream meter tubes. Upstream meter tube ends shall be flanged and equipped with a spacer ring or jack screw so that the tube sections and the flow conditioner can be easily removed for inspection and cleaning. Spacer ring internal diameter shall be 3 mm larger than the meter tube internal diameter and the outer diameter shall be 1.5 mm smaller than the inside bolt circle of the flange.

8.2.2 8.2.3

8.2.4

8.3

Flow Conditioner 8.3.1 8.3.2 A flow conditioning plate (perforated plate) made of stainless steel shall be used as recommended by the meter's manufacturer. The flow conditioning plate shall comply with the pressure and temperature ratings of the adjacent piping, and shall be properly supported. The flow conditioning plate shall be mounted between flanges in the middle of the upstream ultrasonic meter tube. It shall also be installed in a way that provides convenient access for ease of inspection, removal and maintenance. The flow conditioning plate shall have provisions (such as marking or pin) to insure that it will be installed in the same orientation after dismantling the upstream meter tube at the conclusion of flow calibration or whenever the conditioning plate is taken out for inspection or cleaning.

8.3.3

8.3.4

8.4

Downstream Meter Tube

Page 14 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

8.4.1

The downstream meter tube shall have a minimum clear length of 5D. There shall be no pipe connections or fitting within this 5D downstream section. The downstream tube shall have two thermowells made of 316 stainless steel installed at a distance of at least 5D downstream of the ultrasonic flow meter. The thermowells shall be separated by no more than 300 mm. The thermowells shall be installed in 1 inch NPT tap fittings in accordance with Saudi Aramco Standard Drawing AB-036019, Thermowell Assembly and Detail. Saudi Aramco Form 8020-418-ENG, ISS for Thermowells shall be completed for details of the thermowells.

8.4.2

8.4.3

8.4.4

Identification and Tagging 9.1 The following information shall be stamped/embossed on the stainless steel tag permanently attached to the meter body: 9.2 Manufacturer Model No. Serial No. Month & Year of Manufacturing Purchase Order No. Total Weight Tag No. Nominal Size Flange Rating Maximum and minimum actual flow rates at operating conditions Maximum and minimum operating pressure and temperature K-Factor Meter body design code and material Meter flange design code and material

Each transducer shall have a permanently marked serial number and identification number to indicate the location to be installed in. These numbers shall be clear and shall be identical to the numbers indicated in the meters test records (i.e., measurement of the length of each path).

Page 15 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

9.3

Flow direction shall be indicated by an arrow on the meter body and/or by the words IN and OUT on the piping connections.

10

Testing and Inspection 10.1 Quality Program The Vendor shall implement and maintain a Quality Program, which shall include clearly defined and documented procedures for the relevant Quality System functions. The Quality Program documents shall be made available to the Buyer's Representative for review and audit. 10.2 Inspection Requirements The ultrasonic flow meter, its accessories, and the meter tubes (if provided) are subject to inspection by the Buyer's Representative in accordance with the requirements of this material specification. 10.3 Dimensional Measurements The Vendor shall perform dimensional measurements of the gas ultrasonic meter in accordance with AGA Report 9 requirements. The meter body temperature shall be measured at the time these dimensional measurements are made. All measurements shall be corrected to their equivalents at a meter body temperature of 60F by applying the appropriate thermal expansion coefficient for the material of the meter body. All instruments used to perform these measurements shall have valid calibrations traceable to the national standards. The dimensional measurements and calculations shall be documented and shall be made available to the Buyer Representative for review. 10.4 Calculating the Meter's K-Factor The meter's manufacturer shall test the meter to determine the K-Factor (Pulses/SCF). The testing procedure and results shall be documented and shall be made available to the Buyer's Representative for review. 10.5 Leakage Test The meter's manufacturer shall perform a leak test after the final assembly of each meter and prior to shipment of the meter to the metering system fabricator or to the calibration facility.

Page 16 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

The leak test shall be performed using inert gas like nitrogen at a minimum pressure of 200 psig maintained for a minimum of 15 minutes. Leaks should be detected using a non-corrosive liquid solution or ultrasonic leak detectors. The leak test procedure and results shall be documented and shall be made available to the Buyer Representative for review. 10.6 Hydrostatic Test Hydrostatic test of the ultrasonic meter or the meter tube (if provided) may not be required by the meter's manufacturer. Hydrostatic test should be performed on the fully assembled meter skid by the fabricator of the meter skid. 10.7 Zero-Flow Verification Test (Dry Calibration) The manufacturer shall perform a Zero-Flow Verification Test or Dry Calibration in accordance to the requirements of AGA Report 9. The maximum allowable zero-flow velocity shall be less than 12 mm/s (0.040 ft/s) for each acoustic path. If the test results are higher than the acceptable limit, the manufacturer shall verify all factors that can possibility affect the individual paths zero flow velocities. Zero-flow offset factors are not permitted to be applied for correcting the meter's flow rate output. The Zero-Flow Verification Test (Dry Calibration) shall be repeated in case the results exceed the acceptable limit and if the manufacturer has performed any action to adjust the performance of the meter. The Zero-Flow Verification Test (Dry Calibration) shall be witnessed by the Buyer or the Buyer's Representative. The test procedure and results shall be documented and shall be made available to the Buyer or the Buyer Representative for review. 10.8 Flow Calibration Test (Wet Calibration) 10.8.1 Gas ultrasonic meters shall be flow calibrated across their entire flow range at a gas pressure, temperature and density as near as possible to the normal operating conditions specified in the ISS, Form 8020-114ENG. The flow calibration shall be performed in a recognized and internationally traceable flow calibration facility. The selection of the calibration facility shall be concurred by the Chairman of the Custody Measurements Standards Committee. The meter shall be calibrated along with the actual upstream and downstream meter tubes and flow conditioner in the same arrangement that will be installed in the field. The wet calibration may be performed without the downstream meter tube if the calibration lab

Page 17 of 20

10.8.2

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

provides clear piping for 5D downstream of the ultrasonic meter with temperature measurement at 5D to reflect the actual arrangement in the field. 10.8.3 The Flow Calibration Test (Wet Calibration) shall be witnessed by the Buyer or the Buyer Representative. The test procedure and results shall be documented and shall be made available to the Buyer or the Buyer Representative for review. The flow calibration shall be arranged by the meter's manufacturer if the upstream and downstream meter tubes are supplied along with the meter. Otherwise, the flow calibration shall be arranged by the meter skid fabricator. In all cases, a representative of the meter manufacturer should witness the flow calibration. As a minimum, the flow calibration shall be performed at 6 flow rates for meters smaller than 12". Meter that are 12" and larger shall be calibrated at a minimum of 8 flow rates. At each flow rate, calibration shall be performed at least 3 times for a minimum duration of 100 seconds for a single measurement. Calibrations at flow rates between the meter's minimum flow and 10% of the maximum flow shall be repeated for at least 5 times. The repeatability and maximum error during the calibration shall not exceed the limits of the meter's performance requirement listed in section 7.6 of this SAMSS. The flow calibration results shall be presented as a table of meter factors vs. actual and standard flow rates to be stored in the flow computer. Each meter factor is calculated by dividing the reference meter flow rate by the test meter flow rate. The flow rates for calculating the meter factors are determined by averaging the flow rates of the acceptable calibration points. It is not permitted to perform any adjustment to the ultrasonic meter's processor as a result of the flow calibration findings. The meter's manufacturer shall investigate and correct the meter's performance if it exceeds the limits of section 7.6 of this SAMSS. The flow calibration shall be repeated in case the manufacturer has performed any action to enhance the meter's performance. In case the flow calibration cannot be performed at conditions similar to the operating conditions as described in this section, the Chairman of the Custody Measurements Standards Committee shall be consulted

10.8.4

10.8.5

10.8.6

10.8.7

10.8.8

10.8.9

Page 18 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

and shall approve the alternative calibration conditions prior to performing the flow calibration. 11 Shipping Requirements 11.1 General All equipment and internals being shipped shall be braced and temporary supports shall be provided, if required, to prevent damage during shipment. 11.2 Internal Protection The internals of all piping, fabricated and assembled equipment shall be completely cleaned and dried to the satisfaction of the Saudi Aramco Inspector. A non-toxic vapor phase corrosion inhibitor (CORTEC VCI-609, or equivalent) shall be applied to the internal surfaces of all piping fabricated and assembled equipment. 11.3 External Protection Permanent blind flanges or covers shall be installed with the gaskets and bolts required for service. All bolts, nuts and the faces of open flanged connections shall be coated with temporary protective coating such as petroleum paste. Each connection shall be fitted with a neoprene gasket, and vapor tight steel cover. The cover shall be held in place by a minimum of four equally spaced bolts. 11.4 Electronic and Electrical Equipment The vendor shall determine if electronics and instruments are susceptible to damage from shock, weather or extremes of temperature during shipment. If required, such items shall be removed after the functional test and shipped separately. 12 Documentation The vendor shall submit the following documents: Nonmaterial items as shown on Form NMR-7907 Operation and maintenance manual(s) of the ultrasonic meter and the associated accessories Sizing Calculations

Page 19 of 20

Document Responsibility: Custody Measurement Issue Date: 17 September 2007 Next Planned Update: 17 September 2012

34-SAMSS-114 Ultrasonic Flow Meter for Gas Custody Measurement

All test results List of recommended spare parts required for startup and two years operations of the supplied material Drawings of the meter tubes (if supplied with the meter)

Documents and drawings shall comply with the requirements of SAES-J-005.

17 September 2007

Revision Summary New Saudi Aramco Materials System Specification.

Page 20 of 20

Você também pode gostar

- 34 Samss 118Documento9 páginas34 Samss 118naruto256Ainda não há avaliações

- 34 Samss 112Documento14 páginas34 Samss 112naruto256Ainda não há avaliações

- 34 Samss 841Documento68 páginas34 Samss 841naruto256Ainda não há avaliações

- 34 Samss 846Documento35 páginas34 Samss 846naruto256Ainda não há avaliações

- 34 Samss 119Documento15 páginas34 Samss 119naruto256Ainda não há avaliações

- 34 Samss 716Documento12 páginas34 Samss 716naruto256Ainda não há avaliações

- 34 Samss 511Documento9 páginas34 Samss 511Moustafa BayoumiAinda não há avaliações

- 34 Samss 711Documento25 páginas34 Samss 711naruto256Ainda não há avaliações

- Custody Metering of Hydrocarbon GasesDocumento39 páginasCustody Metering of Hydrocarbon GasesUmar Adamu100% (4)

- 31 Samss 002Documento9 páginas31 Samss 002Moustafa BayoumiAinda não há avaliações

- 34 Samss 624Documento23 páginas34 Samss 624Hemac Hander100% (1)

- 34 Samss 515Documento13 páginas34 Samss 515naruto256Ainda não há avaliações

- 34 Samss 122Documento13 páginas34 Samss 122naruto256Ainda não há avaliações

- 23 Samss 020Documento44 páginas23 Samss 020Cherukunnon Jubu100% (1)

- Saep 50Documento33 páginasSaep 50brecht1980Ainda não há avaliações

- Saep 58 PDFDocumento38 páginasSaep 58 PDFRami ElloumiAinda não há avaliações

- 34 Samss 612Documento8 páginas34 Samss 612naruto256Ainda não há avaliações

- 34 Samss 617Documento9 páginas34 Samss 617Rodolfo Garcia HernandezAinda não há avaliações

- 34 Samss 718Documento14 páginas34 Samss 718naruto256Ainda não há avaliações

- 34 Samss 117Documento9 páginas34 Samss 117Cherukunnon JubuAinda não há avaliações

- 34 Samss 634Documento13 páginas34 Samss 634naruto256Ainda não há avaliações

- T10 Turbine Meters PDFDocumento59 páginasT10 Turbine Meters PDFVictor Enrique Rosales Parada100% (1)

- Matson - Jed MPMS Ch. 14.10 Flare Measurement PDFDocumento8 páginasMatson - Jed MPMS Ch. 14.10 Flare Measurement PDFsurusrikant@yahoo.comAinda não há avaliações

- 34 Samss 118 PDFDocumento9 páginas34 Samss 118 PDFCherukunnon JubuAinda não há avaliações

- Laboratory Testing of Chordal Path Ultrasonic Gas Meters With New Noise Reduction T' Designs.12!05!2014Documento12 páginasLaboratory Testing of Chordal Path Ultrasonic Gas Meters With New Noise Reduction T' Designs.12!05!2014Philip A Lawrence C.Eng. F. Inst M.C.Ainda não há avaliações

- IVD 21 BQ 195 AGOCO Nafoora Metering SkidsDocumento7 páginasIVD 21 BQ 195 AGOCO Nafoora Metering Skidsnader mahfoudhiAinda não há avaliações

- Godfrey - Mark Manual of Petroleum Measurement Standards Chapter 21 EFM Final PDFDocumento20 páginasGodfrey - Mark Manual of Petroleum Measurement Standards Chapter 21 EFM Final PDFIman AkbariAinda não há avaliações

- Custody Transfer MeteringDocumento14 páginasCustody Transfer MeteringkanakpandyaAinda não há avaliações

- 34 Samss 621Documento15 páginas34 Samss 621naruto256Ainda não há avaliações

- API MPMS Chapter 8.2 Automatic Petroleum SamplingDocumento3 páginasAPI MPMS Chapter 8.2 Automatic Petroleum SamplingrizkiAinda não há avaliações

- Advance Application of Liquid Flow-Computers ISHM Classroom Presentation May 2013Documento62 páginasAdvance Application of Liquid Flow-Computers ISHM Classroom Presentation May 2013Philip A Lawrence C.Eng. F. Inst M.C.Ainda não há avaliações

- SAES-Y-101 Custody Metering of Hydrocarbon GasesDocumento38 páginasSAES-Y-101 Custody Metering of Hydrocarbon GasesZubair RaoofAinda não há avaliações

- (SB0A001) Measurement Products and Systems For The Oil and Gas IndustryDocumento62 páginas(SB0A001) Measurement Products and Systems For The Oil and Gas IndustryRoberto Carlos Teixeira100% (1)

- API Mpms 56 CoriolisDocumento61 páginasAPI Mpms 56 Coriolishashem aliAinda não há avaliações

- 34 Samss 815Documento9 páginas34 Samss 815naruto256Ainda não há avaliações

- An Introduction To Wet Gas Flow MeteringDocumento28 páginasAn Introduction To Wet Gas Flow MeteringShakeel AhmedAinda não há avaliações

- 34 Samss 851Documento82 páginas34 Samss 851Eagle SpiritAinda não há avaliações

- New flow conditioner optimized for 4-path ultrasonic flowmetersDocumento8 páginasNew flow conditioner optimized for 4-path ultrasonic flowmetersGeethaAinda não há avaliações

- Flow MeasurementDocumento62 páginasFlow MeasurementLiji BrijeshAinda não há avaliações

- Provers & Master Meters: Because Confidence Is CapitalDocumento4 páginasProvers & Master Meters: Because Confidence Is Capitalusman379Ainda não há avaliações

- 34 Samss 621Documento14 páginas34 Samss 621Moustafa BayoumiAinda não há avaliações

- FLUOR - New Delhi: Flow Instruments (Part-1)Documento20 páginasFLUOR - New Delhi: Flow Instruments (Part-1)Tirado Melchor Angel Miguel100% (2)

- Phasetester Oman CsDocumento2 páginasPhasetester Oman CswaelAinda não há avaliações

- PIP PCEFL001-2017 Flow Measurement GuidelinesDocumento28 páginasPIP PCEFL001-2017 Flow Measurement Guidelines刘旭Ainda não há avaliações

- Saep 50Documento40 páginasSaep 50syed jeelani ahmed100% (1)

- Materials System SpecificationDocumento9 páginasMaterials System SpecificationHandri YantoAinda não há avaliações

- SAES-Z-002 Regulated Vendors List For Process Automation SystemsDocumento14 páginasSAES-Z-002 Regulated Vendors List For Process Automation SystemsZubair RaoofAinda não há avaliações

- API 14.3 Flow Conditioner Performance Test For The CPA 50E Flow ConditionerDocumento9 páginasAPI 14.3 Flow Conditioner Performance Test For The CPA 50E Flow ConditionerMahmoud El KhateebAinda não há avaliações

- Ultra Sonic Flow MeterDocumento5 páginasUltra Sonic Flow MeterchandruhbkkAinda não há avaliações

- 34 Samss 821Documento9 páginas34 Samss 821Velmor VillenaAinda não há avaliações

- Flow Measurement Workshop Papers on Reducing UncertaintyDocumento8 páginasFlow Measurement Workshop Papers on Reducing UncertaintyjohnzrwAinda não há avaliações

- Flow MeasurementDocumento17 páginasFlow MeasurementAshirvad NandaAinda não há avaliações

- Saep 747Documento20 páginasSaep 747Anonymous 4IpmN7OnAinda não há avaliações

- 34 Samss 622Documento12 páginas34 Samss 622naruto256Ainda não há avaliações

- Validation of Inlet Gas Metering InstrumentationDocumento13 páginasValidation of Inlet Gas Metering InstrumentationDeborah MalanumAinda não há avaliações

- 34 Samss 319Documento15 páginas34 Samss 319naruto256Ainda não há avaliações

- 34 Samss 117Documento9 páginas34 Samss 117naruto256Ainda não há avaliações

- 6743 6 52 0053Documento72 páginas6743 6 52 0053svijay1969100% (1)

- 34 Samss 511Documento9 páginas34 Samss 511naruto256Ainda não há avaliações

- Astm A611Documento3 páginasAstm A611Fheres ValenciaAinda não há avaliações

- Astm A960-00Documento9 páginasAstm A960-00Asad Bin Ala Qatari100% (2)

- A.N Coating Inspector CVDocumento10 páginasA.N Coating Inspector CVMoustafa Bayoumi100% (1)

- 34 Samss 621Documento14 páginas34 Samss 621Moustafa BayoumiAinda não há avaliações

- A350 - 02Documento8 páginasA350 - 02Moustafa BayoumiAinda não há avaliações

- 55 Samss 004Documento12 páginas55 Samss 004Moustafa BayoumiAinda não há avaliações

- Calculation of Environmental Conditions: Dewpoint & Rel. Humidity (ASTM E-337)Documento4 páginasCalculation of Environmental Conditions: Dewpoint & Rel. Humidity (ASTM E-337)Moustafa BayoumiAinda não há avaliações

- Astm - A285a - 285MDocumento2 páginasAstm - A285a - 285MMoustafa BayoumiAinda não há avaliações

- December 31, 1999 11:54:25 Information Handling Services, 1999Documento8 páginasDecember 31, 1999 11:54:25 Information Handling Services, 1999Moustafa BayoumiAinda não há avaliações

- RefractoryDocumento23 páginasRefractoryHarinarayanan Samsari Kizhake Veetil100% (1)

- Abrasives Size Abrasives Size and Profile ProfileDocumento3 páginasAbrasives Size Abrasives Size and Profile ProfileMoustafa BayoumiAinda não há avaliações

- Iso 8503-2Documento6 páginasIso 8503-2Moustafa Bayoumi0% (1)

- 09 Samss 093Documento6 páginas09 Samss 093Moustafa BayoumiAinda não há avaliações

- 09 Samss 035Documento8 páginas09 Samss 035Moustafa Bayoumi100% (1)

- 04 Samss 003Documento4 páginas04 Samss 003Moustafa Bayoumi100% (1)

- 09 Samss 087Documento7 páginas09 Samss 087AjeetKumarAinda não há avaliações

- 12 Samss 005Documento6 páginas12 Samss 005Moustafa BayoumiAinda não há avaliações

- 09 Samss 088Documento4 páginas09 Samss 088Moustafa BayoumiAinda não há avaliações

- 09 Samss 021Documento8 páginas09 Samss 021Moustafa BayoumiAinda não há avaliações

- 34 Samss 511Documento9 páginas34 Samss 511Moustafa BayoumiAinda não há avaliações

- 05 Samss 002Documento8 páginas05 Samss 002Moustafa BayoumiAinda não há avaliações

- 16 Samss 521Documento8 páginas16 Samss 521Moustafa BayoumiAinda não há avaliações

- 09 Samss 068Documento7 páginas09 Samss 068AjeetKumarAinda não há avaliações

- 26 Samss 056Documento3 páginas26 Samss 056Moustafa BayoumiAinda não há avaliações

- 31 Samss 002Documento9 páginas31 Samss 002Moustafa BayoumiAinda não há avaliações

- 02 Samss 010Documento7 páginas02 Samss 010Moustafa BayoumiAinda não há avaliações

- 32 Samss 019Documento17 páginas32 Samss 019Moustafa BayoumiAinda não há avaliações

- 12 Samss 008Documento4 páginas12 Samss 008Moustafa BayoumiAinda não há avaliações

- 02 Samss 010Documento7 páginas02 Samss 010Moustafa BayoumiAinda não há avaliações

- Power Generation: Selection GuideDocumento114 páginasPower Generation: Selection GuideRobiAinda não há avaliações

- Chapter 2 Structure of AtomsDocumento16 páginasChapter 2 Structure of AtomsCherry T CYAinda não há avaliações

- How Electric Cars Work: A Guide to EV TechnologyDocumento4 páginasHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoAinda não há avaliações

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocumento6 páginasRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoAinda não há avaliações

- Dpu96 Sitras PDFDocumento214 páginasDpu96 Sitras PDFConrad Ziebold VanakenAinda não há avaliações

- Control of Environmental Parameters in A Green HouseDocumento46 páginasControl of Environmental Parameters in A Green Housekenbobalaji100% (1)

- E PM 100Documento29 páginasE PM 100masoudAinda não há avaliações

- P6112 Alstom PG9171E PowerPlant SpecificationsDocumento1 páginaP6112 Alstom PG9171E PowerPlant SpecificationsSunario YapAinda não há avaliações

- SGMF Hose BunkeringDocumento15 páginasSGMF Hose BunkeringFilipAinda não há avaliações

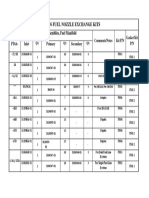

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocumento1 páginaPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchAinda não há avaliações

- Folio SainsDocumento15 páginasFolio SainsMohammad Afifi Rohman80% (5)

- Introduction To The OpenDSSDocumento4 páginasIntroduction To The OpenDSSanoopeluvathingal100Ainda não há avaliações

- Torsional Vibration in CrankshaftsDocumento10 páginasTorsional Vibration in Crankshaftscharans100% (4)

- Tender 10 KW Rooftop SolarDocumento14 páginasTender 10 KW Rooftop Solarsrirajt4uAinda não há avaliações

- Transfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualDocumento32 páginasTransfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualMesseňger HệŢhốngAinda não há avaliações

- GCP: Google Cloud PlatformDocumento25 páginasGCP: Google Cloud Platformalya khan100% (1)

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocumento21 páginasUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeAinda não há avaliações

- Boundary Layer ThicknessDocumento23 páginasBoundary Layer ThicknessPridhar ThiagarajanAinda não há avaliações

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshDocumento65 páginas1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonAinda não há avaliações

- Voith Thyricon Excitation SystemDocumento8 páginasVoith Thyricon Excitation SystemKeshab ShresthaAinda não há avaliações

- Transformer REFDocumento4 páginasTransformer REFs_banerjeeAinda não há avaliações

- Types of Supports For Vessels - Chemical Engineering WorldDocumento10 páginasTypes of Supports For Vessels - Chemical Engineering WorldAdityaAinda não há avaliações

- Pepsin Enzyme Activity LabDocumento4 páginasPepsin Enzyme Activity LabDebrah DebbieAinda não há avaliações

- Rectification ProcessDocumento5 páginasRectification ProcessDilnaz TegispayAinda não há avaliações

- Indirect and Non-Calorimetric MethodsDocumento44 páginasIndirect and Non-Calorimetric MethodsMadhuvanti GowriAinda não há avaliações

- Mahaan FoodsDocumento49 páginasMahaan Foodsamandeep0001Ainda não há avaliações

- JIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEDocumento41 páginasJIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEAmanuelAinda não há avaliações

- 3 Instant Ways To Make Money From People Around You: by Oluwatoyin OmotosoDocumento21 páginas3 Instant Ways To Make Money From People Around You: by Oluwatoyin Omotosoobisesan phillipAinda não há avaliações

- RACORDocumento25 páginasRACORDaniel LaymeAinda não há avaliações

- Total Rewinding and Reconditioning of 3KW MotorDocumento5 páginasTotal Rewinding and Reconditioning of 3KW MotorCBD COLLEGE INCAinda não há avaliações