Escolar Documentos

Profissional Documentos

Cultura Documentos

Eye Format in Cheese-C-1

Enviado por

Elfer Orlando Obispo GavinoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Eye Format in Cheese-C-1

Enviado por

Elfer Orlando Obispo GavinoDireitos autorais:

Formatos disponíveis

Eye formation in cheese C-1

Technical Bulletin By Kristian Elsborg, Marketing Manager, Cheese Cultures

3 September 1996 Revised on Januaryr 2002

Cheese with regular eyes

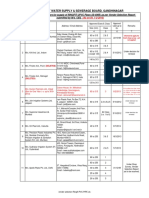

Keywords: cheese, eye formation, citrate fermentation, and gas diffusion In continental cheeses the eye formation is regarded as an important aesthetic and visual property. This brief literature study describes the initial microbiological and physical processes of eye formation. Finally some examples of the factors influencing the quality of eye formation and a description of the most frequent texture defects of cheese are cited.

Cheese types

Cheese with irregular eyes

Few, but large eyes characterize cheese with regular eyes as the curd is pressed under the surface of the whey. The resulting compact texture of the curd gives way to only few eyes which then grow larger due to the pressure released by the CO2. Gouda, Danbo, Edam, Sams etc belong to the group of cheese with regular eyes. The following description primarily focuses on cheeses with regular eyes.

Gas-producing conversions

The gas pressure, which makes the eyes grow during the maturation phase, is a result of microbiological conversions from the starter culture added and from air dissolved in the cheese milk. However at this stage of the process additional unverifiable and/or unwanted gas formation caused by the secondary micro flora may occur: Cheese with irregular eyes is characterized by a large number of small eyes of the size of a rice grain. During filling of the cheese forms atmospheric air is worked in between the cheese grains, whereby the grains are prevented from uniting completely. CO2 expelled during the microbiological process will then enlarge the eyes. Havarti, Tilsiter, Esrom, Port Salut etc belong to the group of cheese with irregular eyes.

KMH/Eye format in cheese-C-1.doc/feb 2002/1:6

Eye formation in cheese

Technical Bulletin

absorbed by the curd and therefore leaves an empty space.

Starter culture

Leuconostoc mesentorides subsp cremoris C12H22O11 + H2O 2C3H 6O3 + 2C2H5OH + 2CO2 Lactose Lactate Alcohol Lactococcus lactis subsp diacetylactis and Leuconostoc mesentorides subsp cremoris 2C6H 8O7 2C2H 4O2 + C4H8O2 + 4CO2 Citrate Acetic acid Acetoin

The phenomenon can be explained as follows (H H Lund, 1978): "For air bubbles in liquids the following law applies for the pressure that influences the bubble: pressure = 2 x surface tension radius of bubble According to this law eyes will only be formed if nuclei sites are already present. Consequently released gases in the cheese will assemble in the already existing empty spaces, the smaller the radius of the bubble, the larger the pressure required to make the bubble grow. If the gas formation takes place fast the diffusion through to the initially growing eyes may not be able to keep pace with the formation and the pressure may then increase to the extent that small bubbles may cause several eyes in the cheese." On basis of the above we may conclude that the time at which the gas formation takes place and the gas pressure are essential parameters for the quality of the eye formation.

Secondary Flora

Heterofermentative Lactobacillus Lactose CO2 + lactate, etc Coli Lactose CO2 + lactate + acetic acid, etc Propionic acid bacteria Lactate CO2 + propionic acid + acetic acid, etc Clostridium tyrobutyricum Lactate CO2 + H 2 + butyric acid, etc Lactobacillus casei types Lactate + O2 CO2 + acetic acid + H2O

Physical aspects of eye formation

As soon as CO2 is released from the microbiological process it will together with air be partly absorbed in the liquid phase of the cheese and partly in the surrounding curd. When the point of saturation of the cheese moisture has been reached the excess gas will diffuse against some of the largest nuclei sites or naturally occurring pinholes or, in worst case, completely diffuse out of the cheese. These nuclei sites and pin holes may be caused by kneading in of atmospheric air or captured whey which is being

Eye formation in cheese

Technical Bulletin

Citrate The enzyme system of the starter breaks down the citrate CO2 (etc)

Air

The curd is not saturated

The curd is saturated

Too heavy saturation

Eyes are not growing

Eyes are growing

A lot of eyes are growing

Factors to obtain satisfactory eye formation

1) Few pinholes

Avoid too strong intermixture of air in the milk and between the cheese grains during pressing.

Regulation of the eye formation

As mentioned earlier air and CO2 are main responsible for the gas pressure in cheese. In practical terms the regulation of eye formation is closely related to the regulation of CO2. Therefore a suitably slow fermentation of the citrate gives suitably few eyes and a regular eye formation as CO2 is formed from the citrate fermentation of the starter culture.

2) Suitable resistance against a growing eye

Higher or lower viscosity will result in more or less physical resistance against the extension of the hole. The viscosity depends on factors such as: a) b) c) d) Water content Fat content and amount of iodine Temperature Decomposition of casein

Citrate fermentation

The speed of the citrate fermentation depends on several factors: 1. The amount of Lactococcus lactis subsp diacetylactis and Leuconostoc cremoris as well as the ratio of these strains in the starter culture. Generally Lactococcus lactis subsp diacetylactis strains break down citrate faster than Leuconostoc cremoris strains. LD cultures consist of acidifying Lactococcus strains as well as citrate-fermenting strains Lactococcus lactis subsp diacetylactis and Leuconostoc cremoris. LD cultures are used for cheese in which a fast citrate fermentation and more eyes are wanted like in e.g. some Gouda types.

3) Suitable pressure in the cheese

The formation of CO2 is to take place at a suitable speed so that saturation occurs and so that only a suitable amount of growing eyes will absorb CO2.

Eye formation in cheese

Technical Bulletin

L cultures do not contain Lactococcus lactis subsp diacetylactis and are used for cheese in which slower citrate fermentation and few eyes are wanted like in e.g. Edam cheese. 2. The acidification activity of the starter culture affects the enzymatic citrate breakdown, as it is pH dependent. A faster pH drop results in - other things being equal - faster citrate fermentation and thereby earlier CO2 formation. 3. The temperature during the cheese process as the enzymatic process is temperature dependent. Below follow example of the influence of some important factors on the residual citrate content after 24 hours on the basis of standard Danbo 45+ cheese making (MOS 3.31 Cheese Simulation Program (1992), Dalum Technical Dairy School): Diacetylactis content of the starter culture (percentage of Leuconostoc unaltered) Approx 25% Diacetylactis 1087 mg/kg citrate Approx 2.5% diacetylactis 1664 mg/kg citrate pH at cooling (12C water/salt brine) pH pH pH pH 6.04 5.94 5.85 5.77 1087 mg/kg citrate 933 mg/kg citrate 797 mg/kg citrate 677 mg/kg citrate

The temperature affects the solubility of CO2 and thereby the saturation point in the curd as shown in the example: Temperature 5C 10C 15C 20C Solubility in the liquid phase 3.35 g CO2/l water 2.32 g CO2/l water 1.97 g CO2/l water 1.69 g CO2/l water

Table 1. Solubility of CO2 at different temperatures (H H Lund, 1978)

In practice it has shown that the citrate content in cheese after 24 hours corresponds well to the quality of the eye formation in cheeses with regular eyes. Different results are available in the tables below from the Danish Government Dairy Research Institute, Hillerd and recommendations from NIZO: mg/kg residual citrate in 24 hours old Danbo cheese < 300 300 900 > 900 Eye formation Over-set, shell eyes Nice eyes Few eyes or blind

Table 2. Recommended level of residual citrate in 24 hours' old Danbo cheese (Danish Government Dairy Research Institute, Hillerd)

Change of cooling temperature 20C 18C 16C 14C 12C 10C water water water water water water 767 mg/kg citrate 847 mg/kg citrate 927 mg/kg citrate 1007 mg/kg citrate 1087 mg/kg citrate 1167 mg/kg citrate

Residual citrate in Gouda cheese after 24 hours 14 days

LD culture 250-400 mg/kg < 100 mg/kg

L culture 1200-2000 mg/kg 800-1200 mg/kg

Influence of temperature on gas pressure and eye formation The cheese grains will swell during cooling and thereby absorb "loose" whey, which leads to a better melting together of the curd and thereby fewer eyes. During salting and storage the temperature affects the firmness of the cheese and the resistance against the eye formation.

Table 3. Recommended level of residual citrate in Gouda cheese (NIZO-nieuws 1985, no 3)

Eye formation in cheese

Technical Bulletin

Most common texture defects

Edge holes

Edge holes are characterized by small irregular eyes in the outer edges of the cheese and are considered to be mechanical defects. Generally the defect is due to poor melting together of the curd as a consequence of either air or whey accumulations or too early cooling. The defect may be caused by the following factors: 1. Absorption of air during pumping and prepressing from e.g. leaking pipes, pumps or too low whey level resulting in too many eyes and thereby edge holes. Too heavy pre-pressure in automatic press towers can cause air intake in the cheese block. Whey levels and pressure on the cheese curd in press towers must be consistent. 2. Too vigorous cooling of the curd during prepressing in e.g. press vats or casomatic types may result in too poor melting of the cheese grains and too many eyes. The same applies if cold forms or covers during pressing are used. 3. Too high pressure may result in too early rind formation, which encapsulates whey and finally leads to unwanted fermentation. Too low pressure may result in poor melting together of the curd. 4. By salting too early the salt solution may enter too early whereby the space between the cheese grains increases and edge holes may occur. This may be remedied by cooling in either cold water or by air-cooling. 5. By rough handling of the pre-pressed cheese when e.g. transferring the cheese to the forms.

Early blowing occurs within the first 48 hours of the cheese making and is often due to infection of coli bacteria. They ferment the lactose and release large amounts of H2. Often the defect is followed by a strong and penetrating unclean smell. The coli bacteria are destroyed by low pasteurization and are therefore regarded as a post-infection of the milk due to leaking pipes, pumps or usually due to defects in the cooling part of the pasteurizer. Late blowing occurs later in the ripening process of the cheese, most often after at least three weeks of storage and is primarily due to infection of propionic acid bacteria or Clostridia. Clostridia are spore forming, lactate-fermenting bacteria and release large amounts of H2. They infect the milk at the farmer where they are propagated via the feed, often in the silage. Clostridia are pH sensitive and therefore they grow best late in the ripening period. Along with the Clostridia infection there will be an unpleasant butyric acid smell. Infection of propionic acid bacteria is often easy to trace as the characteristic "nutty" Emmentaler flavor follows the infection. Propionic acid bacteria grow poorly < 20C, ferment lactate and are pH sensitive as low pH values inhibit the growth. Therefore the problems with propionic acid often occur late in the storage period. Sometimes increasing the pasteurization temperature may solve the problem. Addition of nitrate or lysozyme inhibits the growth of Clostridia.

Few eyes, compact

The defect can be caused by lack of gas forming bacteria or addition of too much salt/saltpeter, which inhibits the development of these bacteria. In addition the process technology used is an important consideration. Changing the growth conditions of the bacteria might solve the problem, using a different culture e.g. LD culture, higher storage temperatures or changing the salt conditions.

Overdeveloped eyes, blowing

The eyes of the cheese are heavily over dimensioned. The cheese may be the size of a football and the curd may be blown. Blowing is often due to a contamination in the cheese. This literature study distinguishes between early and late blowing.

Many eyes

The defect is often due to release of CO2 at a too early stage in the process at which the curd is not yet adequately fused, having a consistency, which gives viable diffusion conditions. This can be caused by too fast citrate breakdown often due to

Eye formation in cheese

Technical Bulletin

an imbalance in the starter culture because of too high content of Diacetylactis . Too acid manufactured cheese may cause skin formation on the cheese grains and thereby poor melting together ability. Too rough treatment of fresh cheese. A lower storage temperature may remedy the problem.

temperature. A too low content of CO2-producing bacteria or other factors preventing an adequate pressure in the curd may also cause small eyes.

Slits

Larger or smaller slits or fissures are seen in the curd. A too strong acidification may result in leaching of Ca++ and thereby a less elastic curd which does not yield to the CO2 pressure. Large temperature fluctuations during storage or shipment may cause the problem. Finally slits could be due to blowing from e.g. Clostridia.

Small eyes

Small eyes can be due to a too low content of citrate-fermenting bacteria or a too low storage

References

1/ H H Lund "Citratforgringshastighedens indflydelse p huldannelsen i opstukken ost" (Thesis 1978), Royal Agricultural University of Copenhagen. 2/ "MOS 3.31" (1992), Dalum Technical Dairy School. 3/ M D Norholt and J Stadhouders "Microbiologische en biochemische normen voor de bereiding van Nederlandse kaassoorten II " (NIZO-nieuws 1985, no 3).

Further literature

1/ W Wagner Nielsen "Omdannelser i ost under syrning og modning" (1994), Royal Agricultural University of Copenhagen. 2/ J M Buch Kristensen "Osteteknologi" (1986), Dalum Technical Dairy School. 3/ J C Akkerman et al "Holes in Dutch-type cheese. 1. Conditions allowing eye formation" (Neth Milk Journal 43, 1989)

Você também pode gostar

- Accepted Manuscript: 10.1016/j.nut.2016.10.016Documento31 páginasAccepted Manuscript: 10.1016/j.nut.2016.10.016Elfer Orlando Obispo GavinoAinda não há avaliações

- 1 PDFDocumento13 páginas1 PDFElfer Orlando Obispo GavinoAinda não há avaliações

- Food Plant Sanitation (2002)Documento708 páginasFood Plant Sanitation (2002)Elfer Orlando Obispo Gavino100% (1)

- Total Antioxidant Capacity of Fruits: ArticleDocumento6 páginasTotal Antioxidant Capacity of Fruits: ArticleElfer Orlando Obispo GavinoAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Iftekhar Sea Service TestimonialDocumento2 páginasIftekhar Sea Service TestimonialTomenko OleksiiAinda não há avaliações

- Shifting Meterials: Ground Floor ReceptionDocumento3 páginasShifting Meterials: Ground Floor Receptionvishwas pandithAinda não há avaliações

- Bio-Sensors and Bio-Devices: Spring 2020Documento22 páginasBio-Sensors and Bio-Devices: Spring 2020barristertoto99 chanAinda não há avaliações

- Geotechnical Engineering 1 (RMIT) Course RevisionDocumento53 páginasGeotechnical Engineering 1 (RMIT) Course RevisionSaint123Ainda não há avaliações

- Capstone Documentation RevisedDocumento5 páginasCapstone Documentation RevisedMary Joy BolinaAinda não há avaliações

- Chapter 19A ConcreteDocumento10 páginasChapter 19A ConcreteMofasa EAinda não há avaliações

- ASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1Documento13 páginasASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1JORGE ARTURO TORIBIO HUERTAAinda não há avaliações

- TDS Sadechaf UVACRYL 2151 - v9Documento5 páginasTDS Sadechaf UVACRYL 2151 - v9Alex MacabuAinda não há avaliações

- Trade List 13 Mar 2019Documento74 páginasTrade List 13 Mar 2019Bharat JainAinda não há avaliações

- Introduction To Wireless Application Protocol (WAP) OGIDocumento12 páginasIntroduction To Wireless Application Protocol (WAP) OGIApram SinghAinda não há avaliações

- Piping Handbook - Hydrocarbon Processing - 1968Documento140 páginasPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- The Right Stuff PDFDocumento4 páginasThe Right Stuff PDFNeelank Tiwari100% (1)

- Know PlywoodDocumento3 páginasKnow PlywoodNirvana NircisAinda não há avaliações

- Siemens Engineering Manual V7Documento338 páginasSiemens Engineering Manual V7Jeremy Branch100% (2)

- GWSSB Vendor List 19.11.2013Documento18 páginasGWSSB Vendor List 19.11.2013sivesh_rathiAinda não há avaliações

- AirStash Manual A01 PDFDocumento15 páginasAirStash Manual A01 PDFArcangelo Di TanoAinda não há avaliações

- Softening Point of AsphaltDocumento2 páginasSoftening Point of AsphaltMuhammad Rizal RamliAinda não há avaliações

- Cache MemoryDocumento20 páginasCache MemoryKeshav Bharadwaj RAinda não há avaliações

- High Integrity Aluminum (GENERAL)Documento140 páginasHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Educational Solutions From Schneider ElectricDocumento164 páginasEducational Solutions From Schneider ElectricfaneeeeeeAinda não há avaliações

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocumento11 páginas4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Biomasse-HKW Sandreuth E NQDocumento8 páginasBiomasse-HKW Sandreuth E NQValeriu StanAinda não há avaliações

- Kinematics-03-Subjective SolvedDocumento11 páginasKinematics-03-Subjective SolvedRaju SinghAinda não há avaliações

- Diet Coke & Mentos Geyser Lab 2011-2012Documento4 páginasDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganAinda não há avaliações

- 20105-AR-HOT-07-105-01 Rev 00Documento1 página20105-AR-HOT-07-105-01 Rev 00Bahaa MohamedAinda não há avaliações

- Chapter 2 - 2 Plane Curvilinear MotionDocumento37 páginasChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaAinda não há avaliações

- Psychrometric Chart - Us and Si UnitsDocumento1 páginaPsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914Ainda não há avaliações

- Kathir CollegeDocumento3 páginasKathir Collegeshanjuneo17Ainda não há avaliações

- Sluice Gates ExportDocumento20 páginasSluice Gates ExportsaishankarlAinda não há avaliações