Escolar Documentos

Profissional Documentos

Cultura Documentos

Permeability

Enviado por

Raven1013Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Permeability

Enviado por

Raven1013Direitos autorais:

Formatos disponíveis

Experiment C2

PERMEABILITY

I.

Introduction/Summary Permeability or hydraulic conductivity refers to the ease with which water can flow in soil. This property is necessary for the calculation of seepage through earth dams or under sheet pile walls, the calculation of the seepage rate from waste storage facilities (landfills, ponds, etc.) and the calculation of the rate of settlement of clay soil deposits [1]. Darcy's Law is a generalized relationship for flow in porous media. It shows the volumetric flow rate is a function of the flow area, elevation, fluid pressure and proportionality constant. It may be stated in several different forms depending on the flow conditions. Since its discovery, it has been found valid for any Newtonian fluid. Likewise, while it was established under saturated flow conditions, it may be adjusted to account for unsaturated and multiphase flow [2]. The saturated hydraulic conductivity of a soil can be predicted using empirical relationships, capillary models, statistical models, and hydraulic radius theories. A well-known relationship between permeability and the properties of pores was proposed by Kozeny and later modified by Carman. The resulting equation is largely known as the Kozeny-Carman equation, although the two authors never published together. In the geotechnical literature, there is a large consensus that the Kozeny-Carman equation applies to sands but not to clays [3].

II.

Objectives The experiment aimed to determine the permeability and the filtration grain diameter of a porous granular media (sand).

III.

References [1] Retrieved fromhttp://www2.ggl.ulaval.ca/personnel/paglover/CD%20Contents /GGL66565%20Petrophysics%20English/Chapter%203.PDF on February 16, 2013 [2] Retrieved from www. legacy.library.ucsf.edu on February 16, 2013 [3] Retrieved from http://infohost.nmt.edu/~petro/faculty/Engler524/PET524-perm-2-ppt.pdf on February 16, 2013

[4] Retrieved from www. onlinelibrary.wiley.com on February20, 2013 [5] Retrieved from www. http://www.discoverarmfield.co.uk/data/w3/?js=enabled on February 20, 2013 [6] Retrieved from [5] Retrieved from http://www.discoverarmfield.co.uk/data/w3/?js=enabled on February 21, 2013 IV. Equipment/Materials

Figure 1 Armfield Permeability and Fluidization apparatus

The apparatus used in the experimentation is shown in Figure 1. The pre-sieve sand, with diameter greater than 0.5mm and weighs 501.9g, was used and dehumidified. Additional equipment includes analytical balance, 50-mL beaker and thermometer (0.1 0C calibration).

V.

Theory

VI.

Operating Conditions and Procedure The pre-sieve sand was placed in the machine dryer to remove the moisture content. Then it was weighed in an analytical balance to obtain 501.9 grams. Valves 1, 2, 3 and 4 of the permeability apparatus were securely closed while valves 5, 6, 7 and 8 were opened. After the sand was put in the Perspex column and filled with water. The valves were adjusted to let the water flow through the sand eliminating the air trapped in the voids of the sand. The water was permitted in the column by opening valves 1 and 4 and its manometer levels were noted for each setting of the flow rate. The valves 5 and 6 were closed once the manometer approached its limits. Then another set of readings of the decreasing flow rate was done.

VII.

Data and Results

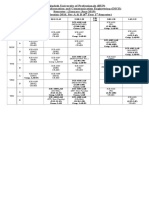

Q (cm3/min) 0 25 50 75 100 125 150 175 150 125 100 75 50 25 0

Va (mm/s) 0 0.367394 0.734787 1.102181 1.469575 1.836968 2.204362 2.571756 2.204362 1.836968 1.469575 1.102181 0.734787 0.367394 0

dh (mm) 8 69 131 181 244 302 375 423 377 311 246 181 136 82 3

dh/dL (mm/mm) 0.014545455 0.125454545 0.238181818 0.329090909 0.443636364 0.549090909 0.681818182 0.769090909 0.685454545 0.565454545 0.447272727 0.329090909 0.247272727 0.149090909 0.005454545

Q (cm3/min) 0 25 50 75 100 125 150 175 200 175 150 125 100 75 50 25 0

Va (mm/s) 0 0.367394 0.734787 1.102181 1.469575 1.836968 2.204362 2.571756 2.939149 2.571756 2.204362 1.836968 1.469575 1.102181 0.734787 0.367394 0

dh (mm) 22 42 87 129 197 252 312 353 422 383 353 299 254 193 143 92 28

dh/dL (mm/mm) 0.04 0.076363636 0.158181818 0.234545455 0.358181818 0.458181818 0.567272727 0.641818182 0.767272727 0.696363636 0.641818182 0.543636364 0.461818182 0.350909091 0.26 0.167272727 0.050909091

Table 1: Data obtained in Trial 1

Table 2: Data obtained in Trial 2

VIII.

Treatment of Results

0.9 0.8 0.7 0.6 dh/dL 0.5 0.4 0.3 0.2 0.1 0 0 0.5 1 1.5 Va 2 2.5 3 y = 0.2961x + 0.0167 R = 0.9976

Figure 2: Head Loss versus Fluid Velocity Graph of Trial 1

500 450 400 350 300 dh 250 200 150 100 50 0 0 0.5 1 1.5 Va 2 2.5 3 y = 162.84x + 9.1711 R = 0.9976

Figure 3: Head Loss versus Fluid Velocity Graph of Trial 2

0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.5 1 1.5 Va 2 2.5 3 3.5

dh/dL

y = 0.2512x + 0.0334 R = 0.9653

Figure 4: Hydraulic Gradient versus Fluid Velocity Graph of Trial 1

0.9 0.8 0.7 0.6 0.5 dh 0.4 0.3 0.2 0.1 0 0 0.5 1 Va 1.5 2 2.5 3 3.5 y = 0.2512x + 0.0334 R = 0.9653

Figure 5: Hydraulic Gradient versus Fluid Velocity Graph of Trial 2 IX. Analysis/Interpretation of Results Plotting the obtained data from trials 1 and 2, the relationship of the head loss and fluid flow rate or velocity can be correlated wherein the head loss also increases as the fluid velocity increases thus demonstrating a direct proportionality as shown in figures 2 and 3. The parameter, R2, is 0.997 for both trials by using the linear regression of the graphs. Averaging the inverse of the slopes will result to 3.378mm/s per mm H2O as their permeability constant. The diameter was also computed obtaining the value of 0.46mm which was close enough in the given diameter in the literature.

X.

Answers to Questions 1. What is the importance of knowing the permeability of a given porous medium? In what particular areas in chemical engineering is the concept of permeability most relevant. Give examples. Evaluation of the permeability of a given medium is important in quantifying flow rate of the fluid which is essential in most of the chemical processing industries. Porous media have many applications in chemical engineering area such as calculation of seepage through earth dams or under sheet pile walls, the calculation of the seepage rate from waste storage facilities (like landfills and ponds) and the calculation of the rate of settlement of clay soil deposits, etc. 2. What operating parameters must be considered in determining the permeability of a given porous media? Does the choice of liquid affect the result of the experiment? The factors that affect the degree of permeability, considering the pressure differential is constant, are grain size and shape, moisture content used in tempering the grain, temperature and lastly, fluid density and viscosity. Also the choice of the liquid affects the result of the experimentation because of its physical properties, the more viscous and denser the fluid is, the more it will inhibit the fluid flow thus it decreases.

XI.

Findings, Conclusion, and Recommendation The experimentation proved that the hydraulic gradient and head loss with volumetric flow per area has linear relationship which is in accordance to Darcys Law. The calculated permeability and diameter of the sand are 3.378mm/s and 0.46mm, respectively and still

acceptable though there were discrepancies comparing the calculated results from the given values in the literature. Furthermore, it is recommendable to tap continuously the Perspex column in the experimentation proper in order to minimize the source error because this ensures that less air will be trapped in the voids of the sand. Squeeze in the bubbles or the air gaps in the pipes wherein this reduces the discrepancies of the results from the theoretical values as well as for an easier determination of the data. The use of other type of porous media is also recommendable in this experiment, except of using clay, which is a limitation to the use of Kozeny-Carman equation because it only applies to materials with uniform pore size distribution.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Probability Theory - VaradhanDocumento6 páginasProbability Theory - VaradhanTom HenAinda não há avaliações

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Documento880 páginas1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- Plastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesDocumento10 páginasPlastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesGopu RAinda não há avaliações

- Hume 100 ReviewerDocumento7 páginasHume 100 ReviewerShai GaviñoAinda não há avaliações

- CoolonDocumento2 páginasCoolonAnySikaAinda não há avaliações

- Norberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishDocumento14 páginasNorberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishGildo Joaquim FranciscoAinda não há avaliações

- Drsent PT Practice Sba OspfDocumento10 páginasDrsent PT Practice Sba OspfEnergyfellowAinda não há avaliações

- Moc3040 MotorolaDocumento3 páginasMoc3040 MotorolaBryanTipánAinda não há avaliações

- Module 1 Supply Chain Management in Hospitality IndustryDocumento39 páginasModule 1 Supply Chain Management in Hospitality IndustryHazelyn BiagAinda não há avaliações

- DLL Drafting 7Documento4 páginasDLL Drafting 7Ram Dacz100% (3)

- HAFOMA Presentation 2022 ENGDocumento9 páginasHAFOMA Presentation 2022 ENGVeljko MilicevicAinda não há avaliações

- Application Letter For Promotion T2 T3Documento24 páginasApplication Letter For Promotion T2 T3FGacadSabadoAinda não há avaliações

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDocumento19 páginasAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Ainda não há avaliações

- Antenna Systems - Standard Format For Digitized Antenna PatternsDocumento32 páginasAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaAinda não há avaliações

- CadburyDocumento21 páginasCadburyramyarayeeAinda não há avaliações

- Pamphlet 89 Chlorine Scrubbing SystemsDocumento36 páginasPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDocumento33 páginasSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- World Trends in Municipal Solid Waste ManagementDocumento11 páginasWorld Trends in Municipal Solid Waste ManagementNeima EndrisAinda não há avaliações

- n4 HandoutDocumento2 páginasn4 HandoutFizzerAinda não há avaliações

- Measures of Indicator 1Documento2 páginasMeasures of Indicator 1ROMMEL BALAN CELSOAinda não há avaliações

- NCRA Membership InformationDocumento1 páginaNCRA Membership Informationbkharkreader1301Ainda não há avaliações

- Hemax-530 PDFDocumento2 páginasHemax-530 PDFNice BennyAinda não há avaliações

- Evidence MODULE 1 Evidence DefinitionDocumento8 páginasEvidence MODULE 1 Evidence Definitiondave BarretoAinda não há avaliações

- DA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Documento6 páginasDA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Likith MallipeddiAinda não há avaliações

- Scope and Sequence 2020 2021...Documento91 páginasScope and Sequence 2020 2021...Ngọc Viễn NguyễnAinda não há avaliações

- Class Routine Final 13.12.18Documento7 páginasClass Routine Final 13.12.18RakibAinda não há avaliações

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDocumento8 páginasPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoAinda não há avaliações

- Kowalkowskietal 2023 Digital Service Innovationin B2 BDocumento48 páginasKowalkowskietal 2023 Digital Service Innovationin B2 BAdolf DasslerAinda não há avaliações

- TransistorDocumento3 páginasTransistorAndres Vejar Cerda0% (1)

- Hypothesis Testing Random MotorsDocumento8 páginasHypothesis Testing Random MotorsLinn ArshadAinda não há avaliações