Escolar Documentos

Profissional Documentos

Cultura Documentos

OM0017-SLM-Unit-01 Operation Management SMU

Enviado por

pradeepjvsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

OM0017-SLM-Unit-01 Operation Management SMU

Enviado por

pradeepjvsDireitos autorais:

Formatos disponíveis

Advanced Production Planning and Control

Unit 1

Unit 1

Production Planning and Control Concepts

Structure: 1.1 Introduction Objectives 1.2 Functions/Tasks of Production Planning 1.3 Levels of Production Planning 1.4 Systems/Aids for Production Control 1.5 PPC Coordination with Other Functions and Role of Production 1.6 PPC Coordination & Interfacing with Marketing 1.7 PPC as an Integrated Function 1.8 PPC for Different Systems of Manufacturing PPC for mass or continuous production PPC for batch or intermittent production PPC for job shop production 1.9 Functions of PPC in Plant / Facilities Planning 1.10 Summary 1.11 Glossary 1.12 Terminal Questions 1.13 Answers 1.14 Case Study

1.1 Introduction

It is very well known that an industry can achieve the highest efficiency in production by manufacturing the required quantities of products. In order to coordinate all manufacturing activities across all processes, the management deploys the production planning and control department. This department is responsible for organising the production process. Production is a transformation process. Here, all the material inputs are processed to get the desired product. The production planning and control section, hereafter referred to as PPC, controls and monitors the whole production process. It follows two processes. First is the transformation by disintegration, which involves converting the raw materials to different sizes, states and geometric shapes, and second is the transformation through integration, which involves but the assembly of components to form the main product.

Sikkim Manipal University Page No. 1

Advanced Production Planning and Control

Unit 1

In this unit, you will study about the functions of production planning along with its levels. Later, you will be studying about production planning and control (PPC) coordination with other functions and as an integrated function. At the end, we will discuss about the PPC for different systems of manufacturing and PPC functions in plant facility. Objectives After studying this unit, you should be able to: Analyse the integrated systems in PPC and System/Aids used. Devise production planning for mass, batch & job type productions through Aggregate and Master Production Systems. Define the functions, different levels and procedures adopted in PPC Assess how PPC works as an integrated system and the positioning policy. Distinguish between planning and control functions.

1.2 Functions/Tasks of Production Planning

Before we discuss about the functions/tasks of production planning, let us first understand the meaning of production planning. Production planning is a process that covers the performance of some critical functions like planning, routing, scheduling, and loading. Manufacture planning and control involves the procurement and allocation of limited resources over a specified time horizon to carry out production activities so as to satisfy the demands of the customer. Planning and control problems are characteristically optimisation problems. Here, the objective is to come up with a plan that meets demand at a minimum cost or that fulfills the demand which maximises profit. The manufacturing planning and control deals with the decisions of utilisation, acquisition, and resources allocation because it is important to satisfy the customer requirements in a cost effective and efficient way. Usually, decisions taken include the level of work force, production lot sizes, assignment of overtime, and sequencing of production runs. Following are the essential functions/tasks of production planning. Planning Production planning is defined as the technique of anticipating every step in a long series of separate operations. It helps the entrepreneur to calculate

Sikkim Manipal University Page No. 2

Advanced Production Planning and Control

Unit 1

the quantity of material, manpower, machinery, and capital required for producing a planned level of output in a specified time period. Routing The main purpose of routing is to find out the best and cheapest sequence of operations and to make sure that this order is exactly followed. Routing involves the following different activities. Evaluating the document to determine what components to make and what components to buy. Ascertaining the quality and type of material. Establishing the sequence of manufacturing operations. Determining lot sizes. Finding out the scrap factors. Analysing the cost of the article. Organising the different production control forms. Scheduling This means evaluating the time that would be required to carry out each function and also the time needed to perform the entire series. It is primarily concerned with the time element and priorities of a job. The model of scheduling differs from one job to another which is explained as below: Production schedule: The main purpose of production schedule is to schedule the amount of work, which can be easily handled by the plant and equipment without any hindrance. It is not an independent decision, as it takes the following factors into account. Physical plant facilities required to process the material being scheduled. Employees who possess the skills and experience to perform the type of work involved and operate the equipment. Required materials and purchased parts.

Master Schedule: Scheduling typically begins with the preparation of the master schedule, which is weekly or monthly categorisation of the requirement of production for each product for a specified time period. This helps the entrepreneur to shift the production from one product to another according to the changed production needs. An operator schedule follows a master schedule. It fixes the total time required to do a specific task on a

Sikkim Manipal University Page No. 3

Advanced Production Planning and Control

Unit 1

given machine or it shows the time needed to do each detailed activity of a given job with a particular machine or process. Manufacturing schedule: It is organised on the basis of the type of manufacturing process involved. It is very useful when manufacturing a single or few products continually at regular time period. Thus, it would give an idea about the required quantity of each product and the order in which the same is to be operated. Scheduling of job order manufacturing: A job order is an order for a product received from a customer or a client or from an internal section of an organisation. Scheduling is a process followed to ensure the speedy execution of job order manufacturing. Scheduling attains greater importance in job order manufacturing. For a small scale industry, scheduling is of prime importance, as it brings out efficiency in the operation and reduces cost. The small entrepreneur should maintain four types of schedules -- namely an enquiry schedule, a production schedule, a shop schedule, and an arrears schedule. Out of the above four, a shop schedule is the most important and most suited to the needs of a small scale industry, as it enables a foreman to see the following at a glance. The section load -- that is, the load at any given section. The sequence of operation. The phase that a job has touched. Loading It entails the assignment of work to the operators/workers at their work places. Therefore, loading determines who will do the work, as scheduling determines when it shall be done. Routing determines where the loading has to be done. Small industries usually make use of Gantt charts to find out the present load on the system and also to evaluate how fast a job can be done. The advantage of using this technique is that it gives a picture of what has been done and what is to be done. Then you can make a comparison between the two. Many small scale enterprises fail due to non-adherence to delivery schedules. Therefore, to be successful, they should have the ability to make the delivery of goods on time, without compromising on product quality. It is important for the entrepreneur to judge ahead of time as to what should be done, where and when.

Sikkim Manipal University Page No. 4

Advanced Production Planning and Control

Unit 1

Self Assessment Questions 1. The objective of routing is to determine the best and cheapest sequence of operations. (True/False)? 2. Scheduling normally starts with preparation of _______________. 3. For a small scale industry scheduling is not important. (True/False)? 4. The___________ is used in small industries to determine the existing load and also to evaluate out how fast a job can be done. 5. Many small scale enterprises fail due to adherence to delivery schedules. (True/False)?

1.3 Levels of Production Planning

In the previous section, you studied about the functions of production planning. Now, let us discuss about the levels of production planning. Before that, let us know that production planning is the process of setting up an overall range of output called as the production plan. The process also consists of other activities that are required to achieve the current planned levels of sales. This is done while meeting the enterprises general goals regarding profit, lead times, productivity, and customer satisfaction, as fixed in the overall plan. The production-planning process requires comparing production capabilities, sales requirements, and inclusion of budgets, financial statements, essential plans for workforce and materials requirements, plus the production plan itself. The main purpose of the production plan is to establish production rates that will achieve the enterprises objective of satisfying the customer demand. Demand/customer satisfaction can be achieved through maintaining, increasing, or lowering of inventories or backlogs, while keeping the workforce reasonably stable. There are three levels of production planning. The level of planning is selected depending on the organisation, and it is selected for optimising the process. The following diagram 1.1 depicts the different levels of production planning:

Sikkim Manipal University

Page No. 5

Advanced Production Planning and Control

Unit 1

Figure 1.1: Levels of Production Planning

Strategic Planning In this level, the top management contemplates its current mission and environment, and further sets forth guidelines for future directions, decisions, and results. Tactical Planning This planning is done on an intermediate term by the middle level management. The focus is on aggregates rather than individual specific products. Operational Planning This planning is carried out by the junior level management at a short-range time span and is concerned with utilisation of existing resources rather than procuring new resources or material.

1.4 Systems/Aids for Production Control

Production comprises several activities. Planning activities are scheduled and carried out within the time and cost frames. This is done in order to achieve maximum efficiency. Despite planning, there may be slippages in certain areas thus affecting the rate of production. Reasons for slippages can be categorised as those due to internal as well as external factors. Such delays can be avoided by the timely intervention of management and planning. A system should be maintained to receive feedback from the production units to those involved in production including the planners. The feedback helps to attend to the defects or issues immediately so as to maintain further

Sikkim Manipal University Page No. 6

Advanced Production Planning and Control

Unit 1

control over production. Thus, production control is a corrective mechanism, which can be applied in many forms, namely: Provisioning of additional workforce, materials, and machines with the intention of balancing the line. Guaranteeing the smooth flow of materials in the shop floor. Arranging additional labour to cope with the production rate or to balance the production quality. Rearranging production without affecting the delivery schedule. Allocating priority to jobs for best utilisation of resources. A range of control aids are used by production control sections. The objective of these aids is to bring up a system, so that the production control activities are taken care of irrespective of the presence or interference of individuals. There may be a variety of aids, but the following are widely used. Dispatching. Follow up. Inspection. Corrective measures. Dispatching Dispatching ensures the appropriate movement of partially manufactured items from equipment to equipment within a specified time. Eventually, the set target at production planning stage is achieved with the aid of dispatching. Follow up All production programmes involve the follow up process in order to check the progress of work. Follow up is important in eliminating bottlenecks in the flow of work and ensuring that production is taking place as planned. It helps to identify delays or deviations in the production plan. It aids in finding defects in routing, scheduling, misunderstanding of instruction, under loading or overloading of work, and so on. All issues or deviations are looked into and remedial actions are carried out to ensure the completion of the task by the planned date. Inspection This is to ensure the quality of the product. It can be employed as an

Sikkim Manipal University Page No. 7

Advanced Production Planning and Control

Unit 1

effective agency of production control. The inspection of a product at the time of manufacturing will be more effective compared to the inspection which is performed once the product is complete. Corrective measures Corrective action may comprise any of the activities of changing the workloads, repairs, maintenance of machinery or equipment, control over inventories, rescheduling of work, and so on. Some decisions regarding the workforce like training, demotion, transfer may also have to be considered. To handle peak loads, alternate methods may be recommended. Self Assessment Questions 6. Production control is a corrective mechanism. (True/False)? 7. Dispatching ensures the appropriate movement of _____________ manufactured items from equipment to equipment within a specified time. 8. ____________________ are taken to ensure the quality of the product. Activity 1: Visit the website of a manufacturing concern and find out the planning and control strategies followed by them. (Hint: http://www.marutisuzuki.com/)

1.5 PPC Coordination with Other Functions and Role of Production

The principal goal of production is to convert the raw materials into finished goods. A business is able to achieve customer satisfaction when it completes this process of producing products that are ready to be used and fit for purpose. To ensure quality, the production department is in charge. Inspections and suitable quality initiatives are carried out. This is one of the important tasks of this department, because if mistakes are made, then the product is rendered useless and this in turn will affect customer satisfaction. Master data, which may contain reference data, is the information that is important for the functioning of a business. This important business information may contain data about employees, customers, materials, suppliers, products, and so on. Usually this happens to be non-transactional in nature.

Sikkim Manipal University Page No. 8

Advanced Production Planning and Control

Unit 1

In Material Requirement Planning (MRP), maintaining master data is crucial. Maintaining master data is necessary for external procurement of material or work. The maintenance of master data forms the basis of MRP. The PPC coordination with MRP is as follows: Planning Tasks It includes functions for implementing the MRP for external production. You can use this to ensure that the stocks are available in right quantities at the right time. You can plan individual materials, for which the requirements or stock situation has changed. The following are the production planning activities performed under planning tasks: Setting and displaying planning file entries manually. Implementing single-item planning. Single-level and single-item planning. Planning using the planning table. Integration Integration is a single role, and it deals with the activity of total planning. It involves planning of all materials in a plant. Evaluations Tasks The evaluation task contains functions to analyse the MRP result for placing external orders. You can use these functions to obtain information about material at your disposal and to recognise possible material shortage situations and exception situations quickly. The following are the production planning activities performed at the time of evaluation tasks. Displaying MRP list and stock list (with individual evaluation layout or standard layout). Displaying missing parts (backlogs). Planned Order Tasks To process external procurement, planned order task functions are used. You can use these functions to adapt the planned orders to the exact current requirements and to then facilitate the procurement of individual assemblies or components by converting the planned orders. Following are the activities of production planning in planned order tasks. Process planned orders. Convert planned orders into purchase orders.

Sikkim Manipal University Page No. 9

Advanced Production Planning and Control

Unit 1

Coordination Tasks Coordination tasks contain important functions in MRP for external procurement that are associated with particular tasks. Using these functions, you can control MRP from a top level. Following are the production planning activities under coordination tasks. Defining MRP controller. Executing the planning process for a plant or an MRP area. Printing and recognising the MRP list. Generating purchase orders automatically.

1.6 PPC Coordination & Interfacing with Marketing

In this section, we will study about the PPC coordination interfacing with marketing. The major decisions in the production functions invariably have an impact on the marketing function. If production plans for layoffs, reducing overtime, and drawing down the inventories, then the marketing may find that their customer promises are not met, delivery times are longer or the products available off-the-shelf are wrong in the mix and so on. Therefore, it is important for you to overcome these problems. To provide variety of items, large inventories are required. These inventories are to be addressed and interfaced. Otherwise you may have to face heavy loss. This is true when marketing forecasts are wide off the mark. Manufacturing and marketing are mutually dependent activities in industrial production organisations. This raises a need for coordination. The feature of the dependence relies very much on the way manufacturing and marketing processes are ordered and controlled. Here, we discuss the mutual dependence of manufacturing and marketing, and the resulting coordination requirements. Based on the coordination properties and requirements, a coordination structure can be modelled. If you want to maintain stability in the enterprise, you have to avoid sales dominance or a manufacturing dominance. The overall strategy of the firm should include both the functions and answer all the questions on the strategies to be adopted. Accordingly, PPC needs to address the problems resulting from demand variability, non-inventory type of output, labour intensiveness, and

Sikkim Manipal University Page No. 10

Advanced Production Planning and Control

Unit 1

distribution systems. It should also strive hard for cooperation between departments. Self Assessment Questions 9. In __________________________ maintaining master data is crucial. 10. MRP stands for ___________________________________. 11. Maintaining master data is an overhead for the company, (True/ False)? Activity 2: Devise a system to accommodate the expectations of planning and control along with the expectations of marketing department. (Hint: PPC coordinating and interfacing with marketing)

1.7 PPC as an Integrated Function

One of the elementary decisions in the production area deals with integration. The integration decision proposes a scheme on manufacturing activity which the enterprise is ready to engage in. Almost every enterprise buys components and materials which are finished (as per the requirement of an enterprise) products from other industries. The manufacturing enterprise spends a lot of money to buy these materials. We consider the automobile industry as being highly integrated, but the auto companies buy over fifty percent of the components required by them. Most manufacturing companies can manage to manufacture components that go into their products. However, they still buy few products. The PPC should make arrangements to ensure smooth integration of all these products. There are three ways by which PPC facilitates the integration function: Vertical integration. Horizontal integration. Conglomerate integration. Vertical integration: It can be stated as the integration of components that are manufactured by the company. Typically, all the components are produced in the same facility. The components are manufactured over many stages. To put it more comprehensively, vertical integration is driving the

Sikkim Manipal University Page No. 11

Advanced Production Planning and Control

Unit 1

ownership into making raw materials. Pushing the other way toward the customer is also vertical integration. Vertical integration gives the enterprise total control over its source of supply. The enterprise can get anything it wants in the way of delivery, quantity, quality, control of research and development and so on. Integrating towards the customer that is making finished goods and selling them through the companys own outlet gives a distinct market value for its own products. It takes money and good management to run all these activities and make the project profitable. Therefore, sometimes vertical integration is a little risky. Often companies that make the raw material do it on a large scale and at a lesser cost. If you are making your own raw material, it can be more expensive. Horizontal integration: The companies that employ horizontal integration produce goods at different facilities all over the country. This provides good protection against stoppage of production everywhere at once due to any unavoidable circumstances. You can incur low operating costs by putting plants closer to customers and in low cost areas. Like vertical integration, horizontal integration requires good managerial skills. Here you do not run a single large factory, but many scattered factories. The advantages of horizontal integration are: Low transportation cost. Better customer service. Often low labour costs. Conglomerate integration: All integration cannot be categorised as either horizontal or vertical. Sometimes a company undertakes different types of products so that their customers can buy all their needs from the same source. In other words, the company opts for diversification of business. Companies take up these businesses based on the inputs provided by their research people.

Sikkim Manipal University

Page No. 12

Advanced Production Planning and Control

Unit 1

1.8 PPC for Different Systems of Manufacturing

It is understood that the customer driven operations strategy reflects the firms long term goals. It requires a cross functional effort by marketing and operations managers. After considering the cost, quality, time, and the flexibility, the process is determined. For these customised services, the decision is taken at the corporate level on the make to stock strategy or assemble to order strategy. When mass customisation is required, we find that the manufacturer will go for mass or continuous production strategy. This is because the products served have continuous demand and is almost a standardised production. Based on the nature of the product and the customer demands, decisions are taken whether to adopt the strategy of batch or intermittent production or going for job shop production. As we have discussed, the preplanning and planning stages dictate the future actions on production activities. These three types of production systems along with the functions of PPC are as follows: 1.8.1 PPC for mass or continuous production Mass production refers to a large quantity of production with standardised products having less variety. Therefore, the determining factor is the demand, which makes us choose between continuous or batch type production. Mass production is preferable when demand is greater than the rate of production. When the demand is less than the rate of production, batch production is preferred. The economic needs of the assembly line must also be addressed. 1.8.2 PPC for batch or intermittent production The technique of batch production is resorted to when the variety and volume of goods to be manufactured are not large enough to demand a separate production line for each product. We observe that batch production employs a process layout (unlike mass production where there is product layout). Rational approach in the economic terms like lot size, set up cost, carrying costs are considered here.

Sikkim Manipal University

Page No. 13

Advanced Production Planning and Control

Unit 1

1.8.3 PPC for job shop production Job shops handle a range of jobs where each job is different. In batch production, though there is a continuous demand for products, the rate of production exceeds that of demand. In job shop, both the jobs and the demand are unpredictable. Job shop handles the unique job each time with a unique set of operations and processing time. Hence, job machines are general-purpose machines and a job exits from a machine to wait on a new machine because of other jobs being carried on in that machine. The reverse is also true where machines may wait for the job.

1.9 Functions of PPC in Plant / Facilities Planning

Plant/facility planning is a long-term planning, which begins with the choice of suitable location for the plant and ends with the installation of the complete production system. Manufacturing plants strive to have a right facility that enables them to produce the desired quantity and quality of the products at minimal cost. Plant planning is the task taken to establish the long-term production capacity to produce the products/services. Therefore, it is a critical operational strategy for corporates. It involves procurement of land and production equipment. Appropriate production technologies must be developed and a detailed industrial engineering study for internal arrangement of workers must be developed. You should also organise production processes and departments within the facilities to achieve the desired volume, quality, and cost of products. Plant planning refers to the designing, installing, and physical arrangement of plants, factories, laboratory, R&D centres and so on. It includes facilities planning or planning of processing equipments, plant utilities, services, building, and other auxiliary facilities. Facility planning refers to determining the requirement of long range production capacity, how much is needed, where production facilities are to be located and layout characteristics.

Sikkim Manipal University

Page No. 14

Advanced Production Planning and Control

Unit 1

Plant planning serves the following: Aims to facilitate the most efficient and cost effective manufacturing process. Optimises integration of all factors to have an effect on the layout. Optimises utilisation of labour, machines, and space. Stipulates for future expansion of the facility. Introduces flexibility in the system towards changes in product design and output volume. The scope of plant planning may include the following: Selecting the plant design and production system. Designing the manufacturing process. Selecting machinery, equipment and materials handling system. Designing of communication and control systems. The objective of the plant/facilities planning department is to design, construct, and efficiently operate. It should also be well-maintained and have infrastructure that supports existing and future activities. It should facilitate growth of the company by providing a safe, healthy, comfortable, clean, and attractive environment for the progress of work. Self Assessment Questions 12. The manufacturer will opt for mass or continuous production when the demand is low. (True/False)? 13. Plant/facility planning is a _____________planning activity. Activity 3: List the tasks you would do as an entrepreneur to ensure quality and on time delivery of products. (Hint: functions of PPC)

1.10 Summary

To achieve production efficiency and higher productivity at the most economic cost; is always the main objective of any manufacturing unit. To manufacture the required quantity of product, of the required quality, at the specified time by the cheapest and best method, the management employs the PPC department and assigns total responsibility of coordinating all manufacturing activities across all processes in the organisation.

Sikkim Manipal University Page No. 15

Advanced Production Planning and Control

Unit 1

As you have observed from the above discussion production incorporates the transformation process wherein all the material inputs are processed. The processing could be of two types disintegration i.e. converting the raw materials to give different shapes, sizes, states and next integrating through assembly processes to form main product. A closed planning, monitoring and controlling of all production activities is essential. As you see PPC has to maintain synchronisation between planning, integration, coordination etc. This is because each task provide input has an effect on the pre-planning activity. And categorising the tasks helps in better understanding and implementation of the manufacturing process. While planning starts-off with the analysis of the data through which the system of utilising the resources is charted out, the control process initiates and supervises the operations with an appropriate control mechanism that feeds back information about the progress of the work. The control process can also be successively modified, redefined and adjusted to the targets set and achieve the set/revised targets. A trade-off between the manufacturing department and the marketing department should be ensured. If there is a clash of interest, it overshadows the production/manufacturing activity. The demand dictates what kind of manufacturing process should be employed in order to service the requirement. We discussed three types of manufacturing processes namely mass production, batch production and job shop production. The type of technique employed will reflect in timely delivery of goods. Finally, we discussed the planning and effort that goes into building a manufacturing plant/facility. In order to set-up a plant proper planning should be done because it translates into delivering the desired product. Without the required equipment or facility it is not possible to achieve the planned goal.

Sikkim Manipal University

Page No. 16

Advanced Production Planning and Control

Unit 1

1.11 Glossary

Terms Job Shop Production Description Technique to allow flexibility in terms of switching between machines, methods, handling problems in production etc It is information which is the key to the operation of business. This key business information may include data about customers, products, employees, materials, suppliers.

Master data

1.12 Terminal Questions

1. State the objectives of production planning and control. 2. What are the three levels of production planning? Elaborate. 3. Explain briefly how the different system/aids are used to ensure smooth working of the production process. 4. To optimise and ensure smooth production, PPC works as an integrated system. Explain briefly how this integrated working will benefit the manufacturing unit? 5. Discuss the PPC coordination with other tasks. 6. Discuss the factors that determine which production planning procedures to use. 7. Explain briefly the functions of planning in Facility Planning for production activities?

1.13 Answers

Self Assessment Questions 1. True. 2. Master schedule. 3. False. 4. Gantt chart. 5. False. 6. True. 7. Partially. 8. Inspection. 9. MRP. 10. Material Requirement Planning. 11. False.

Sikkim Manipal University Page No. 17

Advanced Production Planning and Control

Unit 1

12. False. 13. Long term. Terminal Questions 1. Refer Section 1.1 Functions of production planning 2. Refer Section 1.3 Levels of production planning 3. Refer Section 1.4 System of production control 4. Refer Section 1.4 and 1.5 System of production control and PPC coordination with other functions 5. Refer Section 1.6 PPC coordination and interfacing with marketing 6. Refer Section 1.7 PPC as an integrated function 7. Refer Section 1.8 PPC for different systems of manufacturing

1.14 Case study

Importance of Planning Z Company is into manufacturing automobile spares. The products they manufacture are brake seals, clutch plate, and air filters. The company planned to start manufacturing radiators. However, there was not enough space to accommodate new machines and workforce. The proprietor of the company tried to replace the clutch manufacturing machines with radiator manufacturing machines. They proceeded with the plan and new machines were installed. The existing workforce were trained and put to work. As days passed there was a surge in the demand for clutch plates in the market. This surge was anticipated by the marketing team. Now, there was a problem in assigning the workforce towards clutch plate production because the workforce that used to produce clutch plates was deployed to produce radiators. Working overtime also would not help to deliver the goods within the stipulated timeline. The production planning department was finding it difficult to coordinate the workforce involved in producing clutch plates and radiators. There were issues in integrating the resources and routing the resources. The higher management was now looking out for other alternatives like procuring work externally. These issues would have been addressed effectively if the expansions were pre-planned. The marketing department should have notified the production department before hand in order to facilitate integrating batch production.

Sikkim Manipal University Page No. 18

Advanced Production Planning and Control

Unit 1

If these issues of planning and controlling would have addressed before hand, Z Company would have met the demand and need of the market. 1. What led to the surge in demand of clutch plates? (Hint: customer demand) 2. What do you suggest should have been done to fulfil the demand? (Hint: proper planning) References P. Rama Murthy (2007), Production And Operations Management S. Bhattacharya, Production Planning and Control: An Integrated Approach. Thomas M. Landy, Production planning and control.

Sikkim Manipal University

Page No. 19

Você também pode gostar

- Practical Guide To Production Planning & Control [Revised Edition]No EverandPractical Guide To Production Planning & Control [Revised Edition]Nota: 1 de 5 estrelas1/5 (1)

- Om 0017Documento198 páginasOm 0017praveen4_40% (1)

- Om 0017Documento194 páginasOm 0017praveen4_4Ainda não há avaliações

- Production Plnning & ControlDocumento23 páginasProduction Plnning & ControlVivek VashisthaAinda não há avaliações

- Operations ManagementDocumento15 páginasOperations ManagementJamil KamaraAinda não há avaliações

- Enterprise Resource Planning: Module: Production Planning and Manufacturing ProcessDocumento10 páginasEnterprise Resource Planning: Module: Production Planning and Manufacturing ProcessAnurag RajwardhanAinda não há avaliações

- Functions of PPC Unit 2Documento42 páginasFunctions of PPC Unit 2Sujit ThiruAinda não há avaliações

- Production Planning & ControlDocumento43 páginasProduction Planning & ControlkunjammuAinda não há avaliações

- Clothing Business and ManagementDocumento51 páginasClothing Business and ManagementProfessorTextechAinda não há avaliações

- Traditipn Production Planning and ControlDocumento16 páginasTraditipn Production Planning and ControlpaulineAinda não há avaliações

- Operations ManagementDocumento12 páginasOperations ManagementkeerthiAinda não há avaliações

- Figure 8.1: Production SystemDocumento4 páginasFigure 8.1: Production SystemHaseeb KhalidAinda não há avaliações

- Module 5 PDFDocumento8 páginasModule 5 PDFMechanical EngineeringAinda não há avaliações

- Report Pau FPDocumento16 páginasReport Pau FPpaulineAinda não há avaliações

- Op SuggestionDocumento54 páginasOp Suggestionviswajit balaAinda não há avaliações

- Dr. Rajendra Doiphode Ph.D. (IIT Bombay)Documento36 páginasDr. Rajendra Doiphode Ph.D. (IIT Bombay)2020 83 Harshvardhan PatilAinda não há avaliações

- TOPIC-III-Intro-to-IE 17Documento16 páginasTOPIC-III-Intro-to-IE 17Princess joy De RuedaAinda não há avaliações

- Unit 3 PDFDocumento22 páginasUnit 3 PDFHarshAinda não há avaliações

- Operations Management Lecture NotesDocumento3 páginasOperations Management Lecture NotesDahlia OjalesAinda não há avaliações

- Opc Unit-5Documento18 páginasOpc Unit-5Aashish Singh IIAinda não há avaliações

- Production Planning and ControlDocumento34 páginasProduction Planning and ControlAkanksha RanjanAinda não há avaliações

- PPC Question BankDocumento64 páginasPPC Question BankAbhishek Sai AbhiAinda não há avaliações

- Definition of Production ControlDocumento22 páginasDefinition of Production ControlNorIshamIsmailAinda não há avaliações

- Production Planning and ControlDocumento68 páginasProduction Planning and ControlNardos YizengawAinda não há avaliações

- UntitledDocumento112 páginasUntitledvijayAinda não há avaliações

- Production and Operations Management Digital MaterialDocumento220 páginasProduction and Operations Management Digital MaterialThe OpenstudioAinda não há avaliações

- 05b5aea126563e - Ch-1 - Kiran - Production Planning & ControlDocumento22 páginas05b5aea126563e - Ch-1 - Kiran - Production Planning & ControlRonaldo FlorezAinda não há avaliações

- Production Planning and SchedulingDocumento9 páginasProduction Planning and Schedulingsuriya kishoreAinda não há avaliações

- UNIT II Need For PPC-Objectives-Functions-Information Required For PPC-ProductionDocumento30 páginasUNIT II Need For PPC-Objectives-Functions-Information Required For PPC-Productionmohanmech2006886Ainda não há avaliações

- Production Planning and ControlDocumento6 páginasProduction Planning and Controlpurvik_rathodAinda não há avaliações

- Production Planning and ControlDocumento7 páginasProduction Planning and ControlAbhishek PantAinda não há avaliações

- Production Planning and Control PPC NotesDocumento128 páginasProduction Planning and Control PPC NoteskarthikhindustanAinda não há avaliações

- PRODUCTION PLANNING AND CONTROLPPC Notes PDFDocumento128 páginasPRODUCTION PLANNING AND CONTROLPPC Notes PDFRatna Kommoji100% (2)

- Cadm Assignment No 6 AnkitDocumento11 páginasCadm Assignment No 6 AnkitLowEnd GamerAinda não há avaliações

- EMC 4512 Planning and ControlDocumento14 páginasEMC 4512 Planning and Controlstephen mwendwaAinda não há avaliações

- Unit 2 (OPC)Documento8 páginasUnit 2 (OPC)KANISHK VARDHAN SINGHAinda não há avaliações

- Production Planning and Control (Final)Documento4 páginasProduction Planning and Control (Final)renegades king condeAinda não há avaliações

- CH - 08 - Production Planning-Exam PreDocumento8 páginasCH - 08 - Production Planning-Exam PreK.M. Sabbir NomanAinda não há avaliações

- Material and Procuction Management NotesDocumento68 páginasMaterial and Procuction Management NotesMwanza MaliiAinda não há avaliações

- Production System IsDocumento6 páginasProduction System IsAnjali AgrawalAinda não há avaliações

- Unit - 5 (OPC)Documento7 páginasUnit - 5 (OPC)KANISHK VARDHAN SINGHAinda não há avaliações

- Production Planning and ControlDocumento5 páginasProduction Planning and ControlMahendra BairwaAinda não há avaliações

- Functional Management - Unit - 5: Type Equation HereDocumento8 páginasFunctional Management - Unit - 5: Type Equation Heremisba shaikhAinda não há avaliações

- Functional Management - Unit - 5: Type Equation HereDocumento8 páginasFunctional Management - Unit - 5: Type Equation Heremisba shaikhAinda não há avaliações

- Production Planning and Control: Prepared By, Mr. Nishant AgrawalDocumento52 páginasProduction Planning and Control: Prepared By, Mr. Nishant AgrawalColonel AlbalAinda não há avaliações

- Mb0044 Unit 13 SLMDocumento22 páginasMb0044 Unit 13 SLMamit_idea1100% (2)

- Business OperationsDocumento15 páginasBusiness OperationsManmeet KaurAinda não há avaliações

- Enabliers of BPR IN MANUFACTRING - Production PlanningDocumento8 páginasEnabliers of BPR IN MANUFACTRING - Production Planningneyom bitvooAinda não há avaliações

- Planning Strategic in ProductionDocumento19 páginasPlanning Strategic in ProductionFerdiansyah Iqbal RafandiAinda não há avaliações

- Production PlanningDocumento25 páginasProduction PlanningJosh VictorAinda não há avaliações

- Om0017 Solved AssignmentDocumento13 páginasOm0017 Solved AssignmentAnant KumarAinda não há avaliações

- Unit - 1 PPC KarishmaDocumento6 páginasUnit - 1 PPC KarishmaAkash sinhaAinda não há avaliações

- PPCDocumento12 páginasPPCPardhasaradhi MathiAinda não há avaliações

- Cpim EcoDocumento78 páginasCpim EcoTerrelAinda não há avaliações

- Steps in Production PlanningDocumento12 páginasSteps in Production PlanningriteshvijhAinda não há avaliações

- By: Gerline Mae Ocampo PableoDocumento6 páginasBy: Gerline Mae Ocampo PableoGerline MaeAinda não há avaliações

- Mod 3aDocumento70 páginasMod 3ayashvardhangupta365Ainda não há avaliações

- Cost Management: A Case for Business Process Re-engineeringNo EverandCost Management: A Case for Business Process Re-engineeringAinda não há avaliações

- Purchase Skills QuestionnareDocumento4 páginasPurchase Skills QuestionnarepradeepjvsAinda não há avaliações

- 15 Tax Planning Tips For A.YDocumento6 páginas15 Tax Planning Tips For A.YpradeepjvsAinda não há avaliações

- Key Management - Jan 2012Documento1 páginaKey Management - Jan 2012pradeepjvsAinda não há avaliações

- CRIMP 533 WEI - Pdf504840ccc2d4aDocumento1 páginaCRIMP 533 WEI - Pdf504840ccc2d4apradeepjvsAinda não há avaliações

- Purchase RelatedDocumento2 páginasPurchase RelatedpradeepjvsAinda não há avaliações

- Conformal CoatingDocumento1 páginaConformal CoatingpradeepjvsAinda não há avaliações

- 3G Tariff Plans, Best 3G Plans, Airtel Internet 3G PacksDocumento3 páginas3G Tariff Plans, Best 3G Plans, Airtel Internet 3G PackspradeepjvsAinda não há avaliações

- 40 Outstanding Books On Negotiation - Yahoo! Voices - Voices - YahooDocumento3 páginas40 Outstanding Books On Negotiation - Yahoo! Voices - Voices - YahoopradeepjvsAinda não há avaliações

- 15 Tax Planning Tips For A.YDocumento6 páginas15 Tax Planning Tips For A.YpradeepjvsAinda não há avaliações

- 40 Outstanding Books On Negotiation - Yahoo! Voices - Voices - YahooDocumento3 páginas40 Outstanding Books On Negotiation - Yahoo! Voices - Voices - YahoopradeepjvsAinda não há avaliações

- IMPEX Procedure PDFDocumento174 páginasIMPEX Procedure PDFKrishna SinghAinda não há avaliações

- Aadhar CardDocumento2 páginasAadhar CardpradeepjvsAinda não há avaliações

- Unvf Application Form InstructionsDocumento4 páginasUnvf Application Form InstructionsfieqaAinda não há avaliações

- 5000 TOEFL Words PDFDocumento36 páginas5000 TOEFL Words PDFPrudhveeraj Chegu100% (2)

- P D P: C I D, C M: Design of Coastal RoadsDocumento55 páginasP D P: C I D, C M: Design of Coastal RoadsMohammedAinda não há avaliações

- Final Quiz 2 - Attempt ReviewDocumento6 páginasFinal Quiz 2 - Attempt Reviewkoraijohnson7Ainda não há avaliações

- Rosewood Case AnalysisDocumento5 páginasRosewood Case AnalysisJayant KushwahaAinda não há avaliações

- 12 Logarithm Approximate FloatingDocumento6 páginas12 Logarithm Approximate FloatingPhilippe Englert VelhaAinda não há avaliações

- SRS For Travel AgencyDocumento5 páginasSRS For Travel AgencyHardik SawalsaAinda não há avaliações

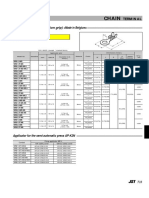

- Chain: SRB Series (With Insulation Grip)Documento1 páginaChain: SRB Series (With Insulation Grip)shankarAinda não há avaliações

- Effective TeachingDocumento94 páginasEffective Teaching小曼Ainda não há avaliações

- 3-A Y 3-B Brenda Franco DíazDocumento4 páginas3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZAinda não há avaliações

- Chapter 5 IppDocumento24 páginasChapter 5 IppRoseann EnriquezAinda não há avaliações

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullDocumento10 páginas(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarAinda não há avaliações

- Charles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)Documento441 páginasCharles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)joan82% (17)

- QAI Golden Pass Fact SheetDocumento2 páginasQAI Golden Pass Fact SheetQatar-America InstituteAinda não há avaliações

- A Detailed Lesson PlanDocumento5 páginasA Detailed Lesson PlanIsaac-elmar Agtarap74% (23)

- UpdateJul2007 3julDocumento10 páginasUpdateJul2007 3julAnshul SinghAinda não há avaliações

- Ionic Bonding Worksheet - Type 1 PracticeDocumento2 páginasIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocumento4 páginas00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahAinda não há avaliações

- S4 Computer Sciences Exercises PDFDocumento2 páginasS4 Computer Sciences Exercises PDFHenriette Desanges UwayoAinda não há avaliações

- Week 1 Familiarize The VmgoDocumento10 páginasWeek 1 Familiarize The VmgoHizzel De CastroAinda não há avaliações

- Ortho TechnologyDocumento196 páginasOrtho Technologyr3doc3Ainda não há avaliações

- VERGARA - RPH Reflection PaperDocumento2 páginasVERGARA - RPH Reflection PaperNezer Byl P. VergaraAinda não há avaliações

- RS-All Digital PET 2022 FlyerDocumento25 páginasRS-All Digital PET 2022 FlyerromanAinda não há avaliações

- General Return Service Agreement (RSA) GuidelinesDocumento2 páginasGeneral Return Service Agreement (RSA) GuidelinesJune Francis AngAinda não há avaliações

- Chrysler CDS System - Bulletin2Documento6 páginasChrysler CDS System - Bulletin2Martin Boiani100% (1)

- Do Now:: What Is Motion? Describe The Motion of An ObjectDocumento18 páginasDo Now:: What Is Motion? Describe The Motion of An ObjectJO ANTHONY ALIGORAAinda não há avaliações

- Speaking RubricDocumento1 páginaSpeaking RubricxespejoAinda não há avaliações

- Lesson Plan 1Documento3 páginasLesson Plan 1api-311983208Ainda não há avaliações

- QF Jacket (Drafting & Cutting) - GAR620Documento15 páginasQF Jacket (Drafting & Cutting) - GAR620abdulraheem18822Ainda não há avaliações

- Nbme NotesDocumento3 páginasNbme NotesShariq AkramAinda não há avaliações

- Derivation Bragg's Snell Law PDFDocumento4 páginasDerivation Bragg's Snell Law PDFVaswati BiswasAinda não há avaliações

- The Determinants of Corporate Dividend PolicyDocumento16 páginasThe Determinants of Corporate Dividend PolicyRutvikAinda não há avaliações

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)