Escolar Documentos

Profissional Documentos

Cultura Documentos

Introduction To Danfoss Pressure Independent Valves - III

Enviado por

James ChanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Introduction To Danfoss Pressure Independent Valves - III

Enviado por

James ChanDireitos autorais:

Formatos disponíveis

Introduction to Danfoss - ABQM

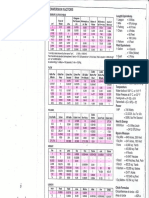

- Pressure Independent Balancing and Control Valves The goal to any HVAC system is clear and simple: to provide a comfortable indoor environment for working and living and to do this with a minimal cost. With the ever rising of materials and labour costs, often Cost Reduction means sacrificing comfort and quality, however with the introduction of Danfoss ABQM will reduce the cost yet the quality of comfort living is not compromised. The Danfoss ABQM Pressure Independent Balancing and Control Valves was introduce less than two years and has since enjoyed significance success evidenced by our ever growing list of projects references and success stories and most of all this product has enjoy the APPROVALS from OWNERS & DEVELOPERS. Danfoss ABQM is capable of providing superb control in hydronic balancing. Consisting of a combination of a control valve and a balancing valve, this two in one valve is to do away the manual balancing valve and the control valves that is once required in the conventional system to limit flows and control temperature. With the use of ABQM, complex calculation during sizing of a two way control valve will be a thing of the past. ABQM only requires the design flow rate of the particular unit which can be easily obtain from the equipment manufacturer. As long as the flow is within the flow range of the valve, the valve can be use. Easy setting procedure on the valve makes it versatile for late changes in design or future systems refitting. Conventional Method requires tedious balancing of the hydronics system which normally takes weeks to months to complete. ABQM is the solution to these tedious and hazardous works. Once the valve is set, no balancing or commissioning is needed, because of its superior design this valve is Pressure Independent thus handling over of individual unit is possible while major renovation is on going and future adaption is possible without the needs to shut down the systems. Conventional Method which requires the use of a shunt to divert overflows of chilled water back to the chiller during part loading. This method causes energy wastage. With DANFOSS ABQM, the system will not have over flow problem in the piping systems thus huge energy bill is saved. Conventional method requires larger sizes valves to be installed at the chillers, risers, pumps and start of every branches, however ABQM is only required at the terminal units such as AHUs and FCUs this will in turn reduce the installation time, materials and capital expenses. This is made possible because of the dynamic modulating membrane integrated in the valve which moves when the pressure in the system varies. ABQM saves energy with or without the use of Variable Speed Drives (VSDs), however, with VSDs, ABQM promises to bring energy-savings to greater heights. With VSDs, ABQM allows for Pump Opimization, a process which reduces pumping frequency with references to the critical unit, yet not compromising the comfort and quality of the environment. BENEFITS of Using DANFOSS Pressure Independent Balancing and Control Valves ABQM: 1) Fewer Products, Lesser Installation, Lesser cost 2) Easy Sizing, No Calculation 3) Set and Forget, No commissioning. 4) Better Comfort, Fewer Complain, Lesser Services. 5) Always right flow no energy wastage. Danfoss ABQM was very well received by local Owners and developers ever since its launch in 2007. Frasers CentrePoint, owner of Project North Point (I & II) in Yishun, has complimented about the energy saving abilities of this product even before the Optimization of pump, they are now proposing to use it in their own headquarter building in Alexandra Point. We have since received a Letter of Compliment from Fraser Centrepoint ever since its first installation in early 2008.

Você também pode gostar

- Conversion FactorsDocumento1 páginaConversion FactorsJames ChanAinda não há avaliações

- Acson-Aircooled ChillerCAT - CWS - 1201 20120612Documento11 páginasAcson-Aircooled ChillerCAT - CWS - 1201 20120612James ChanAinda não há avaliações

- Ventilation WorksheetDocumento14 páginasVentilation WorksheetDeepak JoyAinda não há avaliações

- Cooling Towers4Documento24 páginasCooling Towers4James ChanAinda não há avaliações

- R32 Refrigerant Comparison with R22 and R410ADocumento19 páginasR32 Refrigerant Comparison with R22 and R410AJames Chan100% (1)

- Airflow FormulasDocumento16 páginasAirflow FormulasJames ChanAinda não há avaliações

- Cooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)Documento5 páginasCooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)KaushikAinda não há avaliações

- ACMV Work Method Statement (20151210)Documento18 páginasACMV Work Method Statement (20151210)James Chan100% (1)

- 2014 Span GuidlineDocumento1 página2014 Span GuidlineJames ChanAinda não há avaliações

- Pailing Pressure FittingsDocumento72 páginasPailing Pressure FittingsJames ChanAinda não há avaliações

- Diabetes - How Low Should My Blood Sugar Be? A Guide To Blood Sugar LevelsDocumento6 páginasDiabetes - How Low Should My Blood Sugar Be? A Guide To Blood Sugar LevelsJames ChanAinda não há avaliações

- Weather DataDocumento1 páginaWeather DataJames ChanAinda não há avaliações

- Coil LoadDocumento13 páginasCoil LoadMakarand DeshpandeAinda não há avaliações

- Office 3 - B - Sprinkler Manual PDFDocumento59 páginasOffice 3 - B - Sprinkler Manual PDFabcAinda não há avaliações

- Co 2 Position PaperDocumento6 páginasCo 2 Position PaperMuhammad Faheem ShahbazAinda não há avaliações

- Opening Address by ACEM President Paper 1: Objective ProgrammeDocumento2 páginasOpening Address by ACEM President Paper 1: Objective ProgrammeJames ChanAinda não há avaliações

- Fare Table from Abdullah Hukum Station to Major DestinationsDocumento2 páginasFare Table from Abdullah Hukum Station to Major DestinationsAhmd AlbabAinda não há avaliações

- Uniform Building By-Laws 1984Documento7 páginasUniform Building By-Laws 1984oioian0% (4)

- 27 TDP Cat Int PriceDocumento12 páginas27 TDP Cat Int Pricespotty81100% (3)

- Airflow FormulasDocumento16 páginasAirflow FormulasJames ChanAinda não há avaliações

- Amendment - MS 1525 - 2014 - Prepdf PDFDocumento5 páginasAmendment - MS 1525 - 2014 - Prepdf PDFClaire BernardAinda não há avaliações

- FPA - The Design Guide For The Fire Protection of Buildings 2000Documento320 páginasFPA - The Design Guide For The Fire Protection of Buildings 2000Siva Moorthy100% (1)

- Lecture 2 HvacDocumento1 páginaLecture 2 HvacJames ChanAinda não há avaliações

- VRFDocumento83 páginasVRFapi-25999517100% (6)

- Airflow FormulasDocumento4 páginasAirflow FormulasYoesof HilabyAinda não há avaliações

- Energy Systems of Complex BuildingsDocumento1 páginaEnergy Systems of Complex BuildingsJames ChanAinda não há avaliações

- Cooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)Documento5 páginasCooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)KaushikAinda não há avaliações

- BS6700 Loading UnitDocumento1 páginaBS6700 Loading UnitJames ChanAinda não há avaliações

- Lecture 2 HvacDocumento38 páginasLecture 2 HvacJohn BennettAinda não há avaliações

- C o PDocumento1 páginaC o PJames ChanAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Astm C 639-2001 PDFDocumento3 páginasAstm C 639-2001 PDFzeqs9Ainda não há avaliações

- Multistage Air Compressor FinalDocumento21 páginasMultistage Air Compressor FinalJames TheeAinda não há avaliações

- 50 TMSS 03 R0Documento0 página50 TMSS 03 R0renjithas2005Ainda não há avaliações

- Virtualengine Brochure 2016 Web 20160401Documento2 páginasVirtualengine Brochure 2016 Web 20160401Vusumzi MzimvubuAinda não há avaliações

- Inspection and Test Procedure of SwitchgearDocumento4 páginasInspection and Test Procedure of SwitchgearShahadat HossainAinda não há avaliações

- Sap kr97Documento79 páginasSap kr97tva400% (1)

- Toshiba 13A26 PDFDocumento39 páginasToshiba 13A26 PDFJOMAREYAinda não há avaliações

- ATA24 Bombardier q400 Electrical PowerDocumento85 páginasATA24 Bombardier q400 Electrical PowerAbiyot AderieAinda não há avaliações

- Tundra Navigation InstallDocumento70 páginasTundra Navigation InstallradiobrainAinda não há avaliações

- User Manual RCU Universal Rev01Documento48 páginasUser Manual RCU Universal Rev01Anonymous FGY7goAinda não há avaliações

- OMEGA AIR-Process and Sterile Filtration - EN - 950119Documento12 páginasOMEGA AIR-Process and Sterile Filtration - EN - 950119Junaid AhmedAinda não há avaliações

- Method Statement For Installation of SwitchboardsDocumento5 páginasMethod Statement For Installation of SwitchboardsDimitris NikouAinda não há avaliações

- Pile Soil InteractionDocumento250 páginasPile Soil Interactionnallay1705100% (3)

- IS-216 Queens Boiler Pit Leak RepairDocumento8 páginasIS-216 Queens Boiler Pit Leak RepairShamsherHussainAinda não há avaliações

- Geberit Silent-PP Pipe With One SocketDocumento2 páginasGeberit Silent-PP Pipe With One SocketeneajataganiAinda não há avaliações

- Steel ConstructionDocumento46 páginasSteel ConstructionKhadeeja AslamAinda não há avaliações

- Polyester Partially Oriented Yarn (POY)Documento7 páginasPolyester Partially Oriented Yarn (POY)Dalia MokhmaljeAinda não há avaliações

- Method Statement FOR SIKATOP SEAL 107Documento4 páginasMethod Statement FOR SIKATOP SEAL 107faizbukhariAinda não há avaliações

- Valve Regulated Lead Acid Battery ManualDocumento22 páginasValve Regulated Lead Acid Battery Manualevanelizan100% (1)

- BS 4873 2004 Aluminum Alloy WindowsDocumento18 páginasBS 4873 2004 Aluminum Alloy WindowsJoseph Allan TolentinoAinda não há avaliações

- Masterpact NW-NTDocumento184 páginasMasterpact NW-NTCarito Ahumada100% (1)

- Science Presence of God J2Documento8 páginasScience Presence of God J2Kafui AugustineAinda não há avaliações

- VIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETDocumento7 páginasVIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETAnonymous NUn6MESxAinda não há avaliações

- Xypec Catalog B UVC A MS 9106 R0 DraftDocumento94 páginasXypec Catalog B UVC A MS 9106 R0 DraftJusron MasjhudaAinda não há avaliações

- Sony Dsc-w630 Ver1.1 Level2Documento25 páginasSony Dsc-w630 Ver1.1 Level2Alberto MorenoAinda não há avaliações

- Avant-Garde Mr. K Mohan KumarDocumento46 páginasAvant-Garde Mr. K Mohan KumarSivakumar SelvarajAinda não há avaliações

- Chapter 12 - P-N JunctionDocumento69 páginasChapter 12 - P-N JunctionShelly RismawatiAinda não há avaliações

- Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle ContentDocumento7 páginasPoly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Contentastewayb_964354182Ainda não há avaliações

- Painting Specification for Aegean Refinery ProjectDocumento18 páginasPainting Specification for Aegean Refinery Projectraluca_19735597Ainda não há avaliações

- Tes Praktek Optimizer GoogleDocumento24 páginasTes Praktek Optimizer GooglePramudita BudiantiAinda não há avaliações