Escolar Documentos

Profissional Documentos

Cultura Documentos

MFG CompAge 2013 Su-Final

Enviado por

fritz221Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MFG CompAge 2013 Su-Final

Enviado por

fritz221Direitos autorais:

Formatos disponíveis

The official newsletter of molded fiber glass companies

summer 2013

MFG PRiME Delivers Superior Performance for Structural Applications

Introduced in 2007 by the Molded Fiber Glass Companies, PRiME has become a preferred molding process among OEMs for parts that require high mechanical strength.

PRiME is a proprietary LCM (liquid composite molding) approach that involves specific technologies for compression molding with pre-placed fiber reinforcement. It offers many of the same performance characteristics as compression molding with SMC, and similar cost and volume benefits. The key distinction is PRiMEs superior structural efficiency that improves both mechanical and cosmetic properties of the molded part. This advantage makes it popular for high-volume automotive and truck parts that require greater structural integrity than SMC can provide. Although PRiME has been in use Property PRiME SMC for more than 5 Strength years, the MFG *Minimum Value Higher Research team is *Standard Deviation Lower constantly adding Local Tailoring Yes Limited to the knowledge Density Can be Lower Limited base of how and Toughness (Impact and Hot Strength) Better Good where it can deliver Surface Quality (Waviness) Better Good improved value Part Details to customers. *Ribs No Yes Generally this *Bosses Limited Yes *Molded-in hardware Yes Limited comes about *Molded-in studs No Yes as a result of *Molded-in cores Yes Limited vetting PRiME *Thickness Limited Yes against SMC with Process (Required Molding Pressure) 100500 psig 7001,000 psig actual designs. PRiME is an alternative to SMC compression molding for parts where Recently the team consistent high mechanical (tensile, flexural) strength is important. completed a study evaluating the mechanical property variations of Class A vehicle parts made with PRiME against SMC parts. The result: PRiME parts outperformed the SMC parts stronger, lighter and smoother!

Dave Denny escorting one of the honored veterans in the Iron Mike Rally.

in the community

PRiME & SMC Contrasting Characteristics

MFG Honors Servicemen

In May, MFG participated in the Inaugural Pinehurst Concours DElegance. This first of its kind event at the revered golf resort celebrated three American passions golf, the automobile and the courageous servicemen and women who sacrifice so much for the cause of freedom.

Continued on page 2

MFG Southeast

A new MFG entity MFG Southeast, was launched at the end 2012. Led by Plant Manager Mike Gayford, the Opp, AL based company will primarily focus on light weight, high strength, high-end glass and carbon fiber composite parts for the transportation, water management, construction and renewable energy segments.

Continued on page 2

Because PRiME uses pre-placed reinforcements, the fibers are precisely aligned with the load set of the product, resulting in improved fiber efficiency and lower cost per weight. Use of advanced robotics minimizes the variation in fiber as well as the labor content, further enhancing performance. These factors have been found to expand design allowables and reduce energy costs by up to 50%.

Continued on page 2

Composites Age | Summer 2013

MFG Honors Servicemen, cont.

The three-day event culminated with a judged show pitting cars in 12 classes against one another. Collectors and restorers from across the country applied, but only 118 the age of the Pinehurst Resort were chosen. One of the chosen vehicles was MFGs 1954 Corvette. Executive Vice President Dave Denny was responsible for getting MFG involved and represented the company. During the 3-day event he fielded questions from car enthusiasts and the media about the car on display, how the Corvette came to be, and MFGs role in its development. The kickoff activity was the Iron Mike Rally where the cars made a 70-mile tour from Pinehurst to Ft. Bragg each with a distinguished warrior riding shotgun. Ours was one of 52 vintage cars in the Iron Mike Rally, which culminated in a ceremony and car show for the families of the military. We were honored to have one of the veterans who was wounded in Afghanistan riding along.

MFG PRiME Delivers Superior Performance for Structural Applications, cont.

How does PRiME stack up against SMC?

Dynatup Maximum Load vs. Drop Height

1,400 1,200 1,000 800 600 400 200 0 6 12 18 24 30 35 =45

M A X L O A D

PRIME SMC

Penetration Begins

Penetration Begins

The chart to the left plots the impact energy of PRiME vs SMC. At the various stages of the impact event, PRiME absorbs much more energy than SMC. When comparing the tensile strength of PRiME vs SMC (second chart), the averages are very close for both materials but the range is much tighter for the PRiME part. This is due to more uniform distribution and orientation of the glass fibers. The lower variation allows product designers to use materials very close to their design limits resulting in stronger, lighter and more efficient parts. Chevrolet has been using PRiME for the Corvette since 2007. The PRiME parts reliably meet the essential fiber content and mechanical specifications, yet contain less overall fiber. That makes for lighter, faster Corvettes! To learn more about PRiME and see examples of it in use, visit the MFG website (www.moldedfiberglass. com). There is a dedicated section on PRiME in the section on Processes, and you will find short case studies in the Automotive section under Markets.

Tensile Strength Comparison

17,000 15,000 13,000 11,000 9,000 7,000 5,000 PRIME SMC

EVP Dave Denny being interviewed at the Concours. The 54 Corvette owned by MFG was one of 118 classic automobiles selected for the event.

MFG Southeast, cont.

Mike Gayford has been with MFG since 2011 and brings a strong background in fiber glass manufacturing, including thermoset resin systems, open and closed molding technologies, and tooling. Our ability at MFG SE to produce very large parts from our own high quality production tooling gives us a competitive edge, said Gayford. The new company will report to MFG SVP Dennis Vorse and will become part of the MFG Laminating Group. I am pleased to be part of this motivated team. The various strengths of the companies within our Laminating Group enhance each other, allowing us to grow the business group as a whole, said Vorse.

If youd enjoy seeing some of the gorgeous classic cars at the Concours narrated by Dave, heres a link to an online video: http://www.youtube.com/ watch?v=xnaDZyz7QX8.

Four MFG Leaders Promoted to SVP Positions

In recognition of the strong leadership and management experience they have brought to the MFG business segments they oversee, Peter Emrich, Dennis Vorse, Joe Wilk and David Giovannini were recently promoted to senior vice presidents.

The recent expansion of our business efforts across several divisions has heightened the need to strengthen our top management team, said Richard Morrison, president and CEO. Peter, Dennis, Joe and David are all highly capable, experienced leaders and we expect they will continue to bring growth and profitability to their functional areas. Pete Emrich serves as SVP of Technology at MFG Research Company, where he has spent the last 14 years leading his team to become a highly respected, industry-leading technology resource.

Pete Emrich

New Name for WES Announced at WINDPOWER Show

Name change provides stronger identification with the Molded Fiber Glass Companies and more clearly defines field service offerings.

At the WINDPOWER 2013 show held in Chicago, MFG announced that Wind Energy Services Company (WES) has been officially renamed MFG Energy Services. According to Gary Kanaby, director of sales and marketing for MFG Energy Services, What sets us apart is MFGs deep knowledge of manufacturing blades and other components accumulated over more than 26 years. We are known for being able to handle the most difficult repair jobs providing the best service with the deepest engineering talent. And thats why were growing.

Dennis Vorse

Dennis Vorse serves as SVP overseeing MFG Construction Products, MFG Water Treatment Products, MFG Union City, MFG Southeast and the new MFG Laminating group. In addition to his general management responsibilities, he also guides and coordinates business opportunities for custom, open mold applications. Joe Wilk serves as SVP overseeing MFG North Carolina, MFG de Mexico and MFGs Design Center. He joined the company in 1998 as GM of MFG NC. MFG NC and MFG de Mexico have experienced steady growth under his guidance. Other notable accomplishments include bringing MFG de Mexico from a greenfield startup to full operation.

MFG was well represented at the WINDPOWER show. Pictured at the MFG booth (L to R): Wes Shamp (GM MFG Texas), Richard Morrison (CEO MFG), Rich LaFountain (MFG Texas), Gary Kanaby (Director of Sales/Marketing for MFG Wind and MFG Energy Services), Tom Brazina (GM MFG Energy Services), Greg Tilton (MFG EVP/ COO), Carl LaFrance (Wind Champion).

New Markets

MFG West

Joe Wilk

David Giovannini serves as SVP of MFG Wind where he has responsibility for all wind group operations, including MFG South Dakota, MFG Alabama, MFG Texas, MFG West and MFG Energy Services. He is also leading the David Giovannini new filament winding technology that is coming online in July. Giovannini joined MFG in 2010 as general manager of MFG South Dakota.

MFG West has landed a new contract to manufacture pressurized tanks that meet commercial requirements and have been tested to 150psi. This business win is a first in the area of filtration tanks for the company and according to GM Tony Drake the result of collaborative problemsolving with the customer. MFG Wests strengths in custom design, tooling, fabrication and qualification all played an important part in satisfying the customers vision for their product.

Teammate Alfonso Ramos shows off the pressurized filtration tanks that MFG West has started producing.

MFG CP Shows Off Composites Creativity at World of Concrete

Its common enough for companies to purchase a custom exhibit to show their wares at trade shows. But the teammates at MFG CP took that idea further for the World of Concrete show. As a company that provides out of the box solutions they figured it would be impressive to create a booth using the same innovative thinking, composite materials and processes as they do for customers. The result was a dramatically different, custom-built exhibit using FRP structural elements made by MFG. The booth features four 17-foot fiber glass columns that support oversized branding signage that was visible from anywhere on the exhibit floor. The project team included: MFG CP Operations Manager Jon Alloway, responsible for the booth design; Jane T. Roche of MFG UC, responsible for the booth signage; and the MFG West team who manufactured, shipped and installed the booth.

Brazina Joins MFG Energy Services As New GM

Tom Brazina joined the company in February as general manager reporting to MFG Corporate SVP David Giovaninni. As a well-rounded operations manager in the automotive and heavy equipment industries, Tom has held progressively responsible positions in engineering, product development, material control and production/plant management. His most recent role with Vestas involved site management of multiple large wind farms in Iowa and Oklahoma. Tom has an ideal management experience base in both service and manufacturing operations specifically including oversight of wind farm operations. His proven expertise implementing 5S/6S, Lean, and CrossFunctional Team best practices will support MFG Winds total lifecycle solutions model in many areas as we expand our offerings, reports Giovannini.

Tom Brazina joins MFG ES as general manager.

milestones

standing for excellence

MFG de Mexico Surpasses 50,000 Deliveries for Truck Roofs

In April MFG de Mexico hit a major milestone as the 50,000th roof for a major heavy truck manufacturer rolled off the line. Shown here is the entire crew of teammates from all shifts. The combined effort of this group, including training and support, made this accomplishment possible. Buen trabajo, amigos!

34% of MFG NC Teammates Log Perfect Attendance

MFG North Carolina recently recognized 48 teammates with beautiful fleece jackets for perfect attendance in 2012. Several of those teammates have multiple years of perfect attendance.

Pictured are 20 of the 48 MFG NC teammates with perfect attendance records for 2012. They were recognized and thanked for their contribution by Sr. VP Joe Wilk.

According to Dean Justus, human resources manager at MFG NC, these 48 superstars account for 34% of the team under the companys attendance policy a feat that reflects well on these individuals and the entire company! The measurement for perfect attendance is rigorous. The teammate must clock in within 1 minute of their scheduled start time. We applaud this remarkable achievement and appreciate the example these teammates set for professional discipline and commitment to success.

New Teammates Onboard!

Pat Hawkins Matt Huss

Quality Manager MFG Alabama

Operations Manager MFG Texas

Você também pode gostar

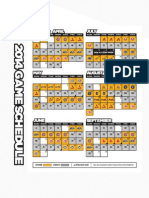

- Pirates Schedule 2014Documento1 páginaPirates Schedule 2014fritz221Ainda não há avaliações

- Basics: Epson Stylus Photo R2000 SeriesDocumento60 páginasBasics: Epson Stylus Photo R2000 Seriesfritz221Ainda não há avaliações

- Environmental Lights CatalogDocumento80 páginasEnvironmental Lights Catalogfritz221Ainda não há avaliações

- How To Write SMART Objectives and SMARTer ObjectivesDocumento32 páginasHow To Write SMART Objectives and SMARTer Objectivesfritz221100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Curriculum BasicskillsDocumento1 páginaCurriculum BasicskillsblllllllllahAinda não há avaliações

- Blood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganDocumento15 páginasBlood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganNokowire TVAinda não há avaliações

- The Roaring TwentiesDocumento17 páginasThe Roaring TwentiesAlexandraNicoarăAinda não há avaliações

- Guia Preguntas IGA (Wizard of Oz)Documento7 páginasGuia Preguntas IGA (Wizard of Oz)Isabella BrollAinda não há avaliações

- Universal Studios Fanfare Arranged by Trey MickelsonDocumento3 páginasUniversal Studios Fanfare Arranged by Trey MickelsonVitor AlexandreAinda não há avaliações

- Onboarding Tool Kit JunDocumento82 páginasOnboarding Tool Kit JunMamatha JayaseelanAinda não há avaliações

- Isfahan TranscriptionDocumento16 páginasIsfahan TranscriptionIñigo Fúster100% (1)

- CrazyTalk Animator 2 Pipeline ManualDocumento796 páginasCrazyTalk Animator 2 Pipeline ManualHữu TâmAinda não há avaliações

- Seed Lab SolutionDocumento11 páginasSeed Lab SolutionMalik ShahidAinda não há avaliações

- Meant To Be MineDocumento37 páginasMeant To Be MineBethany House PublishersAinda não há avaliações

- Unit 1 TEST Test (Z Widoczną Punktacją)Documento6 páginasUnit 1 TEST Test (Z Widoczną Punktacją)Zofia BaranowskaAinda não há avaliações

- Practical Exam For Multimedia Artist ApplicantDocumento3 páginasPractical Exam For Multimedia Artist Applicantcharlescarlos.officeAinda não há avaliações

- Lesson Plan in Contemporary Philippine ADocumento68 páginasLesson Plan in Contemporary Philippine ARonald EstrellaAinda não há avaliações

- LAB 2 PHOTOMODE 70%docxDocumento10 páginasLAB 2 PHOTOMODE 70%docxAiman HaiqalAinda não há avaliações

- Toshiba VTD1552Documento65 páginasToshiba VTD1552thomas-stentzelAinda não há avaliações

- Interpretationoftablewithrrl (May25,2023) (10pm)Documento21 páginasInterpretationoftablewithrrl (May25,2023) (10pm)Laurence Niña X. OrtizAinda não há avaliações

- Shaolin Soccer Movie Review ReportDocumento11 páginasShaolin Soccer Movie Review ReportAsad AttarwalaAinda não há avaliações

- BNI Vision April 2023 Roster BookDocumento16 páginasBNI Vision April 2023 Roster BookTushar MohiteAinda não há avaliações

- Art of The QuickieDocumento123 páginasArt of The QuickieJdalliX83% (6)

- Upgrading The C Class AUDIO 20 System w205Documento14 páginasUpgrading The C Class AUDIO 20 System w205Tudor LiviuAinda não há avaliações

- Wolfe Critical Terms For Science Fiction and FantasyDocumento199 páginasWolfe Critical Terms For Science Fiction and FantasyBezafu100% (3)

- Heather Lee ResumeDocumento1 páginaHeather Lee Resumeheatherlee08Ainda não há avaliações

- Yoohoo Carry Out MenuDocumento2 páginasYoohoo Carry Out MenuYoohoo Chinese0% (1)

- Walking With Miss Millie Readers TheaterDocumento6 páginasWalking With Miss Millie Readers Theaterapi-547921371Ainda não há avaliações

- Penny Is A Golden Retriever Puppy From TexasDocumento2 páginasPenny Is A Golden Retriever Puppy From TexasAlanna MayAinda não há avaliações

- Next3d Offer A4Documento27 páginasNext3d Offer A4apo JacobsAinda não há avaliações

- Active Voice Passive Voic 2796896Documento25 páginasActive Voice Passive Voic 2796896cristhianjosevelascoAinda não há avaliações

- Paket A: Kabupaten GunungkidulDocumento20 páginasPaket A: Kabupaten GunungkidulTrianita Syanata MadjidAinda não há avaliações

- Interim CatalogueDocumento90 páginasInterim CatalogueMorne BotesAinda não há avaliações

- Rules With No NameDocumento27 páginasRules With No NameTudor IliescuAinda não há avaliações