Escolar Documentos

Profissional Documentos

Cultura Documentos

RC04 Bending2

Enviado por

sofianina05Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RC04 Bending2

Enviado por

sofianina05Direitos autorais:

Formatos disponíveis

Strength of Rectangular Section in Bending

4

4

Location of Reinforcement

Behavior of Beam under Load

Beam Design Requirements

Working Stress Design (WSD)

Practical Design of RC Beam

Reinforced Concrete Design

Reinforced Concrete Design

Asst.Prof.Dr.Mongkol JIRAVACHARADET

S U R A N A R E E

UNIVERSITY OF TECHNOLOGY

INSTITUTE OF ENGINEERING

SCHOOL OF CIVIL ENGINEERING

Location of Reinforcement

Location of Reinforcement

Simply supported beam Simply supported beam

Concrete cracks due to tension, and as a result, reinforcement i Concrete cracks due to tension, and as a result, reinforcement is required s required

where flexure, axial loads, or shrinkage effects cause tensile s where flexure, axial loads, or shrinkage effects cause tensile stresses. tresses.

tensile stresses and cracks are

developed along bottom of the beam

BMD

longitudinal reinforcement is placed

closed to the bottom side of the beam

Positive

Moment

Location of Reinforcement

Location of Reinforcement

Cantilever beam

- Top bars

- Ties and anchorage

to support

Continuous beam Continuous beam

Location of Reinforcement

Location of Reinforcement

Location of Reinforcement

Location of Reinforcement

Continuous beam with 2 spans

Figure B-13 : Reinforcement Arrangement for Suspended Beams

Figure B-14 : Reinforcement Arrangement for

Suspended Cantilever Beams

Behavior of Beam under Load

Working Stress Condition

s

c

f f <

c

T = A

s

f

s

C

w

L

c

2.0

r c

f f f < =

c

f f <

Elastic Bending (Plain Concrete)

c

s y

<

T = A

s

f

s

C

Brittle failure mode

s y

f f <

s y

T = A

s

f

s

C

Ductile failure mode

s y

f f =

Crushing

cu

= 0.003

c

< 0.003

Beam Design Requirements

1) Minimum Depth (for deflection control)

oneway

slab

L/24 L/28 L/10 L/20

BEAM L/18.5 L/21 L/8 L/16

2) Temperature Steel (for slab)

A

s

t

b

SR24: A

s

= 0.0025 bt

SD30: A

s

= 0.0020 bt

SD40: A

s

= 0.0018 bt

f

y

> 4,000 ksc: A

s

= 0.0018 4,000 bt

f

y

3) Minimum Steel (for beam)

A

s

A

s min

= 14 / f

y

To ensure that steel not fail before first crack

5) Bar Spacing

> 4/3 max. aggregate size

4) Concrete Covering

.+.

stirrup

.+.v+.

Durability and Fire protection

WSD of Beam for Moment

Assumptions:

1) Section remains plane

2) Stress proportioned to Strain

3) Concrete not take tension

4) No concrete-steel slip

Modular ratio (n):

6

2.04 10 134

15,100

s

c

c c

E

n

E

f f

= =

Effective Depth (d) : Distance from compression face to centroid of steel

d

d

compression face

b

kd

c

s

s s

s s s

T A f

f E

=

=

N.A.

c c c

f E =

C

jd

Cracked transformed section

strain condition force equilibrium

Equilibrium F

x

= 0 :

Compression = Tension

1

2

c s s

f b kd A f =

Compression in concrete:

1

2

c

C f b kd =

Tension in steel:

s s

T A f =

s s

s s s

T A f

f E

=

=

N.A.

c c c

f E =

C

jd

kd

Reinforcement ratio: /

s

A bd =

2

c

s

f

f k

= 1

Strain compatibility:

1

/

/ 1

1

c

s

c c

s s

c

s

kd k

d kd k

f E k

f E k

f k

n

f k

= =

=

2

d

kd

c

Analysis: know find k 1 2

( )

2

2 k n n n = +

Design: know f

c

, f

s

find k 2

1

1

c

s

c s

c

n f

k

f

n f f

n f

= =

+

+

Example 3.1: = 150 ksc , f

s

= 1,500 ksc

c

f

134

10.94 10 (nearest integer)

150

0.375(150) 56 ksc

1

0.2515

1, 500

1

9(56)

c

n

f

k

= =

= =

= =

+

Allowable Stresses

2

0.33 60 kg/cm

c c

f f

=

Plain concrete:

SR24: f

s

= 0.5(2,400) = 1,200 ksc

SD30: f

s

= 0.5(3,000) = 1,500 ksc

SD40, SD50: f

s

= 1,700 ksc

Steel:

2

0.375 65 kg/cm

c c

f f

=

Reinforced concrete:

Resisting Moment

M

T = A

s

f

s

jd

kd/3

1

2

c

C f k bd =

Moment arm distance : j d

3

kd

jd d =

1

3

k

j =

Steel:

s s

M T jd A f jd = =

Concrete:

2 2

1

2

c

M C jd f k j bd Rbd = = =

1

2

c

R f k j =

Design Step: known M, f

c

, f

s

, n

1) Compute parameters

1

1

s c

k

f n f

=

+

1 / 3 j k =

1

2

c

R f k j =

45

50

55

60

65

f

c

(kg/cm

2

)

R (kg/cm

2

)

f

s

=1,200

(kg/cm

2

)

f

s

=1,500

(kg/cm

2

)

f

s

=1,700

(kg/cm

2

)

6.260

7.407

8.188

9.386

10.082

n

12

12

11

11

10

5.430

6.463

7.147

8.233

8.835

4.988

5.955

6.587

7.608

8.161

Design Parameter k and j

45

50

55

60

65

f

c

(kg/cm

2

)

f

s

=1,200

(kg/cm

2

)

f

s

=1,500

(kg/cm

2

)

f

s

=1,700

(kg/cm

2

)

0.310

0.333

0.335

0.355

0.351

n

12

12

11

11

10

k j

0.897

0.889

0.888

0.882

0.883

0.241

0.261

0.262

0.280

0.277

k j

0.920

0.913

0.913

0.907

0.908

k j

0.265

0.286

0.287

0.306

0.302

0.912

0.905

0.904

0.898

0.899

1) For greater f

s

, k becomes smaller smaller compression area

2) j 0.9 moment arm j d 0.9d can be used in approximation

design.

2) Determine size of section bd

2

Such that resisting moment of concrete M

c

= R b d

2

Required M

Usually b d / 2 :

b = 10 cm, 20 cm, 30 cm, 40 cm, . . .

d = 20 cm, 30 cm, 40 cm, 50 cm, . . .

3) Determine steel area

s s s

s

M

M A f jd A

f j d

= =

From

4) Select steel bars and Detailing

o+.++n o.+ .vannv+o.nao.a.ro+r++v.v.av, zr.

a

Bar Dia.

Number of Bars

1 2 3 4 5 6

RB6

RB9

DB10

DB12

DB16

DB20

DB25

0.283

0.636

0.785

1.13

2.01

3.14

4.91

0.565

1.27

1.57

2.26

4.02

6.28

9.82

0.848

1.91

2.36

3.53

6.03

9.42

14.73

1.13

2.54

3.14

4.52

8.04

12.57

19.63

1.41

3.18

3.93

5.65

10.05

15.71

24.54

1.70

3.82

4.71

6.79

12.06

18.85

29.45

o+.++n o.c o.+raovaanara+o+vo+rr+o.+v ei

Member

One-way slab

Beam

Simple

supported

One-end

continuous

Both-ends

continuous

Cantilever

L/20

L/16

L/24

L/18.5

L/28

L/21

L/10

L/8

L = span length

For steel with f

y

not equal 4,000 kg/cm

2

multiply with 0.4 + f

y

/7,000

Example 3.2: Working Stress Design of Beam

w = 4 t/m

5.0 m

Concrete: f

c

= 65 kg/cm

2

Steel: f

s

= 1,700 kg/cm

2

From table: n = 10, R = 8.161 kg/cm

2

Required moment strength M = (4) (5)

2

/ 8 = 12.5 t-m

Recommended depth for simple supported beam:

d = L/16 = 500/16 = 31.25 cm

USE section 30 x 50 cm with steel bar DB20

d = 50 - 4(covering) - 2.0/2(bar) = 45 cm

Moment strength of concrete:

M

c

= R b d

2

= 8.161 (30) (45)

2

= 495,781 kg-cm

= 4.96 t-m < 12.5 t-m NG

TRY section 40 x 80 cm d = 75 cm

M

c

= R b d

2

= 8.161 (40) (75)

2

= 1,836,225 kg-cm

= 18.36 t-m > 12.5 t-m OK

Steel area:

2

5

cm 8 . 10

75 908 . 0 700 , 1

10 5 . 12

=

= =

jd f

M

A

s

s

Select steel bar 4DB20 (A

s

= 12.57 cm

2

)

Alternative Solution:

From M

c

= R b d

2

= required moment M

b R

M

d

R

M

d b = =

2

For example M = 12.5 t-m, R = 8.161 ksc, b = 40 cm

cm 88 . 61

40 161 . 8

10 5 . 12

5

=

= d

USE section 40 x 80 cm d = 75 cm

Revised Design due to Self Weight

From selected section 40 x 80 cm

Beam weight w

bm

= 0.4 0.8 2.4(t/m

3

) = 0.768 t/m

Required moment M = (4 + 0.768) (5)

2

/ 8 = 14.90 < 18.36 t-m OK

Revised Design due to Support width

5.0 m span

30 cm 30 cm

Column width 30 cm

4.7 m clear span

Required moment:

M = (4.768) (4.7)

2

/ 8

= 13.17 t-m

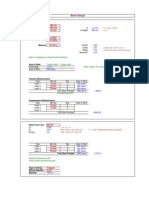

Practical Design of RC Beam

B1 30x60 Mc = 8.02 t-m, Vc = 6.29 t.

fc = 65 ksc, fs = 1,500 ksc, n = 10

k = 0.302, j = 0.899, R = 8.835 ksc

b = 30 cm, d = 60 - 5 = 55 cm

Mc = 8.835(30)(55)

2

/10

5

= 8.02 t-m

Vc = 0.29(173)

1/2

(30)(55)/10

3

= 6.29 t

w = 2.30 t/m

5.00

Load

dl 0.43

wall 0.63

slab 1.24

w 2.30

M

= (1/9)(2.3)(5.0)

2

= 6.39 t-m

As

= 6.3910

5

/(1,5000.89955)

= 8.62 cm

2

As

= 8.62 cm

2

(2DB25)

V = 5.75 t (RB9@0.20 St.)

B2 40x80 Mc = 19.88 t-m, Vc = 11.44 t.

w = 2.64 t/m

8.00 5.00

w = 2.64 t/m

SFD

8.54 9.83

12.58 3.37

BMD

+13.81

-16.17

+2.15

As

13.65

4DB25

2.13

3DB25

15.99

2DB25

GRASP Version 1.02

B11-B12

-47.73 69.70 0.00 81.47 -92.25 6

-52.61 31.27 -92.25 6.59 -28.26 5

-38.92 44.96 -28.26 25.88 -46.35 4

-43.34 40.54 -46.35 20.75 -37.97 3

-39.36 44.52 -37.97 17.36 -53.42 2

-50.84 33.04 -53.42 39.03 0 1

Fy.j [Ton] Fy.i [Ton] Mz.j [T-m] Mz.pos [T-m] Mz.i [T-m]

Membe

r

Analysis of RC Beam

Given: Section A

s

, b, d Materials f

c

, f

s

Find: M

allow

= Moment capacity of section

STEP 1 : Locate Neutral Axis (kd)

( ) n n n k + =

2

2

3 / 1 k j =

where

ratio ent Reinforcem = =

bd

A

s

6

2.04 10 134

15,100

s

c

c c

E

n

E

f f

= =

STEP 2 : Resisting Moment

Concrete:

2

2

1

d b j k f M

c c

=

Steel:

d j f A M

s s s

=

If M

c

> M

s

, Over reinforcement M

allow

= M

s

If M

c

< M

s

, Under reinforcement M

allow

= M

c

Under reinforcement is preferable because steel is weaker

than concrete. The RC beam would fail in ductile mode.

Example 3.3 Determine the moment strength of beam

4 DB 20

A

s

= 12.57 cm

2

80 cm

40 cm

f

c

= 65 ksc, f

s

= 1,700 ksc,

n = 10, d = 75 cm

0419 . 0 , 00419 . 0

75 40

57 . 12

= =

= = n

bd

A

s

916 . 0 3 / 251 . 0 1 251 . 0

0419 . 0 ) 0419 . 0 ( 0419 . 0 2

2

= = =

+ =

j

k

M

c

= 0.5(65)(0.251)(0.916)(40)(75)

2

/10

5

= 16.81 t-m

M

s

= (12.57)(1,700)(0.916)(75)/10

5

= 14.68 t-m (control)

Double Reinforcement

When M

reqd

> M

allow

- Increase steel area

- Enlarge section

- Double RC

only when no choice

c

M

T = A

s

f

s

C = f

c

k b d

1

2

A

s

A

s

s

d

T = A

s

f

s

A

s1

f

s

A

s2

f

s

vaavnvv+uva aauau+a +a.uau+a

T = A

s

f

s

C = f

c

kbd

1

2

T = A

s

f

s

T

1

= A

s1

f

s

C = f

c

kbd

1

2

T

2

= A

s2

f

s

T = A

s

f

s

jd

d-d

2

1

1

1

2

c c

s s

M M f kjbd

A f jd

= =

=

2

2

( )

( )

c

s s

s s

M M M

A f d d

A f d d

=

=

=

Steel area A

s

=

1

c

s

s

M

A

f jd

= +

2

( )

c

s

s

M M

A

f d d

M = M

1

+ M

2

Moment strength

Compatibility Condition

c

d

d

kd

s

s

s

d kd

kd d

From Hooks law:

s

= E

s

f

s

,

s

= E

s

f

s

s s s

s s s

E f f d kd

E f f kd d

= =

1

s s

k d d

f f

k

. .a!!-

2

1

s s

k d d

f f

k

Jaua au+a ( A

s

:

T

2

= A

s2

f

s

T = A

s

f

s

d-d

Force equilibrium [ F

x

=0 ]

T = T

2

A

s

f

s

= A

s2

f

s

Substitute

2

1

s s

k d d

f f

k

2

1 1

2

s s

k

A A

k d d

auv+va.nv ( k :

c

d

d

kd

s

Compression = Tension

c s

C C T

+ =

1

2

c s s s s

f bkd A f A f

+ =

Substitute 2 ,

1

s

s s

A k d d

f f

k bd

= =

1

,

s

s c

A k

f n f

k bd

= =

( ) ( )

2

2

2 2 2 2

d

k n n n

d

= + + + +

Example 3.4 Design 40x80 cm beam using double RC

f

c

= 65 ksc, f

s

= 1,700 ksc,

n = 10, d = 75 cm

k = 0.277, j = 0.908, R = 8.161 ksc

w = 6 t/m

5.0 m

Required M = (6.768) (5)

2

/ 8 = 21.15 t-m

Beam weight w

bm

= 0.4 0.8 2.4(t/m

3

) = 0.768 t/m

M

c

= Rbd

2

= 8.161(40)(75)

2

/10

5

= 18.36 t-m < reqd M Double RC

5

2

1

18.36 10

15.86 cm

1, 700 0.908 75

c

s

s

M

A

f jd

= = =

5

2

2

(21.15 18.36) 10

2.34 cm

( ) 1, 700 (75 5)

c

s

s

M M

A

f d d

= = =

Tension steel A

s

= A

s1

+ A

s2

= 15.86 + 2.34 = 18.20 cm

2

USE 6DB20 (A

s

= 18.85 cm

2

)

Compression steel

2

2

1 1 1 1 0.277

2.34 4.02 cm

2 2 0.277 5/ 75

s s

k

A A

k d d

= = =

USE 2DB20 (A

s

= 6.28 cm

2

)

6DB20

2DB20

0

.

8

0

m

0.40 m

\.: . ......

s s

Você também pode gostar

- O level Physics Questions And Answer Practice Papers 2No EverandO level Physics Questions And Answer Practice Papers 2Nota: 5 de 5 estrelas5/5 (1)

- Lecture 2 Beams - Concrete CenterDocumento99 páginasLecture 2 Beams - Concrete Centerwanksta67Ainda não há avaliações

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesAinda não há avaliações

- Slab On GradeDocumento105 páginasSlab On Gradevijaystructural100% (6)

- Beam Practical Design To Eurocode 2 - Sep 2013Documento105 páginasBeam Practical Design To Eurocode 2 - Sep 2013jrandeep100% (2)

- ch1 1Documento75 páginasch1 1Mohammed Al-HelayelAinda não há avaliações

- Dynamic Damage and FragmentationNo EverandDynamic Damage and FragmentationDavid Edward LambertAinda não há avaliações

- Practical Design To Eurocode 2: Outline - Week 4Documento46 páginasPractical Design To Eurocode 2: Outline - Week 4maminu1Ainda não há avaliações

- A1 - Composite Beam PDFDocumento6 páginasA1 - Composite Beam PDFNaim YaqeenAinda não há avaliações

- Structural Design For Low Rise BuildingDocumento42 páginasStructural Design For Low Rise BuildingMohammed SumerAinda não há avaliações

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityAinda não há avaliações

- Answer For Question 4 Structural DesignDocumento16 páginasAnswer For Question 4 Structural DesignFaizalhizam NoordinAinda não há avaliações

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysNo EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysNota: 1 de 5 estrelas1/5 (1)

- 6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsDocumento17 páginas6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsMuhammadAboubakarFarooqAinda não há avaliações

- Allowable Stress Design: BD A E E NDocumento14 páginasAllowable Stress Design: BD A E E NyhproAinda não há avaliações

- Lesson 6Documento12 páginasLesson 6Zayyan RomjonAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- BS-5950-90 Example 001Documento7 páginasBS-5950-90 Example 001Win ThanAinda não há avaliações

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationAinda não há avaliações

- 11 DesignBeamDocumento31 páginas11 DesignBeamRohith SasidharanAinda não há avaliações

- Tutorial 7 - Connections - Part ADocumento28 páginasTutorial 7 - Connections - Part ACyrus HongAinda não há avaliações

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Topic 6-Beam DesignDocumento73 páginasTopic 6-Beam DesignShahrul Syazwan SalimAinda não há avaliações

- Materials Data for Cyclic Loading: Low-Alloy SteelsNo EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsNota: 5 de 5 estrelas5/5 (2)

- 03 1 Weynand Moment Resistant JointsDocumento71 páginas03 1 Weynand Moment Resistant Jointsdeepak_dce_meAinda não há avaliações

- Elementos de Concreto ArmadoDocumento41 páginasElementos de Concreto ArmadoVictor Rene H. R.Ainda não há avaliações

- Concrete Beam Design Flow ChartDocumento16 páginasConcrete Beam Design Flow Chartdicktracy11Ainda não há avaliações

- O level Physics Questions And Answer Practice Papers 3No EverandO level Physics Questions And Answer Practice Papers 3Nota: 3 de 5 estrelas3/5 (1)

- Deep BeamDocumento8 páginasDeep BeamShashikant Gaur0% (1)

- O level Physics Questions And Answer Practice Papers 1No EverandO level Physics Questions And Answer Practice Papers 1Nota: 3.5 de 5 estrelas3.5/5 (4)

- Calculation of Column Reinforcement Area According To en 1992Documento6 páginasCalculation of Column Reinforcement Area According To en 1992Florian EsnaultAinda não há avaliações

- Structures NontesDocumento41 páginasStructures Nontesdtl projectAinda não há avaliações

- Assignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic DesignDocumento11 páginasAssignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic DesignMai OthmanAinda não há avaliações

- CSA S16 09 Example 001Documento7 páginasCSA S16 09 Example 001thanzawtun1981Ainda não há avaliações

- Steel Beam DesignDocumento26 páginasSteel Beam DesignWazini D. Izani100% (1)

- Design of Slab - One Way Slab Design Learn Everything - CivilDocumento14 páginasDesign of Slab - One Way Slab Design Learn Everything - Civilutsavthaker2541Ainda não há avaliações

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous 9iK0i8h0dPAinda não há avaliações

- RCC Design SheetsDocumento40 páginasRCC Design SheetsIbrahim El SharAinda não há avaliações

- Beam & Colum Design - CE 161Documento198 páginasBeam & Colum Design - CE 161Feigyl MiroAinda não há avaliações

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous nwByj9L100% (2)

- Concrete DesignDocumento169 páginasConcrete DesignabuzahrauAinda não há avaliações

- OHSRDocumento48 páginasOHSRsachingadage100% (2)

- Tied and Spiral ColumnsDocumento8 páginasTied and Spiral ColumnsChristian Kerr Dela CernaAinda não há avaliações

- L12 Bolt Connection 2Documento17 páginasL12 Bolt Connection 2Kidus KidaneAinda não há avaliações

- Crack WidthDocumento2 páginasCrack Widthnagaraju-rachamadugu-275185% (13)

- NOTES SeviceabilityDocumento81 páginasNOTES Seviceabilitydileep 443Ainda não há avaliações

- Influence of Steel Fibres in Steel Fibre Reinforced Concrete On ULS and SLSDocumento7 páginasInfluence of Steel Fibres in Steel Fibre Reinforced Concrete On ULS and SLSErick Martinez OrunaAinda não há avaliações

- Fa D F B: Example 1Documento19 páginasFa D F B: Example 1Sevet Gnow DrachirAinda não há avaliações

- Punching of Flat Slabs: Design Example: Fib Model Code 2010Documento13 páginasPunching of Flat Slabs: Design Example: Fib Model Code 2010Bhagirath JoshiAinda não há avaliações

- Column Design Examples EBCSDocumento7 páginasColumn Design Examples EBCSMesfin Derbew89% (28)

- Manual For Design and Detailing of RCCDocumento340 páginasManual For Design and Detailing of RCCimranmehfoozAinda não há avaliações

- Working Drawings 11.11.14Documento31 páginasWorking Drawings 11.11.14Cristhianares Lonjawon OboLight100% (1)

- Chapter1 0 PDFDocumento22 páginasChapter1 0 PDFNeeraj DubeyAinda não há avaliações

- Ram Connection Data SheetDocumento2 páginasRam Connection Data SheetRubén MenaAinda não há avaliações

- Plumbing Terms & GlossaryDocumento26 páginasPlumbing Terms & GlossaryNick GeneseAinda não há avaliações

- Master Plumber CODE OF ETHICSDocumento1 páginaMaster Plumber CODE OF ETHICSTonet Paredes100% (1)

- Board of Master Plumber-SBDocumento7 páginasBoard of Master Plumber-SBdereckaAinda não há avaliações

- Mathcad - One Way SlabDocumento3 páginasMathcad - One Way SlabCristhianares Lonjawon OboLightAinda não há avaliações

- Safe RC DesignDocumento304 páginasSafe RC DesignCharmaine SumadicAinda não há avaliações

- Caltech Basics.. SampleDocumento5 páginasCaltech Basics.. SampleCristhianares Lonjawon OboLightAinda não há avaliações

- Chapter 3 FinalDocumento20 páginasChapter 3 Finaldavid8055Ainda não há avaliações

- Flexural Safety Cost of Optimized Reinforced Concrete BeamsDocumento21 páginasFlexural Safety Cost of Optimized Reinforced Concrete BeamsIAEME PublicationAinda não há avaliações

- C WSF 2012 Showalter ConnectionsDocumento30 páginasC WSF 2012 Showalter ConnectionskinzienikolAinda não há avaliações

- 'time') ' Hence The Term "Mass-Energy Equivalence"Documento22 páginas'time') ' Hence The Term "Mass-Energy Equivalence"Cristhianares Lonjawon OboLightAinda não há avaliações