Escolar Documentos

Profissional Documentos

Cultura Documentos

ISSN 2249-8516 Original Article Properties of Industrial Fractions of Sesame Seed (Sesamum Indicum L.)

Enviado por

getsweetDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ISSN 2249-8516 Original Article Properties of Industrial Fractions of Sesame Seed (Sesamum Indicum L.)

Enviado por

getsweetDireitos autorais:

Formatos disponíveis

Available online at http://www.urpjournals.

com

International Journal of Agricultural and Food Science

Universal Research Publications. All rights reserved

ISSN 2249-8516 Original Article Properties of industrial fractions of sesame seed (Sesamum indicum L.)

Anil Bukya and T.Poongodi Vijayakumar* Department of Food Science and Nutrition, Periyar University, Periyar Palkalai Nagar, Salem-636011, TamilNadu, India *Corresponding author: Dr.T.Poongodi Vijayakumar, Assistant Professor, Department of Food Science and Nutrition, Periyar University, Periyar Palkalai Nagar, Salem-636011, TamilNadu, India Email: poonvija@gmail.com Received 19 June 2013; accepted 14 July 2013 Abstract Whole sesame seed (WSS) was extracted for its oil using grinding press and defatted using hexane as solvent to obtain sesame cake (SC) and fully defatted sesame flour (DSF) respectively. The seed, cake and defatted flour as oil extraction industrial fractions were determined for its physical, functional, thermal properties and proximate composition to study the quality changes on industrial processing of sesame seed. Sesame cake showed significantly (p<0.05) low bulk density and greater porosity than whole seed and defatted flour. On removing fat, water holding and oil holding capacity of sesame flour were increased significantly at p<0.01. Foaming capacity was high for whole seed flour and at pH 8. The buffering capacity of defatted sesame flour was greater in alkaline medium than in acidic medium. Whole sesame seed consists of 18.3 g% of protein while defatted sesame seed flour contains 47.28 g% of protein. The thermal degradation temperature was increased on removal of fat. Sesame cake was further processed to remove the traces of oil and solvent if any and utilized as a low-cost composite flour component for supplementary food preparation. 2013 Universal Research Publications. All rights reserved Keywords: Whole sesame seed (WSS), Sesame cake (SC), Defatted sesame flour (DSF), Proximate composition, Physical, Functional, Thermal properties 1. Introduction Sesame (Sesamum indicum L.) is a short duration crop grown throughout the year which belongs to the family pedaliaceae. It is called as Queen of oil seeds because of its excellent qualities of the seed, oil and meal. Sesame is one of the most important oilseed crops, cultivated in India, Sudan, China and Burma, which are the major sesameproducing countries, contributing to 60% of the global yield [1]. Sesame seed contains 50% of oil and 25% of protein [2]. Brown or black seeded are valued more for oil extraction, whereas white seeded are rich in iron. Sesame seeds are digestive, rejuvenative, antiaging and rich in vitamins E, A and B complex and minerals like calcium, phosphorus, iron, copper, magnesium, zinc and potassium. The oil rich in linoleic acid can be readily hydrogenated to medium melting fats for use in margarines, shortenings and vanaspathi, make the sesame nearly perfect food [3]. The sesame meal or cake is by-product after oil extraction. The defatted sesame meal is good source of nutrients, containing approximately 50% protein. One of the principal characteristics of this protein is its high methionine and tryptophan content [4] that distinguishes sesame from other oil seeds. This meal has high potential for use as a protein source or as an ingredient in the food industry. For plant proteins to be useful and successful in food application, they should ideally possess several desirable characteristics, referred to as functional properties, as well as providing essential amino acids [5]. Few studies have been done on the characterisation of sesame seed and proteins from defatted sesame meal [6]. Thus it is very important to explore functional potentiality and fundamental knowledge on properties of whole sesame seed and by products from oil industry. The present study was aimed to explore the characteristics of whole sesame seed, de-oiled cake and fully defatted sesame flour. 2. Materials and Methods 2.1 Materials Whole sesame seed (WSS) were purchased from supermarket at Salem, TamilNadu, India. Seeds were thoroughly cleaned to free them from dirt, foreign matter, stubble, mould, rot and other infestation, washed with water and sundried. Sesame cake (SC) was obtained by extracting the oil from the whole sesame seed in an oil mill (traditional press method), solar dried and milled into flour. To obtain fully defatted sesame flour (DSF), sesame cake was repeatedly extracted with -hexane till the fat content reduced to less than 0.05 %.

86

International Journal of Agricultural and Food Science 2013, 3(3): 86-89

Fig.1. Foaming capacity of whole sesame seed, sesame cake and defatted sesame flour Fig.3. DSC thermogram of WSS, SC and DSF WSS-Whole Sesame Seed, SC-Sesame Cake, DSFDefatted Sesame Flour 2.2 Methods 2.2.1 Physical properties Bulk density (g/ml) [5] and true density (g/ml) [7] of all samples were determined; porosity was calculated from bulk density and true density according to the formula indicated by Thompson and Isaac [8].

Fig.2. Buffer capacity of defatted sesame flour

Table 1. Physical and functional properties of WSS, SC and DSF Properties WSS Bulk density ( g/ml) True density (g/ml) Porosity (%) WHC (%) 0.763 0.01 1.05 0.12

a a

SC 0.67 0.00 1.10 0.00

b b

DSF 0.70 0.00c 1.11 0.00b 36.22 0.00c 234.70 1.09a

27.33 0.20a 65.236 1.895c

39.5 0.25b 84.11 1.01b

FAC (%) 70.533 1.08c 150.42 0.73b 181.61 2.66a WSS-Whole Sesame Seed, SC-Sesame Cake, DSF-Defatted Sesame Flour, WHC-Water Holding Capacity, FAC- Fat Absorption Capacity. Table 2. Proximate composition of WSS, SC and DSF Nutrients WSS (Gopalan et al [27] WSS Moisture (g %) 5.3 5.18 0.86b Fat (g %) 43.3 44.53 0.6a Protein (g %) 18.3 18.30 0.14c Crude Fiber (g %) 2.9 3.67 0.15a Ash (g %) 5.2 4.13 0.7c Carbohydrate (g %) 25 24.19 0.72c WSS-Whole Sesame Seed, SC-Sesame Cake, DSF-Defatted Sesame Flour Thermal Degradation Temperature To 137.5 12.6a 146.4 2.12a 155.0 0.64a Tp 168.5 4.8a 174.8 2.55a 178.4 3.04a Tc 182.15 4.60a 185.10 1.98a 187.75 3.32a SC 7.8 0.8a 0.76 0.4b 44.51 0.73b 2.36 0.2c 9.18 0.6a 35.39 0.95a DSF 4.06 0.3c 0.05 0.02c 47.28 0.25a 2.45 0.16b 8.68 0.43b 37.48 0.6b

Table 3. Onset, peak, conclusion thermal degradation temperature and enthalpy of degradation of WSS, SC and DSF Sample WSS SC DSF Enthalpy H (J/g) 1.47 0.39a 1.57 0.06a 1.19 0.01a

WSS-Whole Sesame Seed, SC-Sesame Cake, DSF-Defatted Sesame Flour; Values are the average of two determinants. To Onset temperature (C), Tp Peak temperature (C), T c Conclusion temperature (C)

87

International Journal of Agricultural and Food Science 2013, 3(3): 86-89

2.2.2 Functional properties Water holding capacity (WHC) (%) [9], fat absorption capacity (FAC) (%) [9], foaming capacity (%) [10], foaming stability (%) [10] and buffering capacity [11] were determined as functional properties of WSS, SC and DSF. 2.2.3 Proximate composition Moisture by hot air oven method [12], protein by microkjeldhal method [13], fat by soxhlet method [13], ash by gravimetric method [12], crude fibre by acid and alkali digestion method [13] and total carbohydrate by difference method [14] were determined. 2.2.4 Thermal properties Differential Scanning Calorimetry (DSC 6220 SII model, Japan) was used to determine thermal denaturation characteristics of WSS, SC and DSF [15]. The sample was mixed with distilled water at 10% in hermetically sealed aluminium container, sealed and kept at room temperature for one hour to equilibrate the sample with water. The sample was heated in DSC from 30C to 200C at the rate of 10C/min. The deionised water (10 mg) was used as reference. Onset, peak and conclusion thermal degradation temperatures (C), enthalpy of degradation (H in J/g) were noted to describe thermal nature of samples. 2.2.5 Statistical analysis All determinations were done in triplicate. The data were analyzed using one way analysis of variance (ANOVA) and means were compared by Duncan multiple range test (DMRT) with mean square error at 5% probability using SPSS 17.0. 3. Results and Discussion 3.1 Physical properties Determining the physical properties of food is of high significance as they reflect the interaction between the components, structure, confirmation, physicochemical properties, and nature of the environment or the food matrix [16]. Bulk density of WSS was significantly (p<0.01) greater than SC and DSF (Table 1). The bulk density depends on the combined effects of interrelated factors such as the intensity of attractive inter particle forces, particle size, and number of contact points [17]. The high porosity of SC revealed higher rate of autooxidation than WSS and DSF. Higher porosity resulted in greater contact with atmospheric oxygen thereby higher rate of auto-oxidation [18]. Thus SC was more deteriorative than fully DSF and WSS. 3.2 Functional properties Water and oil holding capacity of DSF was significantly greater than WSS and SC (Table 2). It has been reported that DSF exhibits poor WHC compared to that of defatted groundnut cake (306.67 %) [19] and soy protein isolates (289 %) [20]. The higher protein content in the flour might be responsible for high hydrogen bonding and high electrostatic repulsion as suggested by Altschul and Wilcke [21]. The greater OAC of DSF might be due to enhanced hydrophobic character, non polar side chain and different confirmation features of proteins in the flour [22]. Kinsella [23] suggested that OAC was important, as oil acts as a flavour retainer and improves the mouth feel of foods. Whole sesame seed (WSS) exhibits maximum foaming capacity with respect to SC and DSF at different pH (4, 6,

6.8 and 8) (Fig.1) and foaming capacity was increased significantly at p<0.05 while increasing the pH of the sample which was likely due to increased net charge on the protein, which weakened the hydrophobic interactions but increased the flexibility of the protein as said by Kanu et al [24]. Similar observation was reported for field pea flour [25]. The foam was stable for 5-10 minutes irrespective of samples. One gram of defatted sesame flour when dispersed in 40 ml distilled water had an initial pH of 5.9. The addition of 0.5 M HCl and 0.3 M NaOH brought about changes in pH of the solution (Fig.2). At acidic pH range 5.9 3.1, an average of 2.28 mmol of 0.5 M HCl and at alkaline pH range 5.9 10.1, an average of 1.1 mmol of 0.3 M NaOH was required per gram of DSF to change the pH by one unit. Thus the higher buffer capacity of DSF was noted in alkaline than in acidic medium. 3.3 Proximate composition Proximate composition of WSS, SC and DSF was indicated in Table 2. The WSS had significantly (p<0.05) high fat (44.53%) and crude fiber (3.67%) compared to SC and DSF. The moisture and ash content of SC were significantly (p 0.05) greater than WSS and fully DSF. Protein content of DSF (47.8 g%) was greater than defatted groundnut flour (43.58 g%) reported by Sulieman and Mabrouk [26]. The proximate composition of WSS was statistically comparable with values reported by Gopalan et al [27] (Table 2). 3.4 Thermal properties The temperature To and Tp were the measure of protein denaturation [28] and influenced by heating rate and the protein concentration. In this respect, the higher T o and Tp of DSF (Table 3) indicated that a less heat stable group of protein had been denatured during the process. As stated by Biliaderis [29], the native to denatured change in the protein state was a co-operative phenomenon that accompanied by significant heat uptake which seen as an endothermic peak in the DSC thermogram (Fig.3). The transition heat (H) was calculated by integrating the area below endothermic peak and used to monitor the proportion of protein that does not denature during a process [29, 30]. The DSF showed lower H (Table 3) compared to SC and WSS which suggest that a lower proportion of protein underwent denaturation during the process. DSC thermogram parameters of WSS, SC and DSF were not significantly different at p<0.05. 4. Conclusion The greater water absorption capacity and oil absorption capacity indicated the suitability of defatted flour for the preparation of cake, biscuit, sausages, noodles and other macaroni products. Study on modification of protein to reduce the protein denaturation temperature through various method of processing will throw light on further value addition towards the preparation of high protein food supplement using defatted sesame flour like soy flour. 5. References 1. H. A. Abou - Gharbia, F. Shahidi, A. A. Y. Shahata, M.M. Youssef, Effects of processing on oxidative stability of sesame oil extracted from intact and dehulled seeds, J. Am. Oil Chem. Soc., 74 (1997) 215-

88

International Journal of Agricultural and Food Science 2013, 3(3): 86-89

2. 3. 4.

5. 6. 7.

8. 9.

10.

11.

12. 13. 14. 15.

16.

221. A. Ashri, Sesame, in: G. Raebbelen, R.K. Downey, A. Ashri, (Eds.), Oil crops of the world, McGraw Hill Publ. Co., New York, 1989, pp. 375-387. M. R. Padua, Some functional and utilization characteristics of sesame flour and proteins, J. of Food Sci., 48 (1983) 1145-1147. K. Bandyopadhyay, S. Ghosh, Preparation and characterization of papain modified sesame (Sesamum indicum L.) protein isolates, Agric. Food Chem., 50 (2002) 6854-6857. J. C. Wang, J. E. Kinsella, Functional properties of novel protein: alfalfa leaf protein, J. of Food Sci., 41 (1976) 286-292. E. Onsaard, P. Pomsamud, P. Audtum, Functional properties of sesame protein concentrates from sesame meal, AS. J. Food Ag. Ind., 3 (2010) 420-431. M. Li, D. C. Davis, D. G. L. Obaldo, G. B. BarbosaCanovas, Engineering properties of foods and other biological materials (A Laboratory Manual), ASAE Press, St. Joseph, MI 1998. R. Thompson, W. Isaac, Porosity determination of grains and seeds with air comparison pycnometer, Transactions of the ASAE, 10 (1967) 693-696. A. P. Gandhi, J. Srivastava, Studies on the production of protein isolates from defatted sesame seed (Sesamum indicum) flour and their nutritional profile, ASEAN Food Journal, 14 (2007) 175-180. J. T. Lawhon, L. Rooney, C. M. Carter, K. F. Mattil, A comparative study of the whipping potential of an extract from several oil seed flours, Cereal Sci. Today, 17 (1972) 240-246. N. G. Rao, D. G. Rao, T. Jyothirmayi, Protein solubility and functional properties of Quamachil (Pithecellobium dulce L.) seed flour, J Food Sci. and Tech., 45 (2008) 480-483. S. Ranganna, Hand book of analysis and quality control for fruit and vegetable product, McGraw Hill Publishing Co. Ltd., New Delhi, 2004. S. Sadasivam, A. Manickam, Biochemical methods, second ed., New Age International Publishers, New Delhi, 2005. P. McDonald, R. A. Edwards, J. F. D. Greenhalgh, Animal nutrition, T & A Constable Ltd., Edinburgh. 1973, pp. 2-5. O. Paredes-Lopez, H. Guzman-Maldonado, C. Ordorica-Falomir, Food proteins from emerging seed sources, in: New and developing sources of food proteins; B. J. F. Hudson (Eds.), Chapman and Hall, London, 1994, pp. 240-279. J. E. Kinsella, Milk proteins: physicochemical and functional properties, Crit. Rev. Food Sci. Nutr., 21 (1985) 197-262.

17. M. Peleg, B. Bagley, Physical Properties of Foods, AVI Publishing Company, Westport, CT 1983. 18. T. P. Vijayakumar, J. B. Mohankumar, Formulation and characterization of millet flour blend incorporated composite flour, International Journal of Agriculture Sciences, 1 (2009) 46-54. 19. A. M. Fekric, A. M. Isam, O. A. Suha, E. B Elfadil, Nutritional and functional characterization of defatted seed cake flour of two Sudanese groundnut (Arachis hypogaea) cultivars, Inter. Food Res. J., 19 (2012) 629-637. 20. C. S. Lin, J. F. Zayas, Functionality of defatted corn germ proteins in model system: Fat binding and water retention, J.Food Sci., 52 (1987) 1308-1311. 21. A. M. Altschul, A. L. Wilcke, New protein food, Food Science and Technology, Orlando, FL Academic Press, 1985. 22. J. E. Kinsella, Functional properties of soy proteins, Journal of American Oil Chemists Society, 56 (1979) 242-249. 23. J. E. Kinsella, Functional properties of protein foods. Crit, Rev. Food Sci. Nutr., 1 (1976) 219-229. 24. P. J. Kanu, Z. Kerui, Z. H. Ming, Q. Haifeng, J. B. Kanu, Z. Kexue, Sesame protein 11: Functional properties of sesame (Sesamum indicum L.) protein isolate as influenced by pH, temperature, time and ratio of flour to water during its production, Asian J. Biochem., 2 (2007) 289-301. 25. M. Kaur, K. S. Sandhu, N. Singh, Comparative study of the functional, thermal and pasting properties of flours from different field pea (Pisum sativum L.) and pigeon pea (Cajanus cajan L.) cultivars, Food Chemistry, 104 (2006) 259267. 26. Y. R. Suleiman, A. A. Mabrouk, The nutrient composition of Sudanese feeds, Bulletin III, Central Animal Nutrition Research Laboratory, Kuku Khartoum North, 1999. 27. C. Gopalan, B. V. Ramasastri, S. C. Balasubramanian, Nutritive value of indian foods, ICMR, 2011. 28. E. M. Escamilla-Silva, S. H. Guzman-Maldonado, A. C. Medinal, G. G. lez-Alatorre Simplified process for the production of sesame protein concentrate, differential scanning calorimetry and nutritional, physicochemical and functional properties, J. Sci. Food Agric., 83 (2003) 973-979. 29. C. G. Biliaderis, Differential scanning calorimetry in food research. A. rev. Food chem.., 10 (1983) 239-265. 30. S. D. Arntfield, E. D. Murray, The influence of processing parameters on food protein functionality. I. Differential scanning calorimetry as an indicator of protein denaturation, Can. Inst. Food Sci. Technol. J., 14 (1981) 269275.

Source of support: Nil; Conflict of interest: None declared 89

International Journal of Agricultural and Food Science 2013, 3(3): 86-89

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Review ProblemsDocumento5 páginasReview ProblemsgetsweetAinda não há avaliações

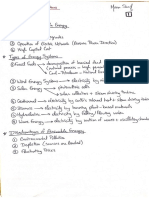

- Renewable Theoretical Summary - Mona - MidtermDocumento11 páginasRenewable Theoretical Summary - Mona - MidtermgetsweetAinda não há avaliações

- Review ProblemsDocumento5 páginasReview ProblemsgetsweetAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Review Problems Soln PDFDocumento10 páginasReview Problems Soln PDFgetsweetAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Review ProblemsDocumento5 páginasReview ProblemsgetsweetAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Review Problems Soln PDFDocumento10 páginasReview Problems Soln PDFgetsweetAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocumento2 páginasHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- Curriculum Vitae Replace With First Name(s) Surname(s)Documento2 páginasCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Solar 2 - Solar Power PlantsDocumento60 páginasSolar 2 - Solar Power PlantsgetsweetAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Bearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°Documento1 páginaBearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°getsweetAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Curriculum Vitae Replace With First Name(s) Surname(s)Documento2 páginasCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Problem 04 Problem 05: Community College of Allegheny CountyDocumento1 páginaProblem 04 Problem 05: Community College of Allegheny CountygetsweetAinda não há avaliações

- Lesson 4 XPDocumento30 páginasLesson 4 XPmaglalang_dexter_024Ainda não há avaliações

- ITEC Application Form 2014-15Documento8 páginasITEC Application Form 2014-15Mangalah Gauari MahaletchnanAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocumento2 páginasEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Media Lecture Notes S5B1C6Documento17 páginasMedia Lecture Notes S5B1C6getsweetAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Sustainable BackgroundDocumento111 páginasSustainable BackgroundgetsweetAinda não há avaliações

- Proposal Tips HintsDocumento4 páginasProposal Tips HintsAravindan NatarajanAinda não há avaliações

- NEWChapter - 3-Mass Balance PDFDocumento10 páginasNEWChapter - 3-Mass Balance PDFAbdelhaleem KhaderAinda não há avaliações

- 6536examples of Air PollutionDocumento50 páginas6536examples of Air PollutiongetsweetAinda não há avaliações

- ST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocumento2 páginasST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Worksheet Week7Documento2 páginasWorksheet Week7getsweet0% (1)

- Problem 01 Problem 02: Community College of Allegheny CountyDocumento1 páginaProblem 01 Problem 02: Community College of Allegheny CountygetsweetAinda não há avaliações

- General Overview Boilers and FlowDocumento22 páginasGeneral Overview Boilers and FlowLiam MoylanAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocumento2 páginasEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetAinda não há avaliações

- Additonal Asgn 02Documento3 páginasAdditonal Asgn 02getsweetAinda não há avaliações

- Home Soln 8Documento4 páginasHome Soln 8getsweetAinda não há avaliações

- Create The Following Solid Models Using Solidworks.: ExerciseDocumento1 páginaCreate The Following Solid Models Using Solidworks.: ExercisegetsweetAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- U U U P T: Quick Visit To Bernoulli LandDocumento9 páginasU U U P T: Quick Visit To Bernoulli LandAkash SodhaAinda não há avaliações

- Chapter 08 2Documento64 páginasChapter 08 2Subhi MohamadAinda não há avaliações

- Recruitment and SelectionDocumento57 páginasRecruitment and SelectionRAKESHAinda não há avaliações

- Cellular Healing Diet EbookDocumento48 páginasCellular Healing Diet Ebookselva92% (12)

- Presentation On Students' Industrial Work Experience Scheme (Siwes) at Sunseed Nigeria LimitedDocumento15 páginasPresentation On Students' Industrial Work Experience Scheme (Siwes) at Sunseed Nigeria LimitedAbdul Nasir0% (1)

- Elimination of 3-MCPD Fatty Acid Esters and Glycidyl Esters During Palm Oil Hydrogenation and Wet FractionationDocumento10 páginasElimination of 3-MCPD Fatty Acid Esters and Glycidyl Esters During Palm Oil Hydrogenation and Wet FractionationAlexAinda não há avaliações

- Required HLB For Oils and LipidsDocumento2 páginasRequired HLB For Oils and Lipidsevelina martono0% (1)

- Vikram ProjectDocumento55 páginasVikram ProjectAshwini H RAinda não há avaliações

- MAL Standard: Malaysian AndardDocumento12 páginasMAL Standard: Malaysian AndardmrkhaireeAinda não há avaliações

- 6 Spices 60 Dishes Indian Recipes That Are Simple Fresh and Big On Taste 1St Edition Ruta Kahate Full ChapterDocumento67 páginas6 Spices 60 Dishes Indian Recipes That Are Simple Fresh and Big On Taste 1St Edition Ruta Kahate Full Chapterclyde.fisher190100% (6)

- Financial Profitability and Sensitivity Analysis of Palm Oil Plantation in IndonesiaDocumento9 páginasFinancial Profitability and Sensitivity Analysis of Palm Oil Plantation in IndonesiaJean-Louis KouassiAinda não há avaliações

- Lecture 1 - Fluid Power - An Introduction PDFDocumento40 páginasLecture 1 - Fluid Power - An Introduction PDFbmdbmdbmd100% (1)

- Modeling of Oil Expression From Palm Kernel (Elaeis Guineensis Jacq.) - 1Documento8 páginasModeling of Oil Expression From Palm Kernel (Elaeis Guineensis Jacq.) - 1TANKO BAKOAinda não há avaliações

- Transformer Insulation Options: Advantages and DisadvantagesDocumento6 páginasTransformer Insulation Options: Advantages and DisadvantagesibrahimAinda não há avaliações

- Technology of Production of Edible Flours and Protein Products From Soybeans. Chapter 3Documento19 páginasTechnology of Production of Edible Flours and Protein Products From Soybeans. Chapter 3Hamid Vahedi LarijaniAinda não há avaliações

- Meat Free Keto by @meatfreeketoDocumento121 páginasMeat Free Keto by @meatfreeketoĪzīdor Ĉech100% (3)

- Project Profile On Soap and Detergent FactoryDocumento33 páginasProject Profile On Soap and Detergent Factorysalman92% (13)

- Final ReportDocumento43 páginasFinal ReportBhargavAinda não há avaliações

- CFD Simulation of Fatty Acid Methyl Ester Production in Bubble Column ReactorDocumento7 páginasCFD Simulation of Fatty Acid Methyl Ester Production in Bubble Column ReactorVenkatesh VenkyAinda não há avaliações

- Cash Crops FinalDocumento16 páginasCash Crops FinalabhishekAinda não há avaliações

- SANTOL (Sandoricum Koetjape) AND LANZONES (Lansium Domesticum) SEEDS As An Alternative FuelDocumento14 páginasSANTOL (Sandoricum Koetjape) AND LANZONES (Lansium Domesticum) SEEDS As An Alternative FuelArchie CabaAinda não há avaliações

- Comp LabellingDocumento42 páginasComp Labellingpitambari pitambariAinda não há avaliações

- B.sc. Home ScienceDocumento160 páginasB.sc. Home ScienceDawnAinda não há avaliações

- 01 Discontinuous HydrogenationDocumento9 páginas01 Discontinuous HydrogenationMaicon Espindola Dos SantosAinda não há avaliações

- Enzymes in OilDocumento49 páginasEnzymes in OilsudhirkromAinda não há avaliações

- EJLST SatyaDocumento5 páginasEJLST Satyasatya vaniAinda não há avaliações

- Oil FilteringDocumento6 páginasOil FilteringDavid Flores MolinaAinda não há avaliações

- Diet For Bodybuilder by Guru MannDocumento58 páginasDiet For Bodybuilder by Guru MannDhanjayAinda não há avaliações

- RSM Based Comparative Experimental Study of Sustainable Biodiesel Synthesis From Different 2G Feedstocks Using Magnetic Nanocatalyst Cafe ODocumento1 páginaRSM Based Comparative Experimental Study of Sustainable Biodiesel Synthesis From Different 2G Feedstocks Using Magnetic Nanocatalyst Cafe OajithjkingsAinda não há avaliações

- Dietary Guidance To Improve CV Health 1639383817 PDFDocumento16 páginasDietary Guidance To Improve CV Health 1639383817 PDFnouraAinda não há avaliações

- Welcome To CN4122/E Process Synthesis and Simulation: IA Karimi (E5 02-12, 6516-6359, Cheiak@nus - Edu.sg)Documento26 páginasWelcome To CN4122/E Process Synthesis and Simulation: IA Karimi (E5 02-12, 6516-6359, Cheiak@nus - Edu.sg)Esmond TanAinda não há avaliações

- Vegetable Butters and Oils As Therapeutically and Cosmetically Active Ingredients For Dermal Use: A Review of Clinical StudiesDocumento17 páginasVegetable Butters and Oils As Therapeutically and Cosmetically Active Ingredients For Dermal Use: A Review of Clinical StudiesFina Mustika SimanjuntakAinda não há avaliações